Blog & News

Sometimes you just want something unique – something that truly reflects your personal style. When looking through the standard Lifeline Interior™ or Lifeline Accents™ colors, it might seem like your options are limited at first glance. The good news? There are actually countless possibilities. So let’s get creative and have some fun discovering the perfect color for your home.

Because interior wood surfaces aren’t exposed to the same harsh environmental conditions as exterior wood, you have much more flexibility to play with color. You can apply one or multiple coats, depending on the look you want to achieve.

You can take your creativity even further by incorporating Lifeline Prelude™ – one of our best-kept interior finishing secrets.

A single coat of Lifeline Prelude applied to clean, bare wood provides UV protection and dries clear, making it an excellent clear primer. Lifeline Prelude also helps your color coat(s) apply more evenly, often resulting in a slightly lighter hue with improved color consistency during application.

Start by applying one coat of Lifeline Prelude, followed by a single interior color coat of your choice. Once that coat has dried, if you’d like to deepen or adjust the color, simply apply an additional color coat and evaluate the result.

You may be surprised by the wide range of looks you can achieve by testing with or without Lifeline Prelude clear wood primer, and by layering one or more color coats. Have some fun experimenting with free samples to discover your perfect shade.

Once you have found the color for your interior walls, ensure easier cleaning and omit odor absorption by applying your choice of either Lifeline Acrylic™ or PCS Clear Shield™ over your color coat(s). Odors? Yes, you read that correctly – wood is porous and will absorb odors through the years, so protect your interior wood!

What if you just want to keep the beautiful, natural color of your interior wood and have no desire to mess with colors, is that an option?

Absolutely! There are two options you can consider for achieving the natural look while providing enduring protection:

1) Apply a single coat of Lifeline Interior Clear, #110 (we recommend adding UV Boost, as it will assist with protecting your interior walls from UV damage that receive sun exposure) and follow it with either PCS Clear Shield or Lifeline Acrylic for added protection.

2) Apply a single coat of Prelude (this already has UV inhibitors in it, so there is no need to purchase UV Boost) and follow it with either PCS Clear Shield or Lifeline Acrylic for durable protection.

Lifeline Acrylic is available in Gloss or Satin finish, and PCS Clear Shield is available in either a Gloss or Matte finish, and both are wonderful at resisting the yellowing that some finishes create. You can also apply multiple coats of both clear topcoats to obtain the lustrous sheen desired. And if you’re daunted by the task of staining the upper reaches of your ceilings, there are nifty tricks of the trade you can use to get the work done safely and inexpensively. Also check out our Interior Picture Gallery for more ideas.

If you have additional questions, please call 800-548-3554 and talk with one of our Customer Service Representatives. We are always delighted to assist you!

Enjoy making your home distinctively yours!

What to do if your log home was flooded?

Log homes are actually more durable than traditional homes, and are more likely to survive natural disasters, including flooding. The clean-up and repair of a log home after flooding is also much easier; follow these steps…

Interior

1) Tear out everything that is obviously ruined or that will interfere with drying out the log walls. All floor coverings (you will not be able to save any wooden floor – even if it looks good now, it will warp), trim, drywall, and insulation must go. You will probably have to replace all wet cabinetry and interior doors that were stained or contained any type of composite wood. Sometimes cabinets and doors can be saved if they were initially painted or if you choose to paint them now. Cut drywall and insulation about a foot above the high water mark. Sometimes tile floors can be saved, depending on the backer used under the tile.

2) Clean – Water usually brings in a great deal of mud or other contaminates. Once areas are cleared of debris and other building components mentioned above, then pressure-wash the log walls, studs, other framing, and sub-floors. Use products like Log Wash or Wood Renew to help lift out dirt and begin to control mold and mildew. Try not to use bleach as it can change the color of wood which can cause problems later. If you MUST use bleach, use no more than a cup per gallon of water and try to keep it off of wood that did not get wet. Apply the cleaners from bottom to top and then wash the dirt down the walls, across the floor, and out the door.

3) Dry out the log and timber components left behind. De-humidifiers are best at this task along with fans. If electricity is not available, just do your best to provide some air circulation. If only one de-humidifier is available, use it in one room at a time – running constantly until the moisture content of the wood in the wettest area of the room is below at LEAST 17%. Moisture meters are available at home centers and hardware stores. If your home is on a crawl space, close all the vents, install a new vapor barrier, and install a couple of de-humidifiers. This will quickly dry the space under the home and the sub-floor. If electricity is not available, consider removing sections of the sub-floor to provide some air circulation.

