Blog & News

Log Home Restoration with Major Log Repair

When you look at these pictures, you probably think to yourself: how is it possible to repair these logs?

Chris Hastings, the second generation of log home restorers knew the answers. The major problem was in the design of the house. The house was designed improperly for the building site. The extensive damage on the lower third of the wall on the exposed side of the house was due to the insufficient overhangs and water damage.

What kind of work will bring this house back to life? The first step for this project is exterior media blasting, followed by log repairs, washing and brightening the exterior wood surface, applying borates to preserve the logs and interior and exterior chinking. Exterior visible water damage prompted Chris to cut away the outer half of this log which shows major water damage in the log’s core.

You can see how carpenter ants ( which are attracted to high moisture content in wood) have the ability to destroy logs in your log home, often in a short period of time, and in this case, causing major structural damage. Prevention of water intrusion by using a high quality log home finish (Lifeline Ultra–7 with Lifeline Advance) and sealants (Perma-Chink and/or Check Mate 2) would have helped eliminate this costly problem.

Following the use of the finish removal system, that stripped off previously applied paint and UV discoloration, you can see (below) how a treatment of Oxcon further brightens the logs without damaging wood fibers. Following a rinsing of the logs with water, your home is now ready for the borate treatment.

After a borate treatment was completed, M-Balm was injected (squeeze bottle) within the log cavity. M-Balm not only hardens the wood, but also stops any further spreading of wood rot. Following the borate treatment and Oxcon to brighten the wood, Chris installed one window to the left for better appearance of this home. Now that house is protected against wood-destroying insects, an application of stain and topcoat will not only enhance your home’s aesthetic appeal, but will offer protection as well.

The semi-transparent stain will protect your wood from the damaging effects of UV exposure. We recommend one coat of Lifeline Advance (clear coat finish, similar technology used in the automobile industry) over the stain color for protection and extending the life of the pigments in the stain. It also will give a maximum protection against water penetration.

The repair of water-damaged log ends will bring us to the final step: applying Perma-Chink between all logs to further protect against air and water intrusion. Prior to the last step of chinking the featured structure, Chris Hastings and his crew replace the outer half of the structurally damaged lower log with a fresh, sound log section.

The final step in the restoration process is to chink all seams (both vertical and horizontal). Perma-Chink chinking that permanently bonds to wood will retain its elastic features in all climates and will provide year round energy efficient comfort.

By Jared Turner

Folks have been trapped inside their homes for lengthy periods of time this winter. Whether it was to escape the cold or shelter from Covid, you are ready for a change. So, as you emerge from your long winter hibernation, take time to stretch, rub the sleepy out of your eyes and put the coffee on. Once you have all of that out of the way, it is time to open your door to Spring and consider the benefits of Forest Living.

For most folks, exposure to forests and trees has wonderful health benefits. For example, both of my parents happen to live in a densely populated urban area. However, each spring and fall they take the time to travel hundreds of miles to dive deep into the forests of Appalachia. They, as well as millions of others, have found these trips to be beneficial to their overall health and wellbeing.

So, what is it about the forests that make them so wonderful for our health? In recent years there is evidence that link people’s exposure to forest with a strengthened immune system, lower blood pressure, reduced stress, improved mood, increased energy level and improved sleep. What is not to like about this list? I believe many of us would be thrilled with improvements in these areas.

Are there other benefits that forests bring to our lives? Absolutely! They help to remove harmful pollution from our air by behaving like giant environmental filters removing harmful toxins from the air we breathe. In addition, forested watersheds provide quality drinking water for over 180 million Americans. Not only do trees filter through the air they also filter through the ground. With temperatures on the rise in most places, forests also help to lower air temperatures by 20-45 ֯F. The evaporation of water from trees has a wonderful cooling influence! Trees absorb carbon dioxide, a harmful greenhouse gas, and store it as carbon while releasing beneficial oxygen back into the air. In addition, trees, properly placed around your home, can help reduce your energy consumption by lowering the cost to cool your home. Finally, trees provide a wildlife habitat for animals to live and thrive.

Densely populated urban areas are just now catching on to all these benefits and are working hard to transform their cities by planting more trees and providing more green space for their citizens. They rightly understand that this approach is part of a more sustainable future. However, living this close to nature does bring with it challenges. At Perma-Chink Systems® we have been helping homeowners live in harmony with nature for over 40 years and as more folks transition to Forest Living, they are going to need a partner who knows how to integrate the two successfully.

Perma-Chink Systems happens to be a one-stop shop for forest living. We supply knowledge, experience, and quality products to help meet the needs of homeowners living in the forest. For example, with spring comes trees blooming and plants flowering, bringing with it pollen and dust. All this dirt, dust and pollen collecting on your home creates challenges for the longevity of your finish system. Once or twice a year we recommend giving your home a good washing. To help with this need we have developed Log Wash™, a highly effective, low pH cleaner designed not to damage your logs or your finish. By removing these contaminates, it will cut down on mold growth and damage caused by absorption of water and sunlight on your finish.

