Library

Lifeline Interior™ is a natural looking, semi-transparent wood finish. It forms a breathable protective layer for your walls and ceilings while highlighting the beauty and grain of the wood. Our unique breathable formula allows natural wood moisture to escape from the wood yet provides a tough surface film that can easily be cleaned and dusted, especially when top coated with our Lifeline Acrylic™ Gloss or Satin clear finish.

WHAT EXACTLY DOES ‘BREATHABLE’ MEAN?

To understand, it takes a little bit of chemistry and physics, but the concept is fairly simple. Technically, for those of you who want to impress friends, the scientific term is vapor permeability – the ability of water vapor to permeate through a film.

Polymer films are composed of long chains of molecules that are bound together in a three-dimensional matrix. This matrix is quite dense in films like polyurethane and alkyd coatings, and there is not much space between the polymer chains. This prevents small water vapor molecules from making their way through the film.

On the other hand, Lifeline finishes form a less-dense matrix with room enough for water vapor molecules to penetrate through the film, but not enough space to allow liquid water to make its way into – or through – the film.

You can think of it in terms of a film with a bunch of small holes, or pores, that filter out large objects but allow smaller objects to pass through them. In chemistry these types of films are known as semi-permeable membranes, but in our industry we call them breathable.

Another factor that influences vapor permeability is the thickness of the film. The thicker the film, the more difficult it becomes for water vapor molecules to make their way through. That’s one reason we encourage you to apply our finishes in thin layers. When applied too thickly, even acrylic latex films can have difficulty breathing.

If you use one of our Lifeline Interior color stains, the colorants in the finish help stabilize color of the wood and slow down, or even prevent the fading that you may notice when removing pictures or furniture from against the wall. If using Lifeline Interior Clear, we recommend the addition of UV Boost to the first coat to help prevent this “picture frame” effect due to UV light exposure. Since interior surfaces are not exposed to harsh weather, two coats of Lifeline Interior are not necessary. However, you can apply multiple coats of Lifeline Interior in order to achieve the appearance you desire.

Lifeline Interior is easy to apply. It can be applied by brush, spray or pad. Lifeline Interior dries to the touch in one hour and clean-up is easy, just use soap and water.

One of the best reasons to use Lifeline Interior is that it reduces the absorption of pet, fireplace, and cooking odors into the wood.

Lifeline Interior resists yellowing and is non-flammable and virtually odorless. Like all of our premium finishes, it allows the natural look and beauty of all species of wood to come through. Lifeline Interior can be used on new or existing log homes as long as the surfaces are clean and dry.

You can now order Lifeline Interior in any color you desire in addition to our 13 standard colors plus Clear. For a custom color, or color matching please call 1-800-548-3554. You can request wet samples to try on your logs by calling 1-800-548-3554.

Note: All Lifeline stains and finishes are water-based and do not contain petroleum distillates. They comply with all State and Federal regulations for contained volatile organic compound (VOC). In addition, being concerned with keeping living areas as healthy as possible, our interior finishes are specifically formulated to meet the highest interior air quality standards.

Perma-Chink Systems has recently added another beautiful wood finish option for our customers. Unlike our traditional Lifeline film-forming wood finishes, Log & Timber Defense™ penetrates your wood. As it absorbs into the wood surface, it forms a strong lattice network within the wood, reinforcing and strengthening the entire system from the inside out. Due to its elastomeric nature and penetration, it greatly reduces the chances of peeling and flaking by leaving the system breathable to water vapor. Many penetrating oil-based finishes can also form a network but unfortunately often contain harmful flammable solvents that make working with them both dangerous for you and our environment. In contrast our Log & Timber Defense is water-based making it both easier and safer to work with.

Log and Timber Defense is designed to be applied to bare wood in one or two coats. However, if applied to wood that already has an existing coating this can interfere with adhesion and could lead to premature failure of the finish. For best results we recommend application of Log & Timber Defense to bare wood that has been cleaned with Wood Renew™.

For all our Lifeline™ wood finishes, we recommend application of a topcoat, however, not so with Log & Timber Defense. The reason for advising against this is because when a maintenance coat is needed in the future there will be difficulty with penetration into the wood because the topcoat forms a barrier to penetration leaving a film on surface. Additionally, this could lead to undesirable surface defects as well as an uneven appearance.

Texture is another property that distinguishes Log and Timber Defense from our Lifeline Stains. Due to its penetrating nature, Log and Timber Defense leaves the surface with a more naturalistic rustic beauty. In general, it will appear flatter than our Lifeline finishes. However, if slightly more gloss is desired, a second coat of Log & Timber Defense may be applied. The second coat will also increase color intensity and provide an increased level of overall protection for the system.

Finally, Log and Timber Defense is formulated with ingredients that inhibit the growth of mold and mildew. Log and Timber Defense is both a stain and sealant in one package. It helps to keep liquid water out, which reduces biological growth that can attack and destroy your wood. In contrast, traditional natural oils – such as Linseed Oil – can easily promote growth of mold and mildew. Log & Timber Defense is waterborne, low in odor, has easy soap and water cleanup, and is non-flammable. Log & Timber Defense offers unique properties designed to give your home the very best protection possible.

