Library

How should I go about making sure that I get started right when it comes to maintenance? How critical is it to begin proper maintenance when the home is new?

Research

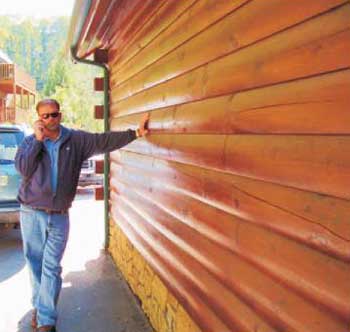

Do your research in finding the right system. We provide a robust library of Tech Tips that provides information you need to take care of your log and timber home. New homes should not have issues, and we recommend homeowners perform inspections of their home to find any small issues and fix those now, before they become big issues.

The Right System

Chose a system of fully compatible log or timber frame home products to protect your home, such as Perma-Chink Systems. When doing your research ask for samples. This allows you to choose the best color combination you prefer. Our products cover all stages of log home finishing from insect and mold prevention to wood cleaners to sealants to finishes. Our “whole-home” approach results in all our products working together in preserving your log home.

The Right Amount

You’ll also need to know how many linear feet will you get out of a pail of the sealant or chinking that you use to order the proper amount. Do you know the square footage of your log home exterior? You’ll need to know that when ordering finish and topcoats. How many square feet of coverage will you get from a gallon of finish? Sometimes the more moderate or even higher priced products are a better value because they go further than the cheaper ones. This is worth considering, as labor rates keep increasing.

Proper Project Prep

Prep is always the number one thing when sealing or staining. Clean logs, proper log texture (not overly smooth), and compatible weather – avoid extremes and rainy weather.

Hiring a Contractor

If you hire a contractor, make sure that they have a solid background, check their references, make sure they are current with their insurance company, and get quotes from more than one contractor. Perma-Chink Systems has a list of Preferred Applicators that know best how to care for your log home. And pro tip – book contractors well in advance, many Preferred Applicators book months in advance.

Log Home Industry Resources

Scroll down to view links to Log Home Manufacturers, Log Siding Suppliers, Log Home Consultants, Log Home Shows and Magazines.

Log Home Manufacturers

Log Siding

Pioneer Log Siding | Wholesale Logs of America |

Trull Forest Products | Trull Forest Products |

Cockburn Island Forest Products |

Log Home Consultants

Randy Fudge Log Home Industry Consultant

Timber Log Design, LLC

www.timberlogdesign.com

Log Building Schools

Log Home Shows

Johnson’s Log & Timber Frame Show

Log Home Magazines

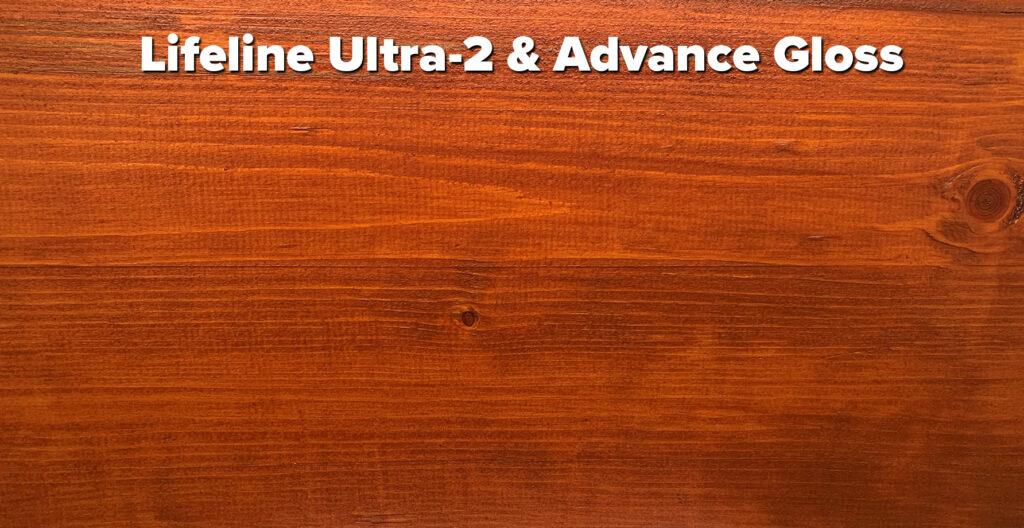

Which Is the Best Log Home Topcoat

Often we get asked which performs better: Advance Gloss or Advance Satin? Overall, both topcoats protect the finish and your log home exceptionally well. While it mainly comes down to personal preference on which log home topcoat you choose, as the manufacturer of the topcoat, we’ve learned some things that can tip the scales if you’re undecided on which topcoat to select for your log or timber home. So the quick answer is we recommend Advance Gloss.

Reflectivity

When it comes to performance and longevity there is no doubt about it- a gloss topcoat will outperform a satin topcoat. Why? The most important factor is reflectivity. A smooth, glossy surface reflects more ultraviolet (UV) light than a less reflective one, like a Satin, or worse, a dull one. This is why a vast number of automotive finishes don’t come in satin versions, and why a shiny coat of wax helps retain a vehicle’s color.

