Blog

What’s the Difference Between Caulking and Log Chinking?

High-quality sealants help older cabins last for generations and give newer ones the rustic good looks many desire. Our sealants provide protection that will let them carry their historic styles far into the future. But when it comes to the language surrounding the sealant between logs, many people call chinking “log caulk.” Log caulk and log chinking are often used interchangeably, but these sealants are completely different. In fact, you should never, ever caulk a log home.

Caulking vs. Chinking

Caulk typically comes from a tube and is used to fill a small crack or seal edges along windows, trim, sinks, and bathtubs. This material is designed to be squeezed out in small amounts, then blend in and disappear. Caulks are completely waterproof, easy to apply, and easy to clean up. Today, there is an overwhelming selection of caulks including waterborne, oil-based, and silicone. Prices range from $2 for an 11oz. tube to $26 for the same size.

There are three main reasons why you don’t want to use a general caulk on a log cabin:

- Caulk is impenetrable. Wood is an organic material and internal moisture is an inherent quality of any log. A caulk will trap moisture, which leads to mold, rot, and unsightly stains.

- Caulk is not engineered to adhere to wood. Some turn hard and develop a cracked “alligator” skin appearance, or they separate from the wood entirely. In these scenarios, the sealant has failed, and water will get underneath, leading to rot and stains. When that happens, more water penetrates the log walls and rotting gaps become a haven for insects.

- Caulk is a low-quality product. Despite the spectrum of price points, caulks are essentially a bottom-line resin effective for a very narrow set of purposes. This does not include sealing your prized log home.

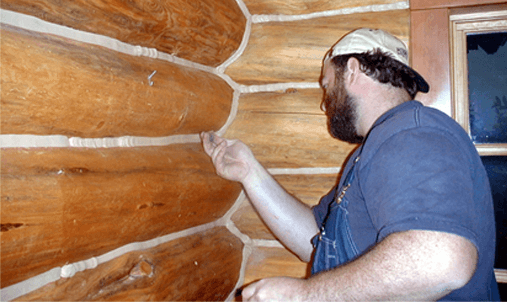

Chinking, on the other hand, is specifically designed for the purpose of sealing log homes, able to withstand the onslaught of environmental attacks and wood movement. Unlike caulk, which tends to be smooth and glossy, chinking has definitive texture that complements wood’s organic surface. Historically, chinking materials were made from what was regionally available. In Northern Europe, they used a special moss that did not cause log rot. Other places mixed horsehair or grass with mud or clay. Even today, it’s possible to purchase “log caulk” that has sand mixed with it to approximate a desirable rustic texture. None of these options are known for their effectiveness in withstanding movement and maintaining a proper seal over time.

In addition to offering the appropriate texture, our chinking is the kind of sealant a log cabin needs and deserves, and has four distinct qualities that sets it apart from caulk. For log homeowners, these qualities should be considered requirements when considering chinking.

- Log Home chinking must be breathable to let moisture escape the wood, while preventing new moisture from entering.

- Log Home chinking must have elastic qualities so it can move with wood’s daily and seasonal expansion and contraction.

- Log Home chinking must stick to the gap between the logs, even for log homes where the chinking remains invisible.

- Log Home chinking must resist the weather’s relentless tests — snow, rain, heat, and ice.

Chinking Superpower

Not only do our log sealants excel in the requirements that a high-performance chinking must possess, but we’ve devised a special formula with a distinct property. Our chinking sealants are thixotropic to provide exceptional peformance and fight environmental damage. A non-thixotropic sealant is prone to slumping and blistering, leading to issues that require a reapplication of the sealant and hoping the same issues don’t happen a second time.

Our thixotropic sealants stay exactly where the applicator leaves it, making them easier to apply with accuracy. In fact, we’ve spent years perfecting our formula to find the ideal balance between viscosity and thixotropic abilities. Our sealants can be easily pumped, squeezed, and applied by professionals and do-it-yourselfers alike. Professionals love our thixotropic sealants because they can get the job done right the first time.

We offer three types of sealants to accommodate different log home construction methods. Perma-Chink, our original elastic log home chinking, is designed for log gaps sized 1-inch or larger. Energy Seal has a more refined texture for log gaps less than 1-inch. Finally, Woodsman is a smooth and lightly textured log sealant that goes between stacked logs with no gaps.

All our sealant products come in an array of rich, earthy colors to complement any log home and work as an extra-strong, protective system with our wood stains and finishes. Perma-Chink lets your log home be permanently beautiful for your permanent enjoyment.

