Blog & News

EDDIE McDANIELS – DIRECTOR OF OPERATIONS, PERMA-CHINK SYSTEMS, INC.

I’ve had the privilege of being with Perma-Chink Systems for 32 years. My journey began when I was unemployed and a friend working at Perma-Chink informed me of an opening. I applied, was hired, and have been dedicated to the company ever since.

Initially, I spent 1.5 years in the shipping department and then 4 years in production. These roles provided me with valuable, independent insights into both the manufacturing of our products and the accuracy required in fulfilling orders, as well as managing finished goods inventory and warehouse operations.

My career took a new direction when our Sr. VP of Operations, Tony Huddleston, approached me with an opportunity to travel and train in log home maintenance and restoration. I eagerly accepted this challenge, which led me to travel extensively across the U.S., gaining experience in nearly every state and accumulating significant road miles.

Under Tony’s mentorship, I deepened my understanding of our products, their applications, and how we could enhance our offerings. This role evolved beyond training to include hosting mobile seminars, attending log home shows, and conducting on-site evaluations of unique customer situations. Over the years, I have personally inspected and assisted with over 10,000 log homes, further expanding my knowledge of log care, manufacturing processes, and industry trends.

My interactions with customers helped shape new product ideas, which I collaborated on with upper management and our chemist, leading to the development of maintenance-friendly products that work seamlessly together.

For 22 years I also served as the Store Manager for our Sevierville, TN branch. This role allowed me to continue engaging with customers, provide training, visit job sites, and build strong relationships within the local community.

This year, I was honored to accept the position of Director of Operations at our Knoxville, TN manufacturing facility. I am excited to leverage my extensive experience to drive continued improvements in our products and customer experience, aligning with Perma-Chink Systems’ commitment to excellence.

Finishes & Stains

Calling our pigmented finishes “stains” can be a bit confusing, but we understand how finishes can be called a stain. The term “stain” implies that the wood fibers are stained with the colorants contained in the products. However, in the case of film-forming water-based finishes, like our LIFELINE™ family of finishes, the wood fibers are not impregnated with the colorants. Our LIFELINE finishes behave more like latex paints than penetrating oil-based stains. Yet we can refer to our finishes as stains or varnish since that is what the market is used to. Our newest finish, Log & Timber Defense, is a semi-transparent finish that penetrates like oils, but without the negative effects of oil-based stains.

Pigmented Finishes

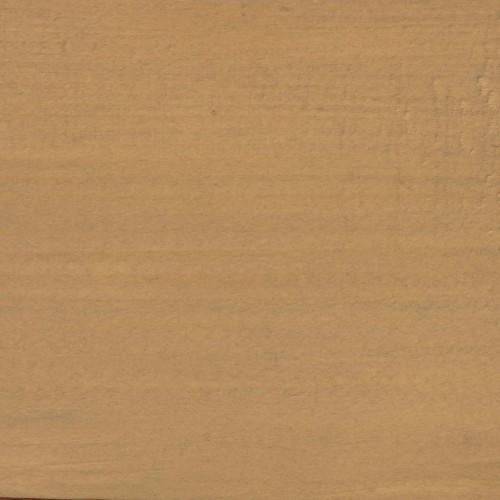

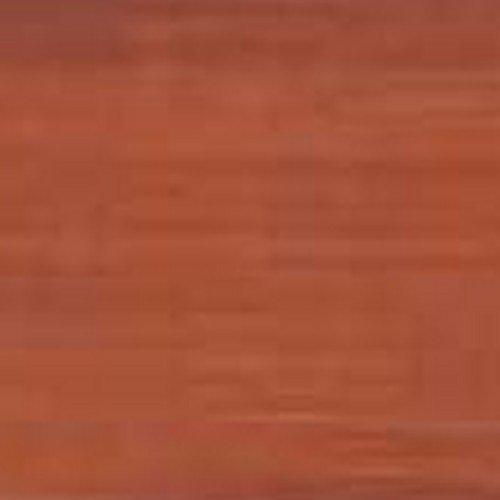

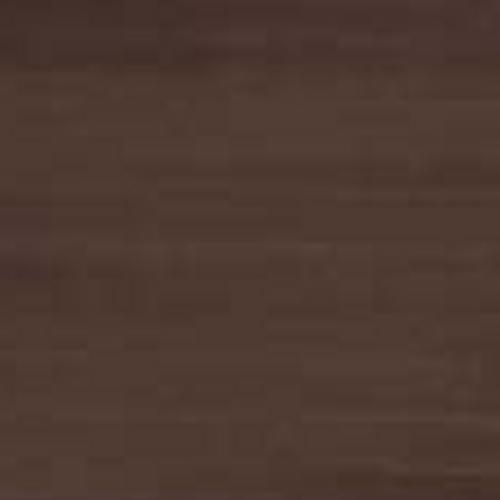

Speaking of pigmented finishes, that’s just a fancy way of saying we have finishes with color. And do we add color. We offer the most color options for log and timber homes of anyone on the market. Many homeowners choose finishes that highlight the natural beauty of wood, selecting colors like Dark Honey, Dark Natural, or Cedar. Others enjoy a deep, rich color base like Chestnut, Walnut, or Classic Brown.

