Blog

Chip Wade and wife Pauli, of Wade Works Creative, are design professionals and lifestyle experts who love sharing their inspiring ideas with DIYers, pros and homeowners.

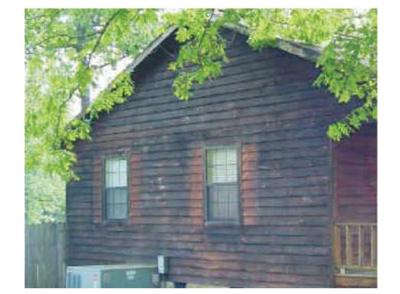

The Wades renovated the Misty Mill log home, located on Lake Sinclair, which was created in 1953 as part of the Georgia Power Company’s reservoir, with over 400 miles of scenic shoreline and just a 1 ½-hour drive from Atlanta.

The premise of Misty Mill is to spend time outdoors taking in views of the lake, without any worries of upkeep and maintenance. That’s why when Wade managed a total makeover of his own 2,400 sq. ft. lake house on Lake Sinclair in central Georgia, he wanted the best, top-of-the-line materials for his Misty Mill.

“All the content for this show house is about the best in innovative products and installations. I have personally selected the products I feel will be the best representation of this theme,” said Wade.

That’s where Perma-Chink Systems came in. After extensive research, Wade chose the premier log home care company to provide dependable, long-lasting and technically advanced products to ensure the creative design of the home meets not only Wade’s expectations, but future clients of Wade Works Creative.

In addition to selecting the best products, Wade also selected one of Perma-Chink Systems’ best Preferred Applicators, Nothing But Logs, to treat, finish and seal the log home. Located in Shady Dale, Georgia, Nothing But Logs has over 20 years of experience in maintaining, repairing and restoring log homes.

As the host of HGTV shows, Wade’s own creative stamp on the home required repairing the exterior to match his vision of the home. The exterior showed a lot of weathering and discoloration that would have to be addressed before applying the stain of choice.

Repair of the aged, grayed wood surfaces was accomplished with Wood ReNew. Being on the water, the home’s exposure to the weather gave the logs varying degrees of aging. Wood ReNew brightened up the wood, bringing back a true wood color, and was now prepared for staining.

The home was finished with two coats of Lifeline Ultra-2 Gentry Gray, and the newly constructed boathouse finished to match the home, making the new structure seem like it had been there all along. The choice of Ultra-2 provides the Wades with exceptional longevity and UV protection designed to prevent the extensive weathering damage. Add in the 5-year warranty of Ultra-2 when Lifeline Advance is applied and the Wades have a durable, cost-effective finish solution.

Along the way, the log home needed chinking repairs, completed with Perma-Chink White, the leading chinking. With repairs done in white, there was the issue of the old, gray chinking. Instead of re-chinking the entire home, the old chinking was freshened with textured Chink Paint in white, bringing a brand-new luster to the home. To improve energy efficiency, the end joints were sealed with Energy Seal Slate Gray, which matches the finish of the logs and presents a seamless joint.

After all the staining and sealing work was done, Chip selected the clear topcoat Lifeline Advance Satin to protect the logs and finish. The end result is a magazine-quality home, and we’re proud to be involved in Wade’s extensive project.

Now this inspirational lake house has all the comforts of the indoors, with exterior materials that will keep performing and protecting the home for generations to come.

You can view Chip Wade’s Misty Mill log home – including design concepts, before and after pictures – online at https://mistymill.com/.

We often get asked whether Perma-Chink’s LIFELINE™ finishes can be applied over an existing stain. Since the answer to this question is somewhat complex we’ll look at the various types of stains individually. First and foremost, for the best look and performance of a LIFELINE finish it’s always best to remove any existing old finish unless it already is a LIFELINE finish. Even then, the existing LIFELINE finish needs to be in pretty good shape before we recommend applying another coat on top of it.