Guest post by Seth Murphy, papadiy.com

A home is more than just a shelter; it serves as our intimate sanctuary. The atmosphere within its walls profoundly influences our emotions, efficiency, and overall well-being. Central to cultivating a calm home atmosphere is the principle of tidiness.

Through consistent cleanliness and organization, we carve out a peaceful niche that rejuvenates our soul. By embracing straightforward daily practices, our living spaces can evolve into serene havens. In this article, which is shared courtesy of Perma-Chink Systems, we will explore straightforward routines that offer both a structured environment and mental clarity.

First, Take a Look at Your Bed

Your day’s first achievement happens in the bedroom. Making your bed might seem trivial, but this quick task offers instant gratification. It creates an immediate sense of order, providing a mental boost for tasks ahead. Moreover, it’s an inviting sight after a long day, beckoning with the promise of restful slumber. So, pull those sheets tight and fluff those pillows; starting right can set the tone for the entire day.

Put Items Where They Belong

Objects scattered around can quickly turn a home into a chaotic mess. Whether it’s a novel, a remote, or a hairbrush, always return items to their designated places post-use. Cultivating this simple habit can drastically reduce clutter. You’ll not only enjoy a tidy environment but also save precious time otherwise wasted on hunting for misplaced items.

Address Those Dirty Dishes

A mountain of dirty dishes can dampen anyone’s spirit. To sidestep this unsightly and overwhelming chore, attend to your dishes immediately after meals. It prevents residues from hardening, making washing quicker and less tedious. Plus, a clean sink and counter space are more inviting for the next cooking venture, ensuring the kitchen remains a space of creativity rather than stress.

Keep the Kitchen Clean

Beyond dishes, the kitchen requires some additional attention. Spills, crumbs, and residues can accumulate, turning your cooking space into a sticky mess. But fear not, with regular wiping of counters and the stovetop, you can easily keep this chaos at bay. This ensures not just cleanliness but also a hygienic environment for food preparation.

Dedicated Spots

The daily mini panic attacks when searching for keys or wallets can be nerve-wracking. Solve this by designating specific spots for these essentials. A tray by the entrance or hooks on the wall can serve as perfect drop-off points. This organizing method streamlines your exit routine and ensures these necessities are always within easy reach.

Embrace the Process

Organizing your home can be a rewarding yet daunting task, but with the right approach, it can be made much simpler. The first step is to schedule it and make time for this activity in your calendar, just like any other important appointment. Set aside specific blocks of time dedicated solely to organizing, ensuring you’re not rushed and can focus on the task at hand. Next, go through your belongings and decide what to keep, donate, or discard. Be thoughtful and honest about the utility and sentimental value of each item. Remember, less clutter means a more organized space.

Finally, take your time with the process. Organizing your home isn’t something that needs to be rushed through in a day. By spreading out the work, you can give each room and each category of items the attention they deserve. This methodical approach not only makes the task more manageable but also more effective in creating a harmonious and organized living space.

Decluttering

As the days pass, our living spaces often gather items that lose their relevance. This accumulation results in clutter that can feel overwhelming and suffocating. Engaging in regular decluttering acts as a therapeutic exercise, clearing out both our surroundings and our minds. While you’re in the process, delving into Feng Shui principles can be enlightening. By harmoniously arranging your space using these guidelines, you achieve more than just visual appeal.

Our homes are reflections of our internal state. By integrating these straightforward tidiness habits, we can nurture a living environment that soothes and rejuvenates. The beauty lies in realizing that maintaining a well-ordered home doesn’t require Herculean efforts. Small, consistent actions can ripple into significant transformations, leading to a relaxed and enjoyable home life. Embrace these habits and witness the calm it ushers into your daily existence.

For a full line of products to meet the needs of log home builders and owners, visit Perma-Chink Systems today!

COLOR CHOICES FOR LOG OR TIMBER INTERIORS

When it comes to log and timber homes, grays and browns are the biggest trending colors, as they offer the widest neutral tones. Gray has been the hot shade for the past several years in homes, from walls to floors.

True to its “neutral” title, gray really goes with almost any color. The key to a great match lies in coordinating the tones. Gray doesn’t have to appear in your palette as a color of the wall – it can also be found in a fireplace exterior, flooring, or on countertops. When you add gray to any room, be sure to consider other shades of gray that might already be there.

“To find the best shade, you need to consider which direction your room faces, what time of day you will be in there, the prevailing weather (even the hemisphere makes a difference), and last of all, the actual shade you like,” says Kate Watson-Smyth, who wrote the book on decorating with gray, Shades of Grey.