A few years ago we saw grays as a key color for paint, home textiles, and interiors. And second only to blue as the most popular color for menswear. We expanded our color options to include more gray tints, offering trend-setting gray tints. Depending on your personal choice, our family of grays extend from a lovely aged-wood Smoke color to a New England-style Barn Gray. And with our ability to make custom colors, you can find a gray somewhere in between – or any other color for that matter.

Whatever color direction you choose, know our products provide exceptional coverage, lasting color, and superior protection when used as part of the Perma-Chink System. If you’re undecided on what color you should finish your log or timber home in, don’t worry! We offer free samples of all our finishes so you can be confident in your choice of color.

Topcoats

One of the most frequently asked questions we receive about our LIFELINE Advance™ topcoat is why don’t we include the topcoat in with the stain. The answer to this simple question is that if we did, it would no longer be a topcoat. Topcoats play a specific role in protecting any finish system.

Our Advance topcoat plays essentially the same role as an automotive clearcoat, protecting the color coats from the weather, sunlight, and dirt.

Unlike other brands, Advance is specifically designed as a high performing topcoat with a unique set of characteristics that has yet to be duplicated by anyone else in our industry. One of the reasons Lifeline Advance outperforms all other topcoats is that it is designed for a very specific purpose and should never be applied to bare wood.

Pairing Finishes and Topcoat – The Winning Combination

When you pair a LIFELINE finish with Advance, you get the maximum protection for your log home. This combination provides long-lasting color for your home, with the topcoat giving the home protection from the elements. Your home will look great for years to come.

Free Samples! And Excellent Customer Service

If you’re ready to finish your log or timber home, or have a renovation project that needs a finish, we are here to help. Sample orders and product orders can be fulfilled online at store.permachink.com or you can call any of our nationwide stores at 800-548-3554.

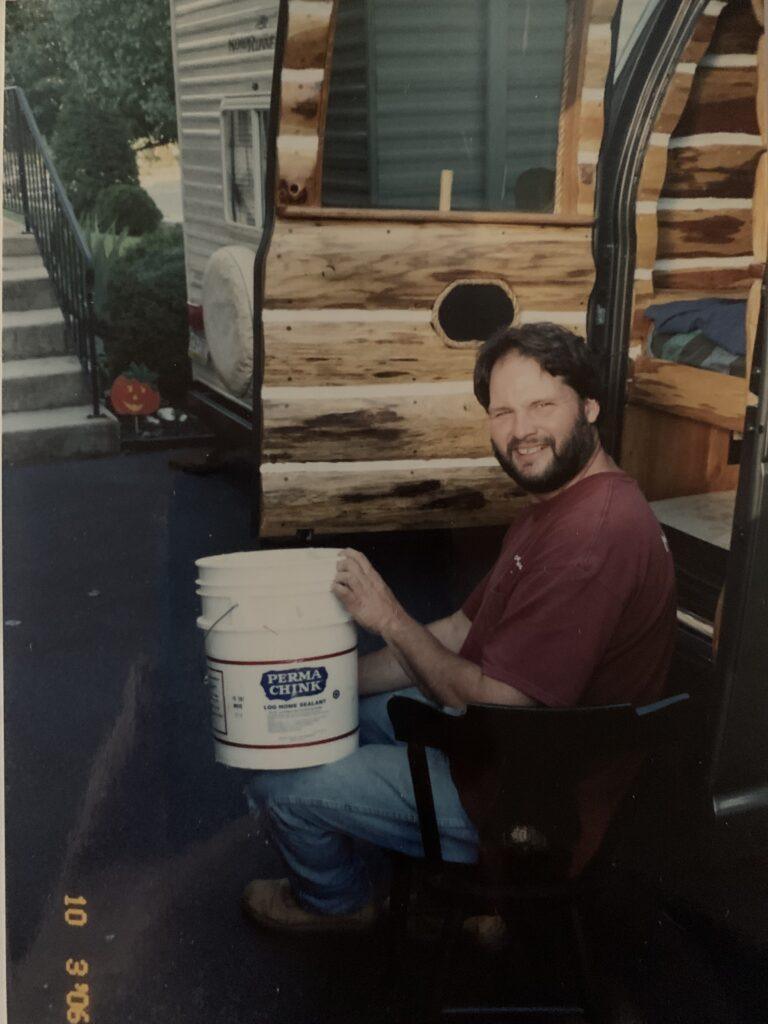

We are excited to share a very unique project, something that could very be a first for this company – a log home interior of a van, sealed with Perma-Chink. Yes, a van as in the automobile variety.

