Applicator Program

Homeowners almost always have a list of projects they want to complete around their home. As a contractor who has worked on the exterior, winter is a great time to reconnect with your customers and check whether they have interior projects they’d like to address during the colder months.

There are several winter indoor maintenance and upgrade projects that are ideal for winter months. Help homeowners improve the look of their home now while keeping you productively booked during the off-season.

1. Freshen Wood Trim and Moldings, Doors and Window Frames, Cabinets, etc.

Freshening wood trims, cabinets, doors and window frames are perfect indoor maintenance projects for winter. Winter is the best time to stain inside because the air is drier than humid summer air and helps the finishes dry more quickly. You also can crack a few windows in winter to provide proper ventilation without worrying about bugs flying inside. Another reason to stain in winter is that you will get your inside projects done and have more time to do exterior projects when the weather improves.

Keep in mind that you do things a little differently when staining interior trim than when staining walls. You’ll need to sand your trim, clean the dust, and then apply finish. You can apply color stain before you finish it with a clear topcoat, or just apply a clear primer like Lifeline Prelude directly to wood and then topcoat it with clear Acrylic Gloss or Satin, or PCS Clear Shield finish. If you would like to add more gloss to your wood trim, PCS Clear Shield is your best choice. Click here for application instructions.

2. Check for Air Leaks

Many indoor winter maintenance projects also help homeowners save money. In fact, one of the best money-saving maintenance tasks is checking for air leaks. According to HomeAdvisor you can “stop energy-sucking, money-wasting air leaks by caulking, sealing and weather-stripping all of the gaps, seams, cracks, and openings in your home.”

According to the U.S. Department of Energy, reducing air leaks cuts heating and cooling costs, improves durability, increases comfort, and creates a healthier indoor environment. It’s especially important to check for air leaks if you have a log-style home since builders intentionally leave room for settling.

What does an energy audit do? Energy audit is the first step in the process; it finds the source of any air leaks and determines how bad those air leaks are.

The three basic tools used for an energy audit are a blower door, a thermal imaging camera and a computer loaded with the appropriate software. The blower door in conjunction with the computer measures the cumulative air leakage within the home and provides a negative internal air pressure, so the thermal imaging camera can better locate air leaks. The thermal imaging camera takes actual pictures of the air leaks, so you’ll have a record of exactly where they are located. Read more about the thermal imaging and blower door testing here.

After you identified the leaks, sealing or caulking and weather-stripping are two common solutions. Seal and weather-strip doors and windows that leak air. You also should caulk and seal air leaks where plumbing, ducting, or electrical wiring enters through walls, floors, ceilings, and soffits. Seal air leaks around chimney, furnace, and gas-fired water heater vents.

Sealing the leak with Energy Seal or Perma-Chink prevents water penetration along with air infiltration. General purpose caulks and sealants found at local hardware stores and DIY outlets just don’t offer the performance that’s required for the unique needs associated with log or timber homes.

Give us a call at 1‑800‑548‑3554 with any questions about the proper application of our products or any technical information you may need. We’re here to help.

Perma-Chink Systems: Advancing the Future of Exterior Wood Finishes

Perma-Chink Systems has been a leader in waterborne exterior finishes for decades. As federal and state environmental regulations increasingly restrict the use of oil-based products, the performance of traditional oil-based stains has declined. While these changes are a win for the environment, they’ve created challenges for manufacturers and homeowners alike.

Fortunately, waterborne transparent stains have evolved dramatically improving in both durability and appearance. At Perma-Chink Systems, we’ve spent years developing finishes that are not only environmentally responsible but also easy to maintain, long-lasting, and designed to enhance the natural beauty of wood.

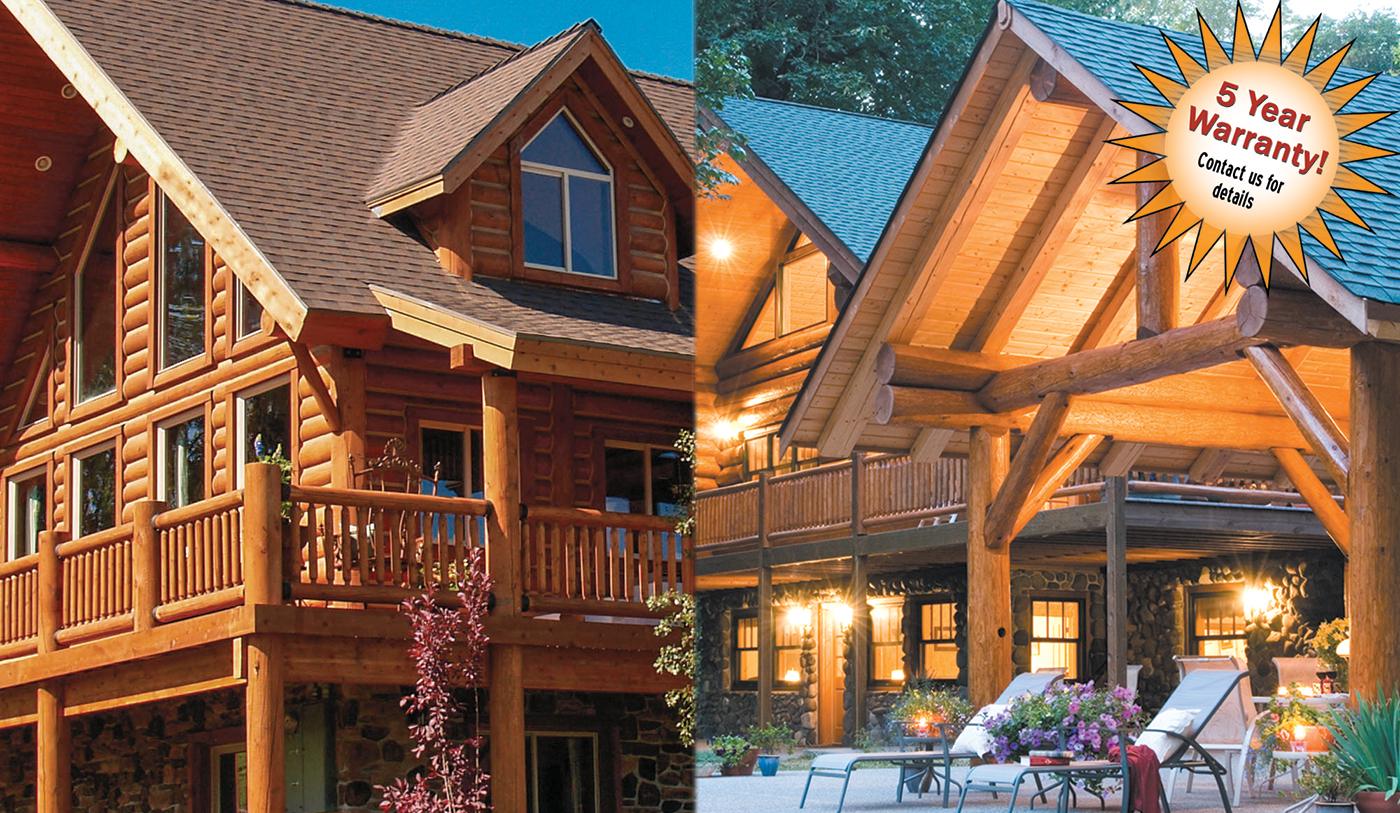

Our Lifeline Ultra-2 and Ultra-7 stains, combined with our Lifeline Advance clear topcoat, represent a major leap forward in the performance of exterior transparent finishes—outperforming both waterborne and oil-based alternatives. These finishes deliver the signature beauty you expect from Lifeline, are simple to apply and clean up, and offer the highest level of durability we’ve ever seen in our testing.

