Blog

Deck Defense Deck Stain for Decks, Railings, and Fencing

Deck Defense™ deck stain was designed for better performance, longer life and easier application. We removed the oils and hazardous driers to produce a friendlier product. Although it is a totally waterborne product, it has the penetrating properties like oil. Unlike oil, Deck Defense hardens into a lattice, supporting and strengthening the natural cellulosic fibers to protect from the inside out, not just on the surface.

Additionally, powerful additives to Deck Defense inhibit the growth of mold, mildew and algae within the cured film. We also have incorporated a bit of wax to help repel surface water. Homeowners can feel secure in the knowledge that their investment is protected from the damaging effects of wind, sun and water.

Deck Defense is easily applied to dry surfaces with a pump-up sprayer, roller, brushes, pads or an airless sprayer. Designed for a one coat application, an additional coat may be applied using a “wet on wet” method in order to achieve a deeper and richer color. Wet product should be back-brushed to eliminate splotchy areas and reduce the chances of lap marks and eliminate pooling of product.

Normal maintenance has also been made easier as there will be no need to strip off the product prior to re-application, as it will not flake or peel when properly applied. Just clean the surface to remove any dirt or dried materials, allow drying before applying your maintenance coat. Clean up with soap and water before the product dries on application equipment.

Deck Defense is available in seven colors to match our most popular colors, but we’ve now added the ability to order custom colors! If you have a particular color in mind for your deck, contact your local Perma-Chink Systems store to discuss our custom color option.

Choose Deck Defense for your home’s deck, railings, and fencing and receive these benefits:

- Excellent weather resistance

- Excellent color retention

- Allows texture and grain to show through

- Low odor and VOC

- Contains Trans-Oxide pigments for enhanced UV protection

- Easy application

- Easy soap and water clean-up

- Coverage rate: 175-250 sq. ft. per gallon, depending on substrate condition and application methods

- See label directions for additional information

Click the question to see the answer.

What makes Deck Defense better than other products?

Deck Defense is a true, penetrating water-borne product without any sort of emulsified oils or alkyds. The product penetrates the wood substrate and forms lattices to strengthen and support the natural cellulosic fibers for protection from the inside out, not only on the surface.

How about water protection?

We have incorporated ingredients in the formula to serve as a deterrent to water intrusion. One must remember that waxes are sacrificial, and the beading on the surface will go away over time. This does not mean a re-coat is necessary. It is just an indication the waxes have worn away from the surface. The protection for the wood is still in place.

I already have a finish on my deck; does this have to be removed before I can apply the improved Deck Defense?

The old rule of thumb says for the best success with a coating, the best practice is to remove any old finish before applying a new product. However, if you are applying over an older, tired oil-based product, you can apply the new Deck Defense after a thorough cleaning with Wood ReNew™ or Log Wash™. If you have previously applied Deck Defense, you can also apply the newer product after cleaning. If there has been a film-forming product applied (Vista, Endure, or “painted” surfaces), then it will need to be removed prior to the application of the new Deck Defense.

Is there protection against UV damage in Deck Defense?

Yes, there are UV inhibitors within the product, plus, as transparent iron oxide pigments are also used to produce the desired color, they will enhance the UV protection through the sun-blocking properties of the color itself.

Is Deck Defense safe for the user as well as the environment?

The product is considered non-toxic, but as with any product, certain precautions should be observed as they just make good sense. Wear gloves and eye protection when applying the product and avoid inhaling vapors (See precautions on the label). Shrubbery and plants should be rinsed before and after application (or covered). Covering adjacent surfaces like concrete or paver pathways is also a good practice.

Pre-Application steps needed?

First and foremost; the surface needs to be clean and dry. New treated wood needs to “season” before application. This process will vary with temperature and humidity and the actual moisture content of the new wood. On older wood, a thorough cleaning with Wood Renew will help to restore the color of the wood and remove stains and dirt. Make sure to adequately rinse with water and check the pH of the run-off water to make sure all the surfaces have been rinsed well. Ph of run-off water should be around 6.5 to 7.5 (depending on the pH of the water source). Make sure to check the fasteners and condition of the wood prior to cleaning, replacing any decayed or unstable wood.

Do I need to sand the wood first?

In an ideal world, sanding would be best. But most applicators and homeowners do not want to go through the effort or labor expense to do so. Sanding increases the mechanical adhesion of the surface and will also make the substrate color match better. The sanded surface also opens the substrate and promotes better penetration of the product. If a decision is made to sand, we recommend 60-grit or possibly even 40-grit paper. Media blasting may also be used but may be considered overkill unless the entire home is being media blasted. After sanding or blasting, wash with Log Wash, rinse well, and allow for complete drying prior to application.

How do I mix the product?

Before applying Deck Defense, mix well. The colorants used in Deck Defense do not settle hard and re-disperse easily. DO NOT USE POWERED MIXING EQUIPMENT, as this action can possibly shear the backbone of the product and cause product failures. As with any product, box the pails together if there are different batch numbers.

How do I apply Deck Defense?

Applying Deck Defense is very easy, and many methods or “tools” can be used. On surfaces such as decking or fencing, a low-pressure pump-up sprayer is the most economical. Deck Defense can also be applied with paint pads designed for deck application or with a quality brush. Rollers can also be used, but due to the low viscosity of the product, there will be some excess “splatter” when rolling. An airless sprayer can be used, and we recommend the use of a 511 or 513 tip due to the low viscosity. Apply the product in a “flooding” method to completely cover the surface to allow good penetration.

Deck Defense should be back brushed when applied by a sprayer, or when using a pad, to make sure the product is spread evenly. Work in the same direction using broad strokes to alleviate “pooling” of product, promoting even coverage for the best appearance. Do not allow “pooling” on surfaces. Work from the bottom up and back brush on vertical surfaces as you go. Do not apply in the hot sun as this can cause “flash drying” and interfere with the penetration of the product. Application temperatures are 40-90 degrees F, and that is surface temperature, not air temperature. DO NOT APPLY DECK DEFENSE OVER FILM-FORMING FINISHES (Vista, Endure, or “painted” surfaces) AS IT NEEDS TO PENETRATE THE SUBSTRATE FOR THE BEST PERFORMANCE.

How many coats are required?

Deck Defense is designed as a one-coat stain, although due to the deep penetrating properties of the product, it may appear lighter than expected. This is especially true on older surfaces that have been exposed for long periods of time. Also, as this is a semi-transparent product that allows the natural grain and texture of the surface to show through, colors may appear blotchy or uneven, and the user may want to apply another coat. If a second coat is to be applied it should be done in a “wet on wet” application, meaning the first coat needs to be wet when the second is to be applied. If a second coat is desired after the initial application has dried, allow one week for the first application to cure completely.

What is the dry time for Deck Defense?

Dry times will vary with application, airflow, temperature, and humidity. Under ideal conditions – 60 degrees F, and 50% humidity – Deck Defense will dry to the touch in about 20-30 minutes. Dry does not mean “cured”. Wait 4-6 hours before walking on the surface and 24 hours before replacing heavy furniture.