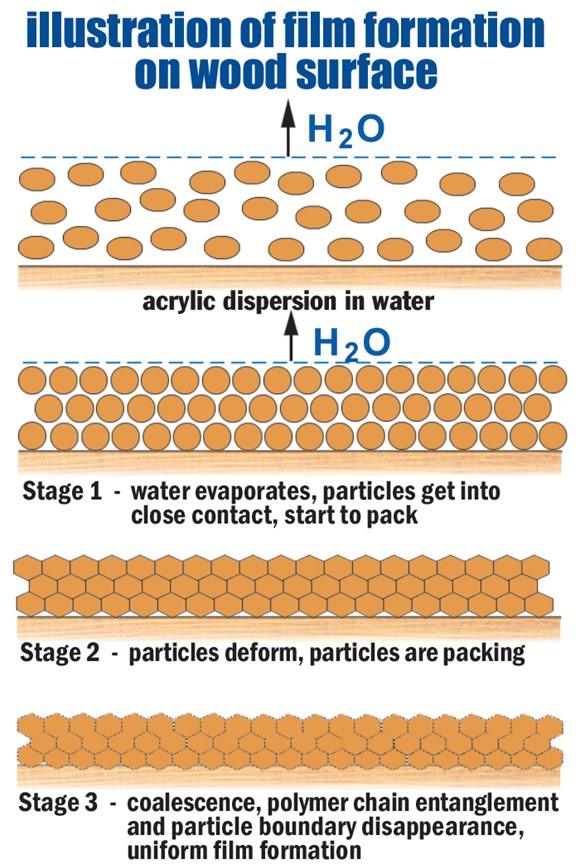

Drying times and curing times relate to two entirely different processes that occur in water-based polymer systems. All water-based products, be it stains, paints, or sealants, contain a percentage of free water, hence their description as water-based.

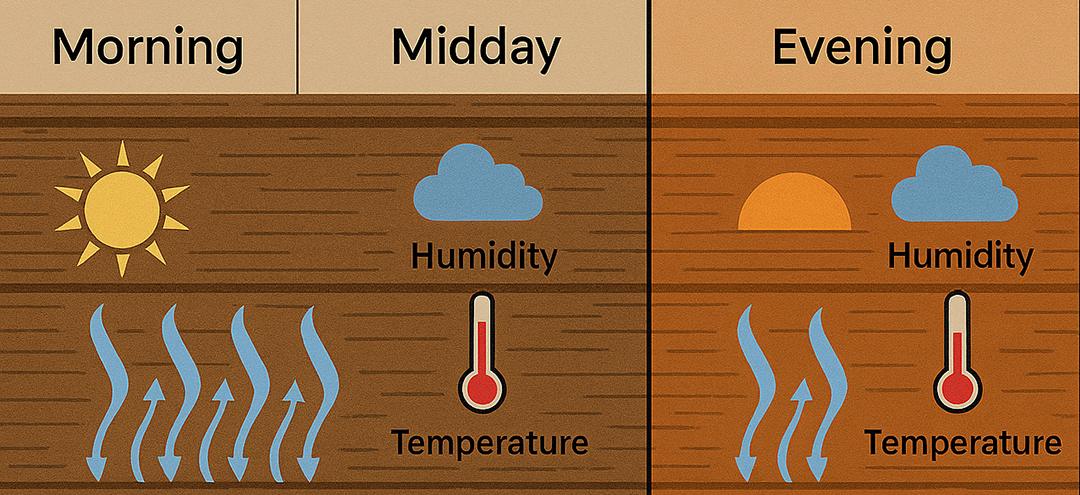

When applied and exposed to air, the free water begins to evaporate. The rate of evaporation is dependent on the humidity as well as the temperature. The higher the temperature and lower the humidity, the faster the rate of evaporation.

Once most of the water has evaporated from the surface, it feels dry – thus the term “dry to the touch.” The time a product takes to become dry to the touch is its “drying time,” although in the case of sealants, we typically talk about the time it takes a product to “skin over.”

Once a material has dried or skinned over, it does gain some strength in that it becomes impossible to brush out or tool smooth, but to achieve its maximum strength and durability it must be allowed to cure.

Curing time relates to the time it takes for a product to gain enough strength to withstand the parameters for which it was designed. As opposed to drying, curing is more of a chemical reaction that takes place on a molecular level. During the curing process environmental factors such as rain, snow, or high humidity can have a significant impact on the look or performance of a product. For example, in our Advance Topcoats, blushing is caused by water molecules becoming trapped within the polymer matrix during the curing process. Once trapped, it may take a long time for this water to escape from the film as long as environmental conditions remain cool and damp.

In addition to temperature and humidity, the time it takes sealants like Perma-Chink®, Energy Seal™, Woodsman™, and Check Mate 2® to cure depends on the thickness of their application. Once a sealant skins over, it inhibits the evaporation of water from the material under the skin. This prolongs the curing process, so although we may state that the curing time for Perma-Chink is two to eight weeks for a thinner or standard application, it may take several months for a 5/16” thick layer of Perma-Chink to attain its maximum strength.

