Perma-Chink Systems, Inc

Log & Timber Home Care Experts

Perma-Chink Systems, Inc

Log & Timber Home Care Experts

Before we get started, let’s look at the difference between shakes and shingles. In many cases the terms are used interchangeably but regional differences do exist. Nationally you will find shake roofs and shingle-sided homes as well as vice-versa. It’s more a matter of semantics than definition.

For the past 30-plus years, the most accepted and effective method for preventing infestations of wood destroying insects and decay fungi in log homes has been by impregnating the wood with a solution containing the element boron. Boron salts are referred to as borates, and the most commonly used borate utilized for this purpose is disodium octaborate tetrahydrate (DOT), the active ingredient found in our wood preservative products.

Deck handrails present a real challenge to film forming finishes, especially if they are new. Here’s why. Round log handrails are typically fabricated using green wood. Once in place and begin to dry, handrails shrink, crack, and develop fissures to relieve the stress due to shrinkage. There is no way to prevent this from occurring. If a finish is applied before these fissures open up, and once they do open, they provide a path for water to soak into the rail behind the finish. When the sun comes out and the rail heats up, the water turns into water vapor which may exert enough pressure to actually push the finish right off the wood. In winter months, the water in the wood will freeze and expand and that, too, can pop the finish off the surface.

One of the greatest mistakes you can make when applying a new finish to your home is to use inexpensive paint or stain brushes. You will be putting a lot of time, money, and effort into your project and saving a few dollars by using cheap brushes can compromise the beauty and performance of your new finish!

There are literally hundreds of wood boring beetle species that infest live trees, but only a few that commonly create problems in log homes. Occasionally a beetle larva that was in a tree when it was harvested will later emerge as an adult out of a log in a home but since these beetles can't reinfest dead wood, these types of infestations end within a few years. It's the beetles that specialize in consuming seasoned wood that present problems in log homes.

Many professional applicators and an increasing number of homeowners prefer to use airless sprayers when applying exterior finishes. One of the reasons that our log home finishes are so popular with professionals is that we formulate our Lifeline log home stains and topcoats with a low viscosity which makes them easier to apply using an airless sprayer.

Sure Shine™ Gloss or Satin is a water-based, urethane-acrylic, interior clear finish for application on both horizontal and vertical surfaces; however, the application of a urethane-acrylic finishes is a bit different than those based on acrylic latex polymers. For example, our pigmented Lifeline™ stains and Advance and Acrylic Topcoats should be thoroughly mixed and brushed out as far as they will go. This may include vigorous back-brushing. However, this technique does not work when applying Sure Shine and its proper application is a bit different than any of our other finish systems.

A fallacy that many people have accepted as fact is that water beading on the surface of wood is the only sign that a finish is repelling water and beading water is an attribute of a quality finish. Nothing could be further from the truth. Beading water is only an indication of the presence of a hydrophobic additive (water-hating or repelling water) like oil, or more commonly, paraffin wax. In addition, there is no correlation between beading water and protecting wood from sun (UV) damage. Furthermore, water beading holds water closer to the finish for a longer period of time, thus increasing the chance of softening the film.

A fallacy that many people have accepted as fact is that water beading on the surface of wood is the only sign that a finish is repelling water and beading water is an attribute of a quality finish. Nothing could be further from the truth. Beading water is only an indication of the presence of a hydrophobic additive (water-hating or repelling water) like oil, or more commonly, paraffin wax. In addition, there is no correlation between beading water and protecting wood from sun (UV) damage. Furthermore, water beading holds water closer to the finish for a longer period of time, thus increasing the chance of softening the film.

Let us assume that you have a brand new log home, or a home that has had an old finish recently removed. The bare wood is nice and bright, and the color is exactly what you always envisioned for your log home. What's wrong with applying one or two coats of some type of clear sealer to hold the color of the wood and protect your logs from rain, snow, and ultraviolet (UV) light damage? There are some problems with this approach.

We have a collection of videos covering common home maintenance tasks specific to log and timber homes. Below are our videos, which are also available on our YouTube channel.

Sealing Logs and Checks |

|

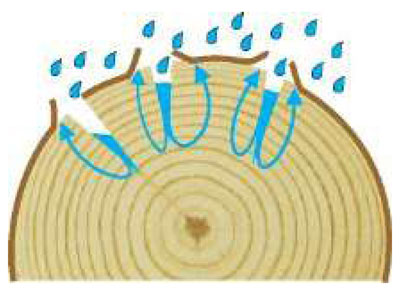

| Sealing Log End Grain | |

| Sealing Log Checks |