4) Disinfect – As soon as the wood is dry to the touch after cleaning. Liberally spray a mold control product on everything that got wet – Concorbium is one brand name. These products are commonly available at stores like Lowe’s or Home Depot. Buy a lot and use it. I have found these products work wonders stopping mold, mildew, and the odors and stains that accompany them. You may have to re-apply if it takes a while to dry your home out due to lack of electricity or equipment.

5) Replace and Re-build – I recommend replacing all electrical outlets and switches that were under water. If in doubt about electrical components, ask an electrician. I did not replace mine initially and had trouble later. Replace all drywall, insulation trim and re-finish. If you have a lot of open interior stud walls, I recommend applying powdered borax like Armor Guard inside the stud cavities and THEN closing them up. The borate will stay there practically forever and kill ants and roaches that crawl through it and then consume it as they groom themselves. Also apply this powder on the floor just before you re-install base cabinets in kitchens and bathrooms – same purpose.

If you had wood walls that did not have a finish applied, they may discolor. The longer wood is wet, the more likely it will have discoloration. Wood Renew or other percarbonate (hydrogen peroxide) cleaners can help remove some or all of this discoloration. Wood brightener- a product containing oxalic acid like Oxcon may also work, but be careful as these products may work TOO well and change the color of the wood beyond the desired color. If you did have a finish on the wood walls and discoloration is occurring UNDER the finish, that finish must be removed by sanding or stripping to remove discoloration.

Do not attempt to replace wooden floors until HVAC has been restored as flooring must be acclimated prior to installation.

Exterior

Luckily, log walls on the exterior are very durable if they were properly finished with a quality stain. They usually dry out nicely and require only some power-washing to clean.

Use a cleaner like Log Wash to clean off dirt. Do not try to be aggressive with the power-washer, you just want to rinse the dirt off. Some of the wood trim components that were engineered – like finger-jointed trim materials – may swell and need to be replaced. Exterior doors and windows (especially wooden ones) should be carefully examined and may need to be replaced as well. Insulated metal and fiberglass doors that get wet sometimes look fine, but they can hold water inside for a long period of time and eventually deteriorate.

Be careful around and under your home. Flood waters displace a lot of critters that may take refuge around and under your home – snakes, racoons, skunks, and opossums are no fun when they are too close.

If you have any questions, feel free to contact us at 1800-548-3554 or by email at techservice@permachink.com. We’re open 8:00AM – 8:00PM EST, Monday thru Friday.

New Color Trends

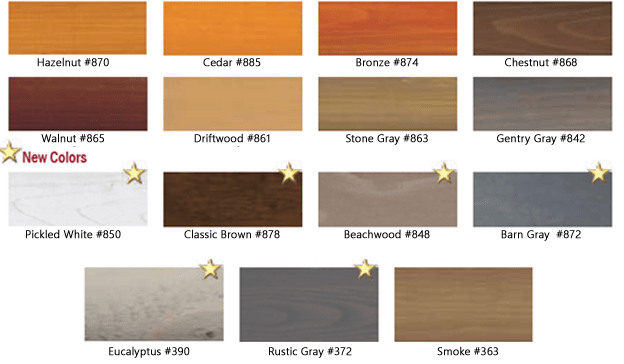

Staining your log or timber home is a humble art and is a critical part of the sense of style and feeling of what the structure creates. Whereas paint simply transforms the color of a surface, leaving no trace of its previous character, stain is typically used to enhance the beautiful grain of wood and generate that back to earth feeling that heavy wood timbers accentuate. Semi-transparent stains from Perma-Chink Systems are designed to let the beauty of the wood shine through and provide increased protection from interior and exterior elements. But what about the colors?

Gray and Browns have been popular in recent years, and this trend is still going strong. If you’re clinging to those gray tones, you’re in luck. 2020 continues to welcome these tones with open arms.

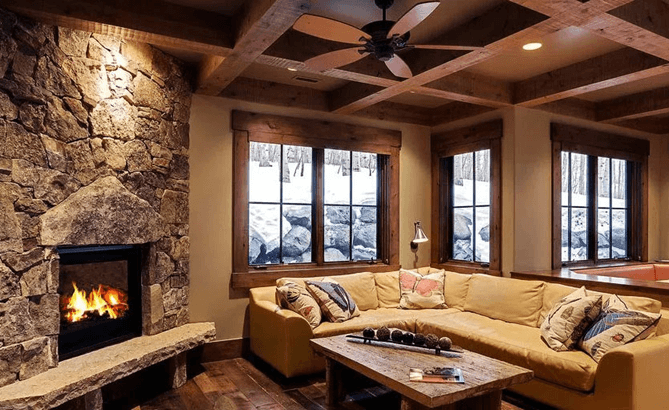

Gray is also a neutral with a reputation for being cold, with more than 50 shades of gray. With some warm beige added you will have gorgeous and stylish color, like one on the photo above, with so many sophisticated hues.

