Blog

Step 2 – Schedule Interviews

Perma-Chink Systems maintains current contact information, insurance and license information for all contractors on the referral list. Obviously, you’ll want to interview the contractors to determine their reliability, reputation, and experience, as well as their procedures that best meet your individual needs.

So here are the top 4 Key Questions you should ask each contractor candidate:

1. Does the contractor carry insurance?

A contractor should carry comprehensive liability insurance and workers’ compensation insurance to protect you in the event of a job accident. Ask for proof of general liability and workers’ compensation coverage for the type of project.

2. Is the contractor licensed?

Ask if the contractor is licensed by your state and/or city. Not all states or cities require contractors to be licensed.

3. Will the contractor provide references from previous jobs?

Most experienced log home contractors will have a portfolio of past jobs, along with photos and customers testimonial letters.

4. What is the contractor’s workmanship warranty?

Some contractors typically warrant their workmanship for one year or more. Longer warranties are not necessarily more valuable than shorter warranties. The length of the warranty is less important than the intent and ability of the contractor to stand behind his warranty. That is best evaluated using customer references.

Choosing a Contractor

There are several more important things to consider as you narrow down your contractor selection. All job bids (if well written) should contain enough detail provisions and terms to clearly state both parties’ expectations. Your contractor’s knowledge of local building laws, their schedule to do the work and, of course, the total price they bid for your project, is all part of the equation. When it comes to caring for your log home, it’s reassuring to know that you can choose a contractor on whom you can rely on for good advice as well trust that they’re dedicated to providing you with the best results possible.

Again, Perma-Chink Systems is happy to offer you all our resources to make this process a successful experience. We will contact you within 7-10 days to follow-up on the contractor’s response and also log information and future follow-up if the job was awarded to one of our preferred log home contractors. Give us a call at 1-800-548-3554 or e-mail info@permachink.com to get a referral to contractors in your area.

Choosing a Log Home Contractor: Getting It Done Right

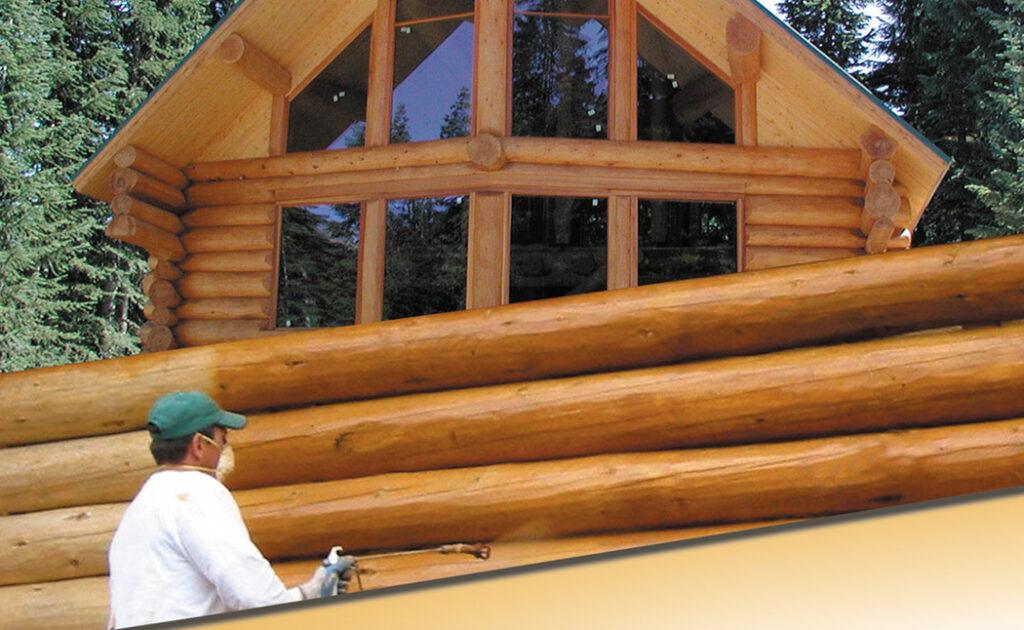

Are you the hands-on type—someone who enjoys weekend trips to the hardware store and tackling projects yourself? At Perma-Chink Systems, we proudly support DIY enthusiasts by offering user-friendly products, expert how-to articles, and robust customer support. But while we make the DIY route possible, it’s not always preferable—or realistic.