Cleanliness

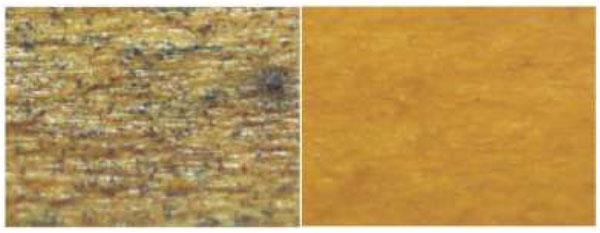

The next factor is cleanliness. The smooth, slick surface provided by Advance Gloss sheds dirt easier than the Satin. That’s because the flatting agent used in Satin results in microscopic roughness in the surface of the finish where airborne dust, pollen and pollutants can lodge. Although particulates can be removed with a good washing, it takes a bit more effort with the Satin finish than removing dirt from the Gloss surface.

Bee Deterrent

The last factor, at least in the Southeast, relates to how Advance Gloss reduces carpenter bee damage. A few years ago we did a survey of customers who used both our satin and gloss topcoats and the results clearly revealed that the gloss topcoat substantially reduced the number of carpenter bee holes. Although there was some reduction in carpenter bee activity using Advance Satin, it was not nearly as significant as the Gloss. Carpenter bees are searching for a wood space to create a chamber to lay their eggs. If this wood surface is coated and that coating is reflective, it creates a mechanical deterrent for carpenter activity.

Order Samples To Test

Whenever requesting exterior finish samples, include a sample of Advance Gloss and Advance Satin, even if you are only interested in one topcoat. By applying both on your wood, you will be able to see the difference for yourself. You may end up choosing the other topcoat because of the way it looks and how it highlights the color of the stain. Although there are other gloss topcoats on the market, none that we have tested retained their level of gloss for more than a few months. Advance Gloss, on the other hand, has been on homes and walls since 2003, and they continue to retain most of their initial gloss.

Just as clear coats are vital to the performance of today’s automotive finishes, our Lifeline Advance™ topcoats are an integral part of all exterior finish systems. Not only do they extend the life of the color coats, but they do much more to protect your log home.

The Benefits of Lifeline Advance

Advance Topcoat significantly improves the look of the finish by enhancing the color, clarity, and depth of the finish. In other words, they make our finishes the most beautiful log home finishes in the world. Second, they help keep the surface clean. The very nature of a pigmented stain makes it susceptible to dirt pick-up through adhesion or impregnation. Since we have designed Advance to form a smooth, strong film, it makes it much more resistant to dirt accumulation. In addition, the smooth surface makes it easy to clean off any dust or pollen that may accumulate on the surface of the logs. A simple application with Log Wash™ and a rinse with a garden hose will remove the dirt and grime that may be hiding the beauty of your home.

Another feature a smooth topcoat provides is greater mechanical resistance to the growth of mold, mildew, and algae. In addition to water, these organisms need something to grip onto. If the spores land on a tough, smooth surface that rapidly sheds water, they won’t have an opportunity to germinate and spread. The surface of your logs stays free of unsightly mold spots and patches of algae.

Of course, the best feature of Advance Topcoat is the protection it provides to the color-containing stain. Years ago, cars left the manufacturer with a coat of paint. More expensive cars may have had several coats of paint, but no matter how many coats were applied, after a few years on the road the paint turned dull and started to flake off. Then car coating experts discovered the benefits imparted by clear topcoats.

Today’s car finishes remain shiny and last longer than ever thought possible, all due to the application of clear topcoats.

How Advance Contributes to Stain Performance Improvement

What is there about topcoats that contributes to this performance improvement? The most performance-enhancing feature of a clear topcoat is that it reflects sunlight. Sunlight is composed of several components, including ultraviolet (UV) light. It’s the UV that is responsible for fading colors and, in the case of wood homes, damaging wood fibers through a process called photo-oxidation. The more UV light that’s reflected off the surface, the slower the color coats will fade. Wood fibers will be also be exposed to less photo-oxidation, thus extending the life of the entire finish system.

Although satin finishes reflect a significant amount of sunlight, gloss topcoats reflect more, which is why car finishes are shiny and not dull. The same holds true for our Lifeline™ exterior finish systems. Because Advance Gloss reflects more sunlight over Advance Satin is one of the reasons that log home gloss finishes are becoming more popular. Read more about the differences of Advance Gloss and Satin finishes here.

An additional beneficial feature of a clear topcoat is the protection it provides to the color coats against degradation by airborne contaminates like sulfur dioxide, ozone, and particulates. Even natural contaminants like tree pollen and bird droppings can damage or discolor the color coats by chemical reactions, or promote mold growth. Our Advance Topcoats provide a barrier that prevents these negative events from occurring.

These are some of the reasons why Lifeline Advance Topcoats play a key role in the performance of all of our exterior film-forming finish systems.

Order Your Advance Topcoat Today

Contact us at 1-800-548-3554 or your local Perma-Chink Store to place your order during business hours, or order online at Store.PermaChink.com. We’ll be glad to help you choose the right sheen of Advance, too, either gloss or satin. If you want to try each sheen on your logs, order free samples online.