What are the coverage rates for Deck Defense?

Coverage rates will vary considerably, based on the type of substrate and methods of application. That’s why most folks buy a bit extra when they repaint, as they don’t want to go back and buy another gallon to finish. On rough-sawn wood, like fences that soak up product, it may be as low as 100-175 sq. ft. per gallon. Older deck surfaces will also tend to soak up lots of product, so figure around 175-250 sq. ft. per gallon. On new wood, expect around 250-300 sq. ft. per gallon. A second coat application will require less product.

Is Deck Defense freeze-thaw stable?

Yes, this product is freeze-thaw stable. It’s not the freezing that could cause issues; it is the number of cycles a product is exposed to that causes damage.

What are the maintenance guidelines?

Good maintenance for decks, as well as other wood surfaces, will prolong the need for re-staining or removal. Deck Defense will not flake or peel when properly applied, so a general cleaning should be done every year with Log Wash. Maintenance requirements will vary with exposure and environmental conditions, and heavy traffic. Expect to see wear in high-traffic areas such as steps and traffic patterns first. This does not mean protection is gone but indicates for appearance purposes that it’s time for a light re-coat.

How do I clean up when I am finished?

If done right after application, tools and equipment are easily cleaned with soap and water. Warm water works best.

Due to the penetrating and adhesion properties of Deck Defense; keep overspray areas wet during application and rinsed promptly when finished. Removal after three hours will be difficult, but after three days it will be almost impossible without the use of strippers or solvents. Dispose of containers in accordance with local, state, and federal guidelines (Do not reuse containers).

Being green isn’t being the color green – although we make a family of bold colors like this green finish in the picture above. Our standard and custom colors aside, being “green” is how our products are produced to be safe for the environment.

We know that in today’s environment being “green” is considered an important factor in the decision process of many of our customers. Being “green” – environmentally friendly – is one reason why log homes are so popular. But what about the finishes used on log homes, can they be “green” as well? The answer depends on the criteria used to define “green.”

For example, there are several manufacturers of oil-based finishes that claim their products are “green” since they contain linseed or soybean oil which are considered renewable resources. What they don’t say is that their products also contain large amounts of petroleum-based solvents and the only way to clean-up these products is to use turpentine or mineral spirits, products that fall under regulated disposal requirements due to their toxicity and high, negative environmental impact.

One standard for being “green” is the amount of volatile organic compounds (VOC) contained in a product. Both state and federal agencies regulate the amount of allowable VOCs contained in coatings, since VOCs have been implicated in both depletion of the ozone layer and global warming. These regulations have had a serious impact on oil-based products forcing manufactures to reduce solvent content by adding fillers and other solids with a subsequent reduction in attractiveness and performance.

All of Perma-Chink Systems’ LIFELINE-brand stains are water-based products that contain no petroleum distillates and comply with all state and federal regulations for contained volatile organic compounds (VOC). Ever since our inception in 1981, we at Perma-Chink Systems, Inc. have always tried to formulate our products to have the least impact on our environment. In addition, we’ve targeted healthy living areas with our specifically-formulated interior finishes by meeting the highest interior air quality standards. Through our testing, we’ve found that solvent or petroleum based finishes don’t perform as well in exposure testing compared to our water-based LIFELINE finishes. In case you doubt testing, here are some real customer testimonials:

I have been very impressed with how well your product has preserved my home for nearly three decades. – Greg D.

Very pleased with Perma-Chink products. They are easy to use and they brightened up our 35-year old cabin with a warmth of color, couldn’t be happier! – Valerie K.

I am a ticketed carpenter and a ticketed log builder. I believe that if you build with wood you must protect it. I believe that Perma-Chink provides you with the best line of products to do so. They are environmentally friendly and if you apply them as they recommend then they will perform as you expect them to. I use only Perma-Chink products and I recommend you do so as well! – Dave B.

Our stains and sealants are recognized by environmental organizations as being truly “green” since they have minimum impact on the ecosystem. And since clean-up requires only soap and water, they do not contribute any toxicants or pollutants to our surroundings.

It’s a sad fact that being “green” has become a meaningless term used by companies’ marketing departments to help promote and sell their products. We are proud to say that our technical staff will continue to produce and develop superior products that do not damage our environment and have no adverse health effects on either the people applying our products or individuals who live in log homes stained or sealed with materials supplied by Perma-Chink Systems, Inc.

In fact, our chemists evaluate all the components that go into our products to ensure they are the safest for our employees, product applicators, the homeowner, and the environment. Our sealants are completely free of petroleum distillates which has improved the sealant’s performance as well as made it safer for people and the environment.

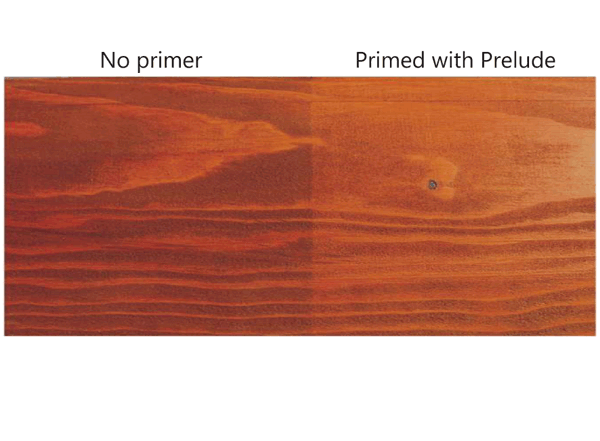

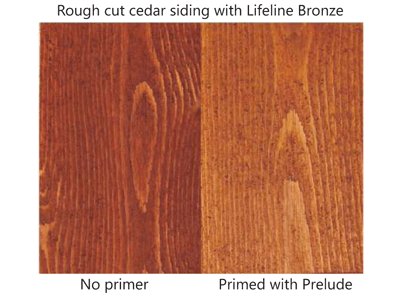

Although paint primers have been used for many years, clear primers for wood are few and far between. Lifeline Prelude™ is the only water-based clear wood primer on the market that’s specifically designed for use on log and timber homes before the application of a water-based stain.

Following are a few situations where we recommend the use of Lifeline Prelude:

1. After a home has been media blasted.

2. If a home is aggressively pressure washed to the point where the surface is feathered and the porosity of the wood varies from area to area.

3. On wood where the surface has been unevenly sanded.

4. On rough cut siding before the application of the color coat(s).

5. If a section of a wall has been repaired or replaced and the new sections don’t match the surface characteristics of the old.

6. Whenever an older log home (more than 80 years old) is going to be restored. Once the surface of old wood is cleaned of grayed wood it typically takes on the porosity characteristics of a blasted surface.

7. Whenever you want to use only clear coats on interior surfaces. Although Lifeline Interior Clear can be used, the use of Lifeline Prelude as the first sealing coat is a somewhat better deal, since it already contains UV Boost. Once the Prelude dries, Acrylic Gloss or Satin or PCS Clear Shield™ Gloss or Matte can be applied over it.

