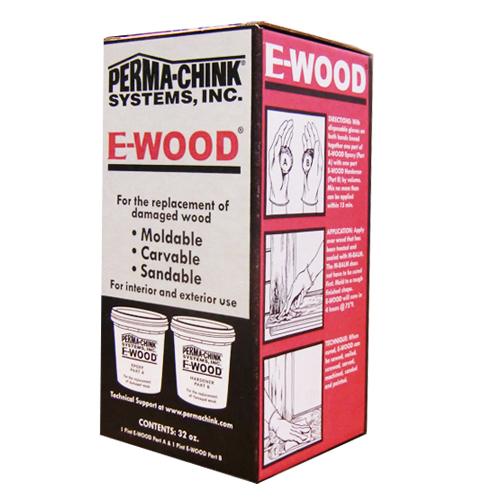

E-Wood is a putty-like, non-shrinking, epoxy filler used to fill in missing sections of logs or dimensional wood members. E-Wood will form a permanent bond to most rigid surfaces. Porous surfaces should always be treated with a compatible, low viscosity epoxy system such as M-Balm.

Use E-Wood to replace missing sections of window sills, frames, furniture, or any wood structure. Use it to add new sections to completed structures.

After repair with E-Wood, restored wood can be shaped with your normal wood working tools, including saws, sanders, planes, routers and drills.

E-Wood Epoxy Wood Putty

Features

- Restores strength to deteriorated wood

- White vinegar and water cleanup

- Does not shrink

- Can be sawed, drilled, routed, nailed, screwed, painted and stained

Resource Links

- SDS E-Wood Part A

- SDS E-Wood Part B

- Log Repair

- E-Wood TDS

Disposal: Dispose of unused product and empty containers in accordance with local, state, and federal regulations. To protect the environment, do not pour unused product into drains or waterways.

Application Temperature

40° to 90°F

Application Methods

By hand

Putty knife or trowel

Surface Preparation

Clean and dry

Restored with M-Balm

Shelf Life

1 Year

Special Instructions

See label

Drying Time

12-24 hours

Application Tech Tips

For log repair that doesn’t require a log replacement, E-Wood Paste is a great product for non-structural applications.

Learn how our M-Balm and E-Wood work together to repair damaged logs.

Your questions about E-Wood answered.

Got Rot? Knock Rot Out of the Park with M-Balm and E-Wood.

How much decay have you found? If it’s not halfway deep through the log, or less than a couple of feet lengthwise, odds are it can be repaired easily. Read this.

What do I do about log rot?

We have the perfect solution for repairing log rot in wood with our E-Wood and M-Balm products. Read more here.

What should I do if my log home is really dark or discolored?

Dark or discolored log homes can mean a couple of things. One is it’s dirty and a thorough cleaning will bring back the original look. Another is the wrong finish was applied and it’s covered in mold, mildew, and other stains. Restoration steps begin here.

Perma-Chink Systems sells two epoxy products, M-Balm®, a wood consolidator that hardens loose, friable wood fibers, and E-Wood®, a putty used to fill voids or cavities in logs and timbers. Both M-Balm and E-Wood are two component epoxies. Like all epoxy products, they consist of a resin and a hardener and rely on a chemical reaction between the two components to become hard. As they react they often become warm, or even hot. M-Balm, in particular, can become quite hot about 15 to 20 minutes after the two components are mixed together.

Tip: Mix M-Balm in a disposable aluminum bread pan. This allows mixed component to release heat (exothermic) and cool while preventing you from melting your mix container or bottle.

There is one thing about epoxies that you should understand: as epoxies age they lose their chemical reactivity. The older they get, the longer it may take for the combined components to become hard. If unused epoxy has been in your garage for a couple of years or more, it’s not unusual for the hardening process to take three or four times longer than when using fresh product. It’s not that it won’t eventually harden, it’s just reacts slower and takes longer.

Never change the ratio of hardener to resin to try and speed things up. Unlike other types of resin and catalyst mixtures, M-Balm MUST be mixed together at a ratio of two parts of Part A to one part of Part B by volume. For E-Wood, equal volumetric parts of Part A and Part B MUST be kneaded together for these products to work.

Tip: Mix only the amount necessary to complete each step of a small job.

Here’s one more tip: M-Balm does NOT have to be cured before applying E-Wood. Epoxies do not “dry” in the sense that they must be in contact with air. They rely on chemical reactions to harden and cure, so M-Balm will harden just as rapidly under E-Wood as it will if left exposed. In fact, applying E-Wood before the M-Balm cures results in an even stronger bond to the wood.

Which is the best way to remove an existing finish, media blasting or chemical stripping? Like most questions of this nature there is no definitive answer, it depends on the situation. Both methods of removing a finish have their positive and negative attributes. The results will depend on the competence of the person or persons doing the work as well as the method used. For the sake of comparison, we will look at the features of each method to help you make a more informed decision about which one to choose.

Media Blasting

Although media blasting can be accomplished by a homeowner, it requires the rental of an industrial size air compressor and a Blaster Buddy unit.Media blasting not only removes the existing finish, but it also removes the top layer of wood. Media blasting can be a very aggressive procedure. In the hands of someone inexperienced with media blasting, extensive damage can be done to the surface of the wood in a very short span of time. That is why media blasting is best left to professionals who have prior experience. After media blasting, it is recommended that the walls be cleaned witha Log Wash™ solution (1 cups per gallon of clean water) to remove debris.