From lab trials to outdoor test panels and real-world building applications, Lifeline Ultra-2 with Lifeline Advance has consistently demonstrated exceptional long-term performance. Based on these results, we’re proud to back this system with a 5-Year Limited Warranty – a testament to its reliability and resilience.

How Does the Warranty Work?

When applied to properly prepared wood, a base coat of Lifeline Ultra-2 or Ultra-7 followed by a clear topcoat of Lifeline Advance qualifies for 3 years of warranty coverage. To extend the warranty to the full 5 years, simply apply one additional coat of Lifeline Advance within the first three years.

This warranty, backed by decades of innovation and rigorous testing, ensures that homes remains protected and beautiful year after year with the most advanced waterborne finish system on the market today.

If you haven’t experienced Lifeline Ultra-2 or Ultra-7 with Lifeline Advance, now’s the time. Contact your nearest Perma-Chink Systems location and request a sample – you’ll see firsthand how beautifully it brings out the character of your wood.

Where to get Free Samples

Order free samples online: Exterior Wood Finishes or call 1-800-548-3554.

Warranty Details

Link to warranty form: Ultra-7 Warranty

Perma-Chink’s Technical Team has devoted a tremendous amount of time on projects to develop high quality products. These projects involved a significant amount of scientific testing that helped define our product portfolio with new and improved products.

Here are 4 things we have learned along the way:

1. The more sterile the log surface is prior to staining, the less chance there is for mold formation underneath the stain.

Although this statement seems to be self-explanatory, it can never be overstated. The most important step prior to applying a wood finish is surface preparation. The surface of the logs really needs to be clean and sterile prior to applying any stain; it helps eliminate adhesion failures due to surface contamination.

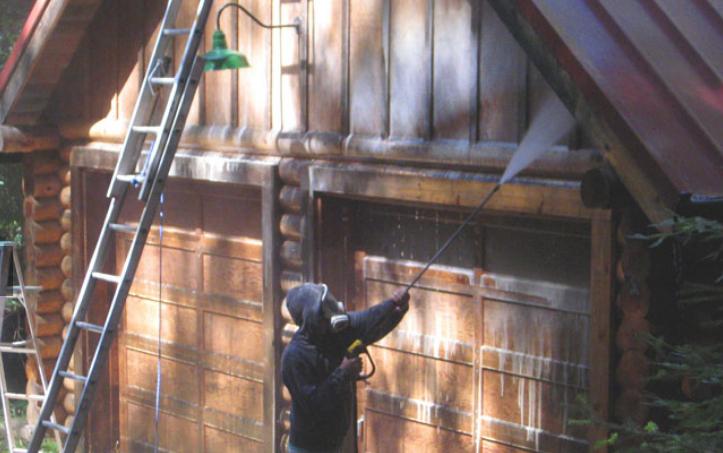

Before you apply a new coat of stain, you should pressure wash or media blast the surface. This cleans off dirt and debris and removes the old finish that has lost ability to adhere to the wood. Along with pressure washing, you may need a chemical log cleaner. The two wood cleaning solutions we recommend are Wood ReNew (Sodium Percarbonate) or Log Wash.

Apply the cleaning solution with a garden sprayer to the logs from bottom to top and allow the solution to remain on the wood for 15-20 minutes (do not let cleaner dry). Now use the pressure washer to wash down the wall with clean water from top to bottom. Use pH strips as a quantitative tool to determine if all of the cleaning chemicals have been removed from the surface of the logs.

Measure the pH of the rinse water to determine a baseline pH. Then measure the pH of the run-off at a several places on the wall once you are through rinsing. You need to continue rinsing until the pH of the run-off is in the range of 6.8-7.4. PH Strips with a range of 6 to 9 can be found at most pool supply stores, local drug stores, or discount stores.

Now here is where many people get into trouble. Let’s say that it has been five days or longer since the logs have been cleaned and you are still not ready to stain. The day before you are going to stain a wall, go out and wash it down with Log Wash.

This process will remove any dirt and pollen that may have accumulated on the logs since you cleaned them, and kills any mold spores that may be adhering to the wood. This helps to eliminate the risk of mold formation under the stain by removing both the mold and its food source.

2. Iron tannates are responsible for some discolorations commonly attributed to mold and mildew.

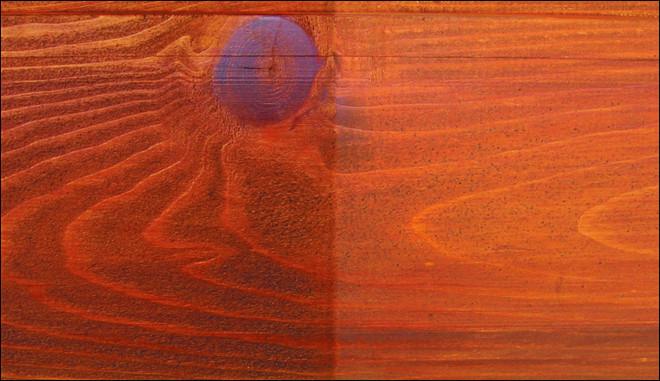

Tannins are compounds in wood that are found at highest concentrations in heartwood and bark. Under the right conditions tannins can react with heavy metals such as iron to form a dark blue/black stain known as metal tannates.

Visually these stains have a similar appearance to mold and mildew. However, under the microscope these stains are crystalline in structure.

One additional visual difference is that metal tannate stains almost always appear on the surface of wood, not on top of the coating. Dark streaks and dark runs down the surface of the log are also indicators of the presence of metal tannates. Wood ReNew (even bleach) will not remove this type of stain since it is not biological in origin. However, an oxalic solution like OxCon will completely remove the metal tannate stain. The oxalic acid reacts to change the oxidation state of the metal (iron tannate) to form a colorless species, thus removing, or “blonding,” the stain.

