Blog

Every spring we get lots of calls about carpenter bees drilling into logs, fascia boards, eaves, decks and other unpainted wood surfaces. Carpenter bees are big black solitary bees that look similar to bumblebees but have bare, shiny backs whereas a bumblebee’s back is hairy. Unlike honey bees that reproduce in hives, carpenter bees drill into wood in order to lay their eggs. Their holes are perfectly round and about 1/4 inch in diameter.

Although carpenter bees prefer hardwoods such as cedar, redwood, or cypress, they happily attack pine and most other species of wood. Even pressure treated wood is not immune from carpenter bee attack. As the bee drills into the wood, coarse sawdust may be seen coming out of the hole and piling up beneath the hole. Since it only takes a couple of hours for a carpenter bee to drill a hole a few inches deep, lots of holes can appear over a fairly short period of time.

Most carpenter bee activity occurs in early spring when male and female bees emerge after spending the winter in old nest tunnels. Once they have paired and mated the female bee drills into a suitable site while the male stays nearby to ward off intruders. Male carpenter bees often frighten people with their aggressive behavior but since they have no stinger they are essentially harmless. Females have a stinger but only use it if molested.

Once the initial hole is drilled through the surface, the bee will make a turn and excavate a tunnel along the grain of the wood. This tunnel, which may run for several inches, becomes the cavity where the female deposits her eggs. Several eggs are laid in individual chambers separated by plugs of pollen on which the larvae feed until they emerge as adults during the summer months. In addition to making new holes, carpenter bees also enlarge old tunnels. If left unattended for several years, serious damage to a wood member may result.

In late fall activity may again be seen as both male and female carpenter bees clean out old nest cavities where they stay over winter. Since carpenter bees tend to migrate back to the same area from which they emerged, it is important to implement some control measures in order to prevent logs and wood members from becoming riddled by these bees.

Prevention

Although carpenter bees prefer bare wood or distressed wood, they will attack wood that is stained. Painted wood surfaces, on the other hand, are rarely attacked since the bees must see or feel the grain of the wood in order to recognize it as wood. One of the most effective measures for preventing extensive carpenter bee damage is to fill old or empty holes with Energy Seal. Carpenter bees are attracted to existing holes. Be sure to treat the hole before you fill it since live adult bees will drill right through the caulk on their way out.

One way to keep carpenter bees from drilling into wood is by spraying pesticides that contain either cypermethrin, deltamethrin, or bifenthrin (Ortho Home Defense Max) onto wood surfaces. When it comes to carpenter bees, these products act more as repellants than contact poisons. However, the effectiveness of these applications is only about three to four weeks, so the treatment will have to be repeated every so often. Pesticides should only be used during the periods of peak activity in the spring and perhaps again in late fall. Be sure to follow label directions and read and understand any precautions that must be taken when using these products.

A few years ago we requested information about the effect of our gloss topcoat on reducing carpenter bee activity via survey. Out of over 20 responses by letter, phone and e-mail, only two reported any penetration of the gloss topcoat by carpenter bees. One home went from 20 to 30 holes the previous year down to 2 this past year and the other went from over 20 holes to 4 holes. This confirms our suspicion that the Lifeline Advance Gloss exterior topcoat appears to provide a finish to the wood that carpenter bees do not find very attractive. That is not saying that the gloss finish repels carpenter bees. It does not. Although bees would occasionally land on the gloss topcoat, they just did not drill through it. So why is that? Well, let’s be clear that the Lifeline Advance Gloss topcoat is not a pesticide nor does it have any pesticide properties. It appears to form a coating on the surface of the wood that carpenter bees are reluctant to drill through. Why? It could be the glossy look or that the hard, slick finish does not appeal to them, so the bees will search for another target. Many other online “How-To” documents related to carpenter bees describe the actions of carpenter bees on bare or distressed wood. That stands to reason that well-maintained log homes with stain and a solid topcoat should dissuade most carpenter bees from nesting inside logs.

Another possible solution, with hit-and-miss results, is a bee trap specifically for carpenter bees. Much like a minature bird house, the bee trap invites the carpenter bees inside, and they get trapped in a glass jar. In the past we offered these types of traps, and the results weren’t 100% positive. You can find bee traps online, both DIY plans and for purchase.

Treating Carpenter Bee Holes

Any carpenter bee holes you can reach should be treated and plugged since existing holes attract more carpenter bees. The way to treat an existing hole and tunnel depends on the time of year, and if bees are present at the time of treatment. If the female is drilling away when you find a hole (you can see sawdust coming out or hear her working inside) spray a contact pesticide like wasp and hornet spray into the hole. She will quickly back out and die. Immediately fill the hole with wood putty or Energy Seal. You need to treat the hole even if it appears empty since the bee may be resting and, if left alive, will drill back through the plug you’ve just inserted.

If you find carpenter bee holes in late spring or early summer it’s difficult to tell if there are bee larvae developing in the tunnels. The best thing to do is to run a length of flexible wire into the tunnels in order to break through the pollen plugs separating the chambers. Then spray a pesticide into the hole and seal it up. The same thing should be done on holes found in the fall or winter to kill any bees that may be over-wintering in the holes. Just remember to plug the holes since they will attract more carpenter bees come spring.

Several people told us that although they sprayed a pesticide into the holes, carpenter bees later emerged, in some cases even after the holes were plugged. How can this happen?