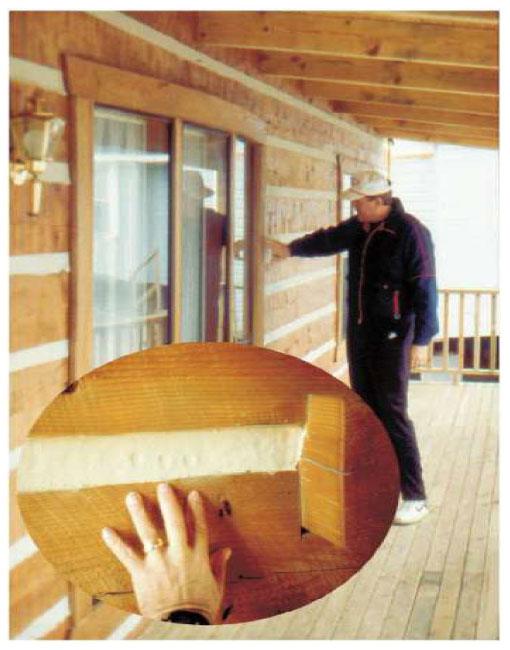

Although we have never identified exactly what it is, there is a magical ingredient in Perma-Chink that acts as a magnet to human fingers. Put an adult or juvenile male anywhere close to a wall with a fresh application of Perma-Chink, and the first thing that happens is one hand comes out of their pocket with one or more fingers magnetically attracted to the chink joint.

Usually with enough force to determine the strength or pliability of the chinking, fingers leave evidence of attraction in the form of small depressions. Occasionally female fingers are magnetically attracted to Perma-Chink. In their case, the amount of applied pressure is usually considerably less since it is more a matter of feeling the texture. In either case, if the Perma-Chink has been freshly applied, evidence of their chinking inspection will be permanently imparted into the chink joint.

So what is the best way to protect freshly applied chinking until it cures? You can always try a “DO NOT TOUCH” sign, but from our experience it appears that most chinking inspectors can not read or it is taken as an invitation to touch. This means that you need to place some type of physical barrier, i.e. plastic or cardboard, between the finger pokers and the chinking. Just be sure that there is enough space between the barrier and chinking so that air can flow to facilitate the drying of the chinking.

The length of time you will need to leave the barrier in place depends on the weather. If it is warm and dry, the chinking will probably be cured enough in three to four weeks to resist finger poking. However, if it is cool and damp, it may take two to three months before it is safe to remove the barrier. In any case, the effort spent in protecting the chinking is worth the time in preserving the aesthetics of a great looking chinking job for many years.

It is virtually impossible to prevent logs from developing cracks and checks as they age and dry. That is because as wood seasons, mechanical stresses build up until the surface stress becomes so great that the wood cracks. We call these stress cracks “checks.”

Do checks need to be sealed? Yes, especially upward facing checks that collect water increasing the interior moisture content of the log. If they continue to collect water and the wood remains damp, they will eventually result in internal wood decay as well as provide nesting sites for carpenter ants and other insects. It is not necessary to seal checks on the bottom half of round logs since they do not collect water, but for a uniform appearance you may want to seal them. It is not usually necessary to seal checks or fissures that are less than 1/4” wide since they can not accumulate that much water.

If your home is new and the logs or siding are green, it may be best to wait a year before addressing the checks. This allows the wood to reach an equilibrium with its environment and by then most of the larger checks will have opened. With seasoned wood or an older home that is in the process of being refinished you can seal the checks either before or after applying a stain.

Check Mate 2

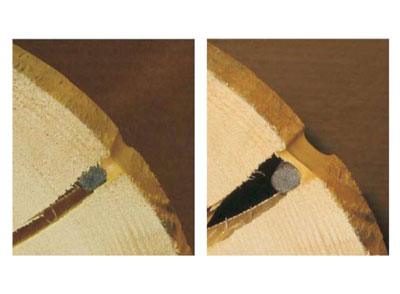

Checks and splits in logs present a different set of dynamics than those addressed by a typical caulk. Checks/splits open and close as the log’s moisture content varies throughout the year. The opening width of a check may change as much as 50% from summer to winter. Check Mate 2 is specifically formulated to meet the requirements for sealing checks that appear in logs and log siding.

When initially applied in a 3/8” thick check, Check Mate 2 bonds to the sides of the check (Figure 1). As the check opens, Check Mate 2 stretches to maintain a water-tight seal (Figure 2). The role the Backer Rod is to maintain a Check Mate 2 thickness of 3/8” during the application and two-point contact with the wood. Two-point adhesion enables Check Mate 2 to elongate and contract.

APPLICATION DIRECTIONS

Step 1: Begin by cleaning any dust, dirt, oil, solvent or previous sealer out of the check. Previously applied caulks can usually be easily pulled or scraped out with a hook knife. If the check is upward-facing and has allowed water penetration, pour some Shell-Guard RTU into it. This will kill any decay fungi present and prevent further deterioration of the log due to rot. If the wood within the check is damp from cleaning, rain, or a borate treatment, make sure the check has time to dry before applying Check Mate 2. You can speed up the drying process by blowing the water out of the check with a leaf blower. The last thing you want to do is to trap any water within the check.