3. Many Industrial Wood Cleaners and Household Cleaners have detrimental effects on log finishes.

Many household and industrial wood cleaners are either strong organic solvents or highly alkaline and corrosive with a pH above 12. These types of cleaners can have detrimental effects on existing wood finishes, especially if they are left on the surface of the finish for too long, or if they are applied at concentration greater than recommended. Although the damage might not be visibly evident at the time, the use of these cleaners can reduce the longevity of the wood finish by increasing the erosion rate.

Our wood cleaner Log Wash will perform all of the functions of a typical cleaner without disrupting the look and performance of our wood finishes. Log Wash has slightly acidic pH, similar to that of wood. This means that when applied to wood it does not disrupt the wood’s chemistry.

4. Wood finish removers do not dissolve finishes; they only soften them enough to allow the finish to be removed with pressure washing.

A few years ago, pressure washing was the only way to go when it came to removing old finishes. With the introduction of media blasting, some people began to consider pressure washing as a secondary, inferior method of finish removal. Actually, pressure washing is still an excellent cleaning method for many situations.

It is always best to use finish removers supplied or approved by Perma-Chink Systems. Never use finish removers containing potassium or sodium hydroxide. They disrupt the chemistry of the wood and can lead to discoloration appearing under the finish. Before purchasing any finish removers, be sure to obtain a sample and test it on your existing finish.

Our S-100 Finish Remover and StripIt are formulated so that they can be applied “as is” using an airless sprayer. Their viscosity is such that they do not need to be diluted with water to be run through airless spray equipment. However, it is a good idea to thoroughly mix the S-100 with a Jiffy Mixer before spraying it. Just be careful to keep dirt and other debris out of the product.

APPLICATION

The first step before starting to remove a finish is to take off downspouts, gutters, and lighting fixtures, and mask off or cover those areas that you don’t want to strip; they may become discolored if contacted by the product you are using. The next step is to wet down and cover any plants and shrubs. Both S-100 and StripIt are pretty gentle on plant life once they are diluted with water during the stripping process, but in their concentrated form they may present a problem. The use of perforated weed blocking film works well over plants, roofs, decks and other areas you want to protect, since it allows water to drain through it but catches lumps of concentrated remover as well as any stripping debris. This makes clean up a lot quicker and easier.

Apply the finish remover to one or two courses of logs at a time in a sweeping motion across the entire wall starting at the bottom of the wall. This will help you avoid coating the chinking or sealant joints if they are present. Be sure to only coat an area that you can finish stripping in the allotted time you have. If you coat the entire wall, or too large an area, the finish remover may end up drying on the wall and become difficult to remove. Always apply finish removers at the recommended thickness or coverage rate. If applied too thinly, they may not work and you will have wasted your time and money. Once the finish remover has been applied to an area, submerge the spray gun and tip in a pail of water to prevent the product from drying at the tip and possibly blocking it.

After waiting an appropriate amount of time for the stripper to soften the finish (remember the cooler temperature it is, the longer it will take), you can begin the pressure washing process. Be sure to wash off any product and wet finish debris that’s still adhering to the wall or other surfaces. If allowed to dry, you may end up having to manually scrub these surfaces clean. Once you reach the top of the wall, or if you run out of time, rinse the entire wall starting at the top before you quit. You don’t want any chemical or finish debris to remain on the surface. If you are through for the day, replace the lid on the pail of finish remover and run clean water through your airless sprayer until clear water comes out of the gun.

Project Highlight

The project: Full exterior renovation of 40-year-old log home, including improving energy efficiency. The project required cleaning and mold/mildew removal, wood lightening, wood brightening and hand sanding. The Log Home Restoration project by T Paul Sec Painting won first place in PWC’s first annual Green Awards.

What made it green: All prep products used were eco-friendly and low VOC, manufactured by Perma-Chink Systems, Inc.

Here is a link to this project with more pictures http://www.greenpaintingcontractor.com

We have tested our cleaning products with our finish systems and have confidence that when properly applied, their use will result in the best possible appearance and performance of the final Lifeline finish.

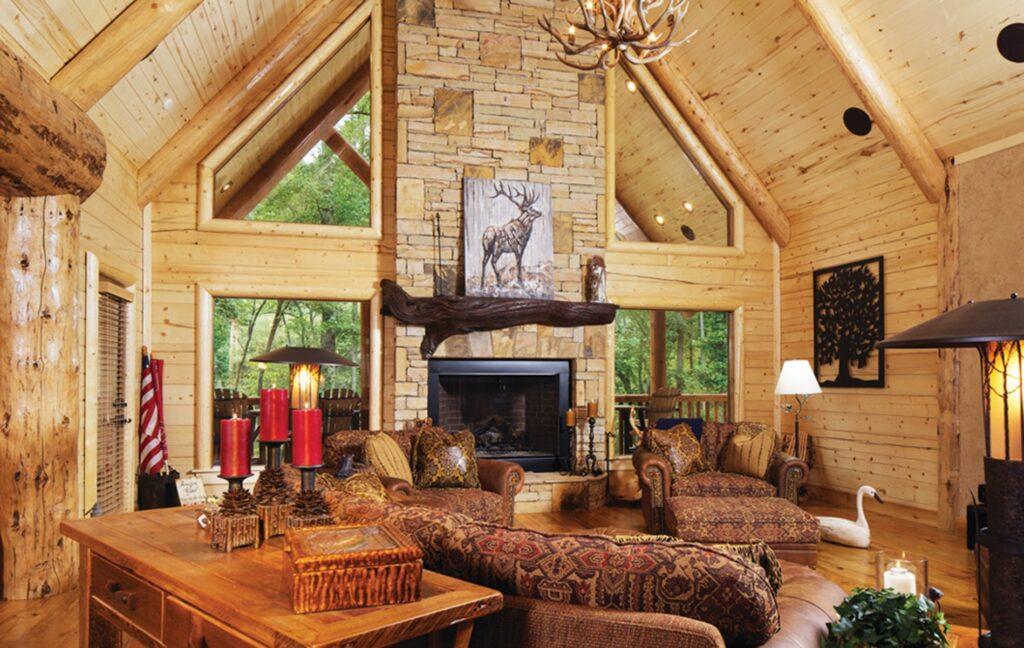

Lifeline Interior™ is a natural looking, semi-transparent wood finish. It forms a breathable protective layer for your walls and ceilings while highlighting the beauty and grain of the wood. Our unique breathable formula allows natural wood moisture to escape from the wood yet provides a tough surface film that can easily be cleaned and dusted, especially when top coated with our Lifeline Acrylic™ Gloss or Satin clear finish.

WHAT EXACTLY DOES ‘BREATHABLE’ MEAN?