8. Whenever a home is completed but may remain without an exterior finish for many months, a coat of Lifeline Prelude will help prevent surface graying and make it easier to clean when it comes time to stain.

There may be other occasions when a priming coat will make a home more attractive, easier to stain or add to the longevity of the finish system, but it should never be used on smooth surfaced wood to obtain a lighter final color.

Lifeline Prelude should never be used as the final coat. It is a primer and must always be covered with one of our interior or exterior finish systems.

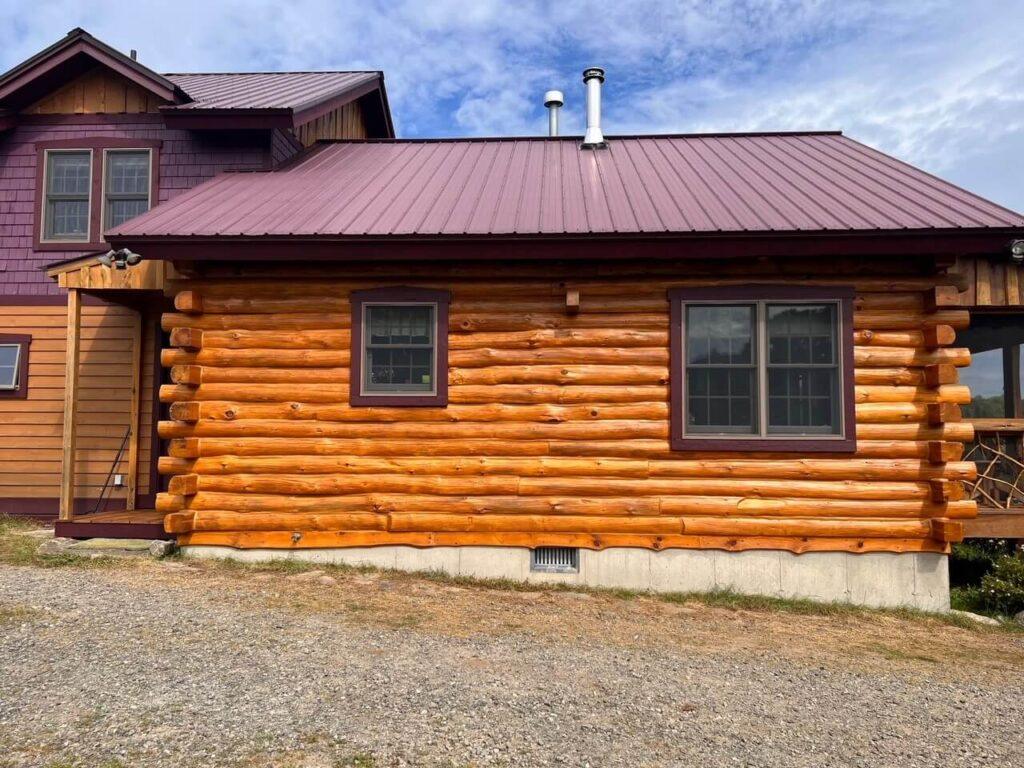

This Custom Luxury Timber Home Is Draped In Perma-Chink Systems Ultra-7 And Advance Satin

This extraordinary custom timber frame home was designed by Jan Donelson with Timberland Design and Hearthstone Homes, in TN. Hearthstone Homes feature an unmatched ability to create any imaginable style of custom, luxury, handcrafted Heavy-Timber or Log-Based Home. Timber framing is a noble type of construction that utilizes exacting variations of mortise-and-tenon type joinery and massive timbers to form the framework of a building. Note Hearthstone’s signature ‘antique weathered’ texturing on the Doug Fir Timbers

Log Home Care crew did the staining and energy seal application in 2018.

Picture Gallery

“Thompson Thrift Construction has been a national residential and commercial builder since 1986 with over 500 employees operating in 21 states. Being asked to complete the interior and exterior stain application on the owner’s personal new build residence was an honor. This client set high standards for every facet of the planning and execution of the build process, including the finish work, and after extensive product testing Perma-Chink Systems LIFELINE Ultra-7 Smoke and LIFELINE Advance Satin were selected for the project. The surfaces were treated with Log Wash, and some areas with Wood ReNew, and the stain/topcoat applied as specified by the manufacturer. The results are stunning.”

Wayne Bell, Owner Log Home Care, www.LogHomeCareOnline.com

For more images of this home visit:https://hearthstonehomes.com/photo_gallery/paris-il-timber-frame/

Most of our labels list the recommended surface temperature range for the application of the product. However, there are situations when you may need to know a bit more detail about the surface temperatures in order to schedule or complete a job. In some cases, there are steps that can be taken to help cope with extreme hot or cold temperatures. Just remember that we are concerned with surface temperatures, not air temperatures. It is the temperature of the logs that must be considered, not the temperature on the thermometer hanging on the porch.

Finish Removers

Recommended Range

StripIt® 55°F – 90°F

S-100™ 50°F – 90°F

Finish removers become less effective as the temperature decreases. It is not that these products can not be used in cold temperatures; however, it may take several more hours of contact time to soften an existing finish to remove it. One positive note about both S-100 and StripIt is that prolonged contact with the surface will not damage the wood fibers.

At high temperatures the challenge is preventing either product from drying. Preventing this can be accomplished by keeping the surface damp. When using S-100 mist the surface with water or if using StripIt add additional StripIt to the coated surface (Note: Do Not mist StripIt with water). Additionally, pressing a sheet of plastic (6 mil) against S-100 or StripIt will slow down the evaporation rate. If S-100 or StripIt dries on the surface, they are no longer active. To remove the dried residue of S-100 or StripIt from the wood surface, apply an additional application of the respective material to re-wet the surface followed by pressure washing. As long as they are kept moist (Water for S-100 and additional material for StripIt) in hot weather, these products do not take very long to do their job.

Cleaners & Brighteners

Recommended Range

Log Wash™ 40°F – 90°F (not stated on label)

Cedar Wash™ 40°F – 90°F (not stated on label)

Wood ReNew™ 50°F – 90°F (not stated on label)

Oxcon™ 50°F – 90°F (not stated on label)

Similar to finish removers, cleaners and brighteners work better at warm temperatures. Of the three products listed above, Log Wash is the least affected by cold temperatures. A wash down with Log Wash even at temperatures close to freezing will still do some good. On the other hand, at very cold temperatures, applications of Wood ReNew and Oxcon may not be very effective. The reason is because they rely on chemical reactions to accomplish their tasks. Reaction rates significantly decrease as the surface temperature approaches 32° F.

If any of these products are allowed to dry, they stop working so in hot weather they too need to be kept wet with an occasional light mist of water. It is especially important to keep Oxcon wet. If Oxcon dries on a wall, crystals will form on the top layer of wood. Once formed they are difficult to rinse off. Even a minor amount of oxalic acid residue can reduce adhesion of a finish.

