Perma-Chink Systems, Inc

Log & Timber Home Care Experts

Perma-Chink Systems, Inc

Log & Timber Home Care Experts

Can Lifeline™ Interior stains be used to finish interior floors? Technically the answer to this question is yes, but we rarely recommend them unless whoever is going to be finishing the floor fully understands the characteristics of water-based, transparent stains and knows how to apply them.

Flavonoids are colorful compounds that are present in most plants. They are what make red beets red, and blueberries blue. They are also responsible for giving flowers their broad range of colors.

Trees, too, contain flavonoids, with some species containing more than others. In some types of wood, these flavonoids are apparent right from the start. The wood may be yellow, red, or other color, depending on the species. But in several species of wood, these colored flavonoids may not become visible unless the wood is exposed to some type of acid.

Applications of all Perma-Chink exterior finish removers, cleaners, stains, topcoats and sealants can be a bit of a challenge in extremely hot weather, which we consider over 90°F. However, if you know what to expect and avoid you can easily cope with applications during the hot summer months. We’ll address each of our product lines individually. And for all our products, we recommend keeping the product pails out of the direct sun on hot days to minimize the heat build-up.

Ever since Perma-Chink Systems introduced borate treatments to the log home industry over 20 years ago, its products have been the preferred method of protecting log homes from wood-destroying insects and decay fungi. We are still the world’s largest supplier of borate-containing preservatives for log homes, and although there are other borate-based products now available, most are based on technology developed by Perma-Chink Systems back in the late 1980s.

Ever since Perma-Chink Systems introduced borate treatments to the log home industry over 20 years ago, its products have been the preferred method of protecting log homes from wood-destroying insects and decay fungi. We are still the world’s largest supplier of borate-containing preservatives for log homes, and although there are other borate-based products now available, most are based on technology developed by Perma-Chink Systems back in the late 1980s.

For many years the product of choice for cleaning bare wood surfaces was a solution of chlorine bleach and water, perhaps with some detergent or TSP (trisodium phosphate) added to help clean the wood. When correctly applied and well rinsed, bleach solutions can work fairly well most of the time. However, household bleach does not come with a set of directions for using it on wood, and even within the log home industry there is no agreement as to how to properly use bleach.

Drying times and curing times relate to two entirely different processes that occur in water-based polymer systems. All water-based products, be it stains, paints, or sealants, contain a percentage of free water, hence their description as water-based.

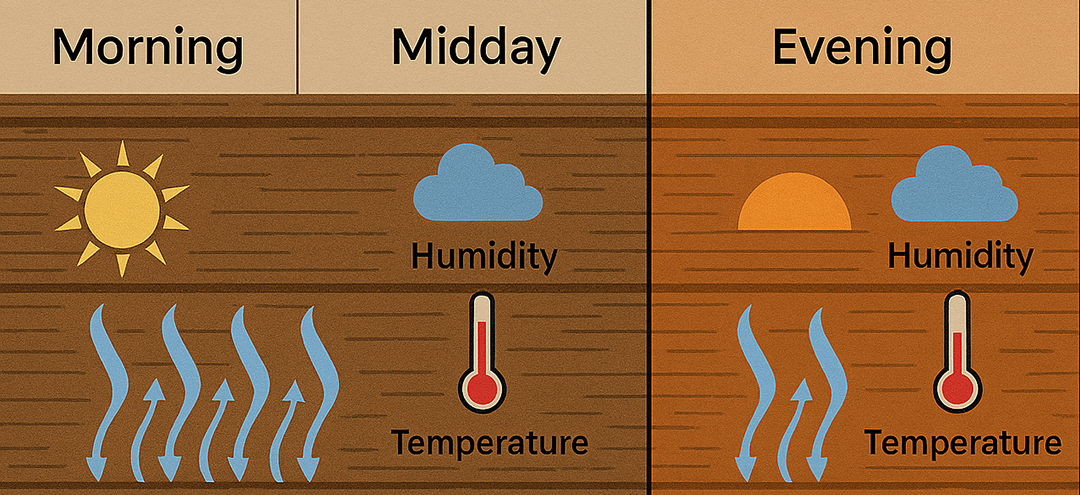

When applied and exposed to air, the free water begins to evaporate. The rate of evaporation is dependent on the humidity as well as the temperature. The higher the temperature and lower the humidity, the faster the rate of evaporation.

Once most of the water has evaporated from the surface, it feels dry - thus the term “dry to the touch.” The time a product takes to become dry to the touch is its “drying time,” although in the case of sealants, we typically talk about the time it takes a product to “skin over.”

Once a material has dried or skinned over, it does gain some strength in that it becomes impossible to brush out or tool smooth, but to achieve its maximum strength and durability it must be allowed to cure.

Curing time relates to the time it takes for a product to gain enough strength to withstand the parameters for which it was designed. As opposed to drying, curing is more of a chemical reaction that takes place on a molecular level. During the curing process environmental factors such as rain, snow, or high humidity can have a significant impact on the look or performance of a product. For example, in our Advance Topcoats, blushing is caused by water molecules becoming trapped within the polymer matrix during the curing process. Once trapped, it may take a long time for this water to escape from the film as long as environmental conditions remain cool and damp.

In addition to temperature and humidity, the time it takes sealants like Perma-Chink®, Energy Seal™, Woodsman™, and Check Mate 2® to cure depends on the thickness of their application. Once a sealant skins over, it inhibits the evaporation of water from the material under the skin. This prolongs the curing process, so although we may state that the curing time for Perma-Chink is two to eight weeks for a thinner or standard application, it may take several months for a 5/16” thick layer of Perma-Chink to attain its maximum strength.

Many people are under the impression that the winter months are hard on their logs and finishes. To some extent that’s true. In cold climates where the exterior log surfaces may be covered with ice and snow for several months can be damaging if the logs aren’t properly finished. But even then, the most damaging effects of weather on wood and coatings actually occur during the hot summer months.

One component of sunlight is ultraviolet light, commonly referred to as UV light, or UV rays. UV light is responsible for most damage to exposed wood because it changes or destroys the wood’s lignin, a component of wood that hardens and strengthens the cell walls. In more scientific terms, this process is called photo-oxidation.

Chink Paint™ is a high quality, elastomeric latex paint used to refresh or change the color of your log home chinking. Chink Paint is available in all eight standard colors of Perma-Chink® in either a textured or smooth finish (with or without aggregate, respectively). This difference provides the customer a choice as to whether or not they would like to add additional texture to the appearance of the chink joint.

Over the past several years we have discovered many things about cleaning wood and existing finishes. First and most importantly is that chlorine bleach is not the best product to use. In addition to its potential for damaging the finish and bare wood fibers, its use and misuse contribute to specific problems including the loss of film adhesion, discolorations due to tannin extraction, streaks, blotches, and premature failures of the finish system. We have also discovered that many wood and deck cleaners available at paint and hardware stores, home improvement centers and Do-It-Yourself outlets contain components that interfere with the proper performance of our finish systems.

Occasionally we get a call from someone with an older log home who wants to “seal and protect” their logs but does not wish to remove the gray patina that has built up over the years.

Typically they think that some type of clear finish can be applied to their home which will keep water from penetrating into the wood and help retard wood erosion due to sun, wind, and rain. The truth is that there is no clear exterior product that will meet their expectations.