Our Lifeline Interior color collection can complement or contrast any paint you chose for your drywalls. Our interior grays combined with natural warm tones of wood will add a beautiful style to any room in your home. But grays aren’t the only option, and some people prefer other colors. That is why our standard library of color has the most colors available on the market, as well as virtually unlimited custom colors.

If you’re concerned that gray would be too cold for your space, beige colors or soft whites could be the answer. The easiest way to make a room feel bigger is by opting for lighter stains, particularly with gloss or satin finishes that create the appearance of even more space by relfecting light.

Keeping With The Trends

PCS designs eye-catching colors in many diverse tones that have the power to transform the entire ambience of a home. And the best part – you don’t have to mix anything – just order free samples to try, and then pick your colors.

And if you are looking to upgrade the wall paint in your house, The Property Brothers have some thoughts for you when it comes to paint colors.

On a “Condo Dreams” episode of HGTV’s Property Brothers: Buying and Selling, Drew and Jonathan Scott are not pleased when they see two colors gracing the walls in the client home – red and yellow.

“Yellow walls don’t really sell these days,” Jonathan quipped on the show, implying that Roseanne could likely fetch a better selling price if she repainted her walls a different hue. Perhaps an even worse offender than yellow, however, is red. At one point in the episode Jonathan warns that they have to “get rid of that angry ’90s red wall.” Read more about paint color choices.

Would you like to know what colors will be trending in the future? Better Homes and Gardens announces new color trends from the major paint companies.

No matter what color palette you choose, we can make custom color stains and finishes for you. Call 1-800-548-3554 or email techservice@permachink.com

Photos by Honest Abe Log Homes

The most important thing that you can do to help maintain the finish of your log or timber home is to keep it clean. An annual washing with Log Wash™ will help prevent airborne contaminates, dirt, bird droppings, and sunlight from degrading the finish. While nothing can withstand the effects of the environment forever, keeping wood clean and maintained can protect it better and longer. How can keeping the surface clean prevent sunlight from injuring the finish? One of the features of our Lifeline Advance clear topcoats is that they reflect UV radiation.

If the surface is dirty and dull, it reflects less sunlight, and the absorbed UV light will eventually fade the color and gray the wood. So just like automotive finishes, the cleaner you keep your home, the longer the finish will last.

That being said, there will come a time when it may become necessary to do some touch-up work to the topcoat and perhaps the color coat, especially on the south and west walls. The question is, when and where should maintenance coats of finish be applied? The first thing to understand is more is not necessarily better. In other words, if the wall does not need another coat of stain or topcoat, leave it alone.

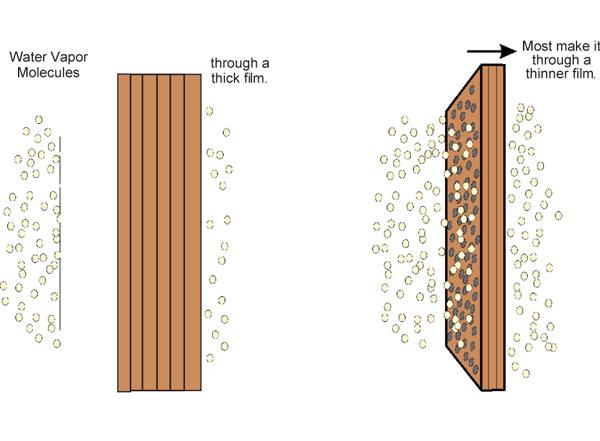

Advanced Breathability

One of the features of Lifeline finishes is the ability to breathe. This allows water vapor to escape from the wood while preventing liquid water from penetrating through the finish. Technically, we call this vapor permeability. If applied at the recommended application rates, one or two coats of stain, depending on the color system chosen from Perma-Chink Systems, and one coats of topcoat maintains enough vapor permeability to allow water that may enter the wood through cracks, checks and fissures to evaporate through the finish. However, each coat of finish that’s applied reduces the vapor permeability of the entire finish system by some percentage. The thicker that a coat is applied, the more it will reduce the vapor permeability. That’s one reason why we always recommend applying thin coats.

How Many Coats Of Stain Are Needed?

Multiple coats of finish can have the same effect as applying coats that are too thick; they can reduce the vapor permeability to the point where the finish can no longer breathe. The consequence of reducing the ability of a breathable finish is the risk of the finish peeling if water gets behind it (see technical tip Peeling Issues). Although occasional maintenance is an important factor in keeping your finish system in good shape, only apply additional coats where they are needed.