That pretty well covers what should be done. However the question is “can a LIFELINE finish be applied over other brands of existing finishes?” If the existing finish is water-based and there are no signs of grayed wood and the color on all of the walls is fairly uniform the answer is typically yes with some reservations. For example, if the existing water-based finish contains wax there may be a problem with adhesion or “fish eyes” forming during application. But you have to be careful, not all water-based finishes are created equal. Water/oil emulsion stains claim to be water-based but in fact contain enough oil that adhesion may become an issue.

In general LIFELINE should never be applied over film-forming oil stains like Sikkens Cetol Log & Siding, Sashco’s Transformation, or other alkyd oil-based stains. These types of finishes should always be removed before applying LIFELINE. But what about penetrating oil stains like WOODguard, Outlast Q8 Log Oil, TWP, Olympic and others? It really depends on the individual situation. Since one-coat oil stains usually don’t last more than a couple of years, we rarely encounter a situation where the condition of the surface is good enough to apply one of our LIFELINE transparent stains without first removing the remaining stain residue. By the time someone typically decides that the existing finish is in need of repair there is usually enough grayed wood or dark mold growth present to require getting back down to a clean bare wood surface.

A more challenging question is when someone decides that he or she wants to apply LIFELINE over a penetrating oil stain that’s less than a couple of years old. The best and safest way to proceed is to remove the existing finish. Attempting to apply LIFELINE directly over an oil-based finish is risky and the last thing any of us want is for you to be disappointed with the results.

So what’s the best way to remove an existing oil finish? If at all possible, chemical stripping is the way to go. The components in most chemical finish removers like our S-100™ and StripIt® not only soften the finish but they also help remove any residual oil that may present in the top layer of wood. Media blasting on the other hand may remove the alkyd film or the oil-based pigments but does not remove any oils that may have penetrated into the wood. If LIFELINE is immediately applied to the blasted surface, there is a chance that the remaining oil residue will come to the surface creating an adhesion problem or blisters in the LIFELINE film, especially on sunny walls. A good washing with Log Wash will help remove some of these residual oils, but it’s best to give a bare blasted surface three months exposure for the oils to evaporate before cleaning with Log Wash and applying the first coat of LIFELINE finish.

Some Rules of Thumb

- If you do not know what specific finish is on your home, remove it.

- If there are black streaks, mold spots or any other discolorations that you do not want to see through the final finish, clean the surface down to bare wood and remove them.

- If there are signs of grayed wood or if the existing finish has areas that have peeled, clean the surface down to bare wood.

- Never apply a LIFELINE finish over oil-based, alkyd film forming finishes.

UV Boost™ is a concentrated water-based, liquid stain additive that contains a hindered amine light stabilizer specifically designed for wood protection.

Some regions of the country such as the southeast, southwest, and higher altitude areas are subject to high intensity sunlight. Over time, the ultraviolet light in sunlight photo-oxidizes the lignin component of wood. When added to the first coat of any of our Lifeline™ water-based stains, UV Boost interacts with the lignin thus slowing the photo-oxidative rate that results in wood darkening and eventually wood graying beneath the stain.

Application Tips

1. UV Boost is only effective when used in the first coat of stain or finish applied to bare wood. UV Boost must be in direct contact with the wood for it to work. It is not effective when added to topcoats or stains applied over an existing finish.

2. UV Boost may be used in both interior and exterior applications. When used inside it will help prevent the “picture frame” or “carpet frame” effect.

3. UV Boost is designed to be used in any Lifeline water-based stain as well as Acrylic Gloss/Satin and Sure Shine™ Gloss/Satin. It is not suitable for use in oil-based finishes or stains produced by manufacturers other than Perma-Chink Systems, Inc.

4. Lifeline Ultra-2™, Lifeline Ultra-7™, and Prelude™ are already formulated with the maximum recommended concentration of UV Boost; therefore, it is not necessary to purchase or add additional UV Boost to these products.

5. UV Boost is available in two sizes, one for the addition to one gallon containers and one for addition to five gallon containers.