Spring is also a wonderful time to conduct an inspection of your home. Look for damage that needs repaired, cracks or openings that need to be sealed, and observe the overall condition of your finish system. Depending on what you discover, Perma-Chink Systems has products designed to solve most of your needs. We at PCS are actively helping to transition folks to a healthier way of life through a more sustainable Forest Living lifestyle. Please take some time to visit our website for more information.

Just as clear coats are vital to the performance of today’s automotive finishes our Advance Topcoats are an integral part of all of our exterior finish systems.

Not only do they extend the life of the color coats but they do much more. They significantly improve the look of the finish by enhancing the color, clarity and depth of the finish. In other words, they make our finishes the most beautiful log home finishes in the world. Second, they help keep the surface clean. The very nature of a pigmented stain makes it susceptible to dirt pick-up through adhesion or impregnation.

Since we have designed Advance to form a smooth, strong film it makes it much more resistant to dirt. In addition, the smooth surface makes it easy to clean off any dust or pollen that may accumulate on the surface of the logs. A simple wash down with Log Wash and a garden hose will remove the dirt and grime that may be hiding the beauty of your home.

Another feature a smooth topcoat provides is greater resistance to the growth of mold, mildew and algae. In addition to water these organisms need something to grip onto. If the spores land on a tough smooth surface that rapidly sheds water they won’t have an opportunity to germinate and spread. So the surface of your logs stays free of unsightly mold spots and patches of algae.

Of course the best feature of Advance Topcoat is the protection it provides to the color containing stain. Years ago cars left the manufacturer with a coat of paint. More expensive cars may have had several coats of paint but no matter how many coats were applied after a few years on the road the paint turned dull and started to flake off. Then car coating experts discovered the benefits imparted by clear topcoats. Today’s car finishes remain shiny and last longer than ever thought possible all due to the application of clear topcoats.

What is it about topcoats that contributes to this improvement? The most performance enhancing feature of a clear topcoat is that it reflects sunlight. Sunlight is composed of several components including ultraviolet (UV) light. It’s the UV that is responsible for fading colors and, in the case of wood homes, damaging wood fibers through a process called photo-oxidation. The more UV light that’s reflected off the surface the slower the color coats will fade and the less the wood fibers will be exposed to photo-oxidation thus extending the life of the entire finish system. Although satin finishes reflect a significant amount of sunlight, gloss topcoats reflect more which is why car finishes are shiny and not dull. The same holds true for our Lifeline exterior finish systems. Advance Satin does reflect much of the sunlight but Advance Gloss reflects even more, which is one of the reasons that log home gloss finishes are becoming more popular.

An additional beneficial feature of a clear topcoat is the protection it provides to the color coats against degradation by airborne contaminates like sulfur dioxide, ozone and particulates. Even natural contaminates like tree pollen and bird droppings can damage or discolor the color coats by chemical reactions or supporting mold growth. Our Advance Topcoats provide a barrier that prevents this from occurring.

Start saving on your heating and air‑conditioning bills now!

Energy Seal™ is a textured acrylic polymer sealant that provides a long-lasting and resilient seal for any style of log home. Since logs constantly twist, turn, swell, expand and shrink, gaps may appear between logs or between the logs and window and door frames or other areas of the home. These gaps retain moisture and allow the seepage of air and water into the home. Energy Seal eliminates these gaps by forming an air and watertight barrier over them.

So why do people use textured sealant Energy Seal?

First and foremost, to keep water, air and bugs out of places where they don’t belong; second, for its attractive appearance; and third, for the reputation of lasting longer and performing better than competitive products. It should not come as a surprise that log homes are a bit difficult to seal up. When you stack logs on top of one another to make a wall, the logs do not naturally fit tightly to one another so there are usually gaps that must be sealed to prevent air and water from getting inside. That’s what Energy Seal is designed to do.

Most people call log sealants “caulk” but we try to refer to them as “sealants” to help differentiate high quality products from cheap caulks that can be bought at any hardware store. Plus, several of our sealants do not fit the conception most people have of a typical caulk.

There are two reasons that Energy Seal is textured. First, it allows the surface of cured Energy Seal to remain looking “flat.” It does not have that shiny look common to most types of caulk. This allows Energy Seal to blend in with the surrounding stained wood. Second, the texture allows Energy Seal to better accept a stain so that it can virtually disappear on a wall.

Here is a TIP; if you plan to stain over Energy Seal, select a color that’s just a bit lighter than the stain you plan to use. It’s much easier to cover light-colored Energy Seal with a darker color stain than it is to cover dark-colored Energy Seal with a light-colored stain.