Lifeline™ Exterior Finishes

Recommended Range

All Lifeline™ stains 40°F – 90°F

Lifeline Advance 40°F – 90°F

Log End Seal™ 40°F – 90°F (not stated on label)

Deck Defense™ 40°F – 90°F

Log & Timber Defense 40°F – 90°F

What happens in early spring and late fall if the temperature falls below freezing a few hours after the finish is applied? As far as we know freezing conditions after film formation has no effect on the look or performance of the finish. The surface temperature limitations pertain to the temperature of the walls while staining, not to temperatures that the walls may be exposed to after film formation.

If a film does not form, applying a second coat can result in failure. Applying a second too soon, will result in the film balling up into little beads during back-brushing. The one thing you never want to do is attempt to stain logs that are frozen. A coherent film will not form and the finish will flake off the wood. At high temperatures drying time is also an issue but in this case, the film may dry so quickly that it will not be able to be back-brushed.

An Advance finish applied at cold temperatures and high humidity presents a somewhat different challenge. The longer it stays uncured, the more susceptible it is to blushing. At high temperatures the fast-drying time may prevent adequate back-brushing.

Although the application surface temperature range on the labels of our finishes is between 40°F and 90°F, the most favorable temperature range for easiest application is between 50°F and 80°F.

The finish most sensitive to cold weather application is Log End Seal. Log End Seal is water sensitive before it completely cures and since cold weather retards the curing time, there is a good chance that the Log End Seal may blush white and stay that way for several months, especially on thicker applications. When the temperature increases, the film will eventually become clear and stay that way. It is recommended to coat Log End Seal with Lifeline Advance Gloss or Satin to protect it from blushing and dirt pick-up.

Sealants

Recommended Range

Perma-Chink® 40° F – 90°F

Energy Seal™ 40° F – 90°F

Woodsman™ 40° F – 90°F (label states 40° F – 120°F)

Check Mate 2® 40° F – 90°F (not stated on label)

When applying any of our sealants in cold weather there are two main factors to consider, the temperature of the logs and the temperature of the product. Provided the logs are dry and not frozen, any of our sealants can be applied without comprising appearance or performance. The problem associated with very cold sealants is viscosity, their viscosity increases as the temperature decreases. This is especially apparent when trying to squeeze product out of an 11 or 30 oz. tube or when attempting to load a bulk loading gun from a pail of sealant. Cold product is also more difficult to tool. It is always best to store our sealants in a controlled environment (50-70°F). That will make them easier to apply and tool. Once applied the only effect that freezing temperatures have on our sealants is lengthening the time it takes for them to cure. In the summer months it may take Energy Seal or Perma-Chink a few weeks to cure, whereas in the winter it may take a couple of months to completely cure.

No matter the time of year, it is advisable to never apply a sealant in direct sunlight. Even if the day is cool, direct sunlight can cause the surface to skin over before the remaining free water has a chance to evaporate resulting in blisters forming on the surface of the sealant. In very hot weather blistering can occur if the sun rapidly heats the wall after chinking has been applied, especially if the underlying wood is green or damp. Draping the chinked wall with a tarp until the chinking cures will help prevent the formation of blisters. Another challenge using our sealants in very hot weather is that the surface may dry so quickly that tooling time may be reduced to only a few minutes. If masking tape was used to protect the surrounding outer surfaces, it is imperative to remove the tape before the surface starts to dry. If the tape is left on too long, it will pull off the skinned-over layer of sealant. Although we do not specifically state an upper limit on the Perma-Chink and Energy Seal labels, we discourage either products’ use above 90°F.

Note: The upper limit of the Woodsman™ application temperature range is 120°F on label. That is fine if the Woodsman is to be used between courses of logs, but if it is going to be used as an external sealant like Energy Seal, 90°F should be considered the upper temperature limit.

The Tool Every Contractor/Applicator Should Have

These days there is no reason for any professional to profess ignorance about the surface temperature of a wall prior to the application of any of our products. Infrared thermometers used to be quite expensive but a quick search on Amazon.com resulted in a number of them that cost between $25 and $50. At that price they are affordable to anyone including a homeowner who wants to eliminate the guesswork of determining if a wall is too hot or too cold before applying a finish or sealant. These days there is no reason for any professional to profess ignorance about the surface temperature of a wall prior to the application of any of our products. Infrared thermometers used to be quite expensive, but a quick search on Amazon.com resulted in a number of them that cost between $25 and $50. At that price they are affordable to anyone, including a homeowner who wants to eliminate the guesswork of determining if a wall is too hot or too cold before applying a finish or sealant.

Perma-Chink Systems History Over 40 Years

The Beginning

In 1980 my neighbor told me about building a log home in Eastern Washington. He said that he loved the home and the lifestyle but was disappointed that with the wind constantly blowing and harsh cold winters, there was no real effective way to seal the gaps between the logs. The house leaked air and heat, and wind-driven rain literally came right through the walls.

He tried various caulking materials with little success. Caulking around a bathtub or sink was significantly different from ‘caulking’ literally miles of seams between logs in a log house. After a number of conversations and experiments, it became apparent that there was no readily available product that could seal the gaps, look like authentic chinking, and last more than a few months.

After literally months of trial and error, it became apparent that if we were going to design a material that would be acceptable, we would have to design it ourselves.

Defining a New Industry Standard

The product we were designing was to be a replacement for what was known in the Log Home Industry as chinking – the sealant that historically provided the seal between the logs. A “chink” is a gap – as in Biblical Times, “A chink in his armor’. Therefore, chinking is a material to fill a gap. Throughout the centuries of constructing dwellings out of logs, a number of methods were used to seal in between them. Early builders used pretty much anything they could get their hands on – mud, straw and mud, cow manure, mixtures of cement and mortar, and a method I discovered in Russia that was a particular type of moss that, when pounded into the gap, excreted a compound that delayed wood rot.

During our investigation we determined that in order to be a true solution the sealant must meet most important requirements.

- It had to be textured to look like authentic mortar chinking.

- It had to ‘look like it belonged there’.

- It had to be able to expand and contract in order to follow perpetual log movement.

As logs dry out in the summer, they shrink in diameter – in the winter and rainy months they absorb moisture and swell, increasing in diameter.

- The sealant had to adhere tightly to the logs and form a continuous watertight seal that would not separate from the wood.

- It had to be easy to apply – in some cases, gaps up to 4 and 5 inches, and not slump or wash out.

- And most importantly, it had to LAST for decades.

Common caulking materials were quickly ruled out. Everyone has seen thin caulking beads applied to exterior trim that inevitably separate, peel off, flake, crack, and ultimately fail.

No ‘caulk’ could adhere to the wood well enough, could not be applied to the thickness and height required without slumping and running out of the joint, and all caulks had that smooth, artificial look that frankly, of course, looked like caulk! It’s okay for around the tub or sink, but not for my log home, thank you.

Creating the Industry Standard

So, after months of experimentation and learning a tremendous amount of the chemistry of what are called polymers (the chemical building blocks of literally everything that we commonly call paint, plastic, vinyl, glue, etc.), we designed a unique sealant that met all of the most important requirements.

