In loving memory of our late president Rich Dunstan.

In The Beginning

In 1980 my neighbor told me about building a log home in Eastern Washington. He said that he loved the home and the lifestyle but was disappointed wind constantly blew and cold, harsh winters meant there was no real effective way to seal the gaps between the logs. The house leaked air and heat and wind-driven rain came right through the walls.

He tried various caulking materials with little success. Caulking around a bathtub or sink was significantly different from ‘caulking’ literally miles of seams between logs in a log house. After a number of conversations and experiments, we discovered there was no readily available product that could seal the gaps, look like authentic chinking, and last more than a few months.

After months of trial and error it became apparent that if we were going to design a material that would be acceptable to our criteria, we would have to design it ourselves.

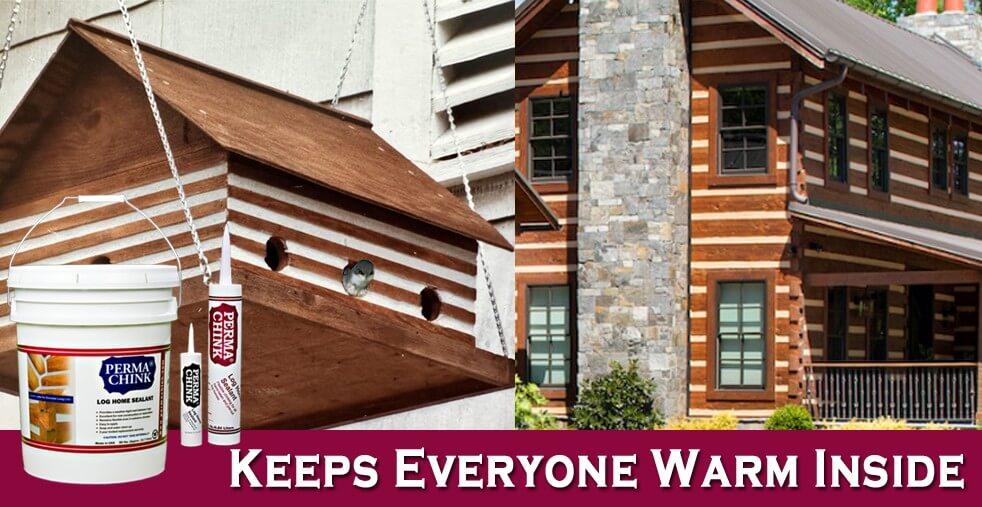

The product we were designing was to be a replacement for what was known in the Log Home Industry as “chinking” – the sealant that historically provided the seal between the logs. A chink is a gap – as in Biblical Times, “A chink in his armor’. Therefore, chinking is a material to fill a gap. Throughout the centuries of constructing dwellings out of logs, numerous methods were used to seal in between them. Early builders used pretty much anything they could get their hands on to seal the gaps – mud, straw and mud, cow manure, or mixtures of cement and mortar.

The Criteria For Crafting The Perfect Chinking

During our investigation we determined that in order to be a true solution, the sealant must meet the most important requirements:

- It had to be textured to look like authentic mortar chinking.

- It had to “look like it belonged there.”

- It had to be able to expand and contract to follow perpetual log movement. As logs dry out in the summer, they shrink in diameter – in the winter or rainy months they absorb moisture and swell, increasing in diameter.

- It had to adhere tightly to the logs and form a continuous, watertight seal that doesn’t separate from the wood.

- It had to be easy to apply in gaps up to 4 or 5 inches and not slump or wash out.

- And most importantly, it had to LAST for decades.

Common caulking materials were quickly ruled out. Everyone has seen thin caulking beads applied to exterior trim that invariably separate, peel off, flake, crack, and ultimately fail. No caulk could adhere to the wood well enough and could not be applied to the thickness and height required without slumping and running out of the joint. And all caulks had that smooth, artificial look that frankly looked like caulk! Okay for around the tub or sink, but not for my log home, thank you.

So, after months of experimentation and learning a tremendous amount of chemistry about polymers (the chemical building blocks of literally everything that we commonly call paint, plastic, vinyl, glue, etc.), we designed a unique sealant that met all the requirements.