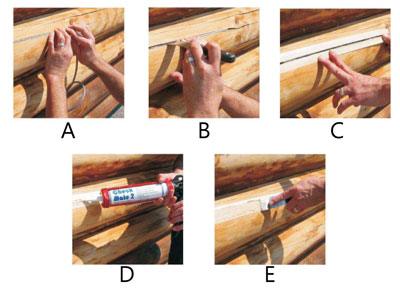

Step 2: For sealing checks 1/4” wide or larger, Check Mate 2 should be always used in conjunction with Backer Rod. Insert the Backer Rod into the check and use a trowel or other implement to push the Backer Rod about 3/8” to 1/2” deep (Pictures A & B). If you push it deeper than 1/2”, the cured Check Mate 2 will be too thick and may rip away from the sides of the check. If the Backer Rod is placed too close to the surface the Check Mate 2 may end up too thin and split.

Step 3: For a neat, clean appearance you can use masking tape to mask off the wood on either side of the check (Picture C). Be sure to remove the masking tape right after you tool the Check Mate 2 smooth. If you remove the masking tape after the Check Mate 2 has begun to dry, you will pull the top layer of Check Mate 2 off along with the masking tape.

Step 4: Cut the tip of the Check Mate 2 tube to about the same diameter as the checks you plan to fill (a little smaller diameter is better than one too large). Fill the space between the Backer Rod and log surface with Check Mate 2 using a standard caulk gun. Check Mate 2 must have good contact with wood on either side of the check and be sure the crack or check is completely sealed from end to end (Picture D).

Step 5: Tool the surface smooth with a trowel, spatula or wet finger and remove overflow immediately with a damp cloth (Picture E). Don’t forget that the masking tape must be removed while the Check Mate 2 is still wet.

Step 6: Check Mate 2 will dry to the touch in about one hour, but complete curing may take several days, depending on application thickness, temperature, and weather conditions. The color of Check Mate 2 as it comes out of the tube is always lighter than the final cured color.

Note: Newly applied Check Mate 2 Clear is white but turns clear when cured.

Step 7: Clean tools and hands with soap and water.

Hi there, sports fans! Can you believe it is November? Seems to me I was just getting used to summer! Cold weather is coming and it pays to get serious about closing those last few orders and thinking about comfort and home protection over the winter.

You can assure customers by suggesting they’ve spent their last winter with drafts, cool air, and high energy costs with a properly sealed home. They will be much more comfortable, increase their home value, and protect their log home investment by chinking now, before the winter cold sets in.

If the logs themselves could use some additional protection, suggest LIFELINE natural wood finish, which is specifically designed for log homes. LIFELINE is easy to apply, enhances the natural beauty of the logs, and provides premium protection against the ravages of the coming winter.

And for sure note that if you apply LIFELINE finishes to the home now, we assure compatibility with Perma-Chink chinking for later applications. Works great the other way around, too – chink now with Perma-Chink or Energy Seal and follow up with LIFELINE for a dynamite sealant system.

Q: I am always pressed for time, how soon after LIFELINE application can I apply Perma-Chink?

A: LIFELINE will dry to the touch in an hour or so, and Perma-Chink can easily be applied the following day.

Q: Do we put Bora-Care wood preservative on the inside or outside of the home?

A: To protect the log completely against the target organism, you must get the required amount of active ingredient into the log surface. To do this you should treat the entire surface of the log per the label instructions. The simplest way is to apply Bora-Care to both sides of the logs before chinking or staining. Don’t worry about overspray on the floor or interior framing- in fact, it’s a good idea to spray Bora-Care two feet in from the walls on all floor members during this phase of construction.

Q: Does LIFELINE Stain have Mildewcide?

A: Yes, LIFELINE stains for exterior wood surfaces have an effective mildewcide, however in conditions conductive to the growth of mildew, even the most effective mildewcide can be overwhelmed. Mildewcide in LIFELINE finishes helps prevent mildew from growing in or on the stain film only. So, mildew or fungus should be removed completely before application of the LIFELINE stain.

Q: How dry should logs be before they are ready to stain?

A: Wet logs pose the most serious problems to oil-based stains that do not adequately penetrate wet wood surfaces, and to any film-forming stains that prohibit evaporation, thereby trapping moisture inside logs. LIFELINE stains and finishes let logs breathe to allow moisture to evaporate from wet logs. Extremely wet logs might reduce the life of the first application of stain, but there are good reasons to stain as soon as is possible. Exposure to the weather causes fading of the natural wood color, which can affect the final home color. The longer bare wood is exposed to the elements, the more mold and mildew spores settle on the surface.

Cleaning the logs, then immediately applying LIFELINE and a topcoat of LIFELINE Advance stabilizes the color, adds a water repellant film, and provides a protective film containing mildewcides and UV inhibitors. If you are in a geographic location where mold and mildew are prevalent, we advise you to include additional mildewcide additives in your first coat of LIFELINE finish.

Q: Will Perma-Chink stick to oil or solvent based stains?

A: Yes. Oils in conventional stains have a tendency to evaporate fairly quickly, leaving loosely bound tint on the surface of the logs. Remove any loose material and try the water drop test. If Perma-Chink doesn’t have to fight its way through a layer of goop or oil, it will bond to the wood tighter than any material.

Q: Can Perma-Chink be applied to a milled log home?

A: Yes. Perma-Chink log chinking can be applied to any style log home. But we recommend our specialty sealant for milled log homes – Energy Seal. It will seal out damaging water and virtually eliminate air infiltration, making your home much more livable and protected in the winter months to come.

Q: Can I apply Deck Defense to treated wood?