Stains & Finishes Application Guide

Download the full Application Guide for Stains & Finishes here.

Sealants Application Guide

Download the full Application Guide for Sealants here.

Application Surface Temperatures for Perma-Chink System products

Most of our labels list the recommended surface temperature range for the application of the product, but there are always situations when you may need to know a bit more detail about application temperatures in order to schedule or complete a job. This is a high-level recommendation for application temperatures. For more in-depth information, it’s recommended you please read the Application Temperatures article. In some cases, there are steps that can be taken to help cope with extreme hot or cold temperatures. Just remember that we are concerned with surface temperatures, not air temperatures. It is the temperature of the logs that must be considered, not the temperature on the thermometer hanging on the porch.

Lifeline™ Exterior Finishes

- Recommended Range

- All Lifeline stains 40°F – 90°F

- Lifeline Advance 40°F – 90°F

- Log End Seal 40°F – 90°F (not stated on label)

Sealants

Recommended Range

- Perma-Chink® Above 40°F

- Energy Seal™ Above 40°F

- Woodsman™ 40°F – 120°F

- Check Mate 2® 40°F – 90°F (not stated on label)

Finish Removers

Recommended Range

Cleaners & Brighteners

Recommended Range

- Log Wash™ 40°F – 90°F (not stated on label)

- Cedar Wash™ 40°F – 90°F (not stated on label)

- Wood ReNew™ 50°F – 90°F (not stated on label)

- Oxcon™ 50°F – 90°F (not stated on label)

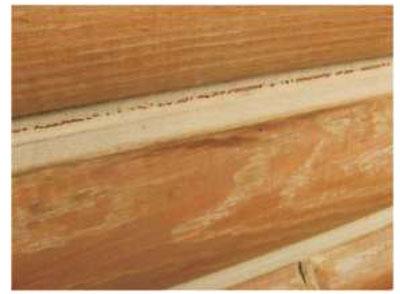

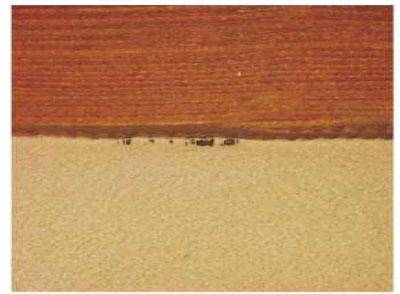

How Do Rips and Tears Happen?

Occasionally rips and tears form in log home chinking, especially in new homes that have been constructed with fairly green wood. Most of the time these tears appear on the top edge of the chink joint. That’s because during the tooling process, most people tend to pull product from the top to the bottom of the chink joint, which results in a thinner than recommended layer of chinking along the top edge. In addition, people forget to “push” the chinking up against the top edge, resulting in inadequate adhesion. When the logs shrink, it puts a strain on the chinking and if it was not properly applied, it can pull away from the wood. So when working Perma-Chink®, it is important to keep pushing the product towards the top of the joint.

Before making any repairs, determine if the chinking was properly applied originally (see our Application Guide here for reference). If you find that the thickness along the top edge is consistently less than 1/8”, you may be faced with constant repairs as it will be better to cut it out and start over again. You won’t be able to apply another layer of Perma-Chink on top of what’s already there to bring it to the proper thickness. If you do, the added layer will probably develop blisters in it.

Our rule of thumb is that if a tear is less than one foot long, it can be repaired. If it is longer than one foot, the chinking should be cut out and replaced. The reason for this is that on long tears, the chinking tends to sag out, and there is no way to hold it in place while the repaired area cures.

Begin with making sure the area that you are repairing is good and clean. You don’t want any dirt to interfere with the adhesion of the chinking. It’s easier to make a repair using a tube of chinking or a bulk loading gun than it is to scoop some out of a pail.

Put a bead of chinking along the tear, making sure that you have good contact with the torn chinking and the wood. Once it’s applied, you can press it into place with a tool or your finger. Now use a small, inexpensive paintbrush with the bristles cut to about 2” long, dip it into some water to get the bristles wet, then work the chinking smooth with the brush. This will help match the texture of the chinking repair with the surrounding cured chinking.

In the cases of older chinking in need of repair, it will be necessary to apply Chink Paint over the repaired area to make the color uniform.

Typically, the Chink Paint painted areas will be cleaner and brighter than the old, existing chinking, so you’ll probably want to Chink Paint all of the chinking to renew the look of your entire home. If you want to change the color of your chinking, this would be a good time to take advantage of Chink Paint.

What Causes Blisters?

There are several causes of blisters forming in uncured chinking. The first is whenever chinking is applied in hot, direct sunlight. The surface quickly skins over, preventing the water vapor from escaping from the underlying material. This problem is usually easy to diagnose, since the blister will start to form in the middle of the product, and if the blister is cut away, you can still see chinking under the blister.

Another common cause of blisters is chinking over unsuitable backing materials. This includes blue board, pink board, and other colored EPS (expanded polystyrene) foam and bare wood. These materials out-gas and as they do, they can form blisters in the soft, uncured chinking.

