The moisture content of a log is defined as the weight of the contained water divided by the dry wood weight times 100. For example, let’s say a green log weighs 100 pounds and we place it in a drying kiln until all of the water is removed. If the dry log now weighs 65 pounds, the original moisture content was approximately 54% (35 pounds water ÷ 65 pounds dry wood = 0.538 x 100).

Using this method of calculation you can see that it is not at all unusual for a recently cut log to contain well over 100% moisture content. In the field, moisture content is typically measured using a pin-type moisture meter that converts the electrical conductivity between the pins into approximate moisture content.

Once a tree is cut and the bark removed, it will begin to dry out. The water contained in the wood is in basically two forms: free water and water that is bound in the cell walls. The free water evaporates from the log first, and although there is some shrinkage during this process, it’s not until the wood reaches its fiber saturation point (FSP) of about 28% and begins to lose its bound water that significant shrinkage occurs. That’s why whenever a log home is built using very green logs, checks may not begin to open for several months, or even years, after the home was constructed.

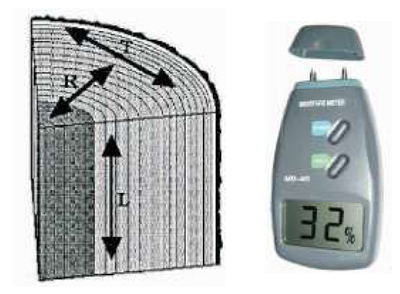

Although shrinkage affects all dimensions of a log, some wood species are more prone to checking than others because their rate of radial shrinkage (R) is not as great as their tangential shrinkage (T). Shrinkage along the length of the log (L) is usually negligible. Radial cross section shrinkage can be quite significant and although it varies from species to species, shrinkage of 5-6% is not unusual. Thus a 10-inch round log with a radial shrinkage of 6% can lose more than 1/2 inch of its diameter as it dries.

Once logs have dried below their fiber saturation point, they will continue to shrink until they reach a moisture level that is in equilibrium with the relative humidity of their environment. In warm, humid areas like Florida or Louisiana, logs may never get below 18% moisture content, whereas in the Southwest, they may hold steady at 9-10% moisture content. In most areas of the country, the relative humidity of the air changes with the seasons. For example, in the Northeast air during the winter months is much drier (low relative humidity) than in summer. On the other hand, in the Pacific Northwest the highest relative humidity occurs during the winter months.

So how does all of this affect the application and performance of our sealants and finishes? Although it’s true that our products can be applied to green logs, if the surface of the logs are above the fiber saturation point, there may be so much free water in the surface cellular structure that both sealants and finishes will not be able to adhere properly to the wood fibers, compromising the adhesion. To be on the safe side, the surface moisture content should be 20% or less, as measured by a moisture meter. This is not the same as requiring that the entire log be less than 20% moisture content. We are only concerned with the surface, not the interior of the log - which may still contain 40-50% moisture, even though the surface may read 18% moisture content.

As previously stated, most of a green log’s shrinkage occurs after it has reached the fiber saturation point. Since log checking is associated with shrinkage, most checks will open up several months after the home is constructed, and continue opening until the logs reach an equilibrium with their environment. It is not unusual for large checks to open up two to three years after a home is constructed. If our finish system is applied before the logs reach the fiber saturation point, checks and fissures that later appear may allow rain water to get into the wood behind the finish. When the sun hits the water, saturated wood heat converts the liquid water to so much water vapor that it can overload the ability of the finish to breathe. This is one of the leading contributors to peeling.

Sealing checks before the logs reach their moisture equilibrium point can be an exercise in frustration for a homeowner. What may start out as a small fissure can easily turn into an inch-wide check within a few months. If sealed too soon with Check Mate 2®, the enlargement of the check can exceed the elongation capability of the Check Mate 2 and may eventually provide an entry point for water.

In the homeowner’s eyes, the Check Mate 2 failed since he or she may not remember how narrow the check was when it was originally sealed. There is no perfect solution to the challenges presented by constructing a home using very green logs. Most new log home owners are in a rush to get their home finished and sealed as soon as possible. However, allowing the logs to air dry a few months will improve the performance of both the sealant and finish systems, and help reduce the maintenance required for the first three to four years.