Actually, the shift toward warmer-toned gray is going so strong, that they referred to as “greige”.

Is Greige Better Than Gray?

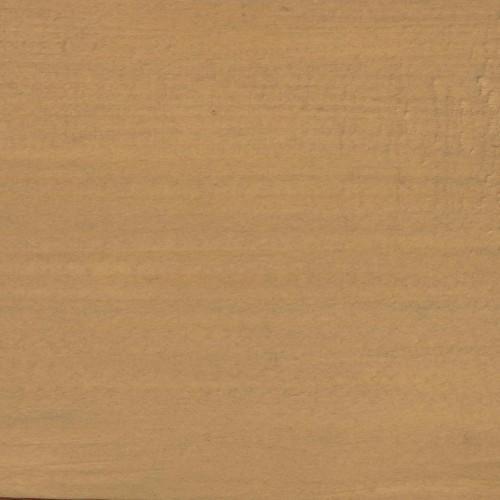

If you love the idea of gray but worry about the coldness of most gray colors, greige could be what you are looking for. With added beige tones you will get the elegance of gray, without the cold blue undertones. Try out our Lifeline Ultra-7 in Eucalyptus or Rustic Gray colors, they are absolutely stylish!

If you love your browns more than grays, but still want a hint of that rustic look, try two new browns from our Lifeline Ultra-2 collection. Maybe we should call them “brays”? And how do you mix browns and grays? You don’t! We made them for you! Check out the trendiest new colors in our Lifeline Ultra-7 and Lifeline Ultra-2 collection. Order your FREE color samples and try it on your wood.

“From colors to textures, we’ve got the scoop on which color trends are going strong and we would like you to know about it,” says Rich Dunstan, the president of Perma-Chink Systems. “We design eye-catching colors in many diverse tones that have the power to transform the entire ambience of your exteriors and interiors”

And the best part – you don’t have to mix anything, just pick your colors and order free samples to try it on your wood. Custom colors available upon request. Call 1-800-548-3554 or email techservice@permachink.com

Chip Wade and wife Pauli, of Wade Works Creative, are design professionals and lifestyle experts who love sharing their inspiring ideas with DIYers, pros and homeowners.

The Wades renovated the Misty Mill log home, located on Lake Sinclair, which was created in 1953 as part of the Georgia Power Company’s reservoir, with over 400 miles of scenic shoreline and just a 1 ½-hour drive from Atlanta.

The premise of Misty Mill is to spend time outdoors taking in views of the lake, without any worries of upkeep and maintenance. That’s why when Wade managed a total makeover of his own 2,400 sq. ft. lake house on Lake Sinclair in central Georgia, he wanted the best, top-of-the-line materials for his Misty Mill.

“All the content for this show house is about the best in innovative products and installations. I have personally selected the products I feel will be the best representation of this theme,” said Wade.

That’s where Perma-Chink Systems came in. After extensive research, Wade chose the premier log home care company to provide dependable, long-lasting and technically advanced products to ensure the creative design of the home meets not only Wade’s expectations, but future clients of Wade Works Creative.

In addition to selecting the best products, Wade also selected one of Perma-Chink Systems’ best Preferred Applicators, Nothing But Logs, to treat, finish and seal the log home. Located in Shady Dale, Georgia, Nothing But Logs has over 20 years of experience in maintaining, repairing and restoring log homes.

As the host of HGTV shows, Wade’s own creative stamp on the home required repairing the exterior to match his vision of the home. The exterior showed a lot of weathering and discoloration that would have to be addressed before applying the stain of choice.

Repair of the aged, grayed wood surfaces was accomplished with Wood ReNew. Being on the water, the home’s exposure to the weather gave the logs varying degrees of aging. Wood ReNew brightened up the wood, bringing back a true wood color, and was now prepared for staining.

The home was finished with two coats of Lifeline Ultra-2 Gentry Gray, and the newly constructed boathouse finished to match the home, making the new structure seem like it had been there all along. The choice of Ultra-2 provides the Wades with exceptional longevity and UV protection designed to prevent the extensive weathering damage. Add in the 5-year warranty of Ultra-2 when Lifeline Advance is applied and the Wades have a durable, cost-effective finish solution.

Along the way, the log home needed chinking repairs, completed with Perma-Chink White, the leading chinking. With repairs done in white, there was the issue of the old, gray chinking. Instead of re-chinking the entire home, the old chinking was freshened with textured Chink Paint in white, bringing a brand-new luster to the home. To improve energy efficiency, the end joints were sealed with Energy Seal Slate Gray, which matches the finish of the logs and presents a seamless joint.