Only those products recommended by Perma-Chink Systems should be used as backing materials for Perma-Chink Log Home Chinking. Some blisters can be directly attributed to the application process. If the chinking is “trowelled” in by hand, small pockets of air can become entrapped during the process. It is very important to “mash” out the chinking in order to work the air out.

Entrapped air also occurs when you apply very small beads of chinking with a tube or a bulk load gun if the tip cut too small, when compared to the size of the joint. Air can be trapped between the beads when it is smoothed out, leading to blistering.

It’s important to work the chinking, although most people are hesitant to do this as it tends to pull during the process. A light mist of water on the surface of the chinking will help prevent pulling, although some chinking professionals only wet the tool they are using, until they get ready to finalize the finish. It is never necessary to flood the surface of the chinking with water, a very light mist is all that you need.

There is no satisfactory way to repair a blister other than to completely cut out the blistered sections and re-chink the entire joint. If you try to cut out and fill in the blisters, you will end up with visible depressions along the chink joint. Once the blistered section is removed, be sure to check the backing material. If it’s the wrong material, replace it with the correct material; if it is bare wood, cover it with masking tape. If you don’t use the correct backing material, you run the risk of blisters reappearing in the repaired sections.

Read Our Application Guide

Read our Sealants Application Guide to learn the best practices, ensuring a beautiful log home for generations.

Inspection Checklist – Downloadable PDF for print

| Wall A | Wall B | Wall C | Wall D | Wall E | Wall F | |

| Are gutters and downspouts clean and working? | ||||||

| Overall condition of roof and dormers. | ||||||

| Are shrubs and tree limbs away from the roof, walls, and foundation? | ||||||

| Sprinklers not hitting the wall? | ||||||

| Are there signs of finish wear or fading? | ||||||

| Check eaves and fascia. | ||||||

| What about the window and door trim? | ||||||

| Is the foundation in good shape? | ||||||

| Check plumbing and electrical penetrations. | ||||||

| Are crawl space vents clear and working properly? | ||||||

| Are there any signs of leaks around windows? | ||||||

| Are there cracks, tears or adhesion loss in chinking or caulking? | ||||||

| Are there any new checks that may need sealing? | ||||||

| Are there any signs of insect or decay infestations? | ||||||

| Are the exposed log ends showing signs of water penetration? | ||||||

| Does the topcoat still look to be intact or is it becoming dull? | ||||||

| Is the color coat showing signs of fading or darkening? | ||||||

| Have any discolorations appeared under the finish? | ||||||

| Are there any signs of peeling around checks and fissures? |

Click the question to see the answer

What makes Deck Defense™ better than other products?

Deck Defense is a true, penetrating water-borne product without any sort of emulsified oils or alkyds. The product penetrates the wood substrate and the forms lattices to strengthen and support the natural cellulosic fibers for protection from the inside out, not only on the surface.

How about water protection?

We have incorporated ingredients in the formula to serve as a deterrent to water intrusion. One must remember that waxes are sacrificial, and over time the beading on the surface will go away. This does not mean a re-coat is necessary. It is just an indication the waxes have worn away from the surface. The protection for the wood is still in place.

I already have a finish on my deck; does this have to be removed before I can apply the improved Deck Defense?

The old rule of thumb says for the best success with a coating, the best practice is to remove any old finish before applying a new product. However; if you are applying over an older, tired oil-based product, you can apply the new Deck Defense after a thorough cleaning with Wood ReNew™ or Log Wash™. If you have previous Deck Defense, you can also apply the newer product after cleaning. If there has been a film-forming product applied (Vista, Endure or “painted” surfaces), then it will need to be totally removed prior to application of the new Deck Defense.

Is there protection against UV damage in Deck Defense?

Yes, there are UV inhibitors within the product, plus, as transparent iron oxide pigments are also used to produce the desired color, they will enhance the UV protection through sun-blocking properties of the color itself.

Is Deck Defense safe for the user as well as the environment?

The product is considered non-toxic, but as with any product, certain precautions should be observed as they just make good sense. Wear gloves and eye protection when applying the product and avoid inhaling vapors (See precautions on the label). Shrubbery and plants should be rinsed before and after application (or covered). Covering adjacent surfaces like concrete or paver pathways is also a good practice.

Pre-Application steps needed?

First and foremost; the surface needs to be clean and dry. New treated wood needs to “season” prior to application. This process will vary with temperature and humidity and actual moisture content of the new wood. On older wood, a thorough cleaning with Wood Renew will help to restore the color of the wood and remove stains and dirt. Make sure to adequately rinse with water and check the pH of the run-off water to make sure all the surfaces have been rinsed well. Ph of run-off water should be around 6.5 to 7.5 (depending on the pH of the water source). Make sure to check fasteners and condition of wood prior to cleaning and replace any decayed or unstable wood.

Do I need to sand the wood first?