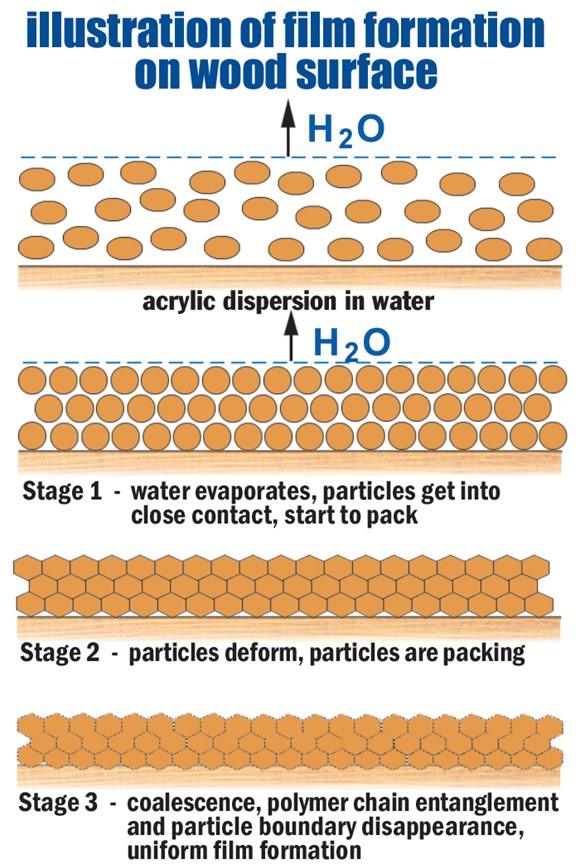

To understand, it takes a little bit of chemistry and physics, but the concept is fairly simple. Technically, for those of you who want to impress friends, the scientific term is vapor permeability – the ability of water vapor to permeate through a film.

Polymer films are composed of long chains of molecules that are bound together in a three-dimensional matrix. This matrix is quite dense in films like polyurethane and alkyd coatings, and there is not much space between the polymer chains. This prevents small water vapor molecules from making their way through the film.

On the other hand, Lifeline finishes form a less-dense matrix with room enough for water vapor molecules to penetrate through the film, but not enough space to allow liquid water to make its way into – or through – the film.

You can think of it in terms of a film with a bunch of small holes, or pores, that filter out large objects but allow smaller objects to pass through them. In chemistry these types of films are known as semi-permeable membranes, but in our industry we call them breathable.

Another factor that influences vapor permeability is the thickness of the film. The thicker the film, the more difficult it becomes for water vapor molecules to make their way through. That’s one reason we encourage you to apply our finishes in thin layers. When applied too thickly, even acrylic latex films can have difficulty breathing.

If you use one of our Lifeline Interior color stains, the colorants in the finish help stabilize color of the wood and slow down, or even prevent the fading that you may notice when removing pictures or furniture from against the wall. If using Lifeline Interior Clear, we recommend the addition of UV Boost to the first coat to help prevent this “picture frame” effect due to UV light exposure. Since interior surfaces are not exposed to harsh weather, two coats of Lifeline Interior are not necessary. However, you can apply multiple coats of Lifeline Interior in order to achieve the appearance you desire.

Lifeline Interior is easy to apply. It can be applied by brush, spray or pad. Lifeline Interior dries to the touch in one hour and clean-up is easy, just use soap and water.

One of the best reasons to use Lifeline Interior is that it reduces the absorption of pet, fireplace, and cooking odors into the wood.

Lifeline Interior resists yellowing and is non-flammable and virtually odorless. Like all of our premium finishes, it allows the natural look and beauty of all species of wood to come through. Lifeline Interior can be used on new or existing log homes as long as the surfaces are clean and dry.

You can now order Lifeline Interior in any color you desire in addition to our 13 standard colors plus Clear. For a custom color, or color matching please call 1-800-548-3554. You can request wet samples to try on your logs by calling 1-800-548-3554.

Note: All Lifeline stains and finishes are water-based and do not contain petroleum distillates. They comply with all State and Federal regulations for contained volatile organic compound (VOC). In addition, being concerned with keeping living areas as healthy as possible, our interior finishes are specifically formulated to meet the highest interior air quality standards.

Perma-Chink Systems has recently added another beautiful wood finish option for our customers. Unlike our traditional Lifeline film-forming wood finishes, Log & Timber Defense™ penetrates your wood. As it absorbs into the wood surface, it forms a strong lattice network within the wood, reinforcing and strengthening the entire system from the inside out. Due to its elastomeric nature and penetration, it greatly reduces the chances of peeling and flaking by leaving the system breathable to water vapor. Many penetrating oil-based finishes can also form a network but unfortunately often contain harmful flammable solvents that make working with them both dangerous for you and our environment. In contrast our Log & Timber Defense is water-based making it both easier and safer to work with.

Log and Timber Defense is designed to be applied to bare wood in one or two coats. However, if applied to wood that already has an existing coating this can interfere with adhesion and could lead to premature failure of the finish. For best results we recommend application of Log & Timber Defense to bare wood that has been cleaned with Wood Renew™.

For all our Lifeline™ wood finishes, we recommend application of a topcoat, however, not so with Log & Timber Defense. The reason for advising against this is because when a maintenance coat is needed in the future there will be difficulty with penetration into the wood because the topcoat forms a barrier to penetration leaving a film on surface. Additionally, this could lead to undesirable surface defects as well as an uneven appearance.

Texture is another property that distinguishes Log and Timber Defense from our Lifeline Stains. Due to its penetrating nature, Log and Timber Defense leaves the surface with a more naturalistic rustic beauty. In general, it will appear flatter than our Lifeline finishes. However, if slightly more gloss is desired, a second coat of Log & Timber Defense may be applied. The second coat will also increase color intensity and provide an increased level of overall protection for the system.

Finally, Log and Timber Defense is formulated with ingredients that inhibit the growth of mold and mildew. Log and Timber Defense is both a stain and sealant in one package. It helps to keep liquid water out, which reduces biological growth that can attack and destroy your wood. In contrast, traditional natural oils – such as Linseed Oil – can easily promote growth of mold and mildew. Log & Timber Defense is waterborne, low in odor, has easy soap and water cleanup, and is non-flammable. Log & Timber Defense offers unique properties designed to give your home the very best protection possible.

Hi there, sports fans! Can you believe it is November? Seems to me I was just getting used to summer! Cold weather is coming and it pays to get serious about closing those last few orders and thinking about comfort and home protection over the winter.

You can assure customers by suggesting they’ve spent their last winter with drafts, cool air, and high energy costs with a properly sealed home. They will be much more comfortable, increase their home value, and protect their log home investment by chinking now, before the winter cold sets in.