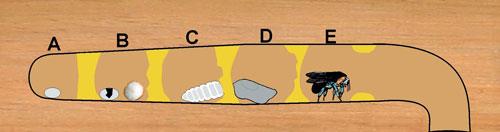

If we take a look at a cross section diagram of a carpenter bee gallery we can see how. After drilling out a four to five inch long gallery, the female carpenter bee lays an egg in back of the gallery then places a plug of pollen she has gathered to form a chamber (A). She continues doing this until there are four to six egg chambers in place. After a few days the egg hatches and a small white grub emerges (B). The grub feeds on the pollen plug for a few weeks (C) until it is ready to pupate (D) and change into an adult bee (E).

If you look at the way the gallery is constructed, you can see why spraying a pesticide in the hole may not kill all of the developing bee larvae. The pollen plugs prevent the pesticide from getting to the rear chambers. So, before you spray any pesticide into a carpenter bee hole be sure to run a stiff wire all the way to the back of the gallery to break through any pollen plugs. That way all of the larval chambers will be exposed to the pesticide.

Perma-Chink Systems History Over 40 Years

The Beginning

In 1980 my neighbor told me about building a log home in Eastern Washington. He said that he loved the home and the lifestyle but was disappointed that with the wind constantly blowing and harsh cold winters, there was no real effective way to seal the gaps between the logs. The house leaked air and heat, and wind-driven rain literally came right through the walls.

He tried various caulking materials with little success. Caulking around a bathtub or sink was significantly different from ‘caulking’ literally miles of seams between logs in a log house. After a number of conversations and experiments, it became apparent that there was no readily available product that could seal the gaps, look like authentic chinking, and last more than a few months.

After literally months of trial and error, it became apparent that if we were going to design a material that would be acceptable, we would have to design it ourselves.

Defining a New Industry Standard

The product we were designing was to be a replacement for what was known in the Log Home Industry as chinking – the sealant that historically provided the seal between the logs. A “chink” is a gap – as in Biblical Times, “A chink in his armor’. Therefore, chinking is a material to fill a gap. Throughout the centuries of constructing dwellings out of logs, a number of methods were used to seal in between them. Early builders used pretty much anything they could get their hands on – mud, straw and mud, cow manure, mixtures of cement and mortar, and a method I discovered in Russia that was a particular type of moss that, when pounded into the gap, excreted a compound that delayed wood rot.

During our investigation we determined that in order to be a true solution the sealant must meet most important requirements.

- It had to be textured to look like authentic mortar chinking.

- It had to ‘look like it belonged there’.

- It had to be able to expand and contract in order to follow perpetual log movement.

As logs dry out in the summer, they shrink in diameter – in the winter and rainy months they absorb moisture and swell, increasing in diameter.

- The sealant had to adhere tightly to the logs and form a continuous watertight seal that would not separate from the wood.

- It had to be easy to apply – in some cases, gaps up to 4 and 5 inches, and not slump or wash out.

- And most importantly, it had to LAST for decades.

Common caulking materials were quickly ruled out. Everyone has seen thin caulking beads applied to exterior trim that inevitably separate, peel off, flake, crack, and ultimately fail.

No ‘caulk’ could adhere to the wood well enough, could not be applied to the thickness and height required without slumping and running out of the joint, and all caulks had that smooth, artificial look that frankly, of course, looked like caulk! It’s okay for around the tub or sink, but not for my log home, thank you.

Creating the Industry Standard

So, after months of experimentation and learning a tremendous amount of the chemistry of what are called polymers (the chemical building blocks of literally everything that we commonly call paint, plastic, vinyl, glue, etc.), we designed a unique sealant that met all of the most important requirements.

During the design phase we located an innovative small company south of Seattle that manufactured a synthetic stucco. They had experience and machinery that helped us scale up lab designs to large-scale production. We began selling early product in 1981, and the first house we did was in Sun Valley, Idaho – in the middle of winter.

Soon after we had a saleable product that met every design requirement, I did a little market research and discovered that the larger part of the national market for log homes was in the eastern part of the United States, and in particular, the southeast. I also discovered that of the numerous styles of log homes, the three largest manufactures of ‘Dovetail’ log homes were within 100 miles of Knoxville, Tennessee. I liked the Dovetail design because the nature of the structure, and the way the logs are stacked resulted in a chinking gap of up to 4 inches! In some cases, almost 25% of the wall area was chinking!

So, we set up a manufacturing plant in Knoxville, Tennessee. Timing was right because as soon as log home owners and log home manufacturers discovered that we could finally provide a dramatic solution to one of the most significant and perplexing aspects of a log home – the business grew rapidly.

Winning the Manufacturers

Early adopters such as Hearthstone, Honest Abe, Stone Mill, and Appalachian Log Homes helped pave the way for essentially all others to follow. As a matter of fact, one of the earliest applications for any manufacturer was Appalachian. Turns out they had a contract with the US Forest Service to build an outhouse. The location was remote, and the house needed to be completely assembled and transported via helicopter. Obviously, mortar chinking could not withstand that type of stress, so they tried Perma-Chink. That outhouse is still standing today and is weather tight – some applications simply CANNOT fail!

The development of synthetic chinking solved one of the most serious and vexing aspects of the Log Home Industry. The chinking formulation is unique and not simply ‘caulk with sand in it’ as others have offered.

Rick Denton, Honest Abe Log Homes President Emeritus said, “Perhaps the invention of Perma-Chink kept Honest Abe in business, as well as every other log home company using a chinked product line.” Read his story here https://www.honestabe.com/blog/perma-chink/.