In an ideal world, sanding would be best. But most applicators and homeowners do not want to go through the effort or labor expense to do so. Sanding increases the mechanical adhesion of the surface and will also make the substrate color match better. The sanded surface also opens the substrate and promotes better penetration of the product. If a decision is made to sand, we recommend 60-grit or possibly even 40-grit paper. Media blasting may also be used but may be considered overkill unless the entire home is being media blasted. After sanding or blasting, wash with Log Wash, rinse well, and allow for complete drying prior to application.

How do I mix the product?

Prior to applying Deck Defense, mix well. The colorants used in Deck Defense do not settle hard and re-disperse easily. DO NOT USE POWERED MIXING EQUIPMENT, as this action can possibly shear the backbone of the product and cause possible product failures. As with any product, box the pails together if there are different batch numbers.

How do I apply Deck Defense?

Applying Deck Defense is very easy, and many methods or “tools” can be used. On surfaces such as decking or fencing, a low-pressure pump-up sprayer is the most economical. Deck Defense can also be applied with paint pads designed for deck application, or applied with a quality brush. Rollers can also be used, but due to the low viscosity of the product, there will be some excess “splatter” when rolling. An airless sprayer can be used, and we recommend the use of a 511 or 513 tip due to the low viscosity. Apply the product in a “flooding” method to completely cover the surface to allow good penetration.

Deck Defense should be back brushed when applied by a sprayer, or when using a pad, to make sure the product is spread evenly. Work in the same direction using broad strokes to alleviate “pooling” of product and promote even coverage for the best appearance. Do not allow “pooling” on surfaces. On vertical surfaces, work from the bottom up and back brush as you go. Do not apply in the hot sun as this can cause “flash drying” and interfere with the penetration of the product. Application temperatures are 40-90° F, and that is surface temperature, not air temperature. DO NOT APPLY DECK DEFENSE OVER FILM-FORMING FINISHES (Vista, Endure or “painted” surfaces) AS IT NEEDS TO PENETRATE THE SUBSTRATE FOR THE BEST PERFORMANCE.

How many coats are required?

Deck Defense is designed as a one-coat stain, although due to the deep penetrating properties of the product, it may appear lighter than expected. This is especially true on older surfaces that have been exposed for long periods of time. Also, as this is a semi-transparent product that allows the natural grain and texture of the surface to show through, colors may appear blotchy or uneven, and the user may want to apply another coat. If a second coat is to be applied it should be done in a “wet on wet” application, meaning the first coat needs to be wet when the second is to be applied. If a second coat is desired after the initial application has dried, allow one week for the first application to cure completely.

What is the dry time for Deck Defense?

Dry times will vary with application, airflow, temperature and humidity. Under ideal conditions – 60° F, and 50% humidity – Deck Defense will dry to the touch in about 20-30 minutes. Dry does not mean “cured”. Wait 4-6 hours before walking on surface and 24 hours before replacing heavy furniture.

What are the coverage rates for Deck Defense?

Coverage rates will vary considerably, based on type of substrate and methods of application. That’s why most folks buy a bit extra when they repaint, as they don’t want to go back and buy another gallon to finish. On rough sawn wood, like fences that really soak up product, it may be as low as 100-175 sqft per gallon. Older deck surfaces will also tend to soak up lots of product, so figure around 175-250 sqft per gallon. On new wood, expect around 250-300 sqft per gallon. A second coat application will require less product.

Is Deck Defense freeze-thaw stable?

Yes, this product is freeze-thaw stable. It’s not the freezing that could cause issues; it is the number of cycles a product is exposed to that causes damages.

What are the maintenance guidelines?

Good maintenance for decks, as well as other wood surfaces, will prolong the need for re-staining or removal. Deck Defense will not flake or peel when properly applied, so a general cleaning should be done every year with Log Wash. Maintenance requirements will vary with exposure and environmental conditions, and heavy traffic. Expect to see wear in high traffic areas such as steps and traffic patterns first. This does not mean protection is gone, but indicates for appearance purposes that it’s time for a light re-coat.

How do I clean up when I am finished?

If done right after application, tools and equipment are easily cleaned with soap and water. Warm water works best.

Due to the penetrating and adhesion properties of Deck Defense; keep overspray areas wet during application and rinsed promptly when finished. Removal after three hours will be difficult, but after three days it will be almost impossible without the use of strippers or solvents. Dispose of containers in accordance with local, state and federal guidelines (Do not reuse containers).

Perma-Chink Systems recently added another beautiful wood finish option for our customers – Log & Timber Defense™. Unlike our traditional Lifeline wood finishes, Log & Timber Defense penetrates your wood much like an oil coating. Once Log & Timber Defense penetrates the wood surface, it forms a strong lattice network within the wood, reinforcing and strengthening the entire system from the inside out. This mechanism greatly reduces the chances of peeling and flaking by leaving the system breathable to water vapor. Many traditional oil-based finishes can also form a network, but are often so high in solids that they can easily blister and peel. Vapor pressure builds up behind the thick, unbreathable solid film and pushes the film away from the wood. This leads to an unfortunate situation requiring removal of the compromised coating down to bare wood.