A: Yes, Deck Defense can be applied to treated wood, cedar and redwood, etc. It is designed for any horizontal surface, particularly if abrasion and traffic patterns are a concern.

Centipedes, millipedes, pill bugs, roaches, crickets, ants, beetles, spiders, wasps, squirrels, opossums, raccoons, bats and mice are just some of the pests that manage to find their way into homes. It’s just about impossible to keep all of them from getting in, but there are several things that you can do to significantly reduce the number of pests that make it inside your home. Most have to do with blocking the ways they can enter. Furthermore, there are also some things you can do outside to make your home less attractive to pest invaders.

Landscaping

Most pests including rodents and insects like shaded, moist environments. All of the plants and shrubs surrounding your home may appeal to you but they also appeal to numerous pests.

It’s not that you have to cut them down and get rid of them, just move or trim them away from your foundation or log walls. What you need is a two foot clear space between the shrubs and your walls and foundation.

Once you move and/or trim them, you need to put some type of cover on the ground to prevent weeds from growing. Do not use pine needles, wood or bark mulch! The objective of these types of mulch is to hold moisture and that’s what you don’t want to do. You want to provide a dry environment that bugs and rodents don’t find attractive. The best thing to use is about three to four inches of coarse crushed stone or pebbles. Yes, it’s more expensive than organic mulch, but it’s permanent. Just keep debris like leaves from building up on top of it, and the stone will keep doing its job for many years.

Gutters

All log homes should be equipped with gutters. One of the most common problems we see is deterioration of lower log courses due to splash up from rain coming off the roof; however, gutters only work if they are kept clean. Blocked gutters provide ideal moist environments for a wide variety of insects including carpenter ants and termites. Although subterranean termites typically live in soil, they can also establish nests above ground as long as there is a consistent source of water. These types of termite colonies are known as aerial infestations and, if left unattended, the termites can cause significant damage over the course of several years.

Chimney Caps

If you don’t already have a cap on your chimney, they are a good investment. It is not uncommon for squirrels, raccoons, and birds to take up residence in a chimney during the summer months and become a nuisance. Raccoons are often infested with fleas that can end up in your living areas.

Door Sweeps, Screens and Weather Stripping

Make sure that you have door sweeps installed on all doors accessible to the outside and check to see if they are in good working order. If you can see visible light coming in at the corners they need to be replaced. It only takes a gap of 1/4” for bugs and mice to gain entry. While you are at it, check the bottom seal of your garage doors. Once mice get into your garage they will probably find a way to get into your living area, too.

Windows are the most common entry points for flying insects in particular. Flies, ladybugs, boxelder bugs, stink bugs, and flying ants are just a few of the insects that can find their way into your home through the windows. Check to see if there are any rips or tears in your window screens, and make sure that the screens fit tightly into the frame. See if the weather stripping is still flexible and maintaining a tight seal when the window is closed. If you have sliding glass doors, check them too.

Weather stripping has a lifespan of about ten to fifteen years so if yours is hard and brittle, it’s time to replace it.

Attic and Crawl Space Vents

Normal window screening is not enough to deter determined pests like squirrels. They can gnaw through normal window screening in a matter of a few hours. To prevent entry of bats, rodents, squirrels and raccoons use 1/4” hardware cloth on the outside followed with small mesh screening on the inside to keep out wasps, ladybugs and large ants.

Caulks and Sealants

If you take a walk around your home and count possible insect entry points, you may be surprised at how many there are. Besides all of the windows and doors you’ll find electrical, telephone, cable, gas, outdoor faucets, air conditioning, and plumbing entry points. If you have a crawl space, you may have a number of vents, plus a door. And don’t forget your clothes dryer vent. All of these are common entry points for insects and rodents.

Let’s first address windows and doors. Round log or log sided homes, in particular, present a real challenge when it comes to sealing around windows and doors. All too often once a window or door is set into place, the edges of the opening are covered with a piece of trim and that’s it. Rarely is the trim properly sealed to the logs and large voids behind the trim are left empty (see “How to Apply Energy Seal and Woodsman” for the proper method for sealing around windows and doors). If these voids are not filled, they become perfect nesting sites for several species of ants, many of which will get into your home.

A good product to use for filling these voids is a Log Gap Cap™. A Log Gap Cap is a pre-cut foam insert that is available in two different sizes that fit most log profiles and log diameters. Once in place, the Log Gap Cap needs to be covered with a layer of Energy Seal™ or Woodsman™, since direct UV light will degrade the foam fairly rapidly.

Foundation vents also need to be sealed to the walls. Screening the vents won’t do any good if open gaps are left between the vent housing and the wall. If there is room for backer rod be sure to use it. If the foundation is brick, block or stone, Gray Energy Seal provides a good color match to the existing mortar.

Examine all of the electrical and plumbing penetrations mentioned earlier. Most were probably initially sealed with mortar. Most likely you’ll find cracks or gaps where the mortar has fallen out over the years. If a cheap construction caulk was used, it’s probably hard and brittle. Try to dig out as much as you can and replace it with a high-quality sealant like Energy Seal or Woodsman. When properly applied, they will keep those pesky bugs out of your home for many years to come.