During the design phase we located an innovative small company south of Seattle that manufactured a synthetic stucco. They had experience and machinery that helped us scale up lab designs to large-scale production. We began selling early product in 1981, and the first house we did was in Sun Valley, Idaho – in the middle of winter.

Soon after we had a saleable product that met every design requirement, I did a little market research and discovered that the larger part of the national market for log homes was in the eastern part of the United States, and in particular, the southeast. I also discovered that of the numerous styles of log homes, the three largest manufactures of ‘Dovetail’ log homes were within 100 miles of Knoxville, Tennessee. I liked the Dovetail design because the nature of the structure, and the way the logs are stacked resulted in a chinking gap of up to 4 inches! In some cases, almost 25% of the wall area was chinking!

So, we set up a manufacturing plant in Knoxville, Tennessee. Timing was right because as soon as log home owners and log home manufacturers discovered that we could finally provide a dramatic solution to one of the most significant and perplexing aspects of a log home – the business grew rapidly.

Winning the Manufacturers

Early adopters such as Hearthstone, Honest Abe, Stone Mill, and Appalachian Log Homes helped pave the way for essentially all others to follow. As a matter of fact, one of the earliest applications for any manufacturer was Appalachian. Turns out they had a contract with the US Forest Service to build an outhouse. The location was remote, and the house needed to be completely assembled and transported via helicopter. Obviously, mortar chinking could not withstand that type of stress, so they tried Perma-Chink. That outhouse is still standing today and is weather tight – some applications simply CANNOT fail!

The development of synthetic chinking solved one of the most serious and vexing aspects of the Log Home Industry. The chinking formulation is unique and not simply ‘caulk with sand in it’ as others have offered.

Rick Denton, Honest Abe Log Homes President Emeritus said, “Perhaps the invention of Perma-Chink kept Honest Abe in business, as well as every other log home company using a chinked product line.” Read his story here https://www.honestabe.com/blog/perma-chink/.

What started out as an idea has revolutionized the entire industry. Worldwide, every log structure uses synthetic chinking, and the largest supplier of the most authentic and highest-performance log home chinking is Perma-Chink.

Expanding the Preservation of Log Homes

The next vexing challenge was with log home stains and finishes. Every log home owner wants a log home that looks like an outdoor piece of furniture. One that blends in with the rustic back to nature look and feel of the surroundings. No one would consider painting a log house. That would be like painting a beautiful hand rubbed antique! Log home owners tend to start down the following path after stains start failing: That beautiful stain we applied only lasted a year or maybe two and after two recoats, we may as well paint it. Why can’t someone develop a stain that looks like a furniture grade finish and LASTS?

We began to have literally thousands of people say, ‘You solved my sealant dilemma – now do you have a solution to the stain and finish dilemma?’ So challenge number two was tackled.

Creating the Best Log Home Stains

We used the knowledge and expertise we developed in formulating Perma-Chink Chinking (remember the polymers?) to design the longest lasting semi- transparent stain in the Industry. The formulation is also unique, provides that ‘furniture grade’ appearance, and outlasts any exterior stain on the market. Also, with a Clear Coat (which Perma-Chink Systems also introduced), when the finish is finally starting to “wear” out, all that is needed is a cleaning and application of an additional clear coat. That eliminates the tint buildup and subsequent hiding of the wood and completely eliminates the phrase ‘After two re-coats, I may just as well paint it.’

I personally require hands-on experience with every product Perma-Chink Systems offers. We are dedicated to providing the best products available for the care and maintenance of Log and Timber Frame Homes. As history has shown, and something we take pride in, is ‘Whenever a log home owner becomes aware of a concern, whether it be sealing, staining, or preservation or maintenance, we already have a solution.’

Take a Look At Total Cost

An interesting story – I recently had a heating problem with my log house in Colorado. The bill to repair the system included a small starting capacitor in one of the air handlers. The bill for the part was $6.25 and the bill for the labor was $220! So why would I try save sixty cents on the capacitor when the cost by far was in the labor to replace it? Same is true with a log home stain. By far the largest cost is in application and labor, so it pays to use the best product available. Cheaper stain is a cheap solution that sets you up for a repeat in a year or two, and in the meantime your exterior looks like crap! Pay the extra sixty cents and buy yourself some peace of mind.

By choosing our high-performance finish like Lifeline™ Ultra-7, you are ensuring that the finish will look as beautiful years after application as it did the second day it was applied thanks to a balanced formula of transparent iron oxides, mildew inhibitors and an advanced polymer resin.

Our Success is From Working With Great Customers, Industry-leading Partners, and Fantastic Employees

I am humbled that Perma-Chink Systems has become a ‘household’ name in the log home industry and is recognized for highest of quality. Our products grace the log houses of such noted Americans as former President Jimmy Carter, clothing designer Ralph Lauren, movie stars Tom Cruise, Olympic champion figure skater Kristi Yamaguchi, Nascar champion Dale Earnhardt (read the story here) and thousands of great American home owners.

I am proud of my company, of my employees and our customers. Beginning with our 40th Anniversary, Perma-Chink Systems’ new slogan is “Simply Unmatched”.

By being engaged in best quality products and the best customer service, we will attain our goals and make great strides towards meeting our customers’ expectations for years to come. We raise a toast to the next 40 years of great products, service, and customers of Perma-Chink Systems.

- The late Rich Dunstan, President Perma-Chink Systems, Inc.

How to Prepare New Construction Log Surfaces for Finishing

New logs may look clean and fresh to you, but it doesn’t mean that they are ready to stain. There is some preparation involved in getting new logs ready for finishing.

Logs that have been exposed to the sun may have slight gray areas on them and dirt, dust and mold spores are probably on most of the logs. It is important to start with a clean, uniform surface before applying a coat of stain, since dirt and discolorations will show through semi-transparent stains and the stain will seal in any blemishes. Cleaning also opens up the pores of the wood, allowing better adhesion of the stain. This is especially true if there is a mill glaze present on the logs. Not only will the mill glaze reduce the stain’s performance, but caulks and chinking will have a difficult time adhering to mill glazed wood.

Aggressive cleaning of a new log or timber home is not required. A light cleaning with Log Wash and a pressure washer will usually remove the dirt and mill glaze, as well as clean the surface to prevent the formation of mold under the stain. If the new logs have started to gray from sitting unprotected in the sun, a percarbonate cleaner like Wood ReNew will restore the wood back to its original color. Log Wash and Wood ReNew are much safer products to use compared to bleach solutions which destroy wood fibers.

The leading cause of stain adhesion failures and discolorations appearing under the semi-transparent stains is inadequate rinsing of a bleach-cleaned surface. Bleach (sodium hypochlorite) solutions are alkaline (high pH). Wood, on the other hand, is slightly acidic (low pH). Whenever low pH materials are exposed to high pH solutions, chemical reactions occur. Often these chemical reactions are minor and do not affect either material, but in the case of wood, exposure to bleach solutions may result in several irreversible reactions that may not become apparent for several months. Once the wood fibers are damaged or destroyed, a stain will not properly adhere to the surface and eventually will chip or peel. Even when used at a low concentration, a bit of bleach residue left of the wood will eventually result in discolorations due to iron tannates coming to the surface under the stain.