Application

1. Shake container of UV Boost.

2. Add entire contents to the appropriately sized full container of stain or finish.

3. Shake or stir the container of stain or finish until the contents are thoroughly mixed.

4. Apply stain or finish according to the labeled directions.

5. Any stain containing UV Boost that is left over once the initial coat is applied may be used for subsequent coats. Just be sure to “box” the remaining stain to assure a uniform color.

Cleanup

UV Boost that has been spilled may be cleaned with soap and water.

Storage/Shelf Life

1. Keep container tightly sealed until ready for use.

2. Do not freeze.

3. UV Boost has a shelf life of three years from date of manufacturing.

Packaging

UV Boost is available in both 120 mL for adding to one gallon of stain or finish and 240 mL for adding to five gallons of stain or finish. Since the concentration of the active components differ, be sure to use the appropriate size for the amount of stain or finish you are using.

Results from panels exposed in an accelerated weathering tester for 1200 hours.

Have you ever seen the exterior of a home that has turned black? Almost without fail it’s the result of using a stain that contained linseed oil. Linseed oil is a yellowish oil derived from the dried seeds of flax plants, which is the reason it is also called flax seed oil.

Linseed oil is used as a carrier in many brands of paints and stains. Since linseed oil is organic, many varieties of mold fungi thrive on it and over time they can proliferate to point where the coated surface can turn dark brown to black. One way to tell if the darkening is due to mold rather than UV damage is that those exposed areas protected from direct sunlight under eaves and overhangs will be the same dark color as the rest of the wall.

When this occurs, washing with Log Wash™ alone will not be enough to remove all of the discoloration due to mold growth. We recommend to first use Wood ReNew™ along with some scrubbing in order to remove the visible mold. Once the surface is cleaned with Wood ReNew, use Log Wash to help remove any residual linseed oil that may still present.

Media blasting alone is not a satisfactory method of removing a heavy growth of mold. Linseed oil penetrates into the wood and although blasting may remove most of the surface discoloration, there may be enough residual linseed oil remaining in the wood to support mold growth underneath the finish. If the home has been blasted, it will be necessary to give the home a good washing with a Log Wash solution (2 cups per gallon of clean water) before applying Prelude™.

The best way to prevent this problem from reoccurring is to avoid the use of any product that contains linseed oil. None of our Lifeline™ finishes contain linseed or other types of organic, naturally derived oils.

Wood-boring beetles can be found all across the United States. There are several types of beetles that can be considered “wood-boring” beetles. Often referred to as “wood worms” or “powder post beetles,” wood-boring beetles are responsible for damage to structural wood, second only to termites.

Wood-boring beetles are difficult to control once an infestation has begun. Therefore, prevention is the best management method. Great NEWS: the treatment for all types of wood-boring beetles is the same.

Shell-Guard RTU is the best way to protect your home from wood-boring beetles, termites, carpenter ants, wood rot, fungi and more. It’s active ingredient Disodium Octaborate Tetrahydrate, or borate, combines with food-grade glycol added to deepen wood penetration that can be used to both treat and prevent pests from eating wood.

Research results shows that the presence of borate in the wood does two things:

- It kills younger beetle larvae that are feeding in the wood.

- It prevents any old house borer eggs from hatching. The borate treatment interrupts the beetle’s life cycle and eventually the infestation will end.

About Wood-Boring Beetles

Wood-boring beetles invade and damage wood furniture as well as structural and decorative wood inside the building. The beetle larvae feed in and do most of the damage to wood, and when they reach the adult stage, they emerge through round exit holes, which they create by chewing through the wood surface. Adults of some species also bore exit holes through plaster, plastic, and even soft metals that might cover the underlying wood.

What are the signs that beetles are present in the wood?

- Sawdust or frass is the first sign of beetle infestation.

- The chewing noise made by older larvae in the wood.