Applying Energy Seal

Before Energy Seal is applied, the surface must be clean, dry, and free of oil, wax, or anything else that will interfere with the adhesion of the sealant.

Wherever possible, Energy Seal should be used along with Backer Rod or Grip Strip™. If backing material is not used, there may not be enough room for the Energy Seal to expand and a crack may appear across the joint. Backer Rod should be used even if the joint is narrow. The width of the band of Energy Seal may end up a bit wider than you expected but the integrity of the seal will be maintained.

Applying Energy Seal over old caulk is never a good idea even if it looks like the caulk is still adhering to the wood.

Although it can be time consuming and somewhat difficult, old caulk should be removed for several reasons. If a caulk no longer adheres to the wood, it may be due to moisture getting under the caulk creating rot. The old caulk must be removed to properly treat and seal the wood, so the new sealant does not fail.

Once in place, Energy Seal may be tooled smooth with a trowel or putty knife. Spraying a light mist of water on the surface will make tooling a lot easier and will result in a smoother surface.

If masking tape is used to protect the surrounding wood be sure to remove the tape while the Energy Seal is still wet.

To protect recently applied Energy Seal from the weather, a loose covering of plastic film will prevent it from being washed out of the joint until it cures enough to withstand a heavy rain. Typically, a week or so is sufficient.

For more information about Energy Seal, give us a call 1-800-548-3554 or check out our Log Home Sealant Application Guide

HOW TO SEAL AROUND WINDOW AND DOOR FRAMES

We have an excellent tutorial on sealing around windows and doors using Energy Seal and Log Gap Caps.

During the winter months it’s important to be aware of the freeze-thaw stability of Perma-Chink Systems’ products. The reason may involve shipping conditions or whether it is okay to store a product or products in an unheated shed. In any case you need to be aware of the consequences of allowing any of our products to freeze.

Without a doubt it is always best to prevent any of our finishes and sealants from freezing. They all contain water and the formation of ice crystals within the products can separate the water from the other components. In some products once this occurs it becomes impossible to regain the properties of the original formulation even after thawing and vigorous mixing.

With a few exceptions most of our products are freeze-thaw stable, however, if a product becomes frozen it needs to be thawed slowly, preferably at room temperature. Speeding up the thawing process by heating the container can seriously damage the product making it unusable. If the product is in pails or containers, once it has completely thawed it will require a thorough mixing.

If a product is subjected to multiple freeze-thaw cycles each cycle will contribute to the degradation process until it is no longer suitable for use. If a product becomes frozen it is better to allow it to stay frozen than it is to bring it inside to thaw and then store it where it may freeze again.

It’s the succession of freeze, thaw, freeze, thaw sequences that really destroys the integrity of a product. Before applying any product that’s been frozen be sure to test a small amount to see if it is still usable.

To reiterate:

- It’s best to protect all of our products from freezing.

- If it does get frozen, thaw it slowly at room temperature then thoroughly mix it.

- It’s better to keep it frozen than to subject it to multiple freeze-thaw cycles.

- Before applying any product that’s been frozen be sure to test a small amount to see if it is still usable.

Perma-Chink Systems’ products that are NOT freeze-thaw stable:

- Chink Paint™ Textured & Smooth

- Log End Seal™

- Oxcon™

- StripIt™

Perma-Chink Systems’ products that have limited freeze-thaw stability (5 cycles):

If you need cold-weather storage guidance for a product not shown, just give us a call at 800-548-3554 – we’re happy to help!

Every spring we get lots of calls about carpenter bees drilling into logs, fascia boards, eaves, decks and other unpainted wood surfaces. Carpenter bees are big black solitary bees that look similar to bumblebees but have bare, shiny backs whereas a bumblebee’s back is hairy. Unlike honey bees that reproduce in hives, carpenter bees drill into wood in order to lay their eggs. Their holes are perfectly round and about 1/4 inch in diameter.

Although carpenter bees prefer hardwoods such as cedar, redwood, or cypress, they happily attack pine and most other species of wood. Even pressure treated wood is not immune from carpenter bee attack. As the bee drills into the wood, coarse sawdust may be seen coming out of the hole and piling up beneath the hole. Since it only takes a couple of hours for a carpenter bee to drill a hole a few inches deep, lots of holes can appear over a fairly short period of time.

Most carpenter bee activity occurs in early spring when male and female bees emerge after spending the winter in old nest tunnels. Once they have paired and mated the female bee drills into a suitable site while the male stays nearby to ward off intruders. Male carpenter bees often frighten people with their aggressive behavior but since they have no stinger they are essentially harmless. Females have a stinger but only use it if molested.