What started out as an idea has revolutionized the entire industry. Worldwide, every log structure uses synthetic chinking, and the largest supplier of the most authentic and highest-performance log home chinking is Perma-Chink.

Expanding the Preservation of Log Homes

The next vexing challenge was with log home stains and finishes. Every log home owner wants a log home that looks like an outdoor piece of furniture. One that blends in with the rustic back to nature look and feel of the surroundings. No one would consider painting a log house. That would be like painting a beautiful hand rubbed antique! Log home owners tend to start down the following path after stains start failing: That beautiful stain we applied only lasted a year or maybe two and after two recoats, we may as well paint it. Why can’t someone develop a stain that looks like a furniture grade finish and LASTS?

We began to have literally thousands of people say, ‘You solved my sealant dilemma – now do you have a solution to the stain and finish dilemma?’ So challenge number two was tackled.

Creating the Best Log Home Stains

We used the knowledge and expertise we developed in formulating Perma-Chink Chinking (remember the polymers?) to design the longest lasting semi- transparent stain in the Industry. The formulation is also unique, provides that ‘furniture grade’ appearance, and outlasts any exterior stain on the market. Also, with a Clear Coat (which Perma-Chink Systems also introduced), when the finish is finally starting to “wear” out, all that is needed is a cleaning and application of an additional clear coat. That eliminates the tint buildup and subsequent hiding of the wood and completely eliminates the phrase ‘After two re-coats, I may just as well paint it.’

I personally require hands-on experience with every product Perma-Chink Systems offers. We are dedicated to providing the best products available for the care and maintenance of Log and Timber Frame Homes. As history has shown, and something we take pride in, is ‘Whenever a log home owner becomes aware of a concern, whether it be sealing, staining, or preservation or maintenance, we already have a solution.’

Take a Look At Total Cost

An interesting story – I recently had a heating problem with my log house in Colorado. The bill to repair the system included a small starting capacitor in one of the air handlers. The bill for the part was $6.25 and the bill for the labor was $220! So why would I try save sixty cents on the capacitor when the cost by far was in the labor to replace it? Same is true with a log home stain. By far the largest cost is in application and labor, so it pays to use the best product available. Cheaper stain is a cheap solution that sets you up for a repeat in a year or two, and in the meantime your exterior looks like crap! Pay the extra sixty cents and buy yourself some peace of mind.

By choosing our high-performance finish like Lifeline™ Ultra-7, you are ensuring that the finish will look as beautiful years after application as it did the second day it was applied thanks to a balanced formula of transparent iron oxides, mildew inhibitors and an advanced polymer resin.

Our Success is From Working With Great Customers, Industry-leading Partners, and Fantastic Employees

I am humbled that Perma-Chink Systems has become a ‘household’ name in the log home industry and is recognized for highest of quality. Our products grace the log houses of such noted Americans as former President Jimmy Carter, clothing designer Ralph Lauren, movie stars Tom Cruise, Olympic champion figure skater Kristi Yamaguchi, Nascar champion Dale Earnhardt (read the story here) and thousands of great American home owners.

I am proud of my company, of my employees and our customers. Perma-Chink Systems has a slogan for our 40th anniversary – “Simply Unmatched”.

By being engaged in best quality products and the best customer service, we will attain our goals and make great strides towards meeting our customers’ expectations for years to come. We raise a toast to the next 40 years of great products, service, and customers of Perma-Chink Systems.

Rich Dunstan, President Perma-Chink Systems, Inc.

How To Create Dust-Free Log Homes

We decorate our log and timber homes for not only holidays, but seasons, too. And after Thanksgiving and Christmas, putting away all those decorations revealed one of the most annoying things about homes: dust.

Dust gets everywhere. It’s never-ending. We have terms for giant amounts of dust called dust bunnies. It makes us sneeze – constantly. It’s ridiculous! No matter what it used to clean the dust, it returns!

Minimizing Dust Tips

The good news is there are ways to lessen the amount of dust. BobVila.com compiled 20 easy ways to keep the dust level in your house to a minimum. And in addition to the usual advice of keeping furnace/HVAC filters clean, vacuuming with HEPA filters, air purifiers, and wiping down surfaces, there are some other cleaning methods and ideas to keep the dust at bay. One of my favorites is limiting the number of textiles in your home. Like throw pillows. If your spouse or partner love a lot of pillows, that’s not the best thing to limit dust (approach this topic with caution! Ha!).

While the list of dust-limiting methods are quite useful, most only address the issue after the dust is inside the home. What about preventing dust from entering the home to begin with? For instance, having open windows may help bring in fresh air, it also allows dust in the form of pollen, spores, pollutants, etc., to enter the home.

Preventing Dust

One key to limiting dust in a log home is making sure your home is completely sealed. We know the amount of sealing a log home needs, based on the number of logs, sizes of log gaps, amount of windows and door frames and so on. However, there exists the chance that some nooks and crannies might get missed or damaged throughout time.

The quickest method to find where dust can enter the home is performing an energy audit. Infrared cameras can locate and identify areas where outside air can penetrate. Learn more about energy audits here.

The most likely areas of air gaps are the nooks and crannies of joints and building material transitions. For instance, doors and windows. Sometimes the seal isn’t as solid as one would hope. That’s where our Log Gap Cap pre-cut foam comes into play. Paired with Energy Seal or Perma-Chink sealant that matches your current sealant, this combo effectively closes up your home around doors and windows. Read more about Log Gap Caps here.