The life cycle of most wood-boring beetles is similar. It starts with an adult female depositing her eggs in the wood. The eggs hatch and a small grub-like larva emerges. It’s the beetle larvae that feed on wood, and they may continue eating the wood for several months or, in some cases, up to 20 years depending on the species. There comes a time in its life cycle when it’s getting ready to make the change that the larva makes a hole to the surface of the wood, so it can get out of the wood as an adult beetle. That’s why the holes are called “emergence holes.” Typically this is the first sign that beetles are present in the wood. Once the hole is complete and the tunnel is cleared of the sawdust or frass, the larva creates a pupa case and makes the transition to an adult beetle. The adult beetle eventually emerges from the hole, feeds on pollen and nectar and looks for a mate. Once impregnated, the female beetle can start the cycle all over again.

Order Your Shell-Guard RTU or Shell-Guard Concentrate to kill any wood ingesting insect it comes in contact with.

Customer Testimonial

For active infestation I have successfully used borates against insects that are actively living in isolated spots on structures. In the pictures below, poweder-post beetles infested barn wood on my porch. I injected Shell-Guard RTU into the actual holes using a syringe made for injecting marinade into food (any plastic syringe with a tip small enough to fit the hole will work).

These holes were treated and within a day there were dead larvae. It has been more than a year and they have not returned.

Protecting wood surfaces in a beach or water front environment is a challenging task. You are faced with numerous variables that contribute to erosion and degradation of the substrate including sunlight, wind, moisture, salt, and sand. The two most destructive environmental variables to an exterior coating system and wood are sunlight and water.

Sunlight is the major cause of damage to a number of materials, including plastics, textile, wood, coatings, and other organic materials. The type of damage, such as loss of gloss, chalking, elasticity, adhesion, and color change, varies depending on the material sensitivity and the spectrum of sunlight. Spectral sensitivity varies from material to material.

One component of sunlight is ultraviolet light, commonly referred to as UV. UV light is responsible for most damage to exposed wood because it changes or destroys the wood’s lignin, a component of wood that hardens and strengthens the cell walls. In more scientific terms this process is called photo-oxidation. The colorants contained in the color coats are responsible for absorbing UV light. The more colorant a finish contains the less UV light will get through to the wood itself.

Opaque finishes like paint and solid body stains are very efficient in blocking all of UV light from hitting the wood. That’s why when they peel off the freshly exposed wood may still look bright. On the other hand the objective of transparent stains is to allow the character of the wood to show through the finish.

In order to accomplish this transparency the pigment loading is significantly less than that contained in opaque finishes. Although some of the UV is blocked by the colorants, enough of it gets through to eventually photo-oxidize the wood. Since darker colors typically contain more colorant than lighter ones they tend to last longer. However, some lighter colors that contain titanium white, or KX colorant, also contain a high colorant loading which extends their life but they do give up some degree of transparency in return.

Lighter colored stains that contain titanium white (KX) will also absorb less heat; therefore, there will be less overall stress (day surface temperature versus night surface temperature) that the finish system and wood substrate is exposed to over the course of a 24-hour period.

Squared logs, timbers, and vertical flat siding are easier to maintain since the sun hits these wood pieces at the same angle and the UV light is evenly distributed over the entire surface. In addition, the flat vertical surfaces cannot accumulate snow and ice and even upward facing checks are not as prone to rainwater entering the logs. Squared wood pieces are subject to the same weathering parameters as round surfaces, but the weathering is mostly uniform over the entire exposed surface.

The second challenging variable for wood in a coastal environment is moisture. Coastal areas are notorious for their high relative humidity and pop-up thunderstorms. Keeping wood dry is the goal to protecting its long term integrity. If wood remains wet for long periods of time without drying out, conditions are favorable for the formation of wood decay fungi, the precursor to wood rot. Four conditions are necessary for the development of wood decay producing fungi. Eliminate any one of these and decay fungi cannot survive: oxygen, temperature (40° – 90°F), moisture content in excess of the fiber saturation point (> 25-30%), and a suitable source of energy and nutrients (that is, the wood).