So what’s the best way to care for your home and extend the life of your finish system? If, after a washing with Log Wash, you see that the surface has dulled, apply a single coat of Lifeline Advance Gloss or Satin. A dull surface is a sign that the finish has eroded. If it shows signs of weathering or fading color, feel free to apply another coat of Lifeline stain to restore the color and a coat of Advance topcoat.

One or two additional coats will not adversely affect the vapor permeability. But while you are at it, you may be tempted to apply another coat of topcoat on those walls that still look good. Additional coats applied to unweathered walls are not necessary and can eventually lead to problems. If applied correctly, the film thickness of the unweathered walls is still optimal and the application of additional coats can decrease the vapor permeability to a point where peeling could become an issue. In other words, leave it alone.

Ongoing Finish Maintenance

As opposed to other manufactures’ finishes, we do not recommend applying additional coats of stain or topcoat on a yearly schedule. If two coats of stain and one coat of topcoat have already been applied, we recommend applying additional coats only on an “as needed” basis. But we strongly recommend a good cleaning with Log Wash at least once a year to keep your home looking great and extending the longevity of your finish system.

In the early 1980s Rich Dunstan, our founder and company president, had to come up with a company name. Although Perma-Chink Log Home Chinking was the only product manufactured at the time, he chose Perma-Chink Systems, Inc. The name was chosen because he had a vision of developing a full line of products to construct, clean, preserve, seal, finish and maintain the wood components of a log home. Over the years Rich has fulfilled his dream and Perma-Chink Systems, Inc. has become a systems company. No other log home related company offers the broad range of products that we do. However, this large product offering presents a challenge to our own salespeople. We expect them to achieve a high degree of expertise in a wide variety of different product lines. To reach this goal we devote hours of training so that they can knowledgably assist our customers.

Since we are a systems-based company, we have put together a family of products that work together and complement each other. We are often asked questions similar to, is our Energy Seal compatible with ABC Stain or can LIFELINE be used on a home that has been cleaned with XYZ Wood Cleaner? There are hundreds of small regional manufacturers of these products scattered across the country, with full disclosure of ingredients not always given. Since we cannot test all products, the compatibility of these with Perma-Chink products are unknown.

We make every effort to communicate with our customers that we do not sell individual products that can be used indiscriminately with products from other manufacturers. We sell a system of products that work together. When a customer chooses to step outside of our system, problems may develop that can be challenging to solve. Homeowners often understand our system concept better than some applicators/contractors. Over the years, some professionals have found a favorite local manufacturer they prefer for a cleaner, caulk or stain. Then a customer wants him/her to use LIFELINE Ultra-2. The home gets cleaned with XYZ Wood Cleaner, followed by LIFELINE Ultra-2 and Advance, with the home being sealed with AAA caulk. A month or so later we get a call that the wood under the stain has developed dark spots and the caulk is falling out of the checks. The applicator or homeowner comes to us for help because they believe the problem is a result of our product since they have been using the same cleaner and caulk for years.

We often have a difficult time determining the root cause of the failure since we do not know the compatibility of XYZ Wood Cleaner or AAA caulk to our stains. That is why it is important to obtain all your products from Perma-Chink Systems, a systems company, to avoid such problems.

The principle of utilizing our systems is that we have spent many years developing products that work, are safe to use and are compatible with one another. We pride ourselves on being the log home industry leader by constantly making improvements to our finish and sealant systems. We stay abreast of the latest developments in polymer technology and additives. This approach has kept us well ahead of our competitors. We have occasionally been criticized for making changes;however, those changes have resulted in better performance, increased beauty, and easier application of our products.

Another vision that Rich Dunstan had from the beginning of Perma-Chink Systems was to manufacture only products that were friendly to our environment. Yes, we were green when the definition of green was the color of grass. We started making water-based stains when 90% of the log home stains were oil-based. We also invented and introduced the first low toxicity borate-based wood preservative that could be applied to an existing log home. Over the years we have consistently considered the environmental impact of all our products and removed or changed those that did not meet our high environmental standards. This too is a part of our systems concept. Not only do our products work with each other but they also work to protect our environment.

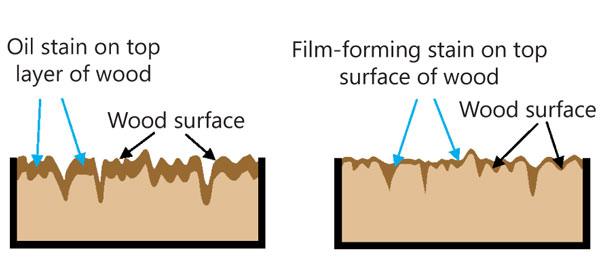

Many people do not understand how film-forming stains work and how they adhere to wood. Much of this misunderstanding relates directly to the term “stain.” In the past, staining wood meant that the wood fibers themselves became impregnated with color and that the color penetrated into the top layer of wood. Even today most oil-based stains work in this manner. Once stained, if the surface is rubbed or scratched, the color of the stain still remains since the solvents carry the colorants into the top layer of wood which make the fibers beneath the surface the color of the stain.