And finally, make sure vents and the foundation seams are sealed and properly finished. Not only will this help keep your home sealed from outside dust, but also keeps bugs and pests from infiltrating your home.

Dust will always be around, but there are ways to mitigate how much, which should give you more time to enjoy your home.

Lifeline Ultra-7 turns ten in 2021!

Introduced ten years ago, Lifeline Ultra-7 quickly became the premier finish for log and timber homes. Upon introduction, Ultra-7 improved coverage rates and added even more color options for the Lifeline family. Today, the best-selling Ultra-7 remains the go-to finish for exceptional longevity and color retention for log and timber homes. Paired with Lifeline Advance topcoat, Ultra-7 keeps your log home looking beautiful for years and years.

Wayne Bell of Log Home Care finished this project ten years ago in Avon, Ohio.

Before:

After, Front Porch:

After, Front Porch Up Close:

After, Wide Shot of Wrap-Around:

Mold and mildew (actually another name for mold) are colonies of living organisms that can grow on the surface of many materials including wood. Their color may range from white to black with just about every color in between. If the discoloration is green, it is most probably algae, a plant, since molds and mildews do not contain green chlorophyll. Like most living organisms, molds require air, water and a food source for survival. Bare wood is quite susceptible to mold growth since the porous surface provides lots of places for spores to germinate and many of wood’s nutrients are available as food. This is especially true for newly harvested wood that still contains a high sugar content. In addition, bare wood absorbs water, thus supplying the moisture these organisms require.

Combating Different Molds

Although it is fairly easy to remove mold from bare wood surfaces (Wood ReNew does an excellent job), preventing its growth on green logs in particular can be somewhat of a challenge. Thanks to the internet, one popular misconception is that borate treatments will prevent the growth of surface molds on wood. This is NOT TRUE! Although the presence of borates will inhibit the growth of some types of surface molds, there are other types that actually thrive on borate treated wood. Borates are quite effective against wood decay fungi, but surface molds are very different from decay fungi and it takes other methods of control to prevent their growth.

Best Methods to Prevent Molds

When it comes to preventing the development of mold on wood, the best and most effective approach is to provide a dry environment. Molds cannot survive in dry conditions so if the logs are stored under cover with lots of air flow around them chances are that mold will not grow on them. But as we all know there are occasions when ideal storage conditions may not be practical so in those cases how can the formation of mold be prevented. There are some chemical treatments that can be applied to bare wood that will kill existing mold colonies and prevent the growth of mold for several months. One of the more commonly used products is didecyl dimethyl ammonium chloride, commonly referred to as DDAC. It works well and several years ago we used to sell a brand of it named Britewood XL. However, one downside of DDAC is that it is corrosive to skin.

Another chemical used for killing and preventing mold growth is chlorothalonil. At low concentrations it is commonly used for preventing fungal growth on peanuts and potatoes as well as being a fungicidal additive to paints and stains. Sostram Corporation makes a chlorothalonil product named CLORTRAM that inhibits surface mold and stain causing fungi growth. Neat chlorothalonil is very toxic to aquatic life.

Mildew-X

Although there are several other products available for controlling mold, the last one we will cover is Mildew-X. Mildew-X is a dry film preservative that prevents mold and mildew growth on interior and exterior surfaces naturally. Mildew-X is exempt from FIFRA registration.

So, is there a role that a Perma-Chink Systems product can play to prevent the growth of mold on bare wood other than one of our complete finish systems? If a manufacturer or contractor wants to protect their logs at the mill or on the job site during construction, they can apply a coat of Prelude that has been dosed with Mildew-X or an equivalent product that is labeled for adding to water-based paints or stains. This will help prevent the growth of mold on top of the Prelude film. The limitation of this combination is that it must be applied to a fairly clean surface since it may not kill all of the mold colonies that are already present. However, it offers some definite advantages over those products that just eliminate and prevent mold. First, since Prelude contains UV Boost, it will help prevent surface graying due to sun exposure. Second, the Prelude film will keep the surface cleaner during transport and construction. And third, it will help regulate the drying process which to some degree should lessen initial checking and fissuring. We already have some manufacturers using this system and they are quite pleased with the results.

Applying and tooling Perma-Chink or Energy Seal sealant you need the right tools to make the job easier and quicker. Depending on the job and type of sealant needed, you have a few decisions to make regarding the tools and accessories you’ll need for the project.

Starting Out On The Right Foot

Having the right tools at hand is critical for a good chinking job. The most popular tool for applying Perma-Chink or Energy Seal is the bulk-loading gun. This tool is available in two sizes, the 20oz. and 30oz. capacity and operates by pulling sealant straight from the pail.

For contractors who have been applying sealants for years, the tools selected have been time tested. Contractors expanding work or new to the trade might want to know all the available options for the job. And since everyone has a different preference on tools, Perma-Chink Systems offers multiple products to get the job done.

1. The Albion Bulk Loading Caulking Gun

This is our most popular tool for applying Perma-Chink or Energy Seal. It is built to meet the demands of serious professionals, utilizing rugged, heavy-duty all steel drives and lightweight aluminum barrels to reliably dispense a wide range of materials.

Available sizes 20oz. and 30oz.

- Professional Quality

- Efficient 12:1 Drive Ratio

- Lightweight Aluminum Barrel

- Double Grip Plates for Long Life

- No Spanner Wrench Needed!