After all the staining and sealing work was done, Chip selected the clear topcoat Lifeline Advance Satin to protect the logs and finish. The end result is a magazine-quality home, and we’re proud to be involved in Wade’s extensive project.

Now this inspirational lake house has all the comforts of the indoors, with exterior materials that will keep performing and protecting the home for generations to come.

You can view Chip Wade’s Misty Mill log home – including design concepts, before and after pictures – online at https://mistymill.com/.

Wood-boring beetles can be found all across the United States. There are several types of beetles that can be considered “wood-boring” beetles. Often referred to as “wood worms” or “powder post beetles,” wood-boring beetles are responsible for damage to structural wood, second only to termites.

Wood-boring beetles are difficult to control once an infestation has begun. Therefore, prevention is the best management method. Great NEWS: the treatment for all types of wood-boring beetles is the same.

Shell-Guard RTU is the best way to protect your home from wood-boring beetles, termites, carpenter ants, wood rot, fungi and more. It’s active ingredient Disodium Octaborate Tetrahydrate, or borate, combines with food-grade glycol added to deepen wood penetration that can be used to both treat and prevent pests from eating wood.

Research results shows that the presence of borate in the wood does two things:

- It kills younger beetle larvae that are feeding in the wood.

- It prevents any old house borer eggs from hatching. The borate treatment interrupts the beetle’s life cycle and eventually the infestation will end.

About Wood-Boring Beetles

Wood-boring beetles invade and damage wood furniture as well as structural and decorative wood inside the building. The beetle larvae feed in and do most of the damage to wood, and when they reach the adult stage, they emerge through round exit holes, which they create by chewing through the wood surface. Adults of some species also bore exit holes through plaster, plastic, and even soft metals that might cover the underlying wood.

What are the signs that beetles are present in the wood?

- Sawdust or frass is the first sign of beetle infestation.

- The chewing noise made by older larvae in the wood.

The life cycle of most wood-boring beetles is similar. It starts with an adult female depositing her eggs in the wood. The eggs hatch and a small grub-like larva emerges. It’s the beetle larvae that feed on wood, and they may continue eating the wood for several months or, in some cases, up to 20 years depending on the species. There comes a time in its life cycle when it’s getting ready to make the change that the larva makes a hole to the surface of the wood, so it can get out of the wood as an adult beetle. That’s why the holes are called “emergence holes.” Typically this is the first sign that beetles are present in the wood. Once the hole is complete and the tunnel is cleared of the sawdust or frass, the larva creates a pupa case and makes the transition to an adult beetle. The adult beetle eventually emerges from the hole, feeds on pollen and nectar and looks for a mate. Once impregnated, the female beetle can start the cycle all over again.

Order Your Shell-Guard RTU or Shell-Guard Concentrate to kill any wood ingesting insect it comes in contact with.

Customer Testimonial

For active infestation I have successfully used borates against insects that are actively living in isolated spots on structures. In the pictures below, poweder-post beetles infested barn wood on my porch. I injected Shell-Guard RTU into the actual holes using a syringe made for injecting marinade into food (any plastic syringe with a tip small enough to fit the hole will work).

These holes were treated and within a day there were dead larvae. It has been more than a year and they have not returned.

Protecting wood surfaces in a beach or water front environment is a challenging task. You are faced with numerous variables that contribute to erosion and degradation of the substrate including sunlight, wind, moisture, salt, and sand. The two most destructive environmental variables to an exterior coating system and wood are sunlight and water.

Sunlight is the major cause of damage to a number of materials, including plastics, textile, wood, coatings, and other organic materials. The type of damage, such as loss of gloss, chalking, elasticity, adhesion, and color change, varies depending on the material sensitivity and the spectrum of sunlight. Spectral sensitivity varies from material to material.

One component of sunlight is ultraviolet light, commonly referred to as UV. UV light is responsible for most damage to exposed wood because it changes or destroys the wood’s lignin, a component of wood that hardens and strengthens the cell walls. In more scientific terms this process is called photo-oxidation. The colorants contained in the color coats are responsible for absorbing UV light. The more colorant a finish contains the less UV light will get through to the wood itself.

Opaque finishes like paint and solid body stains are very efficient in blocking all of UV light from hitting the wood. That’s why when they peel off the freshly exposed wood may still look bright. On the other hand the objective of transparent stains is to allow the character of the wood to show through the finish.

In order to accomplish this transparency the pigment loading is significantly less than that contained in opaque finishes. Although some of the UV is blocked by the colorants, enough of it gets through to eventually photo-oxidize the wood. Since darker colors typically contain more colorant than lighter ones they tend to last longer. However, some lighter colors that contain titanium white, or KX colorant, also contain a high colorant loading which extends their life but they do give up some degree of transparency in return.