Recommendations:

- There are two basic ways to combat the effects of weathering. By far the most effective method is to keep wood surfaces in the shade as much as possible by extending roof overhangs or constructing roofed porches around the home.

- Keep all vegetation at least 24 inches away from wood surfaces to allow for adequate ventilation and drying out of these surfaces.

- Clean the wood surfaces to remove all foreign materials from the wood prior to the application of an exterior finish system. The overall performance of even the best finish system is dependent upon proper surface preparation and application technique.

- Select and apply a highly durable exterior semi-transparent stain, like Lifeline™ Ultra-7 or Ultra-2 to protect the wood and enjoy the beauty of the wood grain. Select Lifeline™ Accents to highlight wood timbers and trim if more opacity is desired.

- Select a color that contains shades of brown, red, or gray. Consider colors that contain titanium white (KX) for lower surface temperature swings as well as good UV protection. (colors: Butternut, Wheat, Driftwood, Stone Gray or Gentry Gray).

- Apply an exterior clear topcoat, like Lifeline™ Advance Gloss or Satin, to protect the color coat and add additional UV and mold and mildew protection. Consider the Gloss for additional reflection of UV light.

- Fill all upward facing checks, cracks in wood, with a specialized acrylic sealant, like Check Mate 2™

- Clean the finish systems at least once a year with Log Wash™, a liquid concentrate for bare wood and maintenance cleaning, to remove all foreign debris for the surface of the finish system and extend its longevity.

- Perform an annual inspection of the coating system as a proactive maintenance approach.

- Darkening of the wood or finish when water is applied, is an indication of water getting through the coating and wetting the wood

- Checks or micro-fissures in the wood, especially upward-facing

- Cracks in the finish

- Color fading

- Pay close attention to the south- and west-facing surfaces

- Keep metal surface clean and freshly painted. Salt spray is highly corrosive.

You can’t completely stop or reverse the weathering of exterior wood, but you can slow the process dramatically by using the right type of finish system and a proactive game plan to combat the environmental elements.

Chink Paint™ is a high quality, elastomeric latex paint used to refresh or change the color of your log home chinking. Chink Paint is available in all eight standard colors of Perma-Chink® in either a textured or smooth finish (with or without aggregate, respectively). This difference provides the customer a choice as to whether or not they would like to add additional texture to the appearance of the chink joint.

Chink Paint can be used in several situations. Some log homes have cosmetic chink joints that serve no purpose other than giving the home the appearance of a chink-style structure. These false chink joints are typically quite shallow and do not allow enough room in the joint for both backing material and the proper recommended thickness of chink. It is much easier to paint the joint with Chink Paint Textured than it is to apply a thin layer (less than 3/8 inch) of Perma-Chink and be more susceptible to negative performance qualities like tears and blistering.

When staining a home that is already chinked, it takes less effort to paint the existing chinking with Chink Paint than it does to try to protect the chinking with masking tape during the staining process. It is virtually impossible to prevent some stain from getting on the chinking and once stained, it is extremely difficult to clean or paint the discolored areas and blend with the surrounding chinking.

If you are applying a new finish to your home, you may as well refresh or even change the color of your existing chinking. This really gives the home a new, clean look. Since Chink Paint has a texture identical to Perma-Chink, it’s impossible to tell if the surface is original Perma-Chink or Chink Paint.

When applying Chink Paint, the first step is to make sure the product is well mixed. Chink Paint, both Textured and Smooth, contain a blend of raw material ingredients that need to be uniformly dispersed to ensure proper color, adhesion and long-term performance. Furthermore, Chink Paint Textured contains an aggregate to give it the similar textured appearance to Perma-Chink. Over time this aggregate may settle to the bottom of the pail, so it’s important to stir it well to make sure the contents of the container are uniform before beginning.