On the other hand, water-based stains like our Lifeline™ products do not actually penetrate into the wood fibers! That’s one reason we try to refer to them as finishes rather than stains. But since the term “stain” has been used for hundreds of years, it’s difficult to change the vernacular that defines the difference between oil-based and water-based products.

When we talk about the penetration of our products, we are referring to their ability to fill the microscopic voids, fissures and pores on the surface of the wood. This enables the film to adhere tightly to the wood’s surface. It’s this property that we call adhesion. However, if the film is scratched or rubbed off of the surface, the original color of the bare wood will be visible.

Why is this important? We’ve had customers call us thinking that the product we shipped them was defective because they were able to rub or scrape the film off and there was no color evident under the film. In their mind, the wood had not “taken the stain.” That’s because they had never worked with a water-based, breathable film stain before, and were used to seeing the results produced by a penetrating oil-based stain.

So how can we best explain how our products work? Most people are familiar with use and behavior of latex paint. It behaves quite similar to a water-based film forming stain in that if it is scraped off of the surface uncolored bare wood becomes visible. Our water-based stains behave in a similar way to latex paint. The benefit is that the protection offered by a film on the surface of the wood is far superior than that provided by a product that soaks into the wood leaving the surface of the wood exposed to the sun and weather.

Microscopic Cross-Section of Wood Surface

The wood surface absorbs an oil-based penetrating stain into the top layer of wood fibers, carrying the pigments along with it. The fibers themselves are thus “stained” with the pigments.

A water-based, film-forming stain sets on top of the wood surface and fills in many of the small cracks and fissures, resulting in a smoother surface; however, the wood fibers themselves retain their original color.

“Which of your products should I use to seal my log home?” is a question often put to us by prospective customers. Why do so many people refer to “sealing” a log home rather than staining or finishing? Nobody talks about sealing siding or trim on a stick built home. They are either stained or painted, yet sealing is the term used by many log home owners. As it relates to log homes the term “sealing” dates back to the early 1900s. Prior to then, most log homes were constructed using heartwood from old growth timber and left bare.

Since heartwood is resistant to insect and decay infestations, and the people who built log homes knew better than to not include porches or leave log ends sticking out beyond the roof line, the best thing for them to do was to leave the logs bare but keep them dry. That’s why so many of them survive to this day.

Sealers

Starting at the end of the 19th century, old growth timber was no longer readily available and people started constructing log homes using second or third growth timber that was mostly sapwood. They also stopped using many of the good construction practices of their ancestors, so problems with bugs and decay began to arise.

At around the same time, the petroleum industry began to develop, for the first time, affordable oil and tar products. Log home owners soon discovered that smearing some of these oil derivatives over their homes helped eliminate some of their insect and decay problems. In their minds, they had “sealed” the logs, and the term has stuck with us to this day. Up to the 1950s, unless the logs were painted, log homes came in two basic colors, black and gray.

So, are any of our Lifeline™ exterior finishes sealers? As the term relates to keeping liquid water from entering the wood, they all are. All of our Lifeline stains (Ultra-7, Ultra-2, Exterior, and Accents), as well as Prelude™ Clear Primer and Advance™ Topcoat, all act as water repellents to keep the underlying wood dry.

There is a misconception that our pigmented finishes alone do not act as water repellents and it’s the Advance Topcoat that seals the surface. That’s why many people call our Advance Topcoat a sealer, but that’s not an accurate description of the product. All of our stains are excellent water repellents. They may not bead water, but they provide a polymer-film barrier that prevents liquid water from penetrating into the wood.

Stains

Calling our pigmented finishes “stains” can also be a bit confusing. The term itself implies that the wood fibers are “stained” with the colorants contained in the products. However, in the case of film-forming, water-based finishes, the wood fibers are not impregnated with the colorants like they are when penetrating oil stains are used. If wood is painted with a latex paint, no one expects the paint to impregnate the underlying wood. So if you believe that your wood is not “taking” our Lifeline stain, it’s important to understand that our finishes behave more like latex paints than penetrating oil-based stains.

Since most people are comfortable with “stain” as a product that alters the color of the wood and still allows the grain to show, using “stain” is more accessible for customers (as well as when searching on the Internet).