Sometimes, life simply demands a professional. Whether it’s due to time constraints, physical limitations, lack of confidence, or simply not wanting to shoulder the task yourself, hiring a contractor becomes the smart move. And not just any contractor—a log home specialist.

Why a Log Home Contractor?

Think about it this way: would you hand over your car keys to a golf-cart mechanic? Both may know engines, but the experience gap matters. Similarly, log and timber homes require a specialized touch. Log home contractors understand the unique materials, techniques, and challenges these structures present. Their expertise means better results and fewer mistakes—and their existing relationships with product manufacturers often work in your favor.

Perma-Chink Systems offers a nationwide referral network of experienced log home contractors homeowners can access online on our website, our Find A Contractor tool. While these professionals aren’t directly affiliated with us, most are self-employed specialists trained to use our products with precision and care. Many of these relationships span years, and we continuously review our referral list to maintain the highest standards.

Two Key Steps & Four Critical Questions

Step 1 – Get Informed

Before speaking with any contractor, empower yourself. Knowledge gives you confidence and ensures better conversations. Dive into our literature, explore detailed application guides, attend one of our free homeowner workshops, or schedule a private webinar with our team of log home experts. Our specialists are ready to walk you through the process, explain the products, and help you understand what to expect. An educated homeowner is a contractor’s best client.

Step 2 – Conduct Smart Interviews

We keep up-to-date records of licensing and insurance for all contractors on our referral list, but it’s essential to vet them yourself too. Ask the right questions to ensure the contractor’s reliability, reputation, and fit for your project.

Here are four questions that should top your list:

- Do you carry insurance?

Look for comprehensive liability and workers’ compensation coverage. Always request proof before work begins. - Are you licensed?

Licensing requirements vary by state and city—make sure your contractor is properly credentialed according to local laws. - Can you provide references?

Seasoned contractors will happily share photos, testimonials, and previous work portfolios. - What warranty do you offer?

While warranty durations vary, what truly matters is the contractor’s integrity and track record of honoring their work—something former clients can confirm.

Making the Right Choice

When reviewing estimates, pay close attention to the details. A well-written bid should spell out clear expectations on both sides. Consider your contractor’s availability, knowledge of local codes, and, of course, overall cost.

Ultimately, you want someone you can rely on—not just to complete the job, but to do it with care and craftsmanship. With the right contractor, maintaining your log home becomes not just easier, but a whole lot more satisfying.

Let Perma-Chink Systems be your guide. We’re here to support you every step of the way, from initial exploration to follow-up after your project is complete. Within 7–10 days of your request, we’ll reach out to record your contractor’s response and keep tabs on next steps.

To get connected with qualified professionals in your area, call us at 1-800-548-3554 or email info@permachink.com. Let’s bring your log home project to life—with the right expert by your side.

The key indicators that your logs need a little R & R (repair and refinish)

It’s difficult to ignore a log home; they possess a personality that always turns heads. Such natural good looks are part of their allure, but the attention they command extends to more than admiration. Log homes need regular maintenance to protect their beauty, performance and longevity. Fortunately, a few simple indicators will tell you exactly what your home needs (and when!). Here’s how to assess your logs’ status:

Annual Inspection of Log and Timbers

An annual inspection and exterior wash are an easy way to stay on top of your home’s maintenance needs. Sometimes a stain may look faded when, in fact, its appearance is just dulled by layers of dust, dirt and pollen. A simple wash will brighten everything up and return your home to its sparkling beauty. Ideally, this annual cleaning and inspection is done in late spring, after pollen season. A product like Log Wash from Perma-Chink Systems, Inc., which is environmentally friendly and is formulated with low pH, cleans the wood and preps it for a new coat of stain or topcoat if one is needed.