This project is a fantastic example on the flexibility of our products, and the creative imagination of our customers. We’ll turn over the background of the project to the customer, Barbara P., in their own words.

“In 2002 and 2003, we discussed the possibility of buying a log cabin that my Dad lived in with his Grandfather back in the 1920’s and early 1930’s. We found out that the price was out of our reach. Shawn, my husband, then thought about customizing a new van to look like a log cabin. I have been a member of Moon Lite Vans, Inc. for 46 years and vanning for over 47 years and never saw a van with this kind of interior.

In 2004, we ordered our new van and when we received it, he started to work on turning it into a log cabin on wheels. We bought the oak slab wood from a sawmill in Berks County and he debarked all of the wood with a draw knife and other hand tools. He insulated the whole van and proceeded to contact Kline Construction Company in Boyertown, PA to find out where we can purchase the Perma-Chink to be used in the making of the interior of the van. He installed all the oak wood and then applied the Perma-Chink.

We also used the Perma-Chink when we remodeled the recreation room in our home. It now looks like the interior of a log cabin. It also is the reason why we visited the Petersburg, PA location because we needed some more of the Perma-Chink.

We have always talked about visiting the Perma-Chink location in Petersburg, Pa and finally did in May, 2024. We are so glad we did. It was great to meet everyone there and hear the history of the company.”

And now, the pictures!

There you have it! A beautiful project that illustrates the flexibility of our product and the creative ingenuity of van (and home) owners. We thank Barbara and Shawn for sharing their labor of love with us, and for choosing Perma-Chink to create the look they desired.

As always, Perma-Chink and our whole line of products is available at Store.PermaChink.com – order your project materials today!

Sunlight offers life to Earth, yet also be one of the most damaging objects in our world. While we relish the warmth from the sun and we love the summertime fun, the sun’s ultraviolet rays damage any surface that isn’t protected. For humans, we get protection from clothing and sunscreen. But for your log home, what does it get? What can be done to lessen weathering brought on by UV light?

Given enough time, the sun and environment will eventually wear down any exterior finish whether it is latex paint, oil-based stain, or a semi-transparent finish. The goal is to prolong the life of the wood as long as possible through a combination of home design and protective log finishes.

Protect Through Planning

Structurally, log home surfaces can be protected by having covered porches or extending eaves to shade log surfaces, but sometimes that is not possible with the home’s design or the owner’s preference. A home could also be shaded by tall trees, minimizing direct sun exposure.

The best non-structural protection from UV exposure is using Lifeline finishes and Advance topcoat. Working in concert, these two layers offer unrivaled protection, minimizing the damage UV light can do to untreated wood. Lifeline finishes can last decades if properly cared for as part of a whole-home defensive strategy against UV and environmental damage.

How Lifeline Finishes Protects Against Weathering

Lifeline Ultra-7 and Ultra-2 finishes block UV light through the color pigments, which means some finish colors are more effective than others at blocking UV light. Darker colors contain more colorants, thus contain more UV blocking power than lighter colors. Certain light colors which include titanium white contain a high colorant loading, making them very effective against UV light and reflective of the sun’s heat. This reduces stress on the logs brought on by temperature swings. This is why we recommend finishes with pigments, rather than just applying a clear coat to exterior logs. Lifeline Exterior and Accents can offer the same protection with the addition of UV Boost to the finish.

Advance topcoat, in gloss or satin, protects the finish by reflecting UV light and defending the surface from other environmental attacks. Gloss does have an advantage over satin, reflecting more than a satin sheen. However, Advance is most effective when it is clean, free from the abrading effects of wind or accumulation of pollen and dirt. That is why we recommend a yearly cleaning of the logs with Log Wash. Much like the clearcoat on a car, a topcoat does all the heavy lifting when it comes to fighting the environment.