Pesticides

We at Perma-Chink Systems, Inc. discourage the broadcast use of pesticides just to keep nuisance pests out of your home. We are a firm advocate of Integrated Pest Management and since there are so many mechanical methods of control available to homeowners, we believe that they should be used as the primary means of preventing pest invasions. Pesticides should be used only as absolutely needed. Yes, there are situations when the use of pesticides may be the only solution to a problem but you may be surprised how effective some of these simple mechanical recommendations can be.

Locations to seal in home:

Resources

Need help getting started? Check out our Tech Tips on mitigating pests.

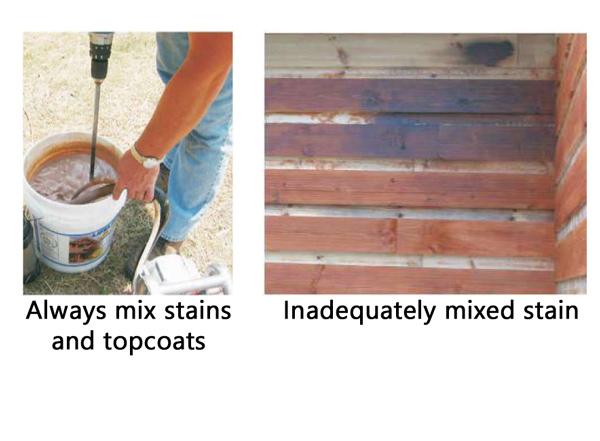

“Stir well before use”

This term, or its equivalent, appears on every container of stain and finish we sell. It is there for a good reason – most of our finishes are formulated with low viscosities, making them easy to apply with an airless sprayer and in thin layers. Any pigments they contain are heavier than the liquids, so over time they may settle to the bottom of the pail.

If the container is not stirred thoroughly and the pigments are not uniformly distributed throughout the product, the color may change as the stain is applied. This situation is easy to avoid with proper mixing both before use and occasionally during use.

What is “Boxing”?

We recommend customers to “box” containers as they get close to empty. When a container of stain gets down to about 1/4 full, you should thoroughly mix up a new container you plan to use and pour about 1/4 of the new container into the used container. Mix the combined stain well, and then use the mixed stain to continue applying the stain. Although we take great strides to maintain consistency within and between manufactured lots, boxing containers ensures that there will be no noticeable color difference as you go from one container to the next.

What should you use to mix our products?

Just about any type of paint mixer that fits into a cordless drill will work. We prefer one called a Jiffy Mixer since it has a ring around the stirring blades that prevents chipping plastic buckets, and its design prevents air being forced into the product.

How Do I Know If The Stain Wasn’t Mixed Properly?

Inadequate mixing is easy to tell: the color on a wall goes from light to dark as the stain gets closer to the bottom of the pail. Unfortunately, there is no fix other than stripping the finish off and starting over again. Proper mixing and boxing of finishes will avoid this issue.

Do I Need to Mix Clear Topcoats?

Short answer: Yes. Since our Lifeline Advance™ Gloss and Satin and Acrylic Gloss and Satin topcoats are clear and colorless, some individuals think that they do not have to be mixed before application. These clear coats consist of several components that may stratify in the container over time. Even though you may not be able to see the different layers, they need to be mixed together for use.

Questions?

In addition to manufacturing the best log home finishes you can buy, one of our commitments is to give you the information you need to do a truly professional job. If you have any questions give us a call at 1-800-548-3554 or chat with us online.

The Difference is Clear, but it’s NOT What You Think.

It makes sense that the more your product costs, the higher the quality of ingredients.

To prove this point, the professionals in the industry performed a careful analysis that shows that in the long run, it’s less expensive to apply the very best quality stain, despite its higher initial cost.

How Does a Low-Cost Option Cost More?

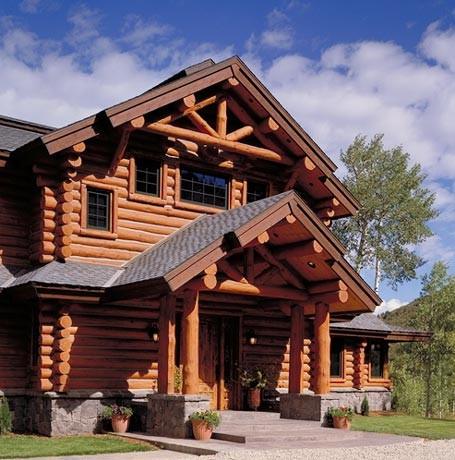

Field tests show that while low-quality finishes last two years or less, top-quality, 100-percent acrylic polymer finishes such as the LIFELINE™ Ultra family from Perma-Chink Systems last five years or more when applied to a properly prepared surface and maintained on a regular basis.

A simple comparison of the cost of a gallon of stain is a mistake because all stains differ in their lifespan, coverage rate and quality of appearance and protection.

A high-performance finish gives long-lasting color retention using a balanced formulation of transparent iron oxides and long-lasting mildew inhibitors.

How Do More Expensive Finishes Last Longer?

The secret behind durability is state-of-the-art resins that create a flexible and tough seal on logs. Perhaps more importantly than the seal’s strength, the resin also ensures that the seal is continuous, providing protection from holes and gaps that might otherwise develop with a lower-quality finish. In addition, it has unsurpassed adhesion to wood.

It’s this continuity that has proven to be much more resistant to UV degradation, color fading and adhesion loss. And just like all LIFELINE finishes, the water-resistant film breathes just like Gore-Tex® to allow trapped moisture to evaporate from the logs.