During the design phase we located an innovative small company south of Seattle that manufactured synthetic stucco. They had the experience and the machinery that helped us scale up lab designs to large scale production. We began selling early product in 1981 and the first house we did was in Sun Valley, Idaho – in the middle of winter.

Going To Market

Soon after, we had a saleable product that met EVERY design requirement. I did a little market research and discovered that the largest part of the national log home market was in the eastern United States, particularly the Southeast. I also discovered that of the numerous styles of log homes, the three largest manufactures of dovetail-designed log homes were within 100 miles of Knoxville, Tennessee. I liked the dovetail design because of the nature of the structure, and the way the logs are stacked resulted in a chinking gap of up to 4 inches! In some cases, almost 25% of the wall area was chinking!

So, we set up a manufacturing plant in Knoxville. The timing was right because as soon as log home owners and manufacturers discovered that we could finally provide a dramatically better solution to one of the most significant and perplexing aspects of a log home – the business grew rapidly.

Solving Manufacturer’s Greatest Construction Need

Early adopters such as Hearthstone, Honest Abe, Stone Mill, and Appalachian Log Homes helped pave the way for essentially all others to follow. As a matter of fact, one of the earliest applications for any Manufacturer was Appalachian. Turns out they had a contract with the US Forest Service to build an outhouse. The location was remote, and the house needed to be completely assembled and transported via helicopter. Obviously, mortar chinking could not withstand that type of stress, so they tried Perma-Chink. That outhouse is still standing today and is weather tight – some applications simply CANNOT fail!

The development of synthetic chinking solved one of the most serious and vexing aspects of the log home industry. The chinking formulation is unique and specifically designed for log homes, and not simply ‘caulk with sand in it’ as others have offered.

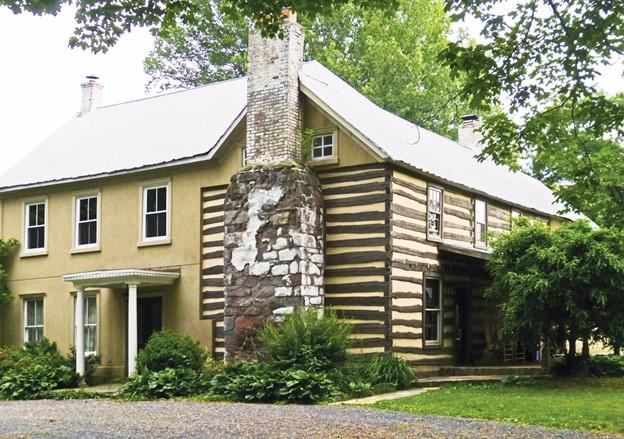

George Washington’s Farm log cabin restored with Perma-Chink Systems log home sealants and stains.

Rick Denton, Honest Abe Log Homes President Emeritus said “Perhaps the invention of Perma-Chink kept Honest Abe in business, as well as every other log home company using a chinked product line.” Read his story here:https://www.honestabe.com/blog/perma-chink/

A Great Success From Fantastic Partners & Customers

What started out as an idea has literally revolutionized the entire industry. Worldwide, most log structures use synthetic chinking, and the largest supplier of the most authentic and highest-performing log home chinking is Perma-Chink.

We used the knowledge and expertise we developed in formulating Perma-Chink Chinking (remember the polymers?) to design the longest-lasting semi-transparent stain in the industry. The formulation is also unique, providing a ‘furniture grade’ appearance that outlasts any exterior stain on the market.

As history has shown, and something we take pride in, whenever a log home owner becomes aware of a concern, whether it be sealing, staining, or preservation or maintenance, we already have a solution.

Driven to Exceed Now & In The Future

We are humbled that Perma-Chink Systems has become the household name in the log home industry and is recognized for its high quality. Our products grace the log homes of such noted Americans as former President Jimmy Carter, clothing designer Ralph Lauren, movie star Tom Cruise, Olympic champion figure skater Kristi Yamaguchi, NASCAR champion Dale Earnhardt (read the story here) and thousands of great American homeowners.

Perma-Chink Systems has a slogan – “Simply Unmatched”. By crafting the best quality products and engaging in providing the best customer service, we will attain our goals and make great strides towards exceeding our customers’ expectations for years to come. To be “Simply Unmatched.”