Chink Paint is best applied using a paint brush with about two to three inches of fairly stiff bristles. An expensive brush is not needed, and can be disposed of once the job is completed. A chip brush works just fine, especially for the textured version. Keep a wet rag handy to wipe off any Chink Paint that may get on stained surfaces and clean-up with soap and water.

A lot of wasted energy is released through poor sealing of windows and doors. Luckily, we at Perma-Chink Systems have a solution to solve these air leaks. Energy Seal and Log Gap Cap work together to seal the windows and doors.

How to Seal Step-by-Step:

1. Use masking tape around the window or door seam.

2. Insert Log Gap Cap into the crevice using trowel. Log Gap Cap provides an even surface for sealant application and makes it easier to apply a uniform thickness across the gap.

3. Apply Energy Seal™ and tool smooth.

4. Remove masking tape as soon as tooling is complete.

We occasionally get calls about repairing spots of finish that have peeled from logs, handrails, etc. In most cases, the peeling is associated with checks or small fissures that have opened up after the finish was first applied. When this occurs, rain water soaks into the bare wood on either side of the check, and when the sun beats on the area the wood turns to water vapor and expands with enough force to push the finish right off of the surface. If the peeling is limited to a few small areas, touching them up is not very difficult.

Before we get started on the best way to perform the repairs, there is one thing we need to cover. If you have leftover product that’s more than two years old, you need to obtain enough fresh stain and topcoat to accomplish the repairs. Using old product is risky and unnecessary. Give us a call, and we’ll see if there is anything we can do to help.

Following are the recommended procedures for touching up peeled areas:

Step 1: Sand the peeled areas with 60 to 80 grit sandpaper. Do not use a finer grit. We want the stain to have something to grab onto. Be sure to sand off any surrounding stain film that looks like it may have lost its adhesion.

Step 2: If it’s just a few small areas wipe down the sanded spots with a damp rag. For larger spots or multiple areas on a wall, it’s best to wash the entire wall with a two cups per gallon Log Wash™ solution. Allow the wall to dry.

Step 3: If the peeling is associated with checks that are 1/4” or more wide, seal them with Check Mate 2® after sanding and cleaning, but before staining. This will help make the Check Mate 2 less visible.

Step 4: Using a rag, not a brush, apply one or two coats of stain to the bare wood. You want to apply enough stain to match the color of the surrounding wood. Since the coarse sanded area may be more absorbent than the original surface, one coat of stain may be sufficient to match what’s already there. Using a rag helps avoid lap marks and gets some stain down into any unsealed checks, as well as small cracks and fissures.

Once the stain has been applied and the color matches the surrounding wood, one coat of Advance™ Topcoat can be applied with a brush or rag. Lap marks are not much of a concern since the Advance is clear and colorless.

How about EuroPlast?

Looking for just the right compliment to enhance the interior walls of your dream home? Consider the ageless appeal of Venetian plaster. For centuries architects, designers, builders, and owners alike have marveled at the splendor of this highly popular form of wall surfacing, and throughout the ages the artisans who were skilled at creating such beauty have been revered and sought after. With today’s advanced technology, you can now have this distinctive elegance and appeal at a fraction of the cost- in as little as two days.

EuroPlast and Euroseal by Stuc-O-Flex International

Consider this revolutionary approach to dramatic design. EuroPlast is a pre-colored, acrylic polymer-based interior and exterior coating system that transforms vertical walls into a classic example of old world Venetian-style plaster. This versatile decorative coating exhibits a rich aesthetic appearance with an unlimited selection of color and texture opportunities. Achieve a wide range of effects from rustic plaster to smooth polished limestone.

EuroPlast is a decorative finish providing color, texture and hard durable surface that resists staining, dirt pick-up, and abuse. Applications easily go over interior and exterior surfaces including stucco, concrete, brick, block, plaster, cement-board sheathings- even primed drywall for interior applications.