Log & Timber Defense Application Guidance

Log & Timber Defense is designed to be applied to bare wood in one or two coats. If it is applied to wood that already has an existing coating, this can prevent it from forming the lattice network inside the wood. Some customers ask: “Can I apply a topcoat such as Lifeline Advance™ to Log & Timber Defense?” We do not recommend application of a topcoat. The reason we do not recommend this is because when a maintenance coat is needed in the future, there will be difficulty with penetration into the wood because the topcoat forms a barrier to penetration leaving a film on surface. This could leave undesirable surface defects as well as an uneven appearance. Furthermore, it could lead to peeling and flaking of the finish.

Texture is another property that distinguishes Log & Timber Defense from our Lifeline Stains. Due to its penetrating nature, Log & Timber Defense leaves the surface with a more naturalistic, rustic beauty. It will appear much flatter in appearance. However, if a slightly different look is desired, a second coat of Log & Timber Defense may be applied, but the appearance will remain relatively flat. The second coat will increase color intensity and provide an increased level of overall protection for the system.

Difference of Lifeline Finishes

In contrast, our traditional Lifeline Stains are breathable film formers. This is to say they form a film directly on the surface of the wood but do not penetrate deeply into the wood. When applied correctly, our Lifeline stains are not likely to peel due to their breathability and excellent adhesion. They are, however, only slightly more likely than Log & Timber Defense to peel due to their film forming nature. In addition, our Lifeline Stains are designed to be applied over our existing topcoat with no problems with adhesion, color development, or film defects. The Lifeline stains will provide a much higher level of gloss development than Log & Timber Defense due to the films being primarily on the surface of the wood, with the added benefit of being able to apply the gloss topcoat to finish the system.

What About Protection From Mold & Mildew?

Both our Lifeline Stains and Log & Timber Defense are formulated with ingredients that inhibit the growth of mold and mildew. Log & Timber Defense is both a stain and sealant in one package. It helps to keep liquid water out, which reduces biological growth that can attack and destroy your wood. In contrast, traditional natural oils such as linseed oil can easily promote growth of mold and mildew.

Finally, both Log & Timber Defense and Lifeline Stains are both waterborne, low in odor, have easy soap and water cleanup, and are non-flammable. Each of our stains and finishes offer unique properties designed to give your home the very best protection possible.

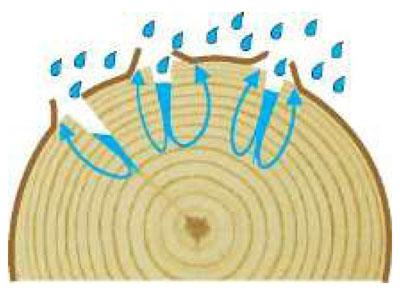

Why is it so Critical to Seal Exposed Ends of Log Homes?

Wood is a hygroscopic material, which means it naturally absorbs and releases moisture from the environment. Logs can safely absorb large quantities of water before reaching moisture content levels that will be inviting for decay fungi.

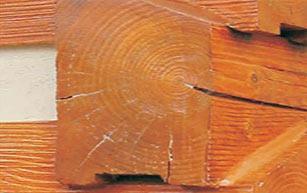

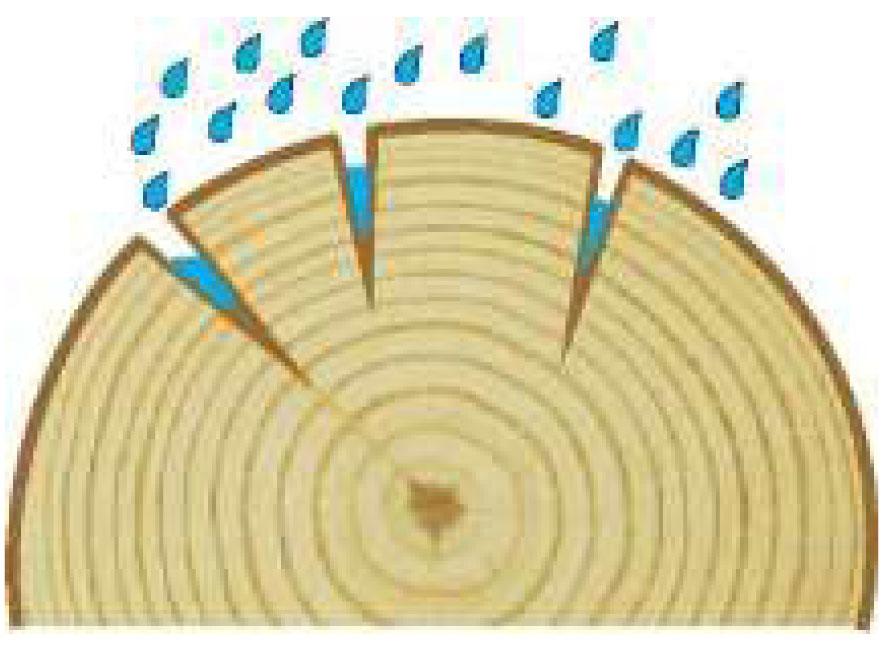

Some of the most vulnerable areas of a log home are the corner log ends. This is because the cross-section end grain is exposed and the ends often stick out beyond the walls allowing sunlight, wind, rain, snow and ice to wear away the stain and expose bare wood.