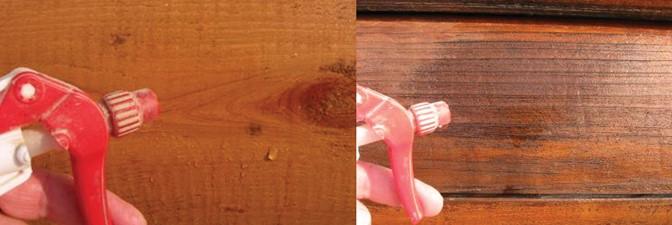

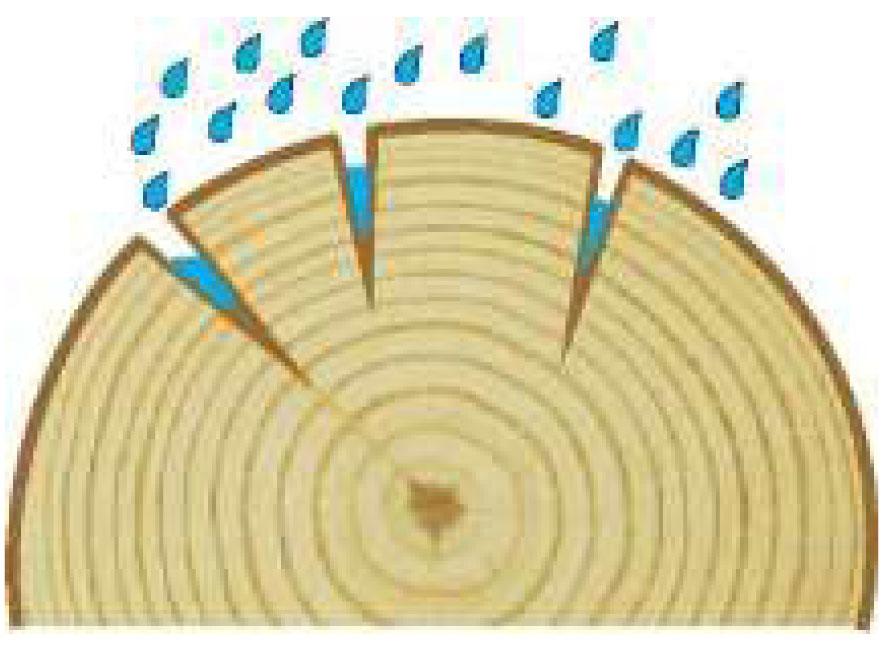

Perform a Water Test for Finish Integrity

Washing your home is also the perfect opportunity to do a water test, which tells you if you need to reapply a topcoat or the stain. When you wash your home, if you see water sheeting over the logs and being repelled, it’s a sign that the finish is working. If you’re unsure, perform a spot test by using a spray bottle filled with plain water to spritz a small section of the dry log with water. If the water soaks in, it’s an indicator that you need to re-apply the finish. If it beads up, your finish is working and you’re in good shape.

Is Your Log Color Beginning to Fade?

Stains add color and dimension to logs, enhancing a home’s aesthetic. However, they play another critical role. A log home’s stain, whether oil or film-forming, is responsible for protecting the wood. So, when the appearance begins to fade, that means the protection is, too. Keep an eye out for areas where your wall color is beginning to fade, indicating it’s time for reapplication of stain.

How to Perform a Tape Test

What if you purchased an older log home and don’t know what was applied prior to your arrival? Conduct a tape test! Simply take a short strip of high-adhesive masking tape and place it on the exterior wall, making sure the tape has good adhesion, then pull it off. If you see 50% or more pigment or stain color on the tape, that’s an indicator that not only do you need to re-stain the exterior, but you need to strip it down to bare wood. If you apply a new stain on top of a product that is peeling or flaking off, the new product isn’t going to stick.