What Does A Clear Coat Do?

By applying a clear topcoat, you also have the opportunity to create a gloss or satin finish and greatly extend the life of the stain system.

Adding a high-performance clear exterior topcoat over the wood finish acts much as an automotive clear coat to enhance the appearance and extend the life of the finish.

UV And Water Protection Are Important

While UV inhibitors are included in some high-quality stains, your finish should also repel rain but be permeable to water vapor to allow trapped moisture in your logs to evaporate, and the Perma- Chink Systems products do just that. For topcoats and base stain, LIFELINE provides you with options that “breathe,” allowing moisture within the logs to evaporate while reducing checking. Clear topcoats boost protection against UV rays and add water repellency – while making your exterior walls easier to clean. Additionally, LIFELINE Advance clear topcoat is environmentally-friendly, as a water-based formula that is low in VOCs and meets regulatory compliance in all 50 states.

We Use What We Sell

“I have personally applied every one of our products on my log house in Colorado. That furniture grade finish not only provides the best protection for the logs, but it also literally distinguishes the house. I and my staff continuously evaluate every stain on the market and when it comes to ultimate endurance, furniture grade appearance, ease of application and environmentally responsible formulation, there is only one choice – Perma-Chink Systems.”

– Rich Dunstan

Contact Us For Questions or Orders

1-800-548-3554 – www.PermaChink.com – Store Locations – As always, we offer free samples; order at Store.PermaChink.com.

Since interior finishes are not exposed to rain, snow, wind, and direct sunlight, long term resistance to weather is not an issue, and homeowners have more flexibility when choosing the color and appearance of interior wood surfaces. However, there are some parameters that need to be followed to take advantage of the benefits of an interior finish, such as preventing odor absorption and making the walls easy to keep clean, while getting the look you desire as well.

The first question to consider is do you want to apply a color to your wood surfaces, or do you want to retain the wood’s natural color? One reason for adding a color is to even out the overall color of the walls. Even if only one species of wood is used for interior surfaces, there may be slight color differences from log to log that disrupt the uniformity of a wall. A colored stain will help diminish these differences. Another reason for applying a color is that over time, sunlight coming in through the windows may darken exposed surfaces. There are ways to slow this process even on unstained surfaces, but the application of a pigmented stain will slow this process even more.

Let’s assume you’ve decided to add a bit of color. How many color coats do you need to apply? As opposed to exterior surfaces, it’s more a matter of obtaining the color you want than being concerned about long term performance. If one coat works, that’s all you’ll need. If, after two coats, you want your walls a bit darker, there is no problem applying a third coat.

One thing we do recommend when applying a color to bare wood is to add a dose of UV Boost to the first coat of stain. It helps make the wood UV stable and further reduces the “picture frame” effect on areas that exposed to direct sunlight. Since it only works when applied to bare wood, it does no good to add it to subsequent coats.

But what if you decide not to apply a colored stain to your walls? In this case we recommend that the bare wood be first primed with Lifeline Prelude™ Clear Water-Based Wood Primer. Prelude seals the wood surface, so you’ll use less Lifeline Acrylic or PCS Clear Shield Gloss or Matte, and since it already contains UV Boost, it adds UV protection to the wood.

If you have applied LIFELINE Interior stain or Lifeline Prelude, do you still need to apply a clear topcoat?

Yes, the formulation of LIFELINE Interior, Accents and Prelude is designed for flexibility and excellent adhesion to wood but the polymers we use to attain these attributes are slightly soft, and dust and dirt can adhere to them. When top-coated with Lifeline Acrylic Gloss or Satin or PCS Clear Shield Gloss or Matte, the finish surfaces become much more impervious to dirt pick-up. Since they are slick and smooth they can be kept clean with much less effort. The bottom line is that the application of LIFELINE Interior, Accents or Prelude should always include applying either Lifeline Acrylic or PCS Clear Shield over them.

Equipment to Have on Hand

Ladders, ladder jacks and platform, if necessary

Electric Drill

Paint mixer (available from Perma-Chink Systems or most paint stores and DIY outlets)

High quality paint or stain brushes (this is not an area to cut costs)

Clean rags and sponge

HVLP Hand Sprayer

Spray equipment if desired

Do not use a standard airless sprayer inside a home, especially if it is furnished. The use of airless sprayers will result in overspray getting on areas that you may not want stained. A much better option is buying or renting an HVLP (High Volume Low Pressure) sprayer. HVLP sprayers are available for less than $100.00, but don’t hold a lot of product at a time. The real advantage to HVLP sprayers is that overspray is kept to a minimum, plus they are very easy to handle and control.

Preparing Interior Wood Surfaces Prior to Applying a Lifeline Finish

Interior walls and ceilings must be cleaned prior to finishing but if your home is furnished you are somewhat limited in the available cleaning methods since the use of a pressure washer is typically not an option. If you want your interior walls smooth, sanding may be your only choice. As opposed to exterior surfaces you can buff interior wood surfaces using 100 grit or finer sandpaper or 120 grit Osborn Brushes. Although your interior wood surfaces may appear to be clean, they are never clean enough to apply a finish to them without first washing them with an appropriate cleaning solution like Log Wash™.