Occasionally, steel straps used to bundle the logs during transportation will leave iron stains that need to be removed with OXcon oxalic acid. Whenever oxalic acid is used, be sure to clean the entire wall to avoid blotches and streaks.

We never suggest media blasting new construction, but if that is what your log home manufacturer recommends, be sure to use a fine grit media to avoid damaging the surface of the wood.

Congratulations on your new home and happy cleaning!

How to Use Deck Defense™ and Log & Timber Defense™ Products

Proper treatment and care of your horizontal and vertical structures can add beauty and longevity to your entire living space. To help seal and protect your deck, fences, or railings we recommend using our waterborne finish Deck Defense. For vertical structures such as wood siding, trim, timberframe, beams, and rough-cut cedar we recommend Log & Timber Defense.

Defense products work by penetrating several layers deep into the wood fibers creating a lattice network that strengthen and protect your wood from the inside out. These products are formulatedfor better performance, longer life, easier application, and upkeep. They also will not flake or peel when applied according to labeled instructions.

All structures should have a surface moisture less than 20% before applying a Defense product. High moisture content will hinder the penetration and adhesion of the finish. If constructing a new deck, boards should be placed bark side down. Also, if the boards have a high moisture content, they should be placed in direct contact with one another when laid down. As the boards dry a gap will open for proper airflow and drainage. If you gap them when they are too wet, the gaps between the boards will likely be too large. Having to estimate what the final gap will be, can be avoided if moisture equilibrated kiln dried boards are used. Finally, let the new boards season for several months prior to application of a finish. This will allow time for the wood to shrink completely and come to an equilibrium with its environment.

Wood Preparation

In situations where a Defense product is going to be applied on an established deck, the deck must be free of the existing finish, in addition to being clean and dry. The cleaning solution required depends on the condition of the boards.

Log Wash™ is an excellent wood cleaner to remove dirt, grime, pollen and surface stains from bare wood (use two cups per gallon of water).

Cedar Wash™ is a ready to use cleaner designed specifically for wood with high extractives content such as Southern Pine, Spruce, Douglas Fir and Cyprus wood.

Wood Renew™ is used when the wood surfaces have been damaged. i.e., grayed wood and mill glaze. It will restore the wood back to its natural color. Wood Renew is also the preferred method for preparing deck boards for staining. It is important to follow all labeled instructions when using this product.

Sanding is used to remove surface imperfections. Although labor intensive, sanding helps to increase mechanical adhesion, provides for better color uniformity and aids in opening the substrate to promote better penetration of the stain. 40 – 60 grit sandpaper is recommended for decks. Always sand in the direction of the grain. When finished with the sanding, clean the surface using our Log Wash solution.

Finish Removers are used to remove an existing finish. There are two relatively safe waterborne finish removers designed to soften the finish so that it can be removed mechanically using a pressure washer.

(1) S-100™: Is supplied as a ready to use high pH gel. The gel helps it to remain active for an extended period.

(2) Strip It®: Is supplied as a ready to use pH neutral finish remover. It is designed to remove multiple layers of finish at a time.

We recommend that you obtain samples of each and test both to determine which works best for removing your finish. Follow all labeled instructions.

Rinsing is very important to completely remove the cleaning solution and debris. Use pH strips to test the rinse water run off to make sure the rinse water is between 6.5 – 7.5. Inadequate rinsing will lead to unnecessary problems and shorten the life of the stain. After rinsing allow the surface to completely dry before application of a finish.

Application Guidelines

• Surface Preparation: Must be applied to clean, dry surface.

• Application Weather Consideration: Do not apply if rain is eminent within 6 hours.

• Personal Protective Equipment: Although Defense products are considered non-toxic, gloves are recommended when applying.

• Protect from overspray: Wet down and cover nearby vegetation and adjacent surfaces. Keep these areas wet during application and rinse promptly when finished.

• Mixing: Mix thoroughly initially and every 15 min. to ensure color uniformity. Do not use powered mixing equipment.

• Boxing: We recommend boxing pails together if using different batch numbers. This will help with uniform color.

• Application Methods: Low-pressure pump-up sprayer, Paint Pads (for deck application), quality brush, or roller. Apply in a flooding manner to completely cover the surface of the wood, allowing the product to soak into the wood. Back-brush the finish into the wood using a quality brush.

• Maintain a wet edge: Work in small sections to help maintain a wet edge. This will help prevent lap marks.

• Work in the same direction: When applying the finish apply in the direction of the grain and stop only at natural breaks such as board ends to prevent lap marks.

• Application Surface Temperature: 40 – 90 degrees Fahrenheit:

• Number of Coats: Defense products works great as a one coat stain. However, for color or if the surface appears blotchy, a second coat may be applied. The second coat should be applied wet on wet. If it is not, wait one week before application of a second coat.

• Drying Times: Drying times will vary with application, airflow temperature and humidity. Under ideal conditions Defense Products will dry to the touch in 20-30 minutes. For horizontal surfaces wait 4 – 6 hours before walking on the surface and 24 hours before replacing heavy furniture.

• Coverage Rates: Coverage rates will vary considerably based on the type of substrate and methods of application. A second coat will require much less. Below are some approximations of coverage rates based on the type of wood.

• Rough Sawn Wood: Rough sawn wood such as fences will soak up a large amount of stain. Perhaps as low as 100 – 175 ft2 per gallon

• Older mature decks: 175 – 250 ft2 per gallon

• New Wood: 250 – 300 ft2 per gallon

• Protect from Freezing: Although freeze thaw stable, this will ensure any possibility of degradation.

Clean Up

If cleaned soon after application, tools and equipment are easily cleaned with soap and warm water. Dispose of unused product in accordance with local, state and federal guidelines.

Maintenance

Good maintenance for decks as well as for other wood surfaces will prolong the need for re-staining or removal. Defense products will not flake or peel when properly applied. Clean with log wash when needed. We recommend using one cup concentrated log wash per gallon water. Expect to see more wear in high traffic areas such as steps and traffic patterns. These areas can be recoated easily where needed after cleaning with log wash. We discourage using a clear topcoat over Defense products. A topcoat will prevent any future recoating.

One of the key bits of information for keeping hardwood floors shiny is knowing what type of finish has been applied to the wood. Was your hardwood sealed with a polyurethane or polyacrylic urethane finish, or was it finished with a paste wax? If you don’t know, here’s a test to help you make the best cleaning choices:

- In a spot with normal foot traffic, place a drop of water on the floor. If the water is quickly absorbed or causes spotting on the finish, this indicates the hardwood has not been sealed and should never be cleaned with water. But if the bead of water just sits on the surface without being absorbed, it means the hardwood floor has been sealed.

- To test for a paste wax finish, grab some fine steel wool and rub it lightly over the floor in a corner. If the floor has been waxed, there will be a gray, waxy film left on the steel wool.

How to Clean Hardwood Floors and Make Them Shine

Unless you have neglected the floors for weeks and have mud and sticky messes everywhere, there is no need to damp mop more than four times per year, suggest experts from The Spruce.