Re-Application Made Easy

Once you’ve assessed your home and decided it’s time to reapply, Perma-Chink’s products not only prevent fading but also make application easier in the future. Unlike most film finishes, Perma-Chink’s system is a two-step process that involves a stain, such as LIFELINE™ Exterior, Ultra-2, or Ultra-7, Accents, then a topcoat finish of LIFELINE Advance. The extra step of adding a topcoat finish may seem like more work at first, but it saves you maintenance headaches down the road. That’s because with the LIFELINE brand, the stain protects the wood and the topcoat protects the stain, therefore extending the life of the stain.

Because the topcoat protects the stain, it may be years before you find that the stain needs to be re-applied. With conventional film-forming products or an oil-based stain, the stain will likely need to be re-applied every 2-3 years depending on the sun exposure.

Alternatively, if your log home has been repeatedly treated with an oil-based stain, it might be a good candidate for Log & Timber Defense. This product is a stain and sealant in one. It’s not film-forming and performs more like an oil by penetrating the wood, yet a water-borne finish that cleans up with soap and water.

Looks and Longevity

Knowing how to take care of your log home and choosing products that make maintenance easy will help ensure the beauty and durability of your log home for years to come. With Perma-Chink Systems, you get peace of mind, gorgeous looks, and a minimal maintenance routine that will give your home the longevity you desire. Order your stains today at Store.PermaChink.com or call us at 1-800-548-3554.

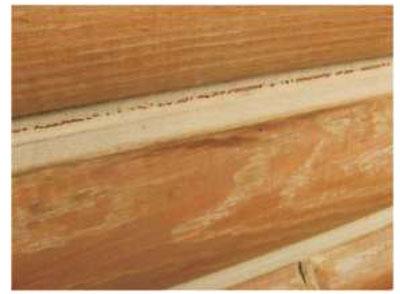

How Do Rips and Tears Happen?

Occasionally rips and tears form in log home chinking, especially in new homes that have been constructed with fairly green wood. Most of the time these tears appear on the top edge of the chink joint. That’s because during the tooling process, most people tend to pull product from the top to the bottom of the chink joint, which results in a thinner than recommended layer of chinking along the top edge. In addition, people forget to “push” the chinking up against the top edge, resulting in inadequate adhesion. When the logs shrink, it puts a strain on the chinking and if it was not properly applied, it can pull away from the wood. So when working Perma-Chink®, it is important to keep pushing the product towards the top of the joint.

Before making any repairs, determine if the chinking was properly applied originally (see our Application Guide here for reference). If you find that the thickness along the top edge is consistently less than 1/8”, you may be faced with constant repairs as it will be better to cut it out and start over again. You won’t be able to apply another layer of Perma-Chink on top of what’s already there to bring it to the proper thickness. If you do, the added layer will probably develop blisters in it.

Our rule of thumb is that if a tear is less than one foot long, it can be repaired. If it is longer than one foot, the chinking should be cut out and replaced. The reason for this is that on long tears, the chinking tends to sag out, and there is no way to hold it in place while the repaired area cures.

Begin with making sure the area that you are repairing is good and clean. You don’t want any dirt to interfere with the adhesion of the chinking. It’s easier to make a repair using a tube of chinking or a bulk loading gun than it is to scoop some out of a pail.

Put a bead of chinking along the tear, making sure that you have good contact with the torn chinking and the wood. Once it’s applied, you can press it into place with a tool or your finger. Now use a small, inexpensive paintbrush with the bristles cut to about 2” long, dip it into some water to get the bristles wet, then work the chinking smooth with the brush. This will help match the texture of the chinking repair with the surrounding cured chinking.

In the cases of older chinking in need of repair, it will be necessary to apply Chink Paint over the repaired area to make the color uniform.

Typically, the Chink Paint painted areas will be cleaner and brighter than the old, existing chinking, so you’ll probably want to Chink Paint all of the chinking to renew the look of your entire home. If you want to change the color of your chinking, this would be a good time to take advantage of Chink Paint.

What Causes Blisters?