In general we take the position that media blasting should be considered carefully and evaluated as a secondary method rather than the preferred method of removing an existing finish. We have received calls from homeowners who are disappointed after seeing what media blasting did to their log home. They call us wanting to know what they can do to restore the logs to their original smooth surface. Unfortunately, the only way to restore the surface is labor intensive hand sanding. Media blasting followed by Osborn brushing can result in a relatively smooth surface if done by a well-trained and experienced individual. However, this is more the exception than the rule.

Some Advantages of Media Blasting

- Does an excellent job removing most paints and stains

- Fairly quick and cost effective

- Avoids water getting into the home, but dry dust and blasting media will most likely penetrate into the interior of the home

- Since the blasting media consists of either recycled crushed glass, or organic materials like corncob grit or walnut shells, there is little chance of well or water contamination

Disadvantages of Media Blasting

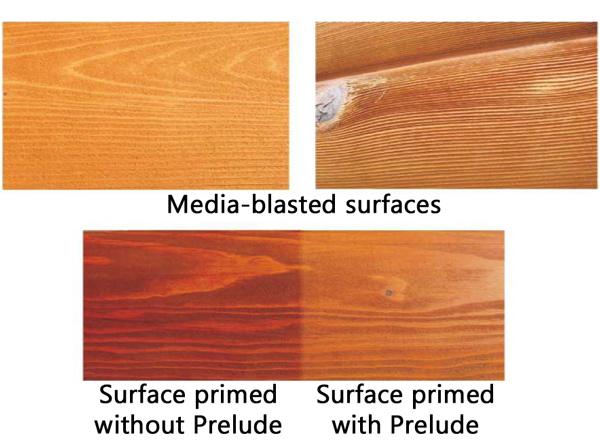

- Media blasting changes the surface characteristics of the wood

- In addition to roughening the surface, it increases the surface porosity

- Many people consider a media blasted surface unattractive and the only way to restore the wood to a smooth surface is with lots of hand sanding

- Prelude™ should always be used as a primer on media blasted surfaces

- Having enough blasting media on hand is critical. You don’t want to run out in the middle of a wall since it may take two or three days to have additional material shipped to your location

Chemical Stripping

Chemical stripping refers to the use of finish removers used in conjunction with a pressure washer. Chemical strippers only soften an existing finish, they must be used along with a pressure washer to remove the finish from the wall. In contrast to media blasting, chemical stripping is much more user friendly. All that is required are a general-purpose pressure washer, available at most do-it-yourself outlets or equipment rental locations, and either our S-100 or StripIt® Finish Remover. A pressure washer is much easier to handle than media blasting equipment. Although aggressive pressure washing can still do surface damage, it is usually relatively easy to repair with a light sanding or an Osborn Buffing Brush.

The main advantage of chemical stripping is that when following the proper procedures, the result is a beautiful smooth clean surface. So why do some stain manufacturers recommend media blasting over pressure washing? Media blasting significantly increases the surface area and porosity of the surface resulting in better adhesion of an inferior product. However, media blasting may result in an unattractive finish.

Some Advantages of Chemical Stripping

- Does an excellent job when correct procedures are used.

- User-friendly. Takes little expertise and no special equipment is required.

- One wall can be refinished at a time.

- Results in a more attractive surface.

Disadvantages of Chemical Stripping

- Water will get into the home.

- Need to protect plants and shrubs from chemicals.

- May take more than one application to completely remove an existing finish.

- Must thoroughly rinse any applied chemicals before applying finish.

Pressure washing (also referred to power washing) is the function of using highly pressurized water to remove mildew, mold, dirt, pollen, UV graying, etc. You’ll hear different recommendations whether or not pressure washing your logs is the best cleaning method.

Generally speaking, pressure washing is the quickest and least expensive choice.

One fallacy is that you’re saturating and “damaging” your logs with water as a result of pressure washing. This simply isn’t true. On hard, sound, rot-free logs, you’re only introducing water into the top fibers of the wood.

The time it takes to pressure wash and the results generated are often directly associated with the type of finish being removed as well as how many coats have been applied. While some older, obsolete linseed based oil stains are more difficult to remove than newer products, practically everything can be removed with proper pressure washing techniques and good finish removers. Some of these older type products will often need S-100 or StripIt stripper applied first in order to soften the bond to the wood.

Condition of Wood Surface

Traditionally, newer, recently peeled logs have a greater surface hardness and can withstand highly aggressive pressure washing (if needed) easier than a log wall which has been fully exposed to direct sun for 20 years. You might notice your upper and lower fascia boards have aged and darkened at an accelerated rate compared to your logs. Because these areas are often made from softer (i.e. pine) wood, they are more likely to absorb water leading to more prominent mildew growth. These areas can easily resemble new wood once cleaned.

Pressure washing of new constructions can also easily remove the UV graying of the logs that can start occurring just weeks after the logs are stacked, particularly if exposed to direct sunlight.

In addition to log and wood sided structures, other areas where pressure washing can be utilized include driveways, stone walkways, pool decking, stone walls, fencing, gutters, downspouts, roofing and other areas. Concrete slowly builds up a browning/green appearance over time which usually consists of grease, dirt, mildew and algae which can easily be cleaned.

Pressure washing can be done in practically any temperature and weather conditions, although chemical strippers, which are often applied prior to cleaning, work much better in warmer weather.

Whether you hire a professional or undertake the project yourself, pressure washing with wood cleaners from Perma-Chink Systems can bring back the beauty of your logs, preparing them for a fresh coat of stain and protective clear topcoat finish.