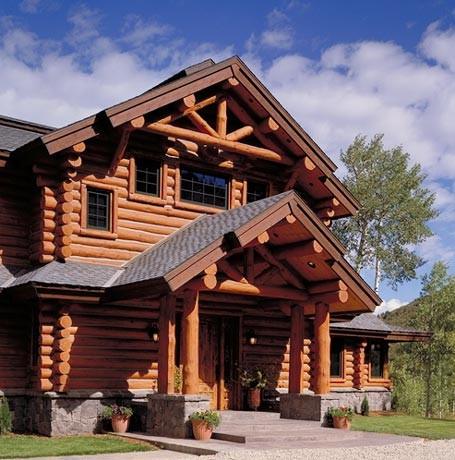

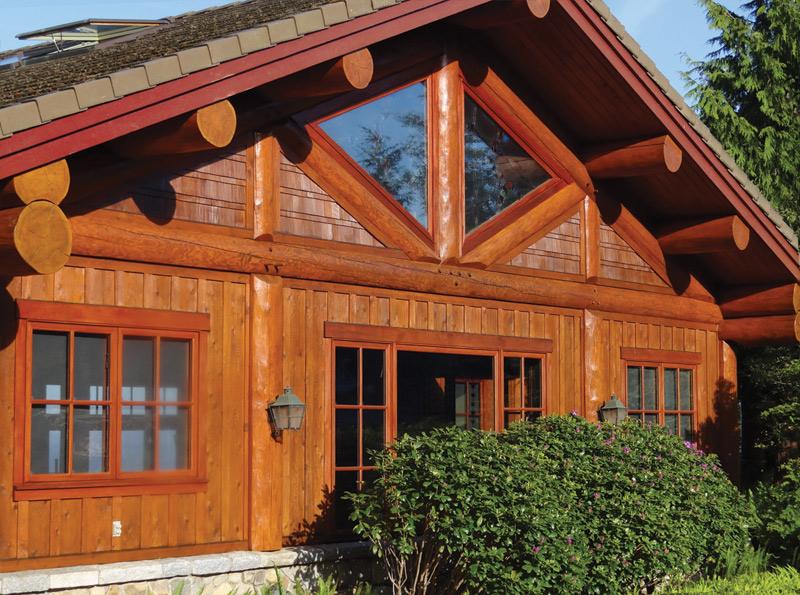

If the logs themselves could use some additional protection, suggest LIFELINE natural wood finish, which is specifically designed for log homes. LIFELINE is easy to apply, enhances the natural beauty of the logs, and provides premium protection against the ravages of the coming winter.

And for sure note that if you apply LIFELINE finishes to the home now, we assure compatibility with Perma-Chink chinking for later applications. Works great the other way around, too – chink now with Perma-Chink or Energy Seal and follow up with LIFELINE for a dynamite sealant system.

Q: I am always pressed for time, how soon after LIFELINE application can I apply Perma-Chink?

A: LIFELINE will dry to the touch in an hour or so, and Perma-Chink can easily be applied the following day.

Q: Do we put Bora-Care wood preservative on the inside or outside of the home?

A: To protect the log completely against the target organism, you must get the required amount of active ingredient into the log surface. To do this you should treat the entire surface of the log per the label instructions. The simplest way is to apply Bora-Care to both sides of the logs before chinking or staining. Don’t worry about overspray on the floor or interior framing- in fact, it’s a good idea to spray Bora-Care two feet in from the walls on all floor members during this phase of construction.

Q: Does LIFELINE Stain have Mildewcide?

A: Yes, LIFELINE stains for exterior wood surfaces have an effective mildewcide, however in conditions conductive to the growth of mildew, even the most effective mildewcide can be overwhelmed. Mildewcide in LIFELINE finishes helps prevent mildew from growing in or on the stain film only. So, mildew or fungus should be removed completely before application of the LIFELINE stain.

Q: How dry should logs be before they are ready to stain?

A: Wet logs pose the most serious problems to oil-based stains that do not adequately penetrate wet wood surfaces, and to any film-forming stains that prohibit evaporation, thereby trapping moisture inside logs. LIFELINE stains and finishes let logs breathe to allow moisture to evaporate from wet logs. Extremely wet logs might reduce the life of the first application of stain, but there are good reasons to stain as soon as is possible. Exposure to the weather causes fading of the natural wood color, which can affect the final home color. The longer bare wood is exposed to the elements, the more mold and mildew spores settle on the surface.

Cleaning the logs, then immediately applying LIFELINE and a topcoat of LIFELINE Advance stabilizes the color, adds a water repellant film, and provides a protective film containing mildewcides and UV inhibitors. If you are in a geographic location where mold and mildew are prevalent, we advise you to include additional mildewcide additives in your first coat of LIFELINE finish.

Q: Will Perma-Chink stick to oil or solvent based stains?

A: Yes. Oils in conventional stains have a tendency to evaporate fairly quickly, leaving loosely bound tint on the surface of the logs. Remove any loose material and try the water drop test. If Perma-Chink doesn’t have to fight its way through a layer of goop or oil, it will bond to the wood tighter than any material.

Q: Can Perma-Chink be applied to a milled log home?

A: Yes. Perma-Chink log chinking can be applied to any style log home. But we recommend our specialty sealant for milled log homes – Energy Seal. It will seal out damaging water and virtually eliminate air infiltration, making your home much more livable and protected in the winter months to come.

Q: Can I apply Deck Defense to treated wood?

A: Yes, Deck Defense can be applied to treated wood, cedar and redwood, etc. It is designed for any horizontal surface, particularly if abrasion and traffic patterns are a concern.

The Difference is Clear, but it’s NOT What You Think.

It makes sense that the more your product costs, the higher the quality of ingredients.

To prove this point, the professionals in the industry performed a careful analysis that shows that in the long run, it’s less expensive to apply the very best quality stain, despite its higher initial cost.

How Does a Low-Cost Option Cost More?

Field tests show that while low-quality finishes last two years or less, top-quality, 100-percent acrylic polymer finishes such as the LIFELINE™ Ultra family from Perma-Chink Systems last five years or more when applied to a properly prepared surface and maintained on a regular basis.

A simple comparison of the cost of a gallon of stain is a mistake because all stains differ in their lifespan, coverage rate and quality of appearance and protection.

A high-performance finish gives long-lasting color retention using a balanced formulation of transparent iron oxides and long-lasting mildew inhibitors.

How Do More Expensive Finishes Last Longer?

The secret behind durability is state-of-the-art resins that create a flexible and tough seal on logs. Perhaps more importantly than the seal’s strength, the resin also ensures that the seal is continuous, providing protection from holes and gaps that might otherwise develop with a lower-quality finish. In addition, it has unsurpassed adhesion to wood.

It’s this continuity that has proven to be much more resistant to UV degradation, color fading and adhesion loss. And just like all LIFELINE finishes, the water-resistant film breathes just like Gore-Tex® to allow trapped moisture to evaporate from the logs.

What Does A Clear Coat Do?

By applying a clear topcoat, you also have the opportunity to create a gloss or satin finish and greatly extend the life of the stain system.

Adding a high-performance clear exterior topcoat over the wood finish acts much as an automotive clear coat to enhance the appearance and extend the life of the finish.