Topcoats

Top coats are clear finishes that protect and cover the pigmented finish on logs, timbers, and other wood features. One of the most frequently asked questions we receive about our Advance Topcoats is why isn’t it included with the stain. The answer is that if we did, it would no longer be a topcoat. Topcoats play a specific role in protecting any finish system.

Take car finishes for example. The pigmented paint provides the color and helps protect the metal from corrosion. It is formulated to adhere to the primer and retain its color. The car’s clear topcoat is designed to protect the color coat from abrasion, dirt and sunlight and the only thing it has to adhere to is the color coat. Our Advance Topcoats play essentially the same role, to protect the color coats from the weather, sunlight, and dirt.

Although our stains adhere to bare wood, previously applied stains, and existing topcoats, it is not necessary for Advance to adhere to bare wood since it clearly states on the label that it’s to be applied only over an existing finish.

Although most topcoats on the market are just unpigmented versions of stains, Advance is specifically designed as a high performing topcoat with a unique set of characteristics that have yet to be duplicated by anyone else in our industry. One of the reasons Lifeline Advance outperforms all other topcoats is that it is designed for a very specific purpose and should never be applied to bare wood.

It’s time to close up remote and vacation cabins for the winter. For most vacation homes, the close-up process usually occurs after Labor Day, but we all try to squeeze out a few more weekends as the weather allows.

Depending on where the home is, the “living” season might be longer, or year-round, especially if the property doubles as a seasonal rental. If you’re lucky enough to live in a mild climate that doesn’t require much seasonal “changeover,” it’s still a good idea to inspect your home for potential issues. We have available information on Fall maintenance and landscaping tips to keep homes maintained.

For those homes that get buttoned-up for the winter, the folks at Cabin Life compiled a checklist of tasks to ensure a protected home for the duration of the winter season.

Preparing for Winter Checklist

(Adjust as needed for your climate and your frequency of winter use.)

Outside Duties

- Waterfront homes: Clean and store boats, dock ornaments, ladder, life jackets and ski equipment.

- Mow the lawn one last time (if you have a lawn at your place).

- Clean and winterize lawnmower and other gas-powered yard equipment.

- Rake and remove leaves within at least 30 feet from your cabin.

- Store fire pit decorations, emptied flower pots, drained hoses and sprinklers, and deflated water toys.

- Keep firewood more than 30 feet away from home.

- Look for air leaks around electrical wiring, dryer vents, pipes, windows and doors; then seal leaks with caulk or insulation to keep out cold air and pests.

- Insulate pipes in crawl spaces by wrapping them with heat tape or thermostatically-controlled heat cables; also open cabinet doors to allow heat to get to un-insulated pipes under sinks and appliances near exterior walls.

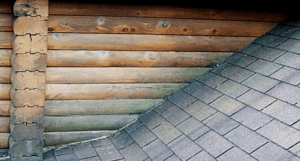

- Clean out gutters and inspect roof for shingles that are raised or cracked; leaking roofs and clogged gutters can lead to significant water damage.

- If your lake is prone to ice movement, take in dock and boat hoists. Remove hoist motor and electric line.

- Turn off outside pump breaker, hoist motor breaker, dock light breaker.

- If you are in the snow belt, store outdoor furniture, picnic tables and hammocks.

- Make sure your winter sports gear is ready to go. Snowmobile and ATV tuned up? Skis waxed? Where are those snowshoes?

Inside Duties

- Ensure that the power and water are in the proper mode for vacancy.

- Set thermostat at the appropriate temperature for the region. If you heat your place in the winter, set the thermostat no lower than 55 degrees; if you keep the A/C on when you are gone, set it to 80 degrees.

- Clean furnace filter to maintain an efficient heating and cooling system and reduce the risk of fire.

- If you are shutting off the refrigerator, leave the door cracked open to prevent musty smells from developing.

- Unplug computers and major appliances to protect them from power surges and lightning strikes.

- Pull shades, or cover furniture to keep it from being bleached by the sun.

- Put mothballs or dryer sheets near linens.

- Restock and store first-aid kit.

- Take out all perishable foods; store those that remain in air-tight/critter-tight containers. If you don’t heat the cabin in winter, carry out canned goods so they don’t freeze.

- Turn off dehumidifier and water heater.

- Close damper for fireplace. Seal box to prevent critters from entering cabin.

- If you don’t heat in winter, drain the pipes by attaching a hose to the lowest point in the plumbing, then blow out all water with an air compressor.

- Winterize washing machine; kitchen appliances.