There are several causes of blisters forming in uncured chinking. The first is whenever chinking is applied in hot, direct sunlight. The surface quickly skins over, preventing the water vapor from escaping from the underlying material. This problem is usually easy to diagnose, since the blister will start to form in the middle of the product, and if the blister is cut away, you can still see chinking under the blister.

Another common cause of blisters is chinking over unsuitable backing materials. This includes blue board, pink board, and other colored EPS (expanded polystyrene) foam and bare wood. These materials out-gas and as they do, they can form blisters in the soft, uncured chinking.

Only those products recommended by Perma-Chink Systems should be used as backing materials for Perma-Chink Log Home Chinking. Some blisters can be directly attributed to the application process. If the chinking is “trowelled” in by hand, small pockets of air can become entrapped during the process. It is very important to “mash” out the chinking in order to work the air out.

Entrapped air also occurs when you apply very small beads of chinking with a tube or a bulk load gun if the tip cut too small, when compared to the size of the joint. Air can be trapped between the beads when it is smoothed out, leading to blistering.

It’s important to work the chinking, although most people are hesitant to do this as it tends to pull during the process. A light mist of water on the surface of the chinking will help prevent pulling, although some chinking professionals only wet the tool they are using, until they get ready to finalize the finish. It is never necessary to flood the surface of the chinking with water, a very light mist is all that you need.

There is no satisfactory way to repair a blister other than to completely cut out the blistered sections and re-chink the entire joint. If you try to cut out and fill in the blisters, you will end up with visible depressions along the chink joint. Once the blistered section is removed, be sure to check the backing material. If it’s the wrong material, replace it with the correct material; if it is bare wood, cover it with masking tape. If you don’t use the correct backing material, you run the risk of blisters reappearing in the repaired sections.

Read Our Application Guide

Read our Sealants Application Guide to learn the best practices, ensuring a beautiful log home for generations.

Inspection Checklist – Downloadable PDF for print

| Wall A | Wall B | Wall C | Wall D | Wall E | Wall F | |

| Are gutters and downspouts clean and working? | ||||||

| Overall condition of roof and dormers. | ||||||

| Are shrubs and tree limbs away from the roof, walls, and foundation? | ||||||

| Sprinklers not hitting the wall? | ||||||

| Are there signs of finish wear or fading? | ||||||

| Check eaves and fascia. | ||||||

| What about the window and door trim? | ||||||

| Is the foundation in good shape? | ||||||

| Check plumbing and electrical penetrations. | ||||||

| Are crawl space vents clear and working properly? | ||||||

| Are there any signs of leaks around windows? | ||||||

| Are there cracks, tears or adhesion loss in chinking or caulking? | ||||||

| Are there any new checks that may need sealing? | ||||||

| Are there any signs of insect or decay infestations? | ||||||

| Are the exposed log ends showing signs of water penetration? | ||||||

| Does the topcoat still look to be intact or is it becoming dull? | ||||||

| Is the color coat showing signs of fading or darkening? | ||||||

| Have any discolorations appeared under the finish? | ||||||

| Are there any signs of peeling around checks and fissures? |

What Do I Use on the Interior of My Logs and Timbers?

The inside is where you do most of your living. As such, it’s important to take time to select the right interior stains and finishes for your log and timber home. In this way, you will achieve an interior that is visually pleasing and performs well for years.

Two Issues

When it comes to interior finishes, there are two phenomena that homeowners tend to overlook:

1. Surprising amount of surface area. Interior walls and ceilings dramatically increase the amount of surface area that requires treatment – there is about twice as much stainable interior surface versus the exterior. You’ll be looking at your stain choice years to come throughout your entire home. Choose wisely the color and stain product, which we recommend Lifeline Interior.

2. Choices, choices, and more choices. During a new build, homeowners are faced with hundreds of decision points along the way. It’s common for homeowners to ask the general contractor (GC) for advice, which is typically the “safe,” neutral off-white color. A GC wants to stay on schedule, but selecting your interior stain takes a little time. You can’t undo stain without a lot of added expense and time removing the old finish and applying the new finish.