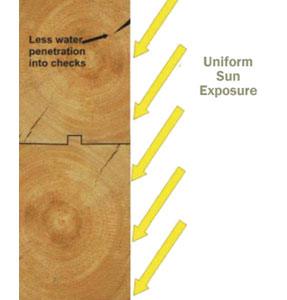

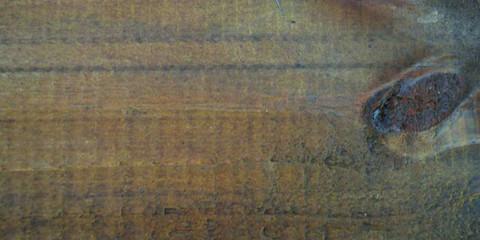

Effect of Weathering on Squared Logs

The construction method of the log home is also something to pay attention to when it comes to weathering. Flat surfaces get attacked by UV light evenly across the surface. Homes built with squared logs will have uniform exposure, so any weathering will appear evenly. Squared logs also do not accumulate as much dirt and debris as round logs, which can keep the finish cleaner.

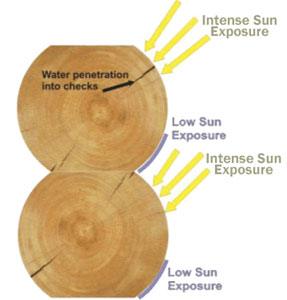

Effect of Weathering on Round Logs

Round logs, the most traditional construction method of log homes, have high and low sun exposure sections, making any weathering first noticeable on the tops of the log. Snow and ice can accumulate on the top portion of the logs, introducing more moisture into the log and log checks. This will accelerate weathering on the tops of the logs if not maintained properly. Conversely, the lower portion of the log is out of direct sun exposure, maintaining its protection and longevity.

Effect of Weathering on Log Siding

Round log siding probably presents the greatest challenge to forestalling the effects of weathering. Typically used in high-exposure locations such as dormers and gable ends, log siding has some features which make it even more difficult to protect from the effects of the weather. Siding is often manufactured from lower quality wood than logs, frequently using green wood. This makes it more susceptible to twisting, warping and cracking.

Log siding is greatly affected by temperature swings, since it does not have the high thermal mass of full logs. Think of it like heating a pot of water and a cup of water – which one will boil faster? That same concept, applied to logs, introduces more mechanical stress (growing, shrinking, twisting) during the course of the day. This movement can introduce small fissures in the wood, ultimately allowing rainwater to get behind the finish and cause damage to the wood and finish.

What Can A Homeowner Do To Prevent Weathering?

A homeowner can fight weathering through protecting logs from harmful UV light using structural or environmental shading, and choosing a finish designed to protect the wood. We have compiled best practice recommendations for keeping your home looking great for generations. All homes will have different levels of UV exposure, and location matters a great deal in the effort required to combat UV damage.

Here are the following best practices to combat weathering:

In short, all our wood stains and finishes perform phenomenally – providing excellent UV protection, allowing wood to breathe as the home acclimates seasonally, and ensuring maximum color retention.

For over 40 years Perma-Chink Systems has been protecting log homes and protecting them right. Our focus is on preserving log and timber homes for future generations. We want log home owners to focus on making memories in their home, not spending all their time maintaining the home.

Recommendations

- There are two basic ways to combat the effects of weathering. By far the most effective method is to keep wood surfaces in the shade as much as possible by extending roof overhangs or constructing roofed porches around the home.

- Keep all vegetation at least 24 inches away from wood surfaces to allow for adequate ventilation and drying out of these surfaces.

- Clean the wood surfaces to remove all foreign materials from the wood prior to the application of an exterior finish system. The overall performance of even the best finish system is dependent upon proper surface preparation and application technique.

- Select and apply a highly durable exterior semi-transparent stain, like Lifeline™ Ultra-7 or Ultra-2 to protect the wood and enjoy the beauty of the wood grain. Select Lifeline™ Accents to highlight wood timbers and trim if more opacity is desired.

- Apply an exterior clear topcoat, like Lifeline™ Advance Gloss or Satin, to protect the color coat and add additional UV and mold and mildew protection. Consider the Gloss for additional reflection of UV light.

- Fill all upward facing checks, cracks in wood, with a specialized acrylic sealant, like Check Mate 2™

- Clean the finish systems at least once a year with Log Wash™, a liquid concentrate for bare wood and maintenance cleaning, to remove all foreign debris for the surface of the finish system and extend its longevity.

- Perform an annual inspection of the coating system as a proactive maintenance approach.