UV And Water Protection Are Important

While UV inhibitors are included in some high-quality stains, your finish should also repel rain but be permeable to water vapor to allow trapped moisture in your logs to evaporate, and the Perma- Chink Systems products do just that. For topcoats and base stain, LIFELINE provides you with options that “breathe,” allowing moisture within the logs to evaporate while reducing checking. Clear topcoats boost protection against UV rays and add water repellency – while making your exterior walls easier to clean. Additionally, LIFELINE Advance clear topcoat is environmentally-friendly, as a water-based formula that is low in VOCs and meets regulatory compliance in all 50 states.

We Use What We Sell

“I have personally applied every one of our products on my log house in Colorado. That furniture grade finish not only provides the best protection for the logs, but it also literally distinguishes the house. I and my staff continuously evaluate every stain on the market and when it comes to ultimate endurance, furniture grade appearance, ease of application and environmentally responsible formulation, there is only one choice – Perma-Chink Systems.”

– Rich Dunstan

Contact Us For Questions or Orders

1-800-548-3554 – www.PermaChink.com – Store Locations – As always, we offer free samples; order at Store.PermaChink.com.

We often get asked this very question. To help answer this we must look to our experience both past and present. For 40 years now Perma-Chink Systems® has been working to develop products that meet both the demands of Nature and our Customers. The result of this experience has been a wide range of products that help solve specific needs. Our wood finishes can be split into four main categories: exterior film forming, exterior penetrating, interior film forming and specialty. Let us take a closer look at these products and discover what makes each one unique.

A Breathable Finish

First, our exterior film forming stains carry the Lifeline designation and are all breathable. Therefore, they allow water vapor to pass through while stopping liquid water from getting through. These types of finishes bond well to vertical wood surfaces but do not penetrate deeply into the wood. The protection is primarily on the surface. However, our Lifeline Ultra-7™, Lifeline Ultra-2™ and Lifeline Accents do contain special additives that help protect specifically the lignin in wood at the interface where the stain and wood meet one another.

Lignin acts as the structural framework for wood much like steel beams in commercial buildings. When lignin breaks down due to UV exposure, the interface between the coating and wood is compromised and delamination of the coating often results.

Lifeline Ultra-7

Lifeline Ultra 7 is our premier all-acrylic wood finish system containing special high-performance additives that reduce UV degradation and biological attack. It is designed for a one coat application however two coats can be applied to provide more protection and color uniformity.

Lifeline Ultra-2

Lifeline Ultra 2 is designed to be a two-coat application of finish. This finish system is very flexible, has inhibitors for ultraviolet light as well as biological growth, giving it an advanced level of protection.

Lifeline Accents

Lifeline Accents is designed to provide our customers with exciting colors and features and an affordable price point.

Lifeline Exterior

Finally, Lifeline Exterior, another two-coat system similar to Lifeline Ultra 2, is also very flexible, has additives designed to provide protection from UV and biological attack and is economical. All three of these wood finish systems have differing levels of protection designed to meet the needs of our customers.

Each of these finish systems should be sealed with our Lifeline Advance™ clear topcoat. This breathable topcoat helps keep the surface clean and relatively dry, reduces biological growth and helps reduce UV degradation which greatly extends the life of your finish system.

Our New Defensive Additions

Log and Timber Defense™ and Deck Defense™ are our two exterior penetrating products designed for both horizontal and vertical surfaces. These two wood finishes dive into the wood and seal the wood from the inside out. While reapplication of product may be necessary more often than our film forming stains, you don’t have to worry about chipping and peeling of the coating with these products. Both products work best on unsealed surfaces allowing for better penetration of each product. Decks are often difficult due to the intense UV exposure and abrasion they receive over time. Protection of these surfaces with Deck Defense is a smart move. However, because these products penetrate, application of a topcoat such as Lifeline Advance or our wood primer Prelude is strongly discouraged.

The Right Choice

Each of our wood finishes helps meet specific needs of your home exterior. Whether it be function, longevity, ease of application, quality, fashion, performance, or economics – Perma-Chink Systems֯ has a wood finish solution suited just for your home.

Lifeline Prelude is a clear wood sealer and primer for surfaces that have been media blasted. Lifeline Prelude is enhanced with UV Boost for maximum protection against graying due to ultraviolet light exposure.

Over the past few years media blasting has become a popular tool for removing old finishes in preparation for applying a new coat of stain. However, media blasting significantly increases the porosity of the wood, thus allowing it to absorb much more stain than those wood surfaces that have been chemically stripped, sanded, or pressure washed.

This high absorption results in a darker final stain color than that typically reflected by a color chart. In addition, wood is not uniform and media blasting often emphasizes the differences in wood grain absorption, even on a single log. This results in streaks and blotches due to varying amount of stain absorbed by different areas of the wood. Lifeline Prelude solves many of the potential problems created by media blasting.

One coat of Prelude primer fills the pores of the wood and provides a uniform surface film in preparation for the application of a pigmented stain. However, it should be noted that Lifeline Prelude is a wood sealer/primer and is not suitable as a clear, final finish!

Recommendations for the use of Prelude:

1. After a home has been media blasted.

2. If a home is aggressively pressure washed to the point where the surface is feathered and the porosity of the wood varies from area to area.

3. On wood where the surface has been unevenly sanded.

4. On rough cut siding before the application of the color coat(s).

5. If a section of a wall has been repaired or replaced and the new sections don’t match the surface characteristics of the old.

6. Whenever an older home (more than 80 years old) is going to be restored. Once the surface of old wood is cleaned of grayed wood it typically takes on the porosity characteristics of a blasted surface.

7. Whenever you want to use only clear coats on interior surfaces. Although Lifeline Interior Clear can be used, the use of Prelude as the first sealing coat is a better deal, since it already contains UV Boost. Once Lifeline Prelude dries, Acrylic Gloss or Satin or PCS Clear Shield Gloss or Matte can be applied over it.

8. Whenever a home is completed but may remain without an exterior finish for many months, a coat of Prelude will help prevent surface graying and make it easier to clean when it comes time to stain. Adding a dose of Stay Clean™ to the Prelude will help also prevent the growth of surface mold and mildew.

For use exclusively with Lifeline wood finishes.

With so many different choices on the market for wood restoration and cleaning products, it can be confusing trying to decide just what to use. Unfortunately, when it comes to cleaning or restoring wood, there is no “one size fits all” approach. Each unique situation has a chemical solution that best solves that problem. Perma-Chink Systems understands these challenges and we have developed specific products to address each situation.