What’s Your Color?

To make the best choice for your log home’s interior stain, think about how you spend time inside your home and the feeling you want to create. Does the space have abundant, natural light? Do you prefer cozy, dark walls and a lighter ceiling or a bright, fresh feeling with lighter walls? Another consideration is that wood absorbs light, so a darker stain may translate into a much darker room than you anticipated.

Then there is the tint base. Do you prefer browns, reds, grays, or a bleached look? Like many things, wood stain decisions can follow design trends, or stay within classic choices. Explore your options and be sure to choose a tint that will look beautiful to you over time. You can always darken a lighter stain, but not the reverse.

To order FREE color samples visit our store.

Distinct Needs

Not all interior wood is the same. Logs and heavy timbers are not like the wood of cabinets, moldings, and furniture. These smaller wood products are usually sprayed with nitrocellulose lacquer for protection, giving them a hard, shiny finish. Larger timbers and logs are more dynamic than cabinets, tables, and trim. If you try and put a similar lacquer on your interior log walls, the finish will crack and peel as these larger pieces of wood naturally contract and expand.

Some homeowners wonder if they can go “au natural” with their interior wood, avoiding the protection an interior finish provides. While interior logs may not be subjected to the same elements as their external counterparts, they will absorb cooking oils and odors, collect dust, handprints, and water stains if not protected. There’s another reason to finish them: Have you ever run your hand across rough-cut wood? It feels mildly like sandpaper. All those little crags and jags on the surface need to be covered in a light film; one that’s strong enough to be wiped down and protect the wood while remaining flexible enough to not crack as the log expands, shifts, and contracts over time.

Choose a stain that’s designed for its job. Exterior stains contain higher levels of biocides and preservatives that you don’t need or want inside your home, especially where you’re eating and sleeping. This is also why you want to avoid an oil-based stain. Oil-based products have high levels of volatile organic compounds (VOCs), which are extremely unhealthy in enclosed spaces.

Smart & Attractive

Start with a stain that gives you the aesthetic and exact level of transparency you desire. Here at Perma-Chink Systems, we recommend using our Lifeline Interior stain, which comes in a wide array of tones, including clear. After staining, add one or two clear coats of Lifeline Acrylic or PCS Clear Shield. Both add just enough film to protect your logs and minimize scratchiness so they can be easily wiped and cleaned. Lifeline Acrylic comes in gloss or satin sheens, with PCS Clear Shield offering gloss and matte sheens.

These stains also contain the right amount of UV protection to avoid “picture framing” with the addition of UV Boost. Picture framing is the shadowy discoloration that remains on the wall when you move a bookshelf or a picture. Your stains should not dictate how you can decorate your home if you have to cover outlines of wall hangings. Perma-Chink interior stains and finishes will ensure that the inside of your log home is just as breathtaking and gorgeous as the outside.

To order color samples, visit our store here.

One or Two Coat Log Stains? Warranty and Color Choices to Consider for Your Log Home Stain.

It does happen occasionally. A customer will call and asks, “Which wood stain should I choose?” We’re glad you called because we’re here to help.

The first question we need answered is the stain for outside or inside? Perma-Chink Systems offers both exterior and interior stains. We’ll cover exterior finishes here, as the original question is predominately referring to exterior finishes. If you’re looking for guidance on choosing interior finishes, read our article on interior finishes here.

Are you looking for a film-forming finish or something more like an oil-based stain? If you’re looking for film-forming finishes, our Lifeline family has multiple options that have you covered. Our newest addition Log & Timber Defense is like penetrating oil-based finishes, but forms a lattice-like coating to protect the logs and offers excellent protection.