The exposed end grain acts like small straws by sucking water into the log, giving rot and decay an opportunity to start eating away the wood. In addition, wood cracks and checks are prone to start at the ends. If left unprotected long enough, log or log corner replacement may eventually be required.

Aware of the susceptibility of log ends to weathering, rot, and decay, we developed Log End Seal, a clear polymer finish that prevents water from penetrating into log ends and provides a layer of protection against log end damage. Although it is a sealer, Log End Seal is designed to allow moisture already in the wood to slowly escape. This helps reduce those large checks that often form on log ends.

The first step when applying Log End Seal is to sand the log ends smooth with a belt or orbital sander or sanding disks (available here). Take care not to leave any deep sanding marks or gouges. Most log homes arrive with the log ends sawn off to the proper length. The sawing may leave a rough surface and when stained the log ends typically end up being much darker than the smooth sides. A log end that has been sanded smooth and then stained will be much closer in color to the log walls.

Applying Log End Seal

Once the log ends are sanded and one of our LIFELINE brand stains is applied to the home and allowed to dry, you are ready to put Log End Seal on the exposed ends. Although you can use a short-bristled brush to apply Log End Seal, we found that an applicator pad works best. Be sure to coat the entire face of each log end to avoid any uncoated spots. Wipe off any excess that may have dripped onto the sides of the logs with a damp rag.

Allow the Log End Seal to dry to the touch and finish the job with LIFELINE Advance clear topcoat in gloss or satin.

Drying and Curing Time

Once Log End Seal dries and cures, it may take a while before it loses its milky appearance, especially in checks and fissures. But the end result will be an appealing, clear surface that will offer the utmost protection to the ends of your logs.

Download the application steps of Log End Seal here: Log End Seal Tech Tip

Deck handrails present a real challenge to film forming finishes, especially if they are new. Here’s why. Round log handrails are typically fabricated using green wood. Once in place and begin to dry, handrails shrink, crack, and develop fissures to relieve the stress due to shrinkage. There is no way to prevent this from occurring. If a finish is applied before these fissures open up, and once they do open, they provide a path for water to soak into the rail behind the finish. When the sun comes out and the rail heats up, the water turns into water vapor which may exert enough pressure to actually push the finish right off the wood. In winter months, the water in the wood will freeze and expand and that, too, can pop the finish off the surface.

Another problem with green handrails is that all finishes have difficulty adhering to damp surfaces. Green logs normally do not present the same difficulties as handrails since it usually takes several months for logs to go from the debarking process to construction, time enough for the surfaces to dry. In the case of handrails, it may only be a week or two from the time they are debarked to when they are installed, not enough time for even the surfaces to dry.

A third problem with new handrails is that they are frequently quite smooth. They are typically hand peeled with a drawknife and may still have cambium residue remaining on the surface. Finishes have a difficult time adhering to cambium, and even if they do, eventually the cambium will dry up and peel off, taking the finish along with it. Trying to sand this cambium off while the wood is still damp is almost impossible, since the cambium and damp wood fibers quickly blind sandpaper or sanding pads making them ineffective.

Starting Point

So, what do we suggest to assure adhesion of a finish to new handrails? The first thing is to wait until the handrails have reached a moisture content of less than 20% before doing anything. This may take two months or six months depending on how green they are and the diameter of the rails. By then most of the cracks and fissures will have opened up and any remaining cambium will have dried up and peeled off. The problem with this is that some people moving into a new home are not willing to wait to finish their handrails. If that’s the case, the best course of action is to sand the handrails with 60 to 80 grit sandpaper as best you can, wash them down with Log Wash™, let them dry and then apply only one coat of any Deck Defense.

It will be best to apply Deck Defense to posts, spindles, balusters and other vertical components of the deck as well for color and coating consistency. Once the handrails have had a chance to dry, the application of a second coat of Deck Defense will seal any cracks and fissures that may have opened up preventing water penetration into the wood.

If you have elected to allow the handrails time to dry before staining, during the waiting period there’s a good chance that some surface graying will have occurred, so a light sanding with 60 to 80 grit sandpaper, nothing finer, as well as a wash-down with Log Wash is recommended before the application of one or two coats of Deck Defense. Be sure to get some stain into all cracks and fissures and again, no topcoat should ever be applied to horizontal handrails or over Deck Defense.

Discolorations

Like logs, handrails are subject to the same types of discolorations due to mold, tannins and water stains. The bottom sockets are especially susceptible to water infiltration and the resulting water stains. There are two ways to prevent this: drill a hole through the bottom of the socket before installation to allow water to drain out of the socket, or seal around the tenon with Energy Seal™ after installation. Just make sure the socket is dry before sealing it.

Discolorations on handrails due to mold, grayed wood, and tannins can be handled exactly the same as on logs. Always start off with a pressure washing with a Log Wash solution (2 cups per gallon of clean water) and then continue on with Wood Renew™ or Oxcon™ as needed. If you decide to sand the rails, just be sure to use 60 to 80 grit sandpaper and wash the sanded surfaces with a Log Wash solution before applying the first coat of finish.