With a lightly dampened microfiber mop, clean in the direction of the wood grain. Never use a sopping-wet mop because too much water can cause floors – even sealed floors – to buckle. For step-by-step instructions, follow these steps from Spruce.

How to Refinish Hardwood Floors?

Up until about 20 years ago, the “Swedish Finish” was the only way to go. Extremely high-performance, it worked well, but as a solvent-based product, it was highly caustic. Certainly not a do-it-yourself project, it required trained professionals and total evacuation for up to a week (including the houseplants!)

Sure Shine offers all that original wearability, durability and beautiful shine, without the toxic fumes and disruption to your life. Instead of solvent-based, it uses a water-based technology that is both environmentally and user-friendly.

If you want a deep, clear finish using fewer coats, Sure Shine premium finish is the one to use!

Sure Shine can be used to re-coat older oil-based floor finishes. Sure Shine cures to a smooth, hard surface that resists scuffing and abrasion. It prevents discolorations from water and most household cleaners and chemicals.

How to Apply Sure Shine Hardwood Floor Finish?

This product shines even brighter from an application standpoint. It’s easy to do yourself, and it dries so quickly (only one hour) you can apply it in one day. Sure Shine never yellows, is non-flammable and there are no fumes, which means there is no reason to suffer the inconvenience of vacating your home. Cleaning up your tools is a simple matter of a little soap and water. And when the work is done, you can walk on your new floor finish in 8 short hours!

More on application of Sure Shine here.

Order your free sample of Sure Shine in Satin or Gloss finish to try on your floor or your walls here.

Although Energy Seal™ and Woodsman™ come in different colors and both may be used for a multitude of purposes, the proper application of these products are quite similar. The main difference between Energy Seal and Woodsman is a matter of surface texture. Energy Seal contains a fine aggregate that gives it texture, whereas Woodsman is a smooth surfaced sealant. The texture of Energy Seal enables it to more closely match the texture of wood and accept a stain, so that it will blend in with the stained wall color if so desired. Although Woodsman is stainable, it will not become as indiscernible as Energy Seal.

Energy Seal and Woodsman are usually recommended for use in joints, seams and gaps that are one inch wide or less. Although they can be used in wider joints, we typically recommend using Perma-Chink Log Home Chinking for wide chink joints. All of the following application directions and conditions are applicable to both Energy Seal and Woodsman but for brevity we will only refer to Energy Seal or the generic term “sealants.”

When should Energy Seal be applied?

The best time to apply Energy Seal is after the home has been cleaned and before the finish is applied. The wood surfaces will be fresh and clean and Energy Seal adheres best to bare wood surfaces. That’s not saying that it won’t adhere to stained and/or top-coated surfaces, but it adheres best to bare wood. Application to surfaces with a freshly applied oil-based stain should be avoided. For the least visible caulk lines, choose a color that’s a shade lighter than the stain color you plan to use. It’s easier to cover a lighter color sealant with a darker color stain than it is to hide a dark colored sealant with a light colored stain. However, if you prefer the look of visible caulk lines, apply Energy Seal after you stain. Just be sure that the surface is clean and dry.

If you are going to be applying Lifeline Advance™ Topcoat, apply the topcoat after the Energy Seal. This results in a more even appearance to the sealed areas and helps them blend in with the rest of the wall. Furthermore, it helps keep the Energy Seal application clean and easier to clean when maintenance cleaning is required.

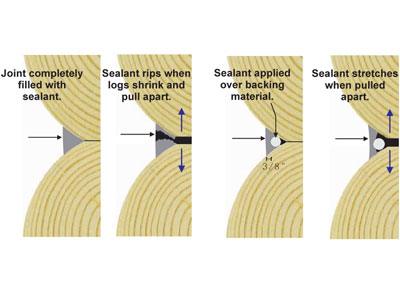

Using Backing Materials

Backing materials furnish an even surface for the application of a sealant and makes it easier to apply a uniform thickness across the joint or gap. They also provide two-point adhesion to ensure maximum elasticity and flexibility after the sealant has cured (they form a bond breaker in the center of the sealant band with adhesion to the wood at both sides). The use of improper or poorly installed backing materials can result in unsightly sealant joints and substandard performance. They are an integral part of the sealant system and should always be used whenever and wherever possible.

There are a number of products specifically designed for use as backing materials for sealants. For smaller gaps, joints, and cracks, the most commonly used material is round Backer Rod. It comes in a range of sizes and is relatively inexpensive. Since it is flexible, it can be pushed into a crevice without needing to be nailed or stapled. Grip Strip is designed for sealing larger gaps. Similar in composition to backer rod, it is shaped like a trapezoid so it can be squeezed in between round logs although it can be used in a variety of situations. It provides a flat surface for chinking or sealing.

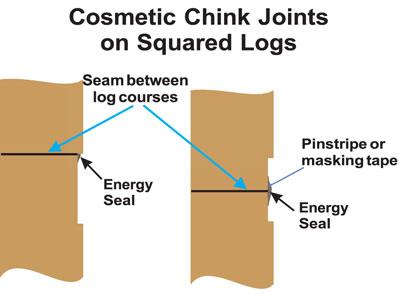

In situations where a joint, seam, or gap is too small to insert Backer Rod, you can hold it in place by applying small dabs of Energy Seal along the seam and then pressing the Backer Rod into them (see picture on previous page). The dabs of Energy Seal will hold the Backer Rod in place while a proper thickness of Energy Seal is applied on top. You can also use a narrow strip of water-resistant masking tape. You don’t want to use masking tape that wrinkles when it gets wet, since the wrinkles may show through the sealant. For extremely narrow seams, an excellent option is to use pinstripe tape; available at most automotive supply stores. The tape is vinyl; therefore, it’s waterproof and since our sealants do not bond to it, it makes an excellent material to use. Pinstripe tape is available in widths down to 1/8”.

Approved Backing Materials

- Log Gap Cap

- Grip Strip

- Backer Rod.

- Expanded polystyrene (EPS) beadboard

- Polyisocyanurate board (Polyiso or R Max)

- Water-resistant masking tape or pinstripe tape

DO NOT USE

- Extruded Polystyrene, XPS (causes blisters)

- Blue Board, Pink Board or any other colored board (outgases and causes blisters)

- Barewood or strips of bare wood (outgases and loss of elasticity, 3-point adhesion)

- Polyurethane foam (PurFill,GreatStuff,etc.)

- Foil Faced Substrates (sealants will adheres well to the foil)

- Anything that you are unsure about, please check with Perma-ChinkSystems before using it

Round Logs

When deciding the width of a sealant joint between round logs, a good guideline to follow is for the width of the sealant to be one-sixth the log diameter. For example, with six-inch diameter logs 6” ÷ 6 = 1.0” wide sealant joint. The width of the backing material you require depends on the profile of your logs but you need to take into account that you will be applying a 3/8” thick layer of sealant over it and you’ll need at least 1/4” top and bottom for adequate adhesion to the wood.