Step 1: Mix one half or one cup of Log Wash Concentrate with one gallon of warm water, if available, in a pail.

Step 2: Apply the Log Wash solution to the wall with a rag or sponge. Allow the solution to remain on the wall for about 10 minutes.

Step 3: Using a clean rag or sponge and a pail of clean water, wipe the Log Wash solution off of the surface. Frequently rinse the sponge or rag in the pail of water and occasionally exchange the water in the pail with clean water.

Step 4: Allow the surface to dry before applying the first coat of finish.

Applying Lifeline Prelude, Interior Stains and Acrylic Topcoats

Step 1: Remove the lid from the pail and stir the contents for at least 5 minutes using an electric drill and a paint mixer. Be sure that all of the pigments are uniformly dispersed throughout the product. Mixing is also required for clear Lifeline products such as Lifeline Prelude clear wood primer and Lifeline Acrylic clear topcoat. When mixing Lifeline Acrylic in Satin make sure that none of the flatting agent remains on the bottom of the pail.

Note: When using pigmented stains we recommend “boxing” containers as they get close to empty. When a container gets down to about 1/4 full, mix up the next container you plan to use and pour about 1/4 of it into the previous container, mix them together and then use the mixed stain to continue. This ensures that there will be no noticeable color difference as you go from one container to the next. It is not necessary to box Lifeline Prelude, Lifeline Acrylic, or PCS Clear Shield.

Step 2: Use a high quality brush or HVLP sprayer to apply the first coat of pigmented interior stain or Lifeline Prelude Clear Wood Primer. Start the application at the top of the wall and work your way down. This avoids having to set a ladder against a wet finish and allows you to work out any drips and runs that may occur during the application process. Be sure to back-brush the finish as you move along.

Step 3: Work on one or two courses of logs at a time. Lifeline finishes are made to go on in thin coats, do not flood the surface with product. Continue brushing until you have spread the finish out as far as it will go.

Step 4: While maintaining a wet edge continue the application process until you come to a break point like a window frame or butt end of the log. Never stop in the middle of a log. If you do, you will end up with a lap mark that will be difficult or impossible to hide.

Step 5: Continue the application process working your way down the wall until the wall is completed.

Step 6: In the case of a pigmented interior stain, allow the finish to dry before deciding whether you want to apply an additional coat. The color will change as it dries so don’t make your decision until the wall is completely dry. Do not attempt to sand or buff Lifeline color coats or Prelude.

Step 7: Once you are satisfied with the color, apply at least one coat of Lifeline Acrylic Gloss and Satin using the same application technique as the color coats. Once the first coat of Acrylic Gloss or Satin has been applied and allowed time to dry, the surface may be sanded smooth using fine sandpaper. Sanding will not be necessary between subsequent coats. If Sure Shine Polyurethane Premium Finish is to be used as the topcoat, read the next section.

Step 8: Clean brushes and equipment with soap and water.

Applying PCS Clear Shield Finish

Step 1: Remove the lid from the pail and gently stir the contents of the pail with a paint paddle. Do not use a paint mixer or vigorously shake the container. It will entrap air into the product. When mixing PCS Clear Shield in Satin, make sure that none of the flatting agent remains on the bottom of the pail.

Step 2: PCS Clear Shield is best applied with a high quality brush or short bristled paint pad using slow, even strokes. Vigorous brushing will form bubbles in the film and result in a rough surface. The viscosity of PCS Clear Shield allows a thicker coat to be applied than when using Lifeline Acrylic Gloss or Satin. You will still need to backbrush but use smooth, slow strokes.

Step 3: Once the first coat has completely dried, the surface may be sanded smooth using 180 grit or higher sandpaper. If the surface is the slightest bit soft, sanding will generate little pills of finish and make a mess of the surface. Sanding will not be necessary between subsequent coats.

Step 4: Clean brushes and equipment with soap and water.

Maintenance of Interior Surfaces

Maintenance of interior finished surfaces is fairly simple. A once a year cleaning with a one cup per gallon Log Wash solution is all that you’ll need to do. You don’t need to use a lot of water. Just wipe the surface with a rag dampened with the Log Wash solution and then go back over it with a rag and clean water. To avoid any water spots you can wipe the surface again with a dry rag.

We’ve all done it – slapped on a coat of paint, then looked at the fresh paint and the old paint, realizing they’re quite a bit different in color. Panic ensues, until the new paint dries and it blends in perfectly with the old color. This situation can occur with Check Mate 2, which does dry darker in color that when initially applied.

Although the color of Check Mate 2® may be apparent right out of the tube (gray verses brown, for example), the final shade of the color will not be evident until the Check Mate 2 has had a chance to dry. The picture below helps show what happens.

Although the Medium Brown looks light when first applied, after five hours the color matches closely the color of Check Mate 2 Medium Brown that had been allowed to cure several days. This test was done inside at room temperature. Cold temperatures and humid conditions will obviously delay the drying process. But the important fact is that the color of Check Mate 2 will darken as it dries.

Check Mate 2 is our specially-designed sealant for checks, and for the How-To to seal checks, read our Tech Tip here.

Perma-Chink Systems has a full line of wood cleaners designed to clean, restore, and prepare your home for maintenance. We cover the basic cleaning, as well as how to handle known wood issues like resin bleed.