- Barrel Rotates for no-stop application

- Kit includes 3 nozzles, one spare piston and a steel ladder hook-pull

2. Smooth Rod Style Caulking Guns for applying Perma-Chink, Energy Seal, Check Mate 2 and Woodsman

Great for professional use where bead consistency, control and clean up save time and money. A simple push of the recoil releases all pressure on the plunger and instantly stops the flow of sealant. To remove the tube, press the lever and pull back on the rod to expose the entire tube and slip it out of the gun.

Available in sizes for 11oz. tubes and 30oz. tubes

- Professional Quality

- Smooth Rod for reliable dispensing

- Efficient 12:1 Mechanical Advantage Drive

- Convenient Thumb-Release for no run-on caulking

- Full size handle for comfortable dispensing

3. Cordless Guns with a State-of-the-Art Performance, Portability and Control

How Fast is Fast! A Cordless Gun can dramatically decrease the amount of time on a chinking job.

Available in sizes for 11oz. tubes and 30oz. tubes AND 20oz. bulk

- Powerful – 400 lbs. of Dispensing Force

- Fast – Dispense 11oz. Cartridge in 16 seconds

- Lightweight Aluminum Barrel

- Long Lasting – 12 V Lithium-Ion Battery

- Control – Variable Speed Trigger with Maximum Speed Dial

- Auto Reverse for No-Drip Dispensing

- Comfortable rubber over molded handle. Swivel barrel

- Fast 30-minute recharge. Battery Fuel Gauge

- Ladder pull hook

How Bulk Loading Guns Operate

Simply insert the 2-inch wide cylinder into the pail and fill the gun by pulling back the plunger, which draws the product from the pail into the body of the gun. After wiping the threads clean and screwing on the end cap with plastic cone nozzle, you’re ready to apply the product. To make your job easier, quicker and much cleaner with less product waste, the gun-compatible follow plate can be used (highly recommended). This 9.5” round metal plate has a 1” rubber gasket which allows for the tapered shape of the pails.

Basic Instructions on how to Tool Perma-Chink Sealants

Smoothing your sealant you have just applied from the gun is not nearly as important as making sure you have really good contact to the top and bottom log, with no air trapped under the sealant.

To move the sealant into position for proper adhesion and to smooth out bumps is what we refer to as “tool” or “tooling.” The best tool we recommend is a bent trowel that’s about the width of the chink joint. The bent trowel makes it much easier to avoid trowel marks in the sealant as it dries and cures. Along with a trowel, you’ll want to have a plant mister or squirt bottle filled with plain water. Perma-Chink Systems offers a variety of stainless-steel trowels ranging from ¾” to 4-inch wide with both rounded and squared off tips in our Tools & Dry-In section.

Anytime you tool the chinking, spray a little water on it first. You want enough water to allow a smooth motion with the trowel, but not so much it pools and runs all down the logs. The water prevents the chinking from sticking to your trowel and gives a nice, smooth surface free of bumps and edges. Make more smoothing passes after you have created good adhesion to those logs to remove any tooling marks. All of these passes are a very light pressure, with ½” to ¾” of the tip of the knife being used. Depending on the appearance you are looking for, you may leave your sealant line as smooth or as rough as you would like.

Hope this helps! Check our Tools and Dry-In section on the website to find all the items needed to get you started on your project! And if you need more information, our professional sales representative is standing by at 800-548-3554 or send us an e-mail to techservice@permachink.com

Click here to view the Log Home Sealants Application Guide

Why Log Boss

Why should you use the Log Boss over what you are currently using? That is a question we are often asked when we are showing these fasteners to potential customers.

We looked a several options that were in use for fastening the logs and timbers together. The search turned up various way builders were putting things together. The old way was the use of long spiral nails that were driven in with a very large hammer, which was very tiring – especially if you had to install the nails every foot or so for the whole house. Also, lag screws were used by builders to assemble logs together. The lag screw installation requires pre-drilling and drilling a countersunk hole for the head to go into. It also required the use of a large electric impact drill to effectively set the lag screws, or a large ratchet along with a very strong person to complete the installation.

To better serve the builder/customer, there must be something better. The fastener we were looking for had to add value to the customer, and this can be accomplished in multiple ways. The best fastener we found lessens the biggest costs – reduces labor cost, speeds up the installation process, and reduces the need for specialized tools. You also must have a product that performs and meets the expectations of the user, and to do this, Perma-Chink Systems chose the Log Boss log and timber fastener to meet the demanding needs of builders and contractors.

Log Boss Design Benefits

The design of the fastener is very critical to overall performance and ease of use. At the request of many of our customers, we’ve redesigned the head for better counter-sinking and uses a 5/16” hex head driver. The wings reduce the friction between the wood and the shank, clearing out the splinters created as the fastener pulls down into the wood. This reduces the torque required to set the fastener into place. Reducing the torque decreases the strain around the wood fibers, which increases the holding power of the wood fibers between the threads. The result is much greater pullout values by eliminating thread strip out.

One of the most outstanding features of the fastener is the ‘wings’ above the threads. The goal was not to disturb the thread holding value but to drive the fasteners into timbers with less torque requirements. The wings act as a reamer, allowing the shank to rotate much easier with less friction in the log. Without wings, the wood fibers bind up on the shank, seizing it to the point it becomes almost impossible to complete the required depth. It also often results in fasteners breaking off just above the threads, which adds wasted time to the project.

Another great feature of the Log Boss is the special rust-resistant coating applied to all fasteners, reducing the chances for rust to discolor the logs during extended exposure times on the jobsite. There is also a special lubricant applied to the fastener to aid in driving operations. Log Boss can be driven with an 18-volt cordless drill, but for best results we recommend the use of a ½” low rpm drill for optimum driving performance.