Perma-Chink was designed to eliminate the undesirable results often obtained by using older less successful methods of wood slabs, mud, and cement types of chinking, as basically they did not work well over the long haul. So it became a constant worry or job to re-chink or repair the failing products. Most of the products used did not have any degree of flexibility or they did not adhere to wood that well. The results were cracking cement caused by the stress of the logs shifting or shrinking. The resulting failure often allowed separation between the chinking and the log surface allowing water intrusion, and possibly early wood decay.

So as for a particular type of home, yes Perma-Chink is designed for any home that incorporates a specific joint design where it could be employed. For example; the large timber square logs that use a dovetail system as seen throughout the Eastern United States, as well as the large handcrafted round logs from the Western part of the United States. These homes were designed to be chinked from the start.

I think it’s important to interject another fact regarding log homes. Not only has the formulations of Perma-Chink changed over the years, so has the entire log home industry. Many people think log homes are still being cut by someone with a pickup truck and a chainsaw, working from a drawing on piece of cardboard. Today’s log home are engineered structures designed and approved by architects and require approval by various build codes in given areas. They are high-quality structures designed and manufactured by professionals using computer programmed tools and equipment to create structures that are built to stringent specifications. These homes are designed to require less maintenance, last longer and to provide a sound investment for your money. They are not just log cabins anymore, they are log homes.

How has log home chinking changed over the past few decades?

Perma-Chink was the first synthetic chinking produced in 1981, there have been many significant changes made in formulations to improve the adhesion, flexibility, and longevity. Early formulations were lacking in elongation and freeze-thaw stability which resulted in performance issues and storage and application concerns. Today’s Perma-Chink offers excellent qualities in all areas to meet the needs of the industry. Application can be accomplished in a much wider range of temperature extremes with little or no worries about product performance. There have also been additions to the color palette of the products keep up with the homeowner’s desire to mix and match shades and hues of today’s finishes.

Who can apply log chinking properly? A DIYer or a Pro?

Basically anyone can apply Perma-Chink properly if they follow instructions. Some homeowners attend workshops or seminars to learn how to apply Perma-Chink, if they decide to DIY. But in today’s busy environments, some homeowners choose to use the services of trained contractors as the design of their dream home may require the use of specialized equipment such as lifts or scaffolding, and a trained contractor can usually shorten the time required to accomplish the job. Therefore the homeowner can tend to the other necessities involved to get moved in, and sometimes there are just not enough hours in the day for the homeowner to do this.

Visit our Find A Contractor tool to find a professional log home chinking contractor near you.

If you’re looking for some ideas this Thanksgiving to partner with your baked, smoked, or deep-fried turkey, we’ve compiled a list of recipes that you might find new and interesting to serve this year.

Side Dishes

Maple Roasted Brussels Sprouts

Not everyone’s favorite, but for those that love Brussels sprouts, this is a winner.

Click here for the recipe from AllRecipes.com

Air Fryer Hasselback Potatoes

Click here for the recipe from AllRecipes.com

Succotash

The list of ingredients for this Southern succotash recipe – including fresh corn, tomatoes, lima beans, and okra – are practically synonymous with summer (something we’re thankful for). And the combination of these five complementary flavors is only heightened with the additions of crumbled bacon and fresh basil.

Click here for recipe from Southern Living

Mashed Sweet Potatoes with Bacon

Bacon makes everything better, doesn’t it? A new addition to the sides could be this delicious dish.

Click here for recipe from Food Network

Awesome Sausage, Apple, and Cranberry Stuffing

This Thanksgiving apple sausage stuffing is fantastic! It is very flavorful and fresh-tasting. This recipe will stuff a 10-pound turkey (which serves six) plus extra. You can replace the usual pork sausage with much healthier turkey sausage. Other dried fruits may also be used in place of cranberries.

Click here for recipe from All Recipes

Desserts

Mini Apple Pies

For me, one apple pie is mini… I think I could eat two or three apple pies. But, if you want to pace yourself this holiday, these bite-sized treats will be a winner!

Click here for recipe from The Pioneer Woman

Glazed Maple Shortbread Cookies

These cookies are fantastic for Fall! Shortbread and maple together make this cookie a sweet treat and a great alternative for those who aren’t a fan of pumpkin pie.

Click here for recipe from Taste of Home

Drinks

Cranberry Fizz (non-alcoholic)

This drink is very popular for holiday gatherings and there’s never enough!

Click here for recipe from Taste of Home

Bourbon Slush

A drink customizable with your favorite tea.

Click here for the recipe on TasteofHome.com

Spiced Bourbon with Red Wine

Liven up the party with a creative cocktail.