- Darkening of the wood or finish when water is applied, is an indication of water getting through the coating and wetting the wood

- Checks or micro-fissures in the wood, especially upward-facing

- Cracks in the finish

- Color fading

- Pay close attention to the south- and west-facing surfaces

This Michigan log home was completed by the homeowners over 2 years in 2016-2017. Red pine logs were regionally sourced from Wisconsin and northern Michigan. The homeowners peeled, sanded, stained, and sealed the log home themselves, making this home a beautiful labor of love.

The exterior is finished with Lifeline Ultra-2 Sequoia with Advance Gloss, and log gaps sealed with Perma-Chink Stone. Interior logs and beams were finished with Lifeline Ultra-2 Dark Natural and Advance Gloss topcoat for the rest. Gaps were filled with Energy Seal – Dark Natural for interior, Dark Walnut for exterior gaps.

“Using your products was so effortless with easy application, no odor, and easy clean up. We have recommended Perma-Chink to others who have log homes in the area.” – Roger & Diane G.

How do I know what color PCS stain will be on my house?

Transparent stains develop color differently, depending primarily upon the wood species, the surface preparation, the application method and the kind of light illuminating it. Even photos can be edited in a way that alters the true color.

The only way you will really know how the stain will look is to try it on your wood. We will provide complimentary samples of Lifeline for you to try on your own wood before purchasing the product.

Not just Beautiful, but also Durable!

In addition to building a strong home, you want to build a beautiful home, too, which is why the finished appearance of your logs is so important. No doubt that high-quality finishes will save you time and money in the long run. Longer lasting PCS finishes equates to less labor expense over the life of the finish.

Simply Unmatched.

The benefits of Lifeline Ultra are endless, but here are some points that differentiate the Lifeline brand from others.

1. Unsurpassed Adhesion to Wood

The secret behind its durability is Lifeline’s state-of-the-art resin that creates a flexible and tough seal on your home’s logs. Perhaps more importantly than the seal’s strength, the resin ensures a continuous seal, providing protection from holes and gaps that might otherwise develop with an inferior finish.

2. More Resistant to UV Degradation and Color Fading

The transparent iron oxides protect your logs without resulting in a “painted” look that hides the natural texture and beauty of the wood grain. Plus, these pigments provide superior UV protection, blocking the fading and bleaching effects of the sun for a much longer period of time.

3. Water-Resistant and Breathable

All Lifeline finishes form water-resistant film that breathes just like Gore-Tex® to allow trapped moisture to evaporate while protecting the wood.

4. 5-Year Warranty

We are so confident in the performance of Ultra-7 and Ultra-2 that it comes with a 5-year warranty against UV exposure when applied to bare wood and covered with an initial coat of Advance clear topcoat.

5. Meets and Exceeds all Standards for low-VOC

Water-based finishes lack the chemicals in oil-based finishes that are harmful to the environment and difficult to clean up.

Unlimited Color Choices

I think we have already convinced you that the Lifeline Ultra brand is the best there in the industry for any wood home. Now here is the icing on the cake – you can choose any color your heart desires!

Choose from any colors below or send us your desired color chip. Then let us know what base you want the color to be in – Lifeline Ultra-7, Lifeline Ultra-2, Lifeline Accents or Lifeline Exterior.

If you’re looking for a different color than what we offer, we will make a custom stain color for you the same day. Don’t wait, call us today for your custom color at 1-800-548-3554.

There’s something to be said for enjoying a tasty beverage outside at the end of a long day, bbqing on a beautiful summer day, or just enjoying the evening air and the setting sun on a crisp fall evening. Settled on a porch swing, rocking chair, or a bench, relaxing outside your home is a nice, therapeutic stress release. For others it is a way of life, a daily ritual to spend quality time with loved ones. Decks and porches are where many gather for dinner, entertaining, relaxing, and on some occasions, napping.

Whatever the reason for sitting outside, exterior entertaining areas will benefit from Deck Defense stain. The new technology developed for Deck Defense offers superior penetration and protection of wood surfaces. A hybrid-like stain, it’s a water-borne stain that penetrates like oil-based stains, creating a lattice-like coating that supports and strengthen wood’s natural fibers.

More Than Decks!

Deck Defense isn’t only for decking, which requires a durable stain to stand up to foot traffic, furniture moving, rolling BBQs around, and a host of other activities that most stains aren’t designed for. Deck Defense is also designed for railings and fences, two wood surfaces that are exposed to the environment more so than decking.

If a deck or porch is covered as part of a wrap-around porch, gazebo or pergola, then Deck Defense will perform even better, as will all our Lifeline exterior stains. With simple proper maintenance, our stains can last years- if not decades- when utilized under a covered area sheltered from the elements. From small logs to giant feature timbers, soffits to siding, our exterior stains will out-perform expectations wood surfaces.