Lighter colored stains that contain titanium white (KX) will also absorb less heat; therefore, there will be less overall stress (day surface temperature versus night surface temperature) that the finish system and wood substrate is exposed to over the course of a 24-hour period.

Squared logs, timbers, and vertical flat siding are easier to maintain since the sun hits these wood pieces at the same angle and the UV light is evenly distributed over the entire surface. In addition, the flat vertical surfaces cannot accumulate snow and ice and even upward facing checks are not as prone to rainwater entering the logs. Squared wood pieces are subject to the same weathering parameters as round surfaces, but the weathering is mostly uniform over the entire exposed surface.

The second challenging variable for wood in a coastal environment is moisture. Coastal areas are notorious for their high relative humidity and pop-up thunderstorms. Keeping wood dry is the goal to protecting its long term integrity. If wood remains wet for long periods of time without drying out, conditions are favorable for the formation of wood decay fungi, the precursor to wood rot. Four conditions are necessary for the development of wood decay producing fungi. Eliminate any one of these and decay fungi cannot survive: oxygen, temperature (40° – 90°F), moisture content in excess of the fiber saturation point (> 25-30%), and a suitable source of energy and nutrients (that is, the wood).

Recommendations:

- There are two basic ways to combat the effects of weathering. By far the most effective method is to keep wood surfaces in the shade as much as possible by extending roof overhangs or constructing roofed porches around the home.

- Keep all vegetation at least 24 inches away from wood surfaces to allow for adequate ventilation and drying out of these surfaces.

- Clean the wood surfaces to remove all foreign materials from the wood prior to the application of an exterior finish system. The overall performance of even the best finish system is dependent upon proper surface preparation and application technique.

- Select and apply a highly durable exterior semi-transparent stain, like Lifeline™ Ultra-7 or Ultra-2 to protect the wood and enjoy the beauty of the wood grain. Select Lifeline™ Accents to highlight wood timbers and trim if more opacity is desired.

- Select a color that contains shades of brown, red, or gray. Consider colors that contain titanium white (KX) for lower surface temperature swings as well as good UV protection. (colors: Butternut, Wheat, Driftwood, Stone Gray or Gentry Gray).

- Apply an exterior clear topcoat, like Lifeline™ Advance Gloss or Satin, to protect the color coat and add additional UV and mold and mildew protection. Consider the Gloss for additional reflection of UV light.

- Fill all upward facing checks, cracks in wood, with a specialized acrylic sealant, like Check Mate 2™

- Clean the finish systems at least once a year with Log Wash™, a liquid concentrate for bare wood and maintenance cleaning, to remove all foreign debris for the surface of the finish system and extend its longevity.

- Perform an annual inspection of the coating system as a proactive maintenance approach.

- Darkening of the wood or finish when water is applied, is an indication of water getting through the coating and wetting the wood

- Checks or micro-fissures in the wood, especially upward-facing

- Cracks in the finish

- Color fading

- Pay close attention to the south- and west-facing surfaces

- Keep metal surface clean and freshly painted. Salt spray is highly corrosive.

You can’t completely stop or reverse the weathering of exterior wood, but you can slow the process dramatically by using the right type of finish system and a proactive game plan to combat the environmental elements.

How about EuroPlast?

Looking for just the right compliment to enhance the interior walls of your dream home? Consider the ageless appeal of Venetian plaster. For centuries architects, designers, builders, and owners alike have marveled at the splendor of this highly popular form of wall surfacing, and throughout the ages the artisans who were skilled at creating such beauty have been revered and sought after. With today’s advanced technology, you can now have this distinctive elegance and appeal at a fraction of the cost- in as little as two days.

EuroPlast and Euroseal by Stuc-O-Flex International

Consider this revolutionary approach to dramatic design. EuroPlast is a pre-colored, acrylic polymer-based interior and exterior coating system that transforms vertical walls into a classic example of old world Venetian-style plaster. This versatile decorative coating exhibits a rich aesthetic appearance with an unlimited selection of color and texture opportunities. Achieve a wide range of effects from rustic plaster to smooth polished limestone.

EuroPlast is a decorative finish providing color, texture and hard durable surface that resists staining, dirt pick-up, and abuse. Applications easily go over interior and exterior surfaces including stucco, concrete, brick, block, plaster, cement-board sheathings- even primed drywall for interior applications.

Euroseal is a pure acrylic sealer that is applied over the EuroPlast finish. Euroseal has a unique ability to transform newly constructed walls into a classic example of centuries-old plaster. This semi-transparent sealer is formulated to obtain an uneven antiqued, or “mottled,” appearance. Euroseal is available in clear or in an unlimited selection of semi-transparent colors. The material can provide a high level of gloss or an eggshell appearance, depending on your design requirements. Euroseal colors are available in pre-tinted containers, ready to apply. The product is intended to create an old world or weathered look while adding a striking characteristic to completed walls.