We offer a wide range of cleaning and restoration products that are designed to be fully compatible with our other wood care products. Our name says it all – Perma-Chink Systems. If you choose to stay within the system, you can have confidence in a fantastic outcome. It is difficult to determine exactly what is in a typical store brand of cleaner. Many of these cleaners, conditioners and brighteners may contain ingredients that are not compatible with our products. Some brands of wood cleaners may leave residues that prevent adhesion of our stains – even after considerable rinsing. Many of these cleaners may even damage the wood to the extent that adhesion of our stains may be a serious problem. Furthermore, a number of these cleaners can even cause unsightly wood discolorations. But do not worry, stop playing the guessing game. For over forty years now, Perma-Chink Systems has been working towards creating and testing products that work together for your success! Let us take a closer look at a few of them.

Log & Timber Wood Cleaners

Our wood cleaner Log Wash™ was originally developed to clean coated wood surfaces of mold, dirt, oils and other debris and not harm the coating. However, it was discovered that Log Wash could also be used to clean bare wood surfaces. The chemistry of wood is complex. For example, wood naturally contains chemicals that help protect it from disease and rot. Some of these natural extracts and resin oils can – and do – cause discolorations that can be undesirable to look at. Wood tannins are one such class of chemicals that, when combined (or complexed) with iron, can form dark discolorations on the surface the wood. Our Log Wash contains Phosphoric Acid which can also form chemical compounds with iron, such as iron II phosphate or iron III phosphate, that compete with the natural tannins present in most wood species. By effectively reducing the amount of free iron available to the tannins, these dark ink-like discolorations can be prevented.

Using Log Wash not only helps to clean but to also stabilize a very complex system! Many available commercial cleaners are also high in pH, such as caustic cleaners. These cleaners can do damage to the coating by softening it. Once these cleaners are rinsed or pressured washed off, the coating comes off with it. Using Log Wash according to our labeled instructions keeps the pH slightly on the acidic side where wood is naturally. By keeping the pH balance close to where wood is naturally, some undesirable chemical reactions that could more easily occur at high pH can be avoided altogether.

Wood is a unique, natural substrate that appeals to us due to its beauty and natural characteristics. Are all wood species the same in chemical composition? The obvious answer is no they are not. Although all wood contains cellulose and hemicellulose, it is the wood extractives and resin oils that contribute in large part to the differentiation of one species from another. In addressing these differences it brings us to our next wood cleaning product: Cedar Wash™. This product was developed to deal with certain species of wood that naturally contain very high levels of extractives and resin oils. The presence of these extractives can cause several problems including discoloration, stains and adhesion problems with a coating. Wood that falls into this category of “extractive-rich” includes Redwood, Western Red Cedar, Walnut and Mahogany. A second class of wood that contains high levels of extractives but not as high as the “extractive-rich” includes Southern Pine, Douglas Fir, Spruce and Cypress.

Cedar Wash is a Ready-To-Use formula designed to effectively remove resin oils and wood extractives from the surface of wood and it will not harm finishes that are in good condition. In addition, the product is safe to use on chinking and sealants and has a low environmental impact due to its safe chemical composition.

Dealing With Dark, Vertical Streaks

What if my wood already has metallic iron tannate stains what can I do about them? First, you need to be certain that the discoloration is from iron tannates. You can perform a simple test with a Q-tip dipped in diluted 3-to-1 bleach solution. Apply this to a small test area and if the dark color disappears, your color problems are most likely from surface mold. In contrast, iron stains will also have the appearance of streak marks running down a wall in a vertical direction and will not go away with the Q-tip test. Oxcon™, which contains Oxalic Acid, was developed to help brighten wood with dark discolorations due to iron stain. Ferric Iron, which is dark in color, will react with Oxalic Acid to form Ferrous Iron which is colorless. The key to all this working properly is good rinsing afterward. If the oxalic acid is not rinsed well, it can leave surface crystals that can interfere with adhesion.

Brighten Bare Wood Back to Original Color

Bare wood when left exposed to the elements will weather. What do we mean by weather? Wood is continually going through changes due to sunlight, water, mechanical forces and heat. Each of these can present problems, but sunlight does considerable damage to the surface of the wood due to a process called photooxidation. In this process lignin, which provides support structure in the cell wall, is broken down and degraded, turning the wood grey in appearance.

After this damage has occurred it would be unwise to stain or paint on the surface of the damaged wood. Ask yourself would you apply paint to an old rusty metal pole and expect it to stay adhered for a long time? Of course not. In the same way, the compromised wood surface must first be removed through mechanical and chemical means before applying a coating to the surface. Perma-Chink’s product to deal with this problem is called Wood Renew™, and when dissolved in water produces hydrogen peroxide.

This, along with additional highly effective cleaning agents, work together to remove resin oils, dirt and disinfect the wood. A pressure washer is used to help mechanically remove the damaged layer of wood leaving behind a bare, clean, and newly restored surface to apply a coating. The appearance of the wood changes from a dark gray to a freshly milled yellow color. It is truly amazing to see the difference this process can have on the wood. Surface mold and spores, dirt and damaged wood fibers are all removed in this process. We are cleaning and restoring wood back to its original, bright clean form.

Finish Removal

If you have an existing finish that you need removed, we have two chemical options for you. The first is called S-100™. S-100 uses a proprietary, environmentally safe ingredient to help soften the existing film prior to removal. It forms a gel on the surface of the film, allowing it to have maximum contact time with the surface. The surface is then rinsed using a pressure washer to remove the film and S-100 from the surface. Our second option, called Strip It®, uses a highly effective but low toxicity active ingredient called Benzyl Alcohol. Like the S-100, this product also acts on the surface to soften the film and is removed with the assistance of a pressure washer. Both S-100 and Strip It are water-based products that are environmentally friendly and safe, as opposed to hazardous solvent-based products like methylene chloride, methanol, and petroleum solvents. Strip It is practically odor free, S-100 has a citrus odor, and both are non-flammable and biodegradable.

Rinse Completely

Finally, there is one important procedural step that all these cleaners and wood restoration products share, and it has to do with proper rinsing. Each product used should be thoroughly rinsed from the wood. You might ask yourself, “How do I know with certainty that I have rinsed enough?” Perma-Chink Systems can provide help with this too. We offer pH Strips that are used for testing the pH of the rinse water and wood. We strongly recommend using pH strips to help you determine if you have rinsed the substrate back close to a relatively neutral pH range of 6.5 – 7.5. Improperly rinsing the wood can lead to many problems that could easily have been avoided if proper rinsing were done in the first place.

Final Notes

At Perma-Chink Systems we have worked tirelessly to develop quality log and timber home products that work for you each step in the process, while at the same time being aware of your safety and the stewardship of our environment. We always strongly recommend that you follow all labeled instructions when using our products.

In addition, we have developed technical tips to help guide you through the process. For example, we have a cleaning guidelines and pH tech tip and many more all designed to assist you in solving your problems. These tips can be accessed on our website www.permachink.com under Info > DYI Section. We also have product specialists available at 1-800-548-3554 to help answer any questions you might have. We hope this information helps you to better understand the purposes and differences behind each of our cleaning and restoration products.