Log Boss fasteners are packaged in jobsite-friendly containers that resist damage from abuse and moisture. All sizes below 14” are packaged in plastic pails containing 250 fasteners and a drive bit.

Picking The Correct Log Boss

Now, how do you determine what size fastener that you need to use and what are the basics?

First, it is important to follow the log manufacturer’s recommendations as to the placement of the fasteners. The length of the fastener is critical to achieve the best performance. The selected fastener length must allow the threads to pass entirely through the first log, and thread into the second. The reason behind this is simple: in the event log movement happens, the log must be anchored to the bottom log, with the head providing pull-down pressure on the top log. It matters not if the screw is a little longer than you need, but make sure the threads will pass clear through the first log.

If you encounter a knot while installing the fastener, you will need to apply more torque to seat properly. It is a good idea to back the fastener out and move it over a little to avoid the knot. Another event that sometime occurs is the fastener may follow twisted grain and come out the side of the log.

So, if you want a fastener with maximum holding power and superior strength with less work, Log Boss is the answer. These fasteners were specifically designed by Perma-Chink Systems for the construction of log and timber structures. Their 3” long thread provides the grip necessary for pulling even the most difficult logs into place while the larger shank diameter increases the overall strength and pulling power.

Log Boss Benefits

Pre-drilling is not required

No washer needed. Drive it one time and forget it!

Flat head design easily counter sinks with maximum pulling power

Replaces the need for spikes or lag bolts

Lubrication coating speeds set time

Large threads prevent stripping out

Teflon® coating exceeds FM 4470 corrosion standards

Ask us for a complete line of wood-to-wood, code-approved fasteners for decks, ledger boards, and large timber applications.

As we settle into the holiday season, the cozy winter time, and potentially longer COVID-related lockdowns, the number of days inside the home can be overwhelming. Already approaching a year of COVID, our time in the home may raise our cabin fever or children if it hasn’t already.

But not to worry! There are things we can do to alleviate the time cooped up inside for the whole family. Country Living offers 25 activities to change up the routine, including classics like making your own Play-Doh! Check out their list here.

One snow-bound winter my family gathered around the fireplace and we listened to classic radio shows on cassette. My imagination became a powerful force to bring 1930’s radio show The Shadow to life during that cold December.

Today’s Parent has an impressive 87 activities, ranging from cardboard dollhouses to tye-dyed t-shirts. A lot of crafts are involved, to help kids learn motor skills. And of course, baking- but haven’t our waistlines had enough baking? You can read the long list of activities here.

Other activities may not seem as fun as making forts or throwing a dance party, but they can be greatly rewarding if more indoor living is in our future. Renovate interior, organize the kitchen “junk” drawer (I have 2!), go through your books and donate or share the ones you’ve read, and general “de-cluttering.” This is also something you can do in your digital life – unsubscribe to unwanted emails (not ours, though!), delete unnecessary emails, or clean up your digital photo albums.

Lastly, don’t forget about traditional card and board games. Some have found their way online, or are online only, and that greatly increases player pools. Many online games have chat features that allow interaction between friendly opponents. Codenames is one game that has online gameplay with others – learn more at https://codenames.game/.

Which Log Home Sealant Should I Use?

We are asked this question very frequently about our two biggest selling log home sealants. Both of these sealants were formulated to weatherproof joinery in log and log sided buildings. Our simplest answer is that in general, Perma-Chink should be used in applications where the seam width is one inch or wider and Energy Seal is a better choice in sealant seams that are narrower than one inch or where joinery was not intended to have chinking applied to it. However, this answer is overly simplistic when you consider the variety of log profiles and joinery types and many different surfaces that come together to make up a finished log structure.

What is the Difference?

Perma-Chink is our original log home sealant (and the company namesake). It was formulated to look like the concrete mortar that was typically used on full-log construction at that time. It is the original elastic log home sealant. Today Perma-Chink is available in eight different colors, some of which look like concrete, the others are various wood tones.

Energy Seal was formulated at the request of our customers at a much later date. These customers had homes that were usually built with log profiles that did not use chinking, but required weatherproofing some time after they were finished and in use. Because the application surfaces were never intended for a sealant application, they don’t have proper geometry that includes a caulking well to allow for sealant and backing material installation. Consequently, we formulated Energy Seal to have higher elongation performance. Energy Seal comes in a wide selection of 12 colors for customers who would prefer to conceal the sealant or even to match the chinking on their log home.

Energy Seal is a Better Choice in the Following Situations:

In general, Energy Seal is a better choice for very demanding, narrow seam application where more stretch is required in a narrow sealant seam. It is also the best choice if you would like the sealant to blend in with the wood surface and not be easily seen. Energy Seal is an excellent choice for use in sealing around doors and windows, butt joints, corners, and junctions between log walls and other surfaces such as beams, rooflines or framed walls.

Perma-Chink is a Better Choice When:

Many log homes are designed, manufactured and constructed with chinking an integral part of the building envelope. Perma-Chink is the clear choice in this situation. Additionally, Perma Chink is ideal to use when sealing up the junction between wood walls and concrete, brick or stone features like fireplaces, stone accents and walls.

Additional Information:

Energy Seal is lightly textured to reduce shine and reflectance and to help it accept stain when you prefer to blend the sealant in with the surrounding woodwork. Perma Chink’s heavier texture mimics the look of concrete mortar.