If this unique product might be that one element to compliment and enhance the beauty of your dream home contact Stuc-O-Flex International, Inc @ 1-800-305-1045 or e-mail: techservice@stucoflex.com

So how do our Communication and Distribution Systems work and how are they different from other suppliers?

Communication

Our Communication System is a nationwide VOIP Internet-based system. That means that each of our Branches and our Knoxville, Tennessee Factory are connected 24/7 like a large office – but the office is nationwide. Answering calls, forwarding calls, etc., happen nationwide the same way as a direct call to a local office are.

That means that every office and every sales desk is connected with a simple stroke of a keyboard. In addition, our Call Forwarding capability automatically connects an incoming call anywhere in the nation. Yes, at times you may be connected with a Customer Service Representative other than the one you typically talk to, BUT – the CSR that does answer the call has your entire order history on the screen in front of them immediately. That is thanks to our second system, which is an online database.

Each time an order is placed, whether it be from a new Retail Customer, or an existing Applicator, Dealer, or Manufacturer, the order is entered in real time into our Accounting Database. That database is immediately updated with any new Customer data – purchased products, colors, quantities, shipping addresses, etc. That means that any order that customer has ever made is instantly available on the screen, and we can tell them anything the customer has ever ordered (for example: I bought Lifeline Ultra-7 for a project 8 years ago and I forgot the color and now I need some touch up and additional for a garage, and by the way, that was for the Rutherford house in Pigeon Forge, not the Pinkerton house in North Carolina). We can tell you in real time what stain was used, what color, how much was purchased, when it was purchased, and where it was sent to. Every CSR in the company has that information, for every customer, on the screen in front of them as soon as the call is answered. Then, if the customer would like to talk to a particular individual (my ‘favorite’ salesperson), we can use the same network to send a notification to that CSR to call you back or attach any particular notifications for the order.

Because of the time difference from the East Coast to the West Coast, this system is available from 8:00 AM Eastern Time until 5:00 PM Pacific Time. That means that a call placed at say, 8:00 PM, on the East Coast will be answered by a salesperson in Redmond, WA that has your Customer History and can take the order or answer any question. That also says that you can make a call at 5:00 AM in Washington State and place an order with a CSR in Tennessee. That is a tremendous advantage for a Contractor who needs to place an order before normal business opening times, or after normal business hours. Remember, it doesn’t make any difference who answers the phone or where they happen to be – they have your Customer History on the screen in front of them and can take the order, handle shipping, and answer any questions you might have – and make the order at your particular price level.

Distribution

If you can’t get the product when you need it, it’s all for naught. If you are an Applicator, Manufacturer, or a Homeowner, you all need the product available at a particular time. Products that arrive a day or two late, or a week late, cause havoc with application crew scheduling or weather changes, and can reverberate through the season if early season jobs are late and will negatively impact schedules.

Our Manufacturing Plant is in Knoxville Tennessee, centrally located in the heart of the Log Home Industry. It is also located at the intersection of the major North/South and East/West highways. It’s no coincidence our factory is in that location! We of course have massive ‘Whole House’ inventories (products for an entire home project), but that location also feeds seven fully-stocked Whole House Company-owned Branches. Each one of those Branches is stocked with a Whole House inventory. Not one or two ‘Overage or Sample’ inventory. Additionally, each Branch location can make any custom stain color you desire and also stocks inventory for a number of Independent Distributors.

The point here is that we are located at strategic locations across the USA and are well-stocked to handle anything from multiple Whole House orders to samples and anything in between. These locations disburse our inventory so that we can fulfill orders from a number of large stocking locations that are close to you, our customers. We are not dependent on large inventory shipments or Whole House shipments arriving from one location. This drastically lowers shipping time and expense.

In addition, each of our seven Branches is staffed with a minimum of three experienced Log Home Specialists. Larger Branches have five and up to eight Inside Customer Care Specialists. No matter when or who you call, be assured you’ll be connected with Industry Experts that can help you get the right product at the right time.

Wayne Bell

Log Home Care Online

Have you ever wished that you could live in a log home but you’re stuck living in conventional housing? If so, join the growing number of people tackling home improvement projects to create a space that has the “feel” of log home living within the limitations of your current home.

Our project was to convert a roughly 30’x50′ unfinished basement in a contemporary suburban neighborhood into a space that would capture the tranquility of a northwoods lodge. Many of the design and construction techniques we used could just as easily be applied to any interior room, log home basement, or other living space. And best of all, most of the skills required are within the reach of the average handyman, so you can add significant value to your home with only a modest financial investment.