Once the initial hole is drilled through the surface, the bee will make a turn and excavate a tunnel along the grain of the wood. This tunnel, which may run for several inches, becomes the cavity where the female deposits her eggs. Several eggs are laid in individual chambers separated by plugs of pollen on which the larvae feed until they emerge as adults during the summer months. In addition to making new holes, carpenter bees also enlarge old tunnels. If left unattended for several years, serious damage to a wood member may result.

In late fall activity may again be seen as both male and female carpenter bees clean out old nest cavities where they stay over winter. Since carpenter bees tend to migrate back to the same area from which they emerged, it is important to implement some control measures in order to prevent logs and wood members from becoming riddled by these bees.

Prevention

Although carpenter bees prefer bare wood or distressed wood, they will attack wood that is stained. Painted wood surfaces, on the other hand, are rarely attacked since the bees must see or feel the grain of the wood in order to recognize it as wood. One of the most effective measures for preventing extensive carpenter bee damage is to fill old or empty holes with Energy Seal. Carpenter bees are attracted to existing holes. Be sure to treat the hole before you fill it since live adult bees will drill right through the caulk on their way out.

One way to keep carpenter bees from drilling into wood is by spraying pesticides that contain either cypermethrin, deltamethrin, or bifenthrin (Ortho Home Defense Max) onto wood surfaces. When it comes to carpenter bees, these products act more as repellants than contact poisons. However, the effectiveness of these applications is only about three to four weeks, so the treatment will have to be repeated every so often. Pesticides should only be used during the periods of peak activity in the spring and perhaps again in late fall. Be sure to follow label directions and read and understand any precautions that must be taken when using these products.

A few years ago we requested information about the effect of our gloss topcoat on reducing carpenter bee activity via survey. Out of over 20 responses by letter, phone and e-mail, only two reported any penetration of the gloss topcoat by carpenter bees. One home went from 20 to 30 holes the previous year down to 2 this past year and the other went from over 20 holes to 4 holes. This confirms our suspicion that the Lifeline Advance Gloss exterior topcoat appears to provide a finish to the wood that carpenter bees do not find very attractive. That is not saying that the gloss finish repels carpenter bees. It does not. Although bees would occasionally land on the gloss topcoat, they just did not drill through it. So why is that? Well, let’s be clear that the Lifeline Advance Gloss topcoat is not a pesticide nor does it have any pesticide properties. It appears to form a coating on the surface of the wood that carpenter bees are reluctant to drill through. Why? It could be the glossy look or that the hard, slick finish does not appeal to them, so the bees will search for another target. Many other online “How-To” documents related to carpenter bees describe the actions of carpenter bees on bare or distressed wood. That stands to reason that well-maintained log homes with stain and a solid topcoat should dissuade most carpenter bees from nesting inside logs.

Another possible solution, with hit-and-miss results, is a bee trap specifically for carpenter bees. Much like a minature bird house, the bee trap invites the carpenter bees inside, and they get trapped in a glass jar. In the past we offered these types of traps, and the results weren’t 100% positive. You can find bee traps online, both DIY plans and for purchase.

Treating Carpenter Bee Holes

Any carpenter bee holes you can reach should be treated and plugged since existing holes attract more carpenter bees. The way to treat an existing hole and tunnel depends on the time of year, and if bees are present at the time of treatment. If the female is drilling away when you find a hole (you can see sawdust coming out or hear her working inside) spray a contact pesticide like wasp and hornet spray into the hole. She will quickly back out and die. Immediately fill the hole with wood putty or Energy Seal. You need to treat the hole even if it appears empty since the bee may be resting and, if left alive, will drill back through the plug you’ve just inserted.

If you find carpenter bee holes in late spring or early summer it’s difficult to tell if there are bee larvae developing in the tunnels. The best thing to do is to run a length of flexible wire into the tunnels in order to break through the pollen plugs separating the chambers. Then spray a pesticide into the hole and seal it up. The same thing should be done on holes found in the fall or winter to kill any bees that may be over-wintering in the holes. Just remember to plug the holes since they will attract more carpenter bees come spring.

Several people told us that although they sprayed a pesticide into the holes, carpenter bees later emerged, in some cases even after the holes were plugged. How can this happen?

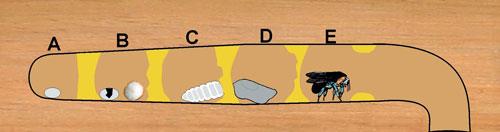

If we take a look at a cross section diagram of a carpenter bee gallery we can see how. After drilling out a four to five inch long gallery, the female carpenter bee lays an egg in back of the gallery then places a plug of pollen she has gathered to form a chamber (A). She continues doing this until there are four to six egg chambers in place. After a few days the egg hatches and a small white grub emerges (B). The grub feeds on the pollen plug for a few weeks (C) until it is ready to pupate (D) and change into an adult bee (E).