Euroseal is a pure acrylic sealer that is applied over the EuroPlast finish. Euroseal has a unique ability to transform newly constructed walls into a classic example of centuries-old plaster. This semi-transparent sealer is formulated to obtain an uneven antiqued, or “mottled,” appearance. Euroseal is available in clear or in an unlimited selection of semi-transparent colors. The material can provide a high level of gloss or an eggshell appearance, depending on your design requirements. Euroseal colors are available in pre-tinted containers, ready to apply. The product is intended to create an old world or weathered look while adding a striking characteristic to completed walls.

If this unique product might be that one element to compliment and enhance the beauty of your dream home contact Stuc-O-Flex International, Inc @ 1-800-305-1045 or e-mail: techservice@stucoflex.com

So how do our Communication and Distribution Systems work and how are they different from other suppliers?

Communication

Our Communication System is a nationwide VOIP Internet-based system. That means that each of our Branches and our Knoxville, Tennessee Factory are connected 24/7 like a large office – but the office is nationwide. Answering calls, forwarding calls, etc., happen nationwide the same way as a direct call to a local office are.

That means that every office and every sales desk is connected with a simple stroke of a keyboard. In addition, our Call Forwarding capability automatically connects an incoming call anywhere in the nation. Yes, at times you may be connected with a Customer Service Representative other than the one you typically talk to, BUT – the CSR that does answer the call has your entire order history on the screen in front of them immediately. That is thanks to our second system, which is an online database.

Each time an order is placed, whether it be from a new Retail Customer, or an existing Applicator, Dealer, or Manufacturer, the order is entered in real time into our Accounting Database. That database is immediately updated with any new Customer data – purchased products, colors, quantities, shipping addresses, etc. That means that any order that customer has ever made is instantly available on the screen, and we can tell them anything the customer has ever ordered (for example: I bought Lifeline Ultra-7 for a project 8 years ago and I forgot the color and now I need some touch up and additional for a garage, and by the way, that was for the Rutherford house in Pigeon Forge, not the Pinkerton house in North Carolina). We can tell you in real time what stain was used, what color, how much was purchased, when it was purchased, and where it was sent to. Every CSR in the company has that information, for every customer, on the screen in front of them as soon as the call is answered. Then, if the customer would like to talk to a particular individual (my ‘favorite’ salesperson), we can use the same network to send a notification to that CSR to call you back or attach any particular notifications for the order.

Because of the time difference from the East Coast to the West Coast, this system is available from 8:00 AM Eastern Time until 5:00 PM Pacific Time. That means that a call placed at say, 8:00 PM, on the East Coast will be answered by a salesperson in Redmond, WA that has your Customer History and can take the order or answer any question. That also says that you can make a call at 5:00 AM in Washington State and place an order with a CSR in Tennessee. That is a tremendous advantage for a Contractor who needs to place an order before normal business opening times, or after normal business hours. Remember, it doesn’t make any difference who answers the phone or where they happen to be – they have your Customer History on the screen in front of them and can take the order, handle shipping, and answer any questions you might have – and make the order at your particular price level.

Distribution

If you can’t get the product when you need it, it’s all for naught. If you are an Applicator, Manufacturer, or a Homeowner, you all need the product available at a particular time. Products that arrive a day or two late, or a week late, cause havoc with application crew scheduling or weather changes, and can reverberate through the season if early season jobs are late and will negatively impact schedules.

Our Manufacturing Plant is in Knoxville Tennessee, centrally located in the heart of the Log Home Industry. It is also located at the intersection of the major North/South and East/West highways. It’s no coincidence our factory is in that location! We of course have massive ‘Whole House’ inventories (products for an entire home project), but that location also feeds seven fully-stocked Whole House Company-owned Branches. Each one of those Branches is stocked with a Whole House inventory. Not one or two ‘Overage or Sample’ inventory. Additionally, each Branch location can make any custom stain color you desire and also stocks inventory for a number of Independent Distributors.