This space needed to harmonize with a contemporary home, so we used a mixture of log siding and drywall in the design.

We included a central fireplace as a gathering point for visitors, kitchen/bar area for entertaining, home theater, game room, guest bathroom and storage areas. To maintain the theme, we used natural materials wherever possible. We sketched out the space and made note of existing features (like the stairs, duct work, support beams and posts) so we could accommodate them in our design.

We’ve seen basement conversions that didn’t address the storage issue and that is a mistake so we framed in the corner that housed the furnace and other utilities to create a generous storage room.

Visitors are impressed with the functionality and attractiveness of the previously unused space. The extensive use of standard construction techniques allow for homeowner participation in the building process, and the use of log siding and natural materials provide for a dramatic effect. When it came to selecting the sealant and finish materials, we chose the same supplier that we have used to professionally finish hundreds of homes: Perma-Chink Systems.

It’s always fun to admire beautiful designs in log home publications, but with some creativity you, too, can enjoy the feeling of a log home wherever you live.

About the Author

Wayne Bell is a log home refinishing, repair and restoration contractor, serving the Midwest and southern United States from his base in Ohio. If you have questions about the materials or processes used in this project, you can contact him at 937-657-4565 or at www.LogHomeCareOnline.com.

From Worst to First With Perma-Chink!

By John & Elaine Judsky

Suches, GA

Perma-Chink Customers Forever

I’ll admit the hard truth. I neglected the exterior of our log cabin in the North Georgia mountains. For years. It was ugly, and we needed restoration.

We had used Perma-Chink products on the interior of our new cabin back in 1999, with Sure Shine on our floors and the Lifeline Interior on our walls. They are holding up well and looking good after 16 years.

But the exterior was a mess from our neglect and from using an inferior product. We used the product recommended and provided by our log manufacturer. It shall remain nameless here because it was an oil-based jug of junk.

This past summer I finally had the time and money to redo the exterior, and there was no question in my mind I was going to use Perma-Chink products. We attended a workshop in Knoxville and learned lots of good tips and info. The logs looked dirty, faded and had no water resistance. I went ahead and sanded the few spots that needed that much care. The S100 finish remover did a great job removing what was left of the old finish. The Wood ReNew made the logs fresh and bright again. Then the Log Wash prepared a good surface for the application of Armor-Guard preservative followed by two coats of the Lifeline Ultra-2, followed by the Lifeline Advance Gloss.

I also used Log End Seal for the logs & Woodsman for caulk touch-up. Our deck and porch floors were treated with Deck Defense. Every single product seemed high-quality and gave the advertised results. The water-based products are a dream to work with and clean-up is easy. All the products used together truly are a log home finishing ‘system’.

Now we have a home with a beautiful finish that looks brand new! My wife says that it looks like we are living inside a piece of fine furniture. The true beauty of the logs is shining through, we have a home we are once again proud of and we could not be more pleased. It was a lot of hard work, but the results are amazing.

I highly recommend Perma-Chink products to all those who want to preserve their logs and want a beautiful home. Their products are not inexpensive, but definitely worth every penny! If you do it yourself or hire it out, make sure you educate yourself on all the excellent how-to’s and advice on the website and make sure the directions are closely followed.

My final advice: You CANNOT go wrong with Perma-Chink.

Some DIY homeowners assume that hot weather simply means that the log finish freshly applied on their log home will dry faster. While this is true, there are circumstances when stained log surfaces dry too quickly. Once the finish is on the wall, it does not really matter if it gets hit by direct sunlight a few hours later. It’s the surface temperature during the application process that’s critical.

How Hot is Too Hot to Stain My Log Home and Deck?

A general rule of thumb is that stain can be applied when the outside temperature is between 40°- 90°F. However, temperature for application is based on the surface temperature of the logs, not the temperature of the air. For instance, a wall in the sun can be 10-25 degrees hotter than the surrounding air.

Can I Stain My Log Home in Direct Sunlight?

It’s best to avoid staining in direct sunlight, especially during the hot summer months. The heat causes the stain to dry out too quickly which prevents it from brushing out properly, resulting in brush marks, lap marks, and inadequate adhesion.

What Part of the Day is Best for Applying Finish to My Log Walls?

For exterior log walls, start as early in the morning as possible, after any dew has evaporated. As the sun rises and areas of the house become shaded, work around the house staining the shaded areas as the sun moves East to West.

What Happens When You Apply Stain to the Log Surface Hotter than 90 F?

- Water-based stains cure by the proper evaporation of water, leaving behind the pigments and protective coating. When water evaporates too rapidly, the ingredients/pigments will not disperse evenly for best adhesion.