We have additional special purpose sealants. Check Mate 2® is specifically formulated to seal checks in your logs. It has very high elasticity for the dry season when your checks open up and it compresses very well when the environment gets damp and those same checks close back up. It is available in clear and six colors to match your wall color.

For more information call Perma-Chink Systems and consult our Sealants Application Guide to gain your best understanding of how and where to apply any of our sealants to get the highest possible performance out of them.

Sometimes you just want something unique – something that truly reflects your personal style. When looking through the standard Lifeline Interior™ or Lifeline Accents™ colors, it might seem like your options are limited at first glance. The good news? There are actually countless possibilities. So let’s get creative and have some fun discovering the perfect color for your home.

Because interior wood surfaces aren’t exposed to the same harsh environmental conditions as exterior wood, you have much more flexibility to play with color. You can apply one or multiple coats, depending on the look you want to achieve.

You can take your creativity even further by incorporating Lifeline Prelude™ – one of our best-kept interior finishing secrets.

A single coat of Lifeline Prelude applied to clean, bare wood provides UV protection and dries clear, making it an excellent clear primer. Lifeline Prelude also helps your color coat(s) apply more evenly, often resulting in a slightly lighter hue with improved color consistency during application.

Start by applying one coat of Lifeline Prelude, followed by a single interior color coat of your choice. Once that coat has dried, if you’d like to deepen or adjust the color, simply apply an additional color coat and evaluate the result.

You may be surprised by the wide range of looks you can achieve by testing with or without Lifeline Prelude clear wood primer, and by layering one or more color coats. Have some fun experimenting with free samples to discover your perfect shade.

Once you have found the color for your interior walls, ensure easier cleaning and omit odor absorption by applying your choice of either Lifeline Acrylic™ or PCS Clear Shield™ over your color coat(s). Odors? Yes, you read that correctly – wood is porous and will absorb odors through the years, so protect your interior wood!

What if you just want to keep the beautiful, natural color of your interior wood and have no desire to mess with colors, is that an option?

Absolutely! There are two options you can consider for achieving the natural look while providing enduring protection:

1) Apply a single coat of Lifeline Interior Clear, #110 (we recommend adding UV Boost, as it will assist with protecting your interior walls from UV damage that receive sun exposure) and follow it with either PCS Clear Shield or Lifeline Acrylic for added protection.

2) Apply a single coat of Prelude (this already has UV inhibitors in it, so there is no need to purchase UV Boost) and follow it with either PCS Clear Shield or Lifeline Acrylic for durable protection.

Lifeline Acrylic is available in Gloss or Satin finish, and PCS Clear Shield is available in either a Gloss or Matte finish, and both are wonderful at resisting the yellowing that some finishes create. You can also apply multiple coats of both clear topcoats to obtain the lustrous sheen desired. And if you’re daunted by the task of staining the upper reaches of your ceilings, there are nifty tricks of the trade you can use to get the work done safely and inexpensively. Also check out our Interior Picture Gallery for more ideas.

If you have additional questions, please call 800-548-3554 and talk with one of our Customer Service Representatives. We are always delighted to assist you!

Enjoy making your home distinctively yours!

What to do if your log home was flooded?

Log homes are actually more durable than traditional homes, and are more likely to survive natural disasters, including flooding. The clean-up and repair of a log home after flooding is also much easier; follow these steps…

Interior

1) Tear out everything that is obviously ruined or that will interfere with drying out the log walls. All floor coverings (you will not be able to save any wooden floor – even if it looks good now, it will warp), trim, drywall, and insulation must go. You will probably have to replace all wet cabinetry and interior doors that were stained or contained any type of composite wood. Sometimes cabinets and doors can be saved if they were initially painted or if you choose to paint them now. Cut drywall and insulation about a foot above the high water mark. Sometimes tile floors can be saved, depending on the backer used under the tile.

2) Clean – Water usually brings in a great deal of mud or other contaminates. Once areas are cleared of debris and other building components mentioned above, then pressure-wash the log walls, studs, other framing, and sub-floors. Use products like Log Wash or Wood Renew to help lift out dirt and begin to control mold and mildew. Try not to use bleach as it can change the color of wood which can cause problems later. If you MUST use bleach, use no more than a cup per gallon of water and try to keep it off of wood that did not get wet. Apply the cleaners from bottom to top and then wash the dirt down the walls, across the floor, and out the door.

3) Dry out the log and timber components left behind. De-humidifiers are best at this task along with fans. If electricity is not available, just do your best to provide some air circulation. If only one de-humidifier is available, use it in one room at a time – running constantly until the moisture content of the wood in the wettest area of the room is below at LEAST 17%. Moisture meters are available at home centers and hardware stores. If your home is on a crawl space, close all the vents, install a new vapor barrier, and install a couple of de-humidifiers. This will quickly dry the space under the home and the sub-floor. If electricity is not available, consider removing sections of the sub-floor to provide some air circulation.

4) Disinfect – As soon as the wood is dry to the touch after cleaning. Liberally spray a mold control product on everything that got wet – Concorbium is one brand name. These products are commonly available at stores like Lowe’s or Home Depot. Buy a lot and use it. I have found these products work wonders stopping mold, mildew, and the odors and stains that accompany them. You may have to re-apply if it takes a while to dry your home out due to lack of electricity or equipment.