If you look at the way the gallery is constructed, you can see why spraying a pesticide in the hole may not kill all of the developing bee larvae. The pollen plugs prevent the pesticide from getting to the rear chambers. So, before you spray any pesticide into a carpenter bee hole be sure to run a stiff wire all the way to the back of the gallery to break through any pollen plugs. That way all of the larval chambers will be exposed to the pesticide.

Perma-Chink Systems History Over 40 Years

The Beginning

In 1980 my neighbor told me about building a log home in Eastern Washington. He said that he loved the home and the lifestyle but was disappointed that with the wind constantly blowing and harsh cold winters, there was no real effective way to seal the gaps between the logs. The house leaked air and heat, and wind-driven rain literally came right through the walls.

He tried various caulking materials with little success. Caulking around a bathtub or sink was significantly different from ‘caulking’ literally miles of seams between logs in a log house. After a number of conversations and experiments, it became apparent that there was no readily available product that could seal the gaps, look like authentic chinking, and last more than a few months.

After literally months of trial and error, it became apparent that if we were going to design a material that would be acceptable, we would have to design it ourselves.

Defining a New Industry Standard

The product we were designing was to be a replacement for what was known in the Log Home Industry as chinking – the sealant that historically provided the seal between the logs. A “chink” is a gap – as in Biblical Times, “A chink in his armor’. Therefore, chinking is a material to fill a gap. Throughout the centuries of constructing dwellings out of logs, a number of methods were used to seal in between them. Early builders used pretty much anything they could get their hands on – mud, straw and mud, cow manure, mixtures of cement and mortar, and a method I discovered in Russia that was a particular type of moss that, when pounded into the gap, excreted a compound that delayed wood rot.

During our investigation we determined that in order to be a true solution the sealant must meet most important requirements.

- It had to be textured to look like authentic mortar chinking.

- It had to ‘look like it belonged there’.

- It had to be able to expand and contract in order to follow perpetual log movement.

As logs dry out in the summer, they shrink in diameter – in the winter and rainy months they absorb moisture and swell, increasing in diameter.

- The sealant had to adhere tightly to the logs and form a continuous watertight seal that would not separate from the wood.

- It had to be easy to apply – in some cases, gaps up to 4 and 5 inches, and not slump or wash out.

- And most importantly, it had to LAST for decades.

Common caulking materials were quickly ruled out. Everyone has seen thin caulking beads applied to exterior trim that inevitably separate, peel off, flake, crack, and ultimately fail.

No ‘caulk’ could adhere to the wood well enough, could not be applied to the thickness and height required without slumping and running out of the joint, and all caulks had that smooth, artificial look that frankly, of course, looked like caulk! It’s okay for around the tub or sink, but not for my log home, thank you.

Creating the Industry Standard

So, after months of experimentation and learning a tremendous amount of the chemistry of what are called polymers (the chemical building blocks of literally everything that we commonly call paint, plastic, vinyl, glue, etc.), we designed a unique sealant that met all of the most important requirements.

During the design phase we located an innovative small company south of Seattle that manufactured a synthetic stucco. They had experience and machinery that helped us scale up lab designs to large-scale production. We began selling early product in 1981, and the first house we did was in Sun Valley, Idaho – in the middle of winter.

Soon after we had a saleable product that met every design requirement, I did a little market research and discovered that the larger part of the national market for log homes was in the eastern part of the United States, and in particular, the southeast. I also discovered that of the numerous styles of log homes, the three largest manufactures of ‘Dovetail’ log homes were within 100 miles of Knoxville, Tennessee. I liked the Dovetail design because the nature of the structure, and the way the logs are stacked resulted in a chinking gap of up to 4 inches! In some cases, almost 25% of the wall area was chinking!

So, we set up a manufacturing plant in Knoxville, Tennessee. Timing was right because as soon as log home owners and log home manufacturers discovered that we could finally provide a dramatic solution to one of the most significant and perplexing aspects of a log home – the business grew rapidly.

Winning the Manufacturers

Early adopters such as Hearthstone, Honest Abe, Stone Mill, and Appalachian Log Homes helped pave the way for essentially all others to follow. As a matter of fact, one of the earliest applications for any manufacturer was Appalachian. Turns out they had a contract with the US Forest Service to build an outhouse. The location was remote, and the house needed to be completely assembled and transported via helicopter. Obviously, mortar chinking could not withstand that type of stress, so they tried Perma-Chink. That outhouse is still standing today and is weather tight – some applications simply CANNOT fail!

The development of synthetic chinking solved one of the most serious and vexing aspects of the Log Home Industry. The chinking formulation is unique and not simply ‘caulk with sand in it’ as others have offered.

Rick Denton, Honest Abe Log Homes President Emeritus said, “Perhaps the invention of Perma-Chink kept Honest Abe in business, as well as every other log home company using a chinked product line.” Read his story here https://www.honestabe.com/blog/perma-chink/.