CHEMIST’S CORNER: Can All Wood Species Be Prepared the Same Way, Using the Same Cleaning Products?

The obvious answer to this question is NO. Although all wood species contain many of the same components – including cellulose and hemicellulose and minor amounts of extraneous materials – it is the wood extractives that differentiate wood species from one another.

Understanding the Bleeding of Wood Extractives.

Wood extractives are compounds present in the softwood and heartwood of a tree that contribute to such properties like color, odor, decay and insect resistance, density, and flammability. When used for log homes, naturally occurring extractives in the wood can migrate to the surface and discolor paint and finishes (water soluble extractives) as well as create adhesion issues (oil soluble extractives) for many coating types.

The organic components of the extraneous materials are referred to as extractives because they can be removed by extraction with solvents without altering the cellulose/lignin structure of the wood. Extractives include tannins and other polyphenolics, coloring matter, essential oils, fats, resins, waxes, gums, and starch. Depending upon such factors as species and growing conditions, the total extractive content of wood substance may range from less than 1% to 30% in extreme cases.

Wood Species and the Level of Extractives

All wood species contain wood extractives; however, there are a handful of wood species that are characterized as extractive-rich woods. This group includes Redwood, Western Red Cedar, Walnut and Mahogany. The second group of wood species that also contains higher levels of wood extractives but less than extractive-rich woods include Southern Pine, Douglas Fir, Spruce and Cypress.

The percentage of extractives in trees is generally low, but a high concentration is found in knots and heartwood of the tree. Knot bleeding can occur when a knot contains an excessive number of extractives. In these cases, the extractives consist mainly of rosin, fats and turpentine, and these extraneous materials can make up as much as 50% of the knot by weight. The ratio of extractives can change with the season and weather (if the tree is stressed).

Extractives Affecting Wood Color

Staining or discoloration of wood may result from chemical processes that convert originally colorless or light-colored extractives into intensely colored products. Most of the “chemical stains” result from oxidation of certain wood extractives during air seasoning or kiln drying. Some resins can bleed out of the wood, as seen in pine wood. Sometimes the extractive can react with foreign material.

Using Cedar Wash for High-Extractive Wood Species

Cedar Wash is a wood cleaner with a high pH solution, which can dissolve, soften, loosen, or react with different types of extractives found in extractive-rich woods used in log homes. If a chemical is soluble in a liquid, it is easier to remove than a chemical that is only softened by that liquid. Being soluble is preferred as this means the particles are broken down to become so tiny we can no longer see them. Cedar Wash is designed to remove surface resin oils and high concentrations of water-soluble wood extractives such as sugar and protoplasm, in addition to dirt, grease, grime, pollen, and surface mold and mildew without harming the wood.

Cedar Wash was developed by Perma-Chink Systems as a Ready-to-Use cleaner specifically formulated for preparing the surface of wood species that contain high levels of wood extractives and resin oils. It is also safe for chinking and sealants.

- Easy to use, Ready-to-Use formula.

- Low environmental impact

- Designed specifically for Western Red Cedar, Redwood (Softwoods), Walnut, and Mahogany (Hardwoods)

- Removes resin oils and wood extractives from the surface of the wood

There is a popular misconception that spraying the wood with water before applying a borate will aid the penetration of the borate into the wood. Wetting the surface does not increase the interior moisture content enough to matter. Pores of the wood get filled with water and less borate is absorbed into the wood, which lessens the effectiveness. When it comes to treating a log home with borates, the drier and more absorbent the surface is, the better the treatment.

What Can You Expect from Applying Borates to Logs and Timbers?

Borate wood preservatives come in two forms: borate/glycol formulations such as Bora-Care and pure soluble borate powders like Tim-Bor. The active ingredient in both is disodium octa borate tetrahydrate, a compound chemically similar to a combination of boric acid and borax, but with a higher concentration of boron responsible for the effectiveness.

Borates are toxic to rot and decay fungi, subterranean and drywood termites, carpenter ants, and wood boring beetles. It is also toxic to beetle eggs that may be in the wood at the time of treatment or deposited later. Tim-Bor will prevent beetle infestations, but is not as effective as Bora-Care for protecting larger logs and timbers or eliminating existing insect and decay infestations.

Applying Bora-Care should end powder-post beetle activity (small round holes) within a few months to a year after treatment. However, if there is an existing infestation of old house borers (oval holes), it may take up to a year before total control is achieved.

Tim-Bor and Bora-Care solutions are best applied using a compressed-air, garden-type sprayer. You can use either a fan or cone spray tip as long as you completely wet the surface.

BORA-CARE Borate/Glycol Formula

The amount of time it takes Bora-Care to dry depends on several factors: the previous finish, if any; the density and porosity of the wood; and the temperature and humidity. In warm, dry climates the drying time may be as little as a few days. Under humid conditions, it may take four to six weeks of drying time before a stain can be applied. You can check to see how drying is progressing by touching the treated wood, especially in the early morning. If the wood still feels damp, it is not ready for a topcoat.

There is a way to speed up the Bora-Care drying process, but it must be done carefully to avoid removing the active ingredient. One of the components of Bora-Care is a slow-drying glycol that helps the borate penetrate the wood. It is the glycol that interferes with the stain adhering to the wood. After a week or so, most of the borate has penetrated deep enough that it will not be removed by washing the glycol off the surface. If washing occurs in the morning, or soon after a rain when the wood is damp, you can lose a significant portion of the active borate ingredient.

Once the Bora-Care is dry, inspect all of the treated surfaces before applying a stain. Occasionally, a white residue may appear over knots and other areas of the logs. These white deposits are created by a small amount of the borate crystalizing on the surface. Their appearance does not mean that the treatment will not work! Wipe this residue off with a damp sponge or rinse it off with a hose. If you stain over any white spots they will show through the stain.

TIM-BOR – Pure Soluble Borate Powder

Like Bora-Care, the solution of Tim-Bor may be applied with a brush or sprayed onto the surface of the wood using any type of compressed air (garden) sprayer. Since Tim-Bor does not penetrate the wood as quickly or completely as Bora-Care, it is important to not expose treated surfaces to rain or snow for at least a day or two after treatment. Tim-Bor solution dries rapidly so is not necessary to wait more than a couple of days before applying stains.

However, longer drying time may be necessary when the weather is humid or cool. Once the solution has dried, inspect all treated surfaces for any signs of white residue. Remove the residue with a damp sponge before applying stains since the white areas will show.

If you have allowed the Bora-Care or Tim-Bor to dry for three or more weeks, we suggest that you give the exterior log surfaces a light wash with Log Wash before applying finishes. This will help remove any pollen, dust, dirt, and mold spores that may have accumulated on the wood during the drying period.

Unused borate solutions should never be left in application equipment overnight. Clean and rinse your equipment after each use.