5) Replace and Re-build – I recommend replacing all electrical outlets and switches that were under water. If in doubt about electrical components, ask an electrician. I did not replace mine initially and had trouble later. Replace all drywall, insulation trim and re-finish. If you have a lot of open interior stud walls, I recommend applying powdered borax like Armor Guard inside the stud cavities and THEN closing them up. The borate will stay there practically forever and kill ants and roaches that crawl through it and then consume it as they groom themselves. Also apply this powder on the floor just before you re-install base cabinets in kitchens and bathrooms – same purpose.

If you had wood walls that did not have a finish applied, they may discolor. The longer wood is wet, the more likely it will have discoloration. Wood Renew or other percarbonate (hydrogen peroxide) cleaners can help remove some or all of this discoloration. Wood brightener- a product containing oxalic acid like Oxcon may also work, but be careful as these products may work TOO well and change the color of the wood beyond the desired color. If you did have a finish on the wood walls and discoloration is occurring UNDER the finish, that finish must be removed by sanding or stripping to remove discoloration.

Do not attempt to replace wooden floors until HVAC has been restored as flooring must be acclimated prior to installation.

Exterior

Luckily, log walls on the exterior are very durable if they were properly finished with a quality stain. They usually dry out nicely and require only some power-washing to clean.

Use a cleaner like Log Wash to clean off dirt. Do not try to be aggressive with the power-washer, you just want to rinse the dirt off. Some of the wood trim components that were engineered – like finger-jointed trim materials – may swell and need to be replaced. Exterior doors and windows (especially wooden ones) should be carefully examined and may need to be replaced as well. Insulated metal and fiberglass doors that get wet sometimes look fine, but they can hold water inside for a long period of time and eventually deteriorate.

Be careful around and under your home. Flood waters displace a lot of critters that may take refuge around and under your home – snakes, racoons, skunks, and opossums are no fun when they are too close.

If you have any questions, feel free to contact us at 1800-548-3554 or by email at techservice@permachink.com. We’re open 8:00AM – 8:00PM EST, Monday thru Friday.

New Color Trends

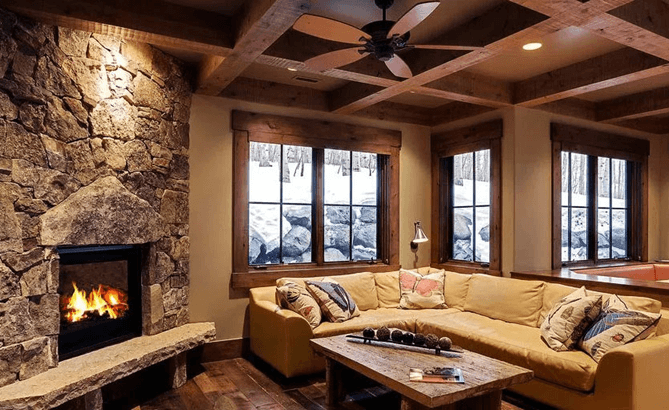

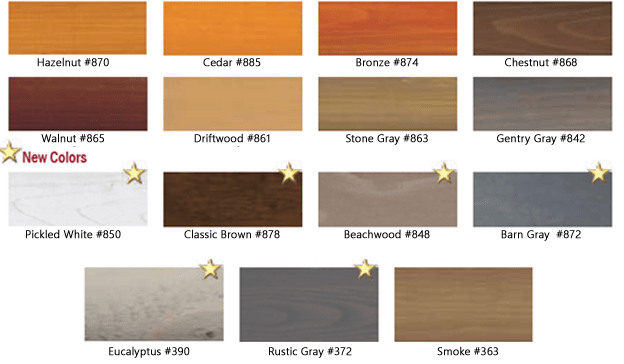

Staining your log or timber home is a humble art and is a critical part of the sense of style and feeling of what the structure creates. Whereas paint simply transforms the color of a surface, leaving no trace of its previous character, stain is typically used to enhance the beautiful grain of wood and generate that back to earth feeling that heavy wood timbers accentuate. Semi-transparent stains from Perma-Chink Systems are designed to let the beauty of the wood shine through and provide increased protection from interior and exterior elements. But what about the colors?

Gray and Browns have been popular in recent years, and this trend is still going strong. If you’re clinging to those gray tones, you’re in luck. 2020 continues to welcome these tones with open arms.

Gray is also a neutral with a reputation for being cold, with more than 50 shades of gray. With some warm beige added you will have gorgeous and stylish color, like one on the photo above, with so many sophisticated hues.

Actually, the shift toward warmer-toned gray is going so strong, that they referred to as “greige”.

Is Greige Better Than Gray?

If you love the idea of gray but worry about the coldness of most gray colors, greige could be what you are looking for. With added beige tones you will get the elegance of gray, without the cold blue undertones. Try out our Lifeline Ultra-7 in Eucalyptus or Rustic Gray colors, they are absolutely stylish!

If you love your browns more than grays, but still want a hint of that rustic look, try two new browns from our Lifeline Ultra-2 collection. Maybe we should call them “brays”? And how do you mix browns and grays? You don’t! We made them for you! Check out the trendiest new colors in our Lifeline Ultra-7 and Lifeline Ultra-2 collection. Order your FREE color samples and try it on your wood.

“From colors to textures, we’ve got the scoop on which color trends are going strong and we would like you to know about it,” says Rich Dunstan, the president of Perma-Chink Systems. “We design eye-catching colors in many diverse tones that have the power to transform the entire ambience of your exteriors and interiors”

And the best part – you don’t have to mix anything, just pick your colors and order free samples to try it on your wood. Custom colors available upon request. Call 1-800-548-3554 or email techservice@permachink.com