- Brush marks and lap marks may occur, resulting in an uneven look of the finish.

- Uneven thickness of the stain coat on the surface will result in blotchy appearance.

Will Humidity Affect the Drying Process of the Stain on the Logs?

The best drying will occur when the relative humidity is 40% to 70%. The ideal temperature for staining is 70 degrees with humidity around 50%. To eliminate dew and condensation on logs that can create uneven sheen, allow approximately 2 hours for the coating to dry before sunset.

PRO Tips for Applying Stain to Log Homes in Hot Weather:

- Work or move around the house to avoid the sun as much as possible. Work in the shade when possible.

- You must keep a “wet edge” at all times. This means a lot of stain on the tools and working fast to avoid lap marks.

- Use heavy duty brushes that hold a lot of stain. Professionals typically use 4” high quality brushes. They are heavy and bulky when loaded with stain. Invest in quality brushes.

- Always “box” your stain and make sure it is completely mixed. Colors can slightly vary from one pail to the next. Use another bucket to mix gallons (like a 5 gallon bucket). Be mindful of the stain in your bucket and keep it closed when taking breaks.

- Buy a laser temperature measurement tool and monitor surface temperatures throughout the job.

- Avoid staining when humidity is extremely high or right after a heavy rainstorm. Stop working if temperatures exceed the limits.

- If in need of a professional help, visit our Find A Contractor tool and choose log home contractors near you.

By Lee Denman, Intensified Wood Restoration

There are essentially two types of log home stains available on the market today:

| Film-Forming FinishesOil-based (Alkyd) Log Home StainsLatex-based Log Home StainsAcrylic Latex-based Log Home StainsVarnishes for Log Homes | Penetrating FinishesOil-based Semi-transparent Log Home Stains |

What are the PROS and CONS of each of these types of log home finishes?

1. Oil Based (Alkyd) Log Home Stain

PROS: Wood grain visibility, UV Protection, Non Porous, Easy application, longer open times.

CONS: Trap Moisture, Brittle, Can’t Breathe, Weather Quickly, Coat build-up over time, Blistering occurs if moisture is present behind finish, High Maintenance.

2. Latex based Solid Color Log Home

PROS: Breathable, Flexible, Durable, High UV Protection, Porous, Easy application, Low maintenance, Long life, low odor.

CONS: Won’t prevent decay if conditions are favorable, Short Shelf Life.

3. Semi-Transparent Acrylic Latex based Log Home Stain

PROS: Breathable, Flexible, Durable, High UV Protection, Wood grain visibility, Porous, Low maintenance, Long life, low odor.

CONS: More difficult to apply than oil based stains and solid color stains, fast drying times.

4. Log Home Varnishes

PROS: Allow for natural look of logs.

CONS: High maintenance, prone to Cracking, Peeling and Blistering, Requires recoating every 1-2 years, Partial UV protection.

5. Oil based Semitransparent Log Home Stains

PROS: Penetrate into wood, Wood grain visibility, Breathable, High UV protection.

CONS: Perform best on rough sawn, weathered, or course textured wood. Compatibility issues with most log home sealants due to waxes found in most penetrating finishes. Don’t have a furniture grade finish look (dull), must apply second coat before first coat dries in order for stain to penetrate wood. Vapor barrier, non-breathable.

What types of log home stains work the best?

So we have all this helpful information on the types of log home stains but which log home stain is the best? It is hard to say which one is the absolute best because there are many factors that ultimately decide how well or long a log home stain will perform. Some of these factors are:

- What season the logs were cut (winter cut logs only)

- Proper surface preparation

- Environment surrounding building

- Moisture content of logs

Of all these factors none is more important than proper surface preparation of the logs before applying a log home stain. If the surface of the logs has not been prepped properly none of these log home stains will perform as they state they will. This is why it is important to only hire a qualified log home restoration expert to work on your log home! They will have the knowledge and expertise to work with the products available in the current log home market. This will ensure your investment is protected well into the future.

While we can’t say which log home stain is the overall best, we can recommend which type of log home finishes we feel perform exceptionally well and keep maintenance costs down throughout the years. This only holds true if proper surface preparation is kept in mind before and during any finish or sealant application. In our opinion, film-forming, latex based waterborne log home finishes such as Perma-Chink Systems’ Lifeline is best bang for your buck!

While Perma-Chink Systems finishes aren’t the cheapest out there they seem to require the least amount of maintenance based on our 25+ years of experience restoring log homes and log cabins of all sizes and shapes. They also offer an unmatched 5 year warranty on their log home stains when applied properly and maintained accordingly.

Lee Denman is the founder of Intensified Wood Restoration Company

Perma-Chink Systems Free Samples

Want to try Perma-Chink Systems products? Order free samples online here.