What started out as an idea has revolutionized the entire industry. Worldwide, every log structure uses synthetic chinking, and the largest supplier of the most authentic and highest-performance log home chinking is Perma-Chink.

Expanding the Preservation of Log Homes

The next vexing challenge was with log home stains and finishes. Every log home owner wants a log home that looks like an outdoor piece of furniture. One that blends in with the rustic back to nature look and feel of the surroundings. No one would consider painting a log house. That would be like painting a beautiful hand rubbed antique! Log home owners tend to start down the following path after stains start failing: That beautiful stain we applied only lasted a year or maybe two and after two recoats, we may as well paint it. Why can’t someone develop a stain that looks like a furniture grade finish and LASTS?

We began to have literally thousands of people say, ‘You solved my sealant dilemma – now do you have a solution to the stain and finish dilemma?’ So challenge number two was tackled.

Creating the Best Log Home Stains

We used the knowledge and expertise we developed in formulating Perma-Chink Chinking (remember the polymers?) to design the longest lasting semi- transparent stain in the Industry. The formulation is also unique, provides that ‘furniture grade’ appearance, and outlasts any exterior stain on the market. Also, with a Clear Coat (which Perma-Chink Systems also introduced), when the finish is finally starting to “wear” out, all that is needed is a cleaning and application of an additional clear coat. That eliminates the tint buildup and subsequent hiding of the wood and completely eliminates the phrase ‘After two re-coats, I may just as well paint it.’

I personally require hands-on experience with every product Perma-Chink Systems offers. We are dedicated to providing the best products available for the care and maintenance of Log and Timber Frame Homes. As history has shown, and something we take pride in, is ‘Whenever a log home owner becomes aware of a concern, whether it be sealing, staining, or preservation or maintenance, we already have a solution.’

Take a Look At Total Cost

An interesting story – I recently had a heating problem with my log house in Colorado. The bill to repair the system included a small starting capacitor in one of the air handlers. The bill for the part was $6.25 and the bill for the labor was $220! So why would I try save sixty cents on the capacitor when the cost by far was in the labor to replace it? Same is true with a log home stain. By far the largest cost is in application and labor, so it pays to use the best product available. Cheaper stain is a cheap solution that sets you up for a repeat in a year or two, and in the meantime your exterior looks like crap! Pay the extra sixty cents and buy yourself some peace of mind.

By choosing our high-performance finish like Lifeline™ Ultra-7, you are ensuring that the finish will look as beautiful years after application as it did the second day it was applied thanks to a balanced formula of transparent iron oxides, mildew inhibitors and an advanced polymer resin.

Our Success is From Working With Great Customers, Industry-leading Partners, and Fantastic Employees

I am humbled that Perma-Chink Systems has become a ‘household’ name in the log home industry and is recognized for highest of quality. Our products grace the log houses of such noted Americans as former President Jimmy Carter, clothing designer Ralph Lauren, movie stars Tom Cruise, Olympic champion figure skater Kristi Yamaguchi, Nascar champion Dale Earnhardt (read the story here) and thousands of great American home owners.

I am proud of my company, of my employees and our customers. Perma-Chink Systems has a slogan for our 40th anniversary – “Simply Unmatched”.

By being engaged in best quality products and the best customer service, we will attain our goals and make great strides towards meeting our customers’ expectations for years to come. We raise a toast to the next 40 years of great products, service, and customers of Perma-Chink Systems.

Rich Dunstan, President Perma-Chink Systems, Inc.

How To Create Dust-Free Log Homes

We decorate our log and timber homes for not only holidays, but seasons, too. And after Thanksgiving and Christmas, putting away all those decorations revealed one of the most annoying things about homes: dust.

Dust gets everywhere. It’s never-ending. We have terms for giant amounts of dust called dust bunnies. It makes us sneeze – constantly. It’s ridiculous! No matter what it used to clean the dust, it returns!

Minimizing Dust Tips

The good news is there are ways to lessen the amount of dust. BobVila.com compiled 20 easy ways to keep the dust level in your house to a minimum. And in addition to the usual advice of keeping furnace/HVAC filters clean, vacuuming with HEPA filters, air purifiers, and wiping down surfaces, there are some other cleaning methods and ideas to keep the dust at bay. One of my favorites is limiting the number of textiles in your home. Like throw pillows. If your spouse or partner love a lot of pillows, that’s not the best thing to limit dust (approach this topic with caution! Ha!).

While the list of dust-limiting methods are quite useful, most only address the issue after the dust is inside the home. What about preventing dust from entering the home to begin with? For instance, having open windows may help bring in fresh air, it also allows dust in the form of pollen, spores, pollutants, etc., to enter the home.

Preventing Dust

One key to limiting dust in a log home is making sure your home is completely sealed. We know the amount of sealing a log home needs, based on the number of logs, sizes of log gaps, amount of windows and door frames and so on. However, there exists the chance that some nooks and crannies might get missed or damaged throughout time.