Check out this deck project that used Deck Defense deck stain.

If you love enjoying being outdoors, even if it’s only a foot or two from the front door, Deck Defense and our family of exterior finishes will protect wood surfaces and add richness to wood’s natural beauty. If your deck is an extension of your entertaining environment, our finishes offer a warm, inviting, and elegant charm to your space.

Available in seven standard colors and any custom color you desire. Call us today at 1-800-548-3554 or order online for Deck Defense or samples.

Deck Inspiration Gallery

Anyone who has trees on their property has probably seen a carpenter ant here or there at one time or another. Foraging ants roam far and wide looking for food and an occasional sighting is common.

However, if you’ve seen more than a few, there are some things you should know. First of all, carpenter ants do not eat wood, but they sure can damage it. They get their name because they chew through wood creating tunnels and galleries. Usually they nest in moist wood, however, if that’s not available they will expand into sound, dry wood where structural damage can take place quickly. Some even nest in foam, fiberglass insulation, or wood/foam composites.

So, whether you have even seen a carpenter ant or not, it is to your benefit to protect your home against them. Shell-Guard RTU is an excellent solution for preventing any problems. It is easy to use, completely odorless and requires just one application for the life of your home. It penetrates the wood where they nest, resulting in quicker control and protection against future infestations. Plus, it is deadly to most wood destroying organisms, so you can remedy a whole slew of problems with one easy application.

When insects come into contact with Shell-Guard treated wood, they live long enough to transport the active ingredients back to their nesting sites on their bodies where it continues to kill other insects in the nest. It works on all types of bare wood, is odorless and can be applied by spray or injection. Shell-Guard RTU is perfect for pre-treatment, remedial treatment and will not discolor your wood. It is the ultimate protection for your home.

For more information you can contact us direct at 1-800-548-3554 or visit our product page online.

Perma-Chink Systems products protect and enhance more than just log homes.

By Wayne Bell, LogHomeCareOnline.com

Log homes come in many varieties – milled, hand-scribed, square (Appalachian style) logs, D-logs, and more. Other forms of solid-timber construction include timber frame and post and beam homes, which provide flexibility to build the architectural style of home you desire, from rustic to modern, while employing modern building and energy-efficient construction methods. In this article, we’ll explore the differences between timber frame and post and beam homes compared to traditional log homes.

Some of these homes blend combinations of timber frame, post and beam, log, and even repurposed barn lumber or other building materials. These “hybrid” homes can include SIP (structural insulated panel) walls and roof components to boost energy efficiency.

Timber frame homes feature posts, beams, and trusses that are square or rectangular in design. These timbers are often cut on CNC machines, hand-fit in a shop, machined for proper fasteners, and finally reassembled on-site where wooden pegs hide any fasteners. Timber frame homes typically feature large timbers and intricate hand-pegged mortise-and-tenon joinery. Post and beam homes, while similar, are typically not fit together with joinery but rather beams sit atop the posts where they butt up to other components and are connected by hardware such as metal plates or “T” connectors.

Caring for a timber frame or post and beam home is very similar to maintenance performed with a log home, and Perma-Chink Systems products have earned the respect of professionals everywhere to protect and enhance the appearance of these beautiful structures. Whether you own a traditional log home or a timber frame home that has exquisite wood features, Perma-Chink Systems is the wood care resource you need.

Proper wood care is important, whether it is a log home or a timber home. Perma-Chink Systems has products that protect, beautify, restore, and repair virtually any wood surface. Perma-Chink log home sealant revolutionized the log home industry. Let our wood finishes revolutionize your timber home. Log & Timber Defense and Deck Defense are two products that will work on any home that features real wood, not just log homes. From siding to fences to decks, we have your wood covered.

Images courtesy of Log Home Care Online.

Looking At Refinishing Your Log Home?

One of the facts of life in preserving the beautiful look of natural logs is that they eventually need to be refinished. Conventional homes are repainted, but log homes are restained. There is a lot more to consider with the latter: Is the existing finish intact enough to simply restain? Do you want to restain in a different color? Has the home been a little neglected in the past? Are there water stains or you want a lighter color, what do you do?

If the stain is aged or has water stains, or the logs look quite weathered, returning the logs to a consistent natural appearance is necessary in the restaining process. But what options do you have for getting those logs back to their natural look before applying the stain? We have listed the options for finish removal below, to help you determine which method is the best choice for your situation.