Squared Logs

We rarely see squared log chink joints less than 2” wide, so Energy Seal or Woodsman is seldom used in these situations. However, for cosmetic chink joints less than 3/8″ deep, we recommend sealing the seam with Energy Seal and then applying Chink Paint over the entire joint. On the other hand, Energy Seal is often used on squared logs for sealing corners, butt joints, widows, door frames and other areas where a visible chink joint is not desired.

Applying Energy Seal or Woodsman

The overall performance of any sealant system is dependent on the use of proper application methods. Any sealant must be applied in a manner that will allow it to stretch in order to compensate for log movement. If it is applied too thick, once it cures it won’t be able to stretch enough to compensate for the movement and it may tear away from the wood. Think of it like a rubber band. A thick rubber band will not stretch as far as a thin one. However if the rubber band is too thin, it will break when it is stretched. The same thing applies to sealants. If applied too thick, they can’t stretch and if too thin they may be weak and will tear when pulled apart. In the case of our sealants, the magic number is an applied wet thickness of 3/8”. When cured, this results in the best elongation with maximum strength.

Have the Proper Tools

Before you start have all of the tools that you will need at hand and be sure that they are clean and in good working order. These may include:

- Caulk gun or bulk loading gun

- Rags

- Trowels and/or spatulas

- Plant mister with water

- Masking tape

Weather Conditions

Freshly applied sealants should be protected from direct rainfall for a minimum of 24 hours. Either watch the weather or drape a newly sealed wall with plastic film. Be sure to allow some airspace between the wall and the plastic to facilitate drying. Avoid applying sealants in direct sunlight or when the temperature is less than 40°F. In cold weather it’s important that the logs be free of frost and dew in order to ensure that the sealant adheres tightly to the wood. The best surface temperature range for easiest application and best results is between 50°F and 80°F.

Application

Cut the applicator, or tube tip, to the desired diameter of the sealant bead you want to apply.

Step 1: Begin by holding the tip firmly against the seam or joint and apply a bead of sealant. You need to apply enough sealant to maintain a wet thickness of at least 5/16” and no more than ½” (target = 3/8”) across the entire seam or joint after tooling. Only apply as much sealant as you can tool smooth in about 15 minutes.

Step 2: Once the joint is filled trowel it out to approximately 3/8th of an inch thick across the entire joint. Do not spray it with water at this time! Make sure there is good contact between the sealant and the exposed edges of the wood. The most difficult areas to tool are corners. You tend to drag product out of the corners resulting in the sealant becoming too thin. You can occasionally check the thickness of the sealant using a toothpick to see if you are maintaining the proper thickness.

Step 3: Once the sealant is roughly in place and any entrapped air worked out of it, spray it with a light mist of water. Do not saturate the surface with water. If water begins to run down the wall, you have applied too much.

Step 4: Tool the surface smooth with a trowel or spatula. If you used masking tape to protect the surrounding wood, be sure to remove it as soon as you are finished tooling and make sure that you have not left any lip on the top edge of the sealant that may catch water. If you have, tool it smooth.

Clean-Up

If you get any sealant on the surface of the wood, be sure to wipe it off with a wet rag as soon as possible. If you allow it to dry, it will be just about impossible to completely remove. Make sure to clean your tools and equipment with clean water occasionally during application. Dried sealant is difficult to remove from just about anything – including clothes.

Drying and Curing

Drying time and curing time are two entirely different terms. In warm or hot weather, Energy Seal and Woodsman may begin to skin over in as little as ten minutes, while a complete cure may take a couple of weeks. Cooler temperatures will slow both the drying time and curing process.

Sealing Window & Door Frames

A lot of wasted energy is released through poor sealing of windows and doors. Luckily we at Perma-Chink Systems have a solution to solve these air leaks. Energy Seal and Log Gap Cap work together to seal the windows and doors.

How to Seal Windows & Door Frames Step-by-Step:

1. Use masking tape around the window or door seam.

2. Insert Log Gap Cap into the crevice using trowel. Log Gap Cap provides an even surface for sealant application and makes it easier to apply a uniform thickness across the gap.

3. Apply Energy Seal™ and tool smooth.

4. Remove masking tape as soon as tooling is complete.

Projects can be daunting if you have limited or no experience. You gain experience by doing, and getting expert advice when you need, whether it’s before the project, during, or after. Our customer service exists to help all log home owners get the best results using the best products for their log or timber home.

One recent homeowner project done by our customer Beth H. required removing the old finish and sealant, then restoring the home with Lifeline Ultra-2 Natural and Energy Seal in Cedar. Lifeline Advance Gloss topcoat encapsulated the wood, ensuring a long-lasting finish and great look.

| Products Used | |

| Log Wash | Log gap caps |

| Prelude | 1/4″, 3/8″, and 1/2″ backer rod |

| Lifeline Ultra-2 – Natural | Lifeline Advance Gloss |

| Energy Seal – Cedar |

With DIY-friendly products, anyone can tackle a home project and have fantastic looking results like this. In addition to our excellent customer service available to all customers, we have a library of Tech Tips for in-depth information on maintaining your log home.

Take a look at these pictures from Beth, showing the home before and after.

Take note of the proper use of Log Gap Caps and Energy Seal. We get a lot of questions about the best method to seal around windows and doors. We have a quick reference Tech Tips article here, but here are some pictures to illustrate how they work.

Lifeline Interior™ is a natural looking, transparent wood finish. It forms a breathable, protective layer for your walls and ceilings while highlighting the beauty and grain of the wood. Our unique breathable formula allows natural wood moisture to escape from the wood, yet provides a tough film surface that can easily be cleaned and dusted, especially when top coated with our Lifeline Acrylic Gloss or Satin clear finish.

If you use one of our Lifeline Interior color stains, the colorants in the finish help stabilize color of the wood and slow down, or even prevent, the fading that you may notice when removing pictures or furniture from against the wall. If using Lifeline Interior Clear, we recommend the addition of UV Boost to the first coat to help prevent this “picture frame” effect due to UV light exposure. The addition of UV Boost should also be considered when using lightly tinted stains like Light Honey and Light Natural. Since interior surfaces are not subjected to the adverse effects of weather, two coats of Lifeline Interior are not necessary. However, you can apply multiple coats of Lifeline Interior in order to achieve the appearance you desire.

Lifeline Interior is easy to apply. It can be applied by brush, spray or pad. Lifeline Interior dries to the touch in as little as one hour and clean-up is easy- just use soap and water.

One of the best reasons to use Lifeline Interior is that it reduces the absorption of pet, fireplace, and cooking odors into the wood of the home.

Lifeline Interior resists yellowing and is non-flammable and virtually odorless. Like all of our premium finishes, it allows the natural look and beauty of all species of wood to come through. Lifeline Interior can be used on new or existing log homes, as long as the surfaces are clean and dry.

Now you can order Lifeline Interior in any color you desire in addition to our 13 standard colors plus Clear. For a custom color or color matching, please call 1-800-548-3554. You can request wet samples to try on your logs by calling 1-800-548-3554 or by visiting our online store.