The quickest method to find where dust can enter the home is performing an energy audit. Infrared cameras can locate and identify areas where outside air can penetrate. Learn more about energy audits here.

The most likely areas of air gaps are the nooks and crannies of joints and building material transitions. For instance, doors and windows. Sometimes the seal isn’t as solid as one would hope. That’s where our Log Gap Cap pre-cut foam comes into play. Paired with Energy Seal or Perma-Chink sealant that matches your current sealant, this combo effectively closes up your home around doors and windows. Read more about Log Gap Caps here.

And finally, make sure vents and the foundation seams are sealed and properly finished. Not only will this help keep your home sealed from outside dust, but also keeps bugs and pests from infiltrating your home.

Dust will always be around, but there are ways to mitigate how much, which should give you more time to enjoy your home.

Lifeline Ultra-7 turns ten in 2021!

Introduced ten years ago, Lifeline Ultra-7 quickly became the premier finish for log and timber homes. Upon introduction, Ultra-7 improved coverage rates and added even more color options for the Lifeline family. Today, the best-selling Ultra-7 remains the go-to finish for exceptional longevity and color retention for log and timber homes. Paired with Lifeline Advance topcoat, Ultra-7 keeps your log home looking beautiful for years and years.

Wayne Bell of Log Home Care finished this project ten years ago in Avon, Ohio.

Before:

After, Front Porch:

After, Front Porch Up Close:

After, Wide Shot of Wrap-Around:

Why Log Boss

Why should you use the Log Boss over what you are currently using? That is a question we are often asked when we are showing these fasteners to potential customers.

We looked a several options that were in use for fastening the logs and timbers together. The search turned up various way builders were putting things together. The old way was the use of long spiral nails that were driven in with a very large hammer, which was very tiring – especially if you had to install the nails every foot or so for the whole house. Also, lag screws were used by builders to assemble logs together. The lag screw installation requires pre-drilling and drilling a countersunk hole for the head to go into. It also required the use of a large electric impact drill to effectively set the lag screws, or a large ratchet along with a very strong person to complete the installation.

To better serve the builder/customer, there must be something better. The fastener we were looking for had to add value to the customer, and this can be accomplished in multiple ways. The best fastener we found lessens the biggest costs – reduces labor cost, speeds up the installation process, and reduces the need for specialized tools. You also must have a product that performs and meets the expectations of the user, and to do this, Perma-Chink Systems chose the Log Boss log and timber fastener to meet the demanding needs of builders and contractors.

Log Boss Design Benefits

The design of the fastener is very critical to overall performance and ease of use. At the request of many of our customers, we’ve redesigned the head for better counter-sinking and uses a 5/16” hex head driver. The wings reduce the friction between the wood and the shank, clearing out the splinters created as the fastener pulls down into the wood. This reduces the torque required to set the fastener into place. Reducing the torque decreases the strain around the wood fibers, which increases the holding power of the wood fibers between the threads. The result is much greater pullout values by eliminating thread strip out.

One of the most outstanding features of the fastener is the ‘wings’ above the threads. The goal was not to disturb the thread holding value but to drive the fasteners into timbers with less torque requirements. The wings act as a reamer, allowing the shank to rotate much easier with less friction in the log. Without wings, the wood fibers bind up on the shank, seizing it to the point it becomes almost impossible to complete the required depth. It also often results in fasteners breaking off just above the threads, which adds wasted time to the project.

Another great feature of the Log Boss is the special rust-resistant coating applied to all fasteners, reducing the chances for rust to discolor the logs during extended exposure times on the jobsite. There is also a special lubricant applied to the fastener to aid in driving operations. Log Boss can be driven with an 18-volt cordless drill, but for best results we recommend the use of a ½” low rpm drill for optimum driving performance.

Log Boss fasteners are packaged in jobsite-friendly containers that resist damage from abuse and moisture. All sizes below 14” are packaged in plastic pails containing 250 fasteners and a drive bit.

Picking The Correct Log Boss

Now, how do you determine what size fastener that you need to use and what are the basics?

First, it is important to follow the log manufacturer’s recommendations as to the placement of the fasteners. The length of the fastener is critical to achieve the best performance. The selected fastener length must allow the threads to pass entirely through the first log, and thread into the second. The reason behind this is simple: in the event log movement happens, the log must be anchored to the bottom log, with the head providing pull-down pressure on the top log. It matters not if the screw is a little longer than you need, but make sure the threads will pass clear through the first log.

If you encounter a knot while installing the fastener, you will need to apply more torque to seat properly. It is a good idea to back the fastener out and move it over a little to avoid the knot. Another event that sometime occurs is the fastener may follow twisted grain and come out the side of the log.