Removing Finishes With Chemical Strippers

If the existing stain is completely worn out, and needs to be removed, finish remover (chemical strippers) is an option. Finish removers do not dissolve finishes; they only soften them enough to allow the finish to be removed with pressure washing. Some finish removers are more environmentally-friendly than others. Never use finish removers containing potassium or sodium hydroxide as they disrupt the chemistry of the wood, leading to discolorations appearing under the finish. Before purchasing any finish remover, be sure to obtain a sample and test it on your existing finish to see how well it works. You can order your free samples online of our StripIt or S-100 removers by clicking on the product name. For a DIY’er, this method can be the easiest method.

To see a video displaying how S-100 works, click here.

Removing Finishes By Sanding Logs

Sanding off the finish is an option. The problem is trying to work with a flat belt on round logs (with lots of corners and crevices) makes sanding a time-consuming process and a lot of work.

The use of sanding disks rather than sandpaper can save you both time and money, but you need to be careful not to create swirl marks in the wood. When sanding exterior surfaces, never use anything finer than 80 grit. You can order Sanding Disks and Osborn brushes on our online store under tools.

Removing Finishes by Using Media Blasting

Sandblasting is yet another alternative, the downside is sand chews up the logs and you are left with a whole pile of it surrounding the house.

A faster and also environmentally-friendly method of removing old finishes from log homes is the Blaster-Buddy. Instead of sand, the blast media used to abrade the finish off the wood is recycled crushed glass. We prefer crushed glass since it is very efficient, relatively inexpensive, and does not impregnate the wood with organic material that can later mold. Also, it is lighter than sand so it removes the stain but doesn’t harm the wood as much. With dry media, you don’t run the risk of blowing water into your house. It will re-expose those beautiful logs quickly and affords minimal cleanup.

There Are Options To Make Your Project A Success

Restaining a log home can be a traumatic process if you’re unaware of the best methods of finish removal, but it is a necessary evil. Do it right – do it as cleanly, efficiently, and easily as possible. You can rent the equipment and do it yourself or hire someone to do it for you. We usually advise do-it-yourself homeowners to use chemical finish removers along with pressure washing because the process can be easily accomplished by the average homeowner. And since it is less susceptible to surface damage, chemical finish removers result in a more attractive finished surface. And we all know the best result of a project is ensuring a proper foundation – or prep work – goes along way in making the job go smoothly.

More than 20 years has passed since NASCAR’s Mike Helton announced to the world, “we lost Dale Earnhardt.” Arguably one of the greatest racers ever, Earnhardt both divided and united fans with his on-track persona as “The Intimidator” and his relationship with his fans and fellow drivers. His loss is still felt within the racing community. In remembrance of Earnhardt on the anniversary of his death at the end of the 2001 Daytona 500, our own late Tony Huddleston conveys working with Earnhardt on his log home years earlier.

THE LEGEND LIVED IN A LOG HOME

My first meeting with Dale Earnhardt happened at the Knoxville airport as he flew in to meet with me regarding the color choices on his new home. I took stain samples with me for the meeting and he and I applied what we currently had, and he was very clear that he wanted it darker and felt I should travel to the jobsite so we could work out the colors.

I made the trip to Mooresville, NC a short time later armed with a bevy of various tints and clear base to tint the product on the site. Upon arrival at the site, I was unable to find Dale and one of the workers in the shop told me he was down at the chicken house, and to just drive on down to find him. I found Dale working on a piece of equipment and after we talked a bit he said “let’s go up to the house and see what we can put together”. As we approached my truck he said “Give me your truck keys and I will drive.” I asked, “Can you drive a Ford?”, as he was definitely a Chevrolet man. He said “I used to drive a Ford and, as a matter of fact, it was pink one.”

Once at the house, he and I kept adjusting the tint strength and he kept insisting that he wanted it darker, after several tries, we actually ended up with a color he liked, and it was very dark. I remember a comment from one of his crew members asking Dale if he was going to paint a big white number three on the roof to match his car.

Back to Knoxville with the selected color and we worked up the product so I could take it back and get his approval of the color before going any further. He did approve the color and plans went forward for the application. He insisted that I be available at various times for the application to insure the progress.

During the visits to the site, I learned that Dale was a very intense person and worked very hard when he was home. It seemed that he never got many spare moments due to the race schedule and the constant phone calls for him. He always found time when I was there to talk and discuss his project. Being on site various times, I was always welcomed by him and his wife Teresa, and was invited to go with him to the Charlotte night race where they would be racing under the lights for the first time. I have to say I was not prepared for the intensity and pace of the race and the activity that went on in the pits. Crewmembers were friendly, as was team owner Richard Childress, but it was very clear their focus was on the task at hand during the race. Some time later the next year, I received a call from Dale inviting me to the Daytona 500, he said “If you can get here, I would like to have you and everything is on me.”