The point here is that we are located at strategic locations across the USA and are well-stocked to handle anything from multiple Whole House orders to samples and anything in between. These locations disburse our inventory so that we can fulfill orders from a number of large stocking locations that are close to you, our customers. We are not dependent on large inventory shipments or Whole House shipments arriving from one location. This drastically lowers shipping time and expense.

In addition, each of our seven Branches is staffed with a minimum of three experienced Log Home Specialists. Larger Branches have five and up to eight Inside Customer Care Specialists. No matter when or who you call, be assured you’ll be connected with Industry Experts that can help you get the right product at the right time.

While adequate air exchange is essential for health and safety, many older log homes have a far higher rate of air exchange than is necessary. This is often due to poor design and/or construction which allow air leakage from the inside or outside of the building, but log homes are additionally prone to settling, seasonal expansion and contraction of the logs, and other factors that can cause log joints to move over time.

Given that the typical 30 x 40 log home can easily have more than a linear half mile of log-on-log surface area, determining leakage pathways is often complex and extremely difficult to visualize; leaving log homeowners no other choice than to apply a sealant to all log joints in hopes of locating and correcting the problem areas.

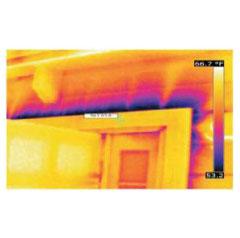

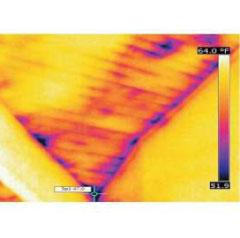

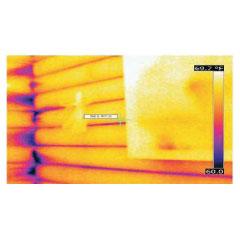

To identify areas of energy waste, infrared thermal imaging has quickly become a valued tool in identifying problems related to energy loss, water and insect infiltration, inefficient HVAC systems and much more. A thermal imaging camera identifies patterns of heat loss that are invisible to the naked eye and quickly indicates the air leaks within the log home with measurement data that can easily be compiled into a written report.

Professional log home applicators are using leading-edge infrared technology coupled with a computer controlled blower door to depressurize the home to an industry standard of -50 pascals, which simulates a 20 mph wind blowing on all four sides of the structure simultaneously. As air is drawn through failed log joints the temperature of the log surfaces changes, producing a thermal image that can be recorded. This allows the applicator to accurately identify and repair the problem areas to stop the energy loss immediately.

Wayne Bell, owner of Log Home Care, uses this technology and reports: Thermal imaging provides both an immediate cost benefit from the reduction in labor required to seal the home and future savings on energy costs. The computerized blower door provides information about air exchange within the structure, expressed in square inches, which can easily be understood when expressed in terms of an open door or window.

“Don’t confuse this equipment with the inexpensive infrared thermometers sold at home improvement stores,” Wayne clarifies. “Advances in technology have reduced the prices of this equipment but it still represents a major financial investment for the applicator. Prices vary by applicator, but homeowners can expect to spend several hundred dollars for blower door testing and thermal imaging services, but a portion of that charge is rebated back as a credit to the homeowner if our firm does the sealant work”, says Wayne.

“Whether we simply provide a printed report that illustrates what needs to be done or we handle the entire process of applying sealant to the home, our company couldn’t be happier with Perma-Chink Systems products. When dealing with log joints that may allow for both air and water infiltration, we use Energy Seal and backer rod on the outside of the structure. If the joint is leaking air but there is little risk of water infiltration, we can alternately use Check Mate 2 (often the clear color) in the interior if needed, but our preference is to do our sealant work on the exterior surfaces. By reducing air leakage, the homeowner obtains a better level of comfort in their log home and Perma-Chink Systems provides the products to make that possible.”

The home featured in these photos indicated an open surface area of 66.5 square inches which equates to a 24” wide window being left open nearly 3” but many log homes exhibit air exchange rates several times higher.