Maintenance

Since the top rail takes the most beating from the sun, wind, and rain, it will probably need some maintenance every year or two. One thing to look for is any large checks that open up. If the width of a split or check exceeds 1/4 inch, it should be sealed with Check Mate 2®. That will help prevent large amounts of water from getting into the rail. There is not much you can do about small checks and fissures other than making sure to get some finish into them whenever you are applying a coat of Deck Defense.

Repair

Your handrails and railings have suffered and now you have some rot in the railings. Now what? Before you replace the entire railing, you might be able to salvage what’s left of the wood and repair it with E-Wood paste. To save the rails, remove any loose or decayed wood, and brush away any debris. For best results, apply borate wood preservatives to stop rot. Allow to dry and apply M-Balm, a wood consolidator that helps harden damaged wood. Then apply E-Wood paste to replace the damaged wood, shaping it to match the natural contour of the wood. Allow the E-Wood to cure before applying a stain, which will result in a natural-looking repair.

For more information on how to use E-Wood and M-Balm, read our Tech Tip here.

Over the past several years we have discovered many things about cleaning wood and existing finishes. First and most importantly is that chlorine bleach is not the best product to use. In addition to its potential for damaging the finish and bare wood fibers, its use and misuse contribute to specific problems including the loss of film adhesion, discolorations due to tannin extraction, streaks, blotches, and premature failures of the finish system. We have also discovered that many wood and deck cleaners available at paint and hardware stores, home improvement centers and Do-It-Yourself outlets contain components that interfere with the proper performance of our finish systems.

Therefore, we have decided that the only cleaning products approved for use with our finishes are those products supplied or recommended by Perma-Chink Systems, Inc. We are not doing this to increase our sales of cleaning products. It is because we have tested our cleaning products with our finish systems and have confidence that when properly used and applied, their use will result in the best possible appearance and performance of the final LIFELINE finish. We can not say the same about the use of other types and brands of wood cleaners, and strongly discourage their use with any of our LIFELINE stains.

Guidelines for Cleaning Bare Wood Prior to Applying Lifeline Stains

New Log Homes

1. If the wood has not grayed, wash the surface with a two (2) cups per gallon Log Wash™ solution and a pressure washer no more than seven (7) days prior to staining. Smooth log siding should be washed using Wood ReNew™. Rinse well and allow the wood to dry.

2. If you are finishing Western Red Cedar, Redwood, Walnut, or Mahogany, use Cedar Wash™, a ready-to-use cleaner, instead of Log Wash for better surface preparation and finish longevity on these specific wood substrates.

3. If there are signs of grayed wood, use Wood ReNew according to the label along with a pressure washer. Rinse well and allow wood surfaces to dry before staining. If more than seven (7) days pass before the home is ready for staining, wash the surface with a two (2) cups per gallon of water Log Wash solution, rinse well with a garden hose, and allow wood surface to dry.

4. If, after steps one or two, there are still dark streaks or discolorations on the surface, use a solution of OxCon™, which contains oxalic acid, on the entire wall according to the directions for use. Rinse well and allow the wood to dry before staining.

Older Log Homes That Have Had a Previous Finish Removed

1. If there are no signs of gray surface wood, wash the surface with a two (2) cups per gallon Log Wash solution no more than seven (7) days prior to staining. Rinse well and allow the wood to dry.

2. If you are finishing Western Red Cedar, Redwood, Walnut, or Mahogany, use Cedar Wash, a ready-to-use cleaner, instead of Log Wash for better surface preparation and finish longevity on these specific wood substrates.

3. If there are areas where grayed wood is still evident or if the wood has darkened after the finish was removed, use Wood ReNew according to the label along with a pressure washer. Rinse well and allow the wood to dry before staining. If the wood has darkened or more than seven days has passed before the home is ready for staining, wash the surface with a two (2) cups per gallon of water Log Wash solution, rinse well with a garden hose, and allow the wood surface dry.

4. If, after steps #1 or #2, there are still dark streaks or discolorations on the surface, use OxCon, an aqueous oxalic acid solution, on the entire wall according to the directions for use. Rinse well and allow the wood to dry before staining.

Log Homes with an Existing Finish That is Still in Good Condition

1. If a maintenance coat of Lifeline stain or topcoat is going to be applied over an existing Lifeline finish, wash the coating surface with a two (2) cups per gallon Log Wash solution no more than seven (7) days prior to staining. Pressure washing is not recommended. Rinse well and allow the wood to dry. For maintenance cleaning of finished surfaces that are not going to be stained or top-coated, use a one (1) cup per gallon Log Wash solution.

A NOTE ABOUT RINSING

No matter what product you use to clean bare wood, nothing is more important than making sure you have adequately rinsed the surface. Any chemical residue remaining on the surface can have serious consequences later on. We always recommend using pH Strips to make sure that the surface of the wood has been sufficiently rinsed. A pH between 6.5 and 7.5 indicates the surface has been properly rinsed. pH Strips are available at most pool supply dealers, aquarium supply shops and Perma-Chink Systems, Inc. They are not expensive, are very easy to use and a great tool to ensure adequate rinsing.