In looking back at my short-lived association with Dale and those around him, I found him to be pleasant, yet demanding of those around him, and everyone worked hard to make him successful in his endeavors. It truly was a great experience for me, and it was like a family as everyone was fully involved and doing their part.

– The late Tony Huddleston, VP of Sales and Operation

The Legacy of Dale Earnhardt’s Log Home

Today, the grounds of Dale Earnhardt Incorporated no longer house the burgeoning race team led by the legendary driver. Instead, the property has been developed as a premier venue space with a unique history. The Venues at Dale Earnhardt Incorporated is now known as the area’s best venue for corporate and private events, with multiple facilities including the former home of Earnhardt. Whether you are looking for a pristine location for your wedding and reception or a corporate event, be sure to check this place. The Legend lived here.

The Lodge

A luxurious log home sitting on pristine grounds overlooking a lake. Old World charm is in the interior decor highlighted by the large stone fireplace. Outside you will find covered and open decks, stone patios and beautifully manicured lawns which give entertaining an over-the-top outdoor experience.

The Pavillion

For more information regarding the event facilities at Dale Earnhardt Incorporated, visit http://www.daleearnhardtvenues.com/.

Making an Old Deck New Again with Deck Defense

By Danny M. Nichols

A Transforming Experience

Spring finally arrived. With continued rains in our area, much of spring silently slipped away before we realized summer 2020 was upon us and a project launched the year before needed to be completed. A house my wife and I own and currently used as a rental house was in dire need of renovation. During a short period in 2019 when the house was empty, we set about doing a facelift of the entire interior of the home. Walls were painted, some new fixtures installed and floors were sanded and refinished throughout the house.

With the inside of the house finished and ready to go, a new renter moved in whose priorities did not immediately include the need or use of the wooden deck outside the kitchen door. The deck was built as an original feature of the house in 1990 and was much-used when my wife was raising her children there. Most of the outside woodwork of the home was in need of painting or replacing. To put it more correctly, it looked sad. We agreed to wait until the following spring to tackle the deck and front porch needs.

Assessment

The front porch posts, gingerbread trimmings and door could all do with a fresh coat of paint. The wooden deck off the kitchen, however, needed a miracle. Floor boards had deteriorated as well as the steps, banister and railings. Only the treated 4×4 wooden posts and floor joists providing the underneath support for the deck were still holding up well. A new deck floor would have to be constructed along with new banisters and railing. And finally, a sealer with stain would have to be applied to the boards.

Action

Off with the old and on with the new! Our first step involved moving all the old boards and railings. To our dismay and surprise, all the deck boards were nailed with 3” construction grade nails making them a bit difficult to remove. The upside was that it may well have been those nails that helped this deck survive the 30 years of its life!

Once all the deck boards and railings were removed, we hired a carpentry service to install all new wood again.

Affixed in place during the fall and winter, the deck boards were allowed to dry thoroughly before attempting to stain and finish the floor. This provided us with an opportunity to search and compare the various stains and finishes available in the marketplace. Our desire was not to have to reapply a finish to the deck for a long time.

One product stood out among the many we looked at. Perma Chink Systems, Inc. makes a product called Deck Defense, which appeared to offer all the qualities we hoped for. It offered UV protecting pigments that protected it from the sun and was specifically formulated to protect against mold and mildew. Exactly what we were looking for!

We were able to select from a wide variety of stain colors from their website. We chose Honey Maple #1930 for our stain. Other factors we found desirable was the clean-up could be done with soap and water, and the product is manufactured in the U.S.A. At 40 lbs. per 5 gallon bucket, it helped also that this product could be conveniently delivered to our front door.

Application

With help from a family friend, the project was coordinated with the painting of the railings, bannister, step riser and underpinning. Painting came first as we believed it would be easier to accomplish while saving the deck for the last step. Once begun, however, we were surprised at how easy the stain and finish could be applied.

We used a pad specifically designed for this purpose, and it worked very well. The stain was beautiful as it contrasted and blended the beige vinyl siding on the house with the dark green paint we selected for the railing and bannister. The staining process was far easier than that of painting.

In stepping back and looking at our work once the project was completed, we were in awe at the transformation possible when using well-chosen products and materials. We are very happy with the results.

Questions About Deck Defense?

Read our Deck Defense FAQs for more information about Deck Defense.