So, if you want a fastener with maximum holding power and superior strength with less work, Log Boss is the answer. These fasteners were specifically designed by Perma-Chink Systems for the construction of log and timber structures. Their 3” long thread provides the grip necessary for pulling even the most difficult logs into place while the larger shank diameter increases the overall strength and pulling power.

Log Boss Benefits

Pre-drilling is not required

No washer needed. Drive it one time and forget it!

Flat head design easily counter sinks with maximum pulling power

Replaces the need for spikes or lag bolts

Lubrication coating speeds set time

Large threads prevent stripping out

Teflon® coating exceeds FM 4470 corrosion standards

Ask us for a complete line of wood-to-wood, code-approved fasteners for decks, ledger boards, and large timber applications.

As we settle into the holiday season, the cozy winter time, and potentially longer COVID-related lockdowns, the number of days inside the home can be overwhelming. Already approaching a year of COVID, our time in the home may raise our cabin fever or children if it hasn’t already.

But not to worry! There are things we can do to alleviate the time cooped up inside for the whole family. Country Living offers 25 activities to change up the routine, including classics like making your own Play-Doh! Check out their list here.

One snow-bound winter my family gathered around the fireplace and we listened to classic radio shows on cassette. My imagination became a powerful force to bring 1930’s radio show The Shadow to life during that cold December.

Today’s Parent has an impressive 87 activities, ranging from cardboard dollhouses to tye-dyed t-shirts. A lot of crafts are involved, to help kids learn motor skills. And of course, baking- but haven’t our waistlines had enough baking? You can read the long list of activities here.

Other activities may not seem as fun as making forts or throwing a dance party, but they can be greatly rewarding if more indoor living is in our future. Renovate interior, organize the kitchen “junk” drawer (I have 2!), go through your books and donate or share the ones you’ve read, and general “de-cluttering.” This is also something you can do in your digital life – unsubscribe to unwanted emails (not ours, though!), delete unnecessary emails, or clean up your digital photo albums.

Lastly, don’t forget about traditional card and board games. Some have found their way online, or are online only, and that greatly increases player pools. Many online games have chat features that allow interaction between friendly opponents. Codenames is one game that has online gameplay with others – learn more at https://codenames.game/.

Which Log Home Sealant Should I Use?

We are asked this question very frequently about our two biggest selling log home sealants. Both of these sealants were formulated to weatherproof joinery in log and log sided buildings. Our simplest answer is that in general, Perma-Chink should be used in applications where the seam width is one inch or wider and Energy Seal is a better choice in sealant seams that are narrower than one inch or where joinery was not intended to have chinking applied to it. However, this answer is overly simplistic when you consider the variety of log profiles and joinery types and many different surfaces that come together to make up a finished log structure.

What is the Difference?

Perma-Chink is our original log home sealant (and the company namesake). It was formulated to look like the concrete mortar that was typically used on full-log construction at that time. It is the original elastic log home sealant. Today Perma-Chink is available in eight different colors, some of which look like concrete, the others are various wood tones.

Energy Seal was formulated at the request of our customers at a much later date. These customers had homes that were usually built with log profiles that did not use chinking, but required weatherproofing some time after they were finished and in use. Because the application surfaces were never intended for a sealant application, they don’t have proper geometry that includes a caulking well to allow for sealant and backing material installation. Consequently, we formulated Energy Seal to have higher elongation performance. Energy Seal comes in a wide selection of 12 colors for customers who would prefer to conceal the sealant or even to match the chinking on their log home.

Energy Seal is a Better Choice in the Following Situations:

In general, Energy Seal is a better choice for very demanding, narrow seam application where more stretch is required in a narrow sealant seam. It is also the best choice if you would like the sealant to blend in with the wood surface and not be easily seen. Energy Seal is an excellent choice for use in sealing around doors and windows, butt joints, corners, and junctions between log walls and other surfaces such as beams, rooflines or framed walls.

Perma-Chink is a Better Choice When:

Many log homes are designed, manufactured and constructed with chinking an integral part of the building envelope. Perma-Chink is the clear choice in this situation. Additionally, Perma Chink is ideal to use when sealing up the junction between wood walls and concrete, brick or stone features like fireplaces, stone accents and walls.

Additional Information:

Energy Seal is lightly textured to reduce shine and reflectance and to help it accept stain when you prefer to blend the sealant in with the surrounding woodwork. Perma Chink’s heavier texture mimics the look of concrete mortar.

We have additional special purpose sealants. Check Mate 2® is specifically formulated to seal checks in your logs. It has very high elasticity for the dry season when your checks open up and it compresses very well when the environment gets damp and those same checks close back up. It is available in clear and six colors to match your wall color.

For more information call Perma-Chink Systems and consult our Sealants Application Guide to gain your best understanding of how and where to apply any of our sealants to get the highest possible performance out of them.