Before you apply coatings to interior surfaces, always thoroughly wash them with a recommended cleaning solution. Log Wash is made for this purpose and should be used as follows:

Mix 1/2 cup of Log Wash Concentrate in a pail with one gallon of warm water. Apply the Log Wash solution to the wall with a rag or sponge. Allow the solution to remain on the wall, keeping it wet for at least 10-15 minutes. Using a clean rag or sponge and a pail of clean water, wipe the Log Wash solution off of the surface. Frequently rinse the sponge or rag in the pail of water and frequently exchange the water in the pail with clean water.

To make sure you have the correct amount of finish, read this Tech Tip on determining square footage, as log homes are built in various layouts which all affect square footage.

Applying Interior Finishes

1. Stir the containers of LIFELINE finishes thoroughly before starting. Remember that even clear coats require stirring to blend different ingredients within the container. Use a drill-powered paint agitator for 5 minutes on a newly opened container to completely mix settled ingredients.

2. NOTE: Sure Shine should be hand-stirred, using a paddle or a paint stick to avoid entraining air in the liquid.

3. When using multiple containers of colored finishes, they should be ‘boxed’ (see ‘Mixing and Boxing Stains & Topcoats‘). Do this by thoroughly stirring LIFELINE in its original container and then combining contents of different containers together in a separate container.

4. To avoid leaning ladders against freshly applied LIFELINE, it is best to start at the top of the wall. Place ladder end on unfinished logs below your work line.

5. Wipe up runs and drips immediately. They will come off best using a wet rag.

6. When you take a break, submerge the sprayer tip in water to prevent clogging with partially-dried LIFELINE.

7. Avoid lap marks. Work on one or two courses of logs at a time and never stop in the middle of a log. Work to natural break points such as corners, window edges, butt ends of logs, or other natural break points.

8. Continue application by running a wet edge until a break point is reached. As you approach a break point, feather your wet edge and continue working the LIFELINE from your brush until the product runs out. Start spray pattern away from the break point and finish back-brushing to the break.

9. Apply LIFELINE in thin coats. If it runs down the wall, you are applying too much. OBSERVE CORRECT COVERAGE RATES as listed on label.

Beauty is a Duty.

Your log home manufacturer built you a beautiful home. Now it is your duty to finish it with the best log home products to highlight and preserve that beauty. Let Perma-Chink Systems offer you the world-class stain and finish brand: Lifeline Ultra.

Simply Unmatched.

The benefits of Lifeline Ultra are endless, but here are some points that differentiate the Lifeline brand from others.

Not just Beautiful, but also Durable!

In addition to building a strong home, you want to build a beautiful home, too, which is why the finished appearance of your logs is so important. No doubt that high-quality finishes will save you time and money in the long run. Longer lasting finishes equates to less labor expense over the life of the finish.

Top 5 Benefits of The Lifeline Ultra brand:

1. Unsurpassed Adhesion to Wood

The secret behind its durability is Lifeline’s state-of-the-art resin that creates a flexible and tough seal on your home’s logs. Perhaps more importantly than the seal’s strength, the resin ensures a continuous seal, providing protection from holes and gaps that might otherwise develop with an inferior finish.

2. More Resistant to UV Degradation and Color Fading

The transparent iron oxides protect your logs without resulting in a “painted” look that hides the natural texture and beauty of the wood grain. Plus, these pigments provide superior UV protection, blocking the fading and bleaching effects of the sun for a much longer period of time.

3. Water-Resistant and Breathable

All Lifeline finishes form water-resistant film that breathes just like Gore-Tex® to allow trapped moisture to evaporate while protecting the wood.

4. 5-Year Warranty

We are so confident in the performance of Ultra-7 and Ultra-2 that it comes with a 5-year warranty against UV exposure when applied to bare wood and covered with an initial coat of Advance clear topcoat.

5. Meets and Exceeds all Standards for low-VOC

Water-based finishes lack the chemicals in oil-based finishes that are harmful to the environment and difficult to clean up.

UNLIMITED COLOR CHOICES

I think we have already convinced you that Lifeline Ultra brand is the best there is in the industry for any wood home. Now here is the icing on the cake – you can choose any color your heart desires!

Choose from any colors below or send us your desired color chip. Then let us know what base you want the color to be in – Lifeline Ultra-7, Lifeline Ultra-2, Lifeline Accents or Lifeline Exterior.

If you’re looking for a different color than what we offer, we will make a custom stain color for you the same day. Don’t wait, call us today for your custom color at 1-800-548-3554.

Just A Sample Of Available Colors