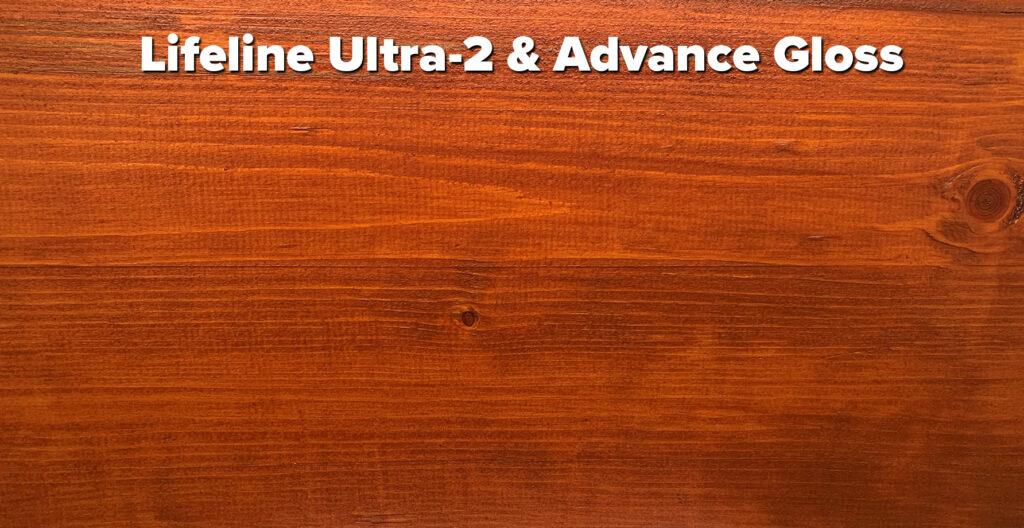

The next question is do you want a log stain that is one-coat or two-coat application? For one coat applications, Lifeline Ultra-7 is your best option. Available in nine colors, Ultra-7 is the premier finish for log and timber homes. Lifeline Ultra-2, Lifeline Exterior, and Lifeline Accents all benefit from a two-coat application. Additionally, Lifeline Advance topcoat will ensure your stain lasts the test of time.

Color Choices

The third question we need answered is what color do you want? With over 70 color options among our Lifeline family, it’s likely you’ll find a color you’ll love on your home. If not, we can produce custom colors to enhance the beauty of your logs or timbers.

Ultra-2 log home stain offers the most color options of all our finishes, and along with Ultra-7, has the added benefit of UV Boost (additive to fight harmful UV damage) added to the finish. It’s a long-lasting finish that provides low maintenance for your log home, superior color retention, and exceptional coverage rates. Ultra-7 and Ultra-2 are one of the few log home stains that offer a 5-year limited warranty, when paired with Lifeline Advance Topcoat and scheduled maintenance.

Lifeline Accents and Exterior finishes offer a tremendous value, without sacrificing coverage rates, durability, or color loss compared to other log finishes.

Still not sure on which log finish to choose? You can order free samples of all our finishes to test on your home. We want you to have confidence in the color you choose.

In short, all our wood stains and finishes perform phenomenally – providing excellent UV protection, allowing wood to breathe as the home acclimates seasonally, and ensuring maximum color retention.

For over 40 years Perma-Chink Systems has been protecting log homes and protecting them right. Our focus is on preserving log and timber homes for future generations. We want log home owners to focus on making memories in their home, not spending all their time maintaining the home.

Click the question to see the answer

What makes Deck Defense™ better than other products?

Deck Defense is a true, penetrating water-borne product without any sort of emulsified oils or alkyds. The product penetrates the wood substrate and the forms lattices to strengthen and support the natural cellulosic fibers for protection from the inside out, not only on the surface.

How about water protection?

We have incorporated ingredients in the formula to serve as a deterrent to water intrusion. One must remember that waxes are sacrificial, and over time the beading on the surface will go away. This does not mean a re-coat is necessary. It is just an indication the waxes have worn away from the surface. The protection for the wood is still in place.

I already have a finish on my deck; does this have to be removed before I can apply the improved Deck Defense?

The old rule of thumb says for the best success with a coating, the best practice is to remove any old finish before applying a new product. However; if you are applying over an older, tired oil-based product, you can apply the new Deck Defense after a thorough cleaning with Wood ReNew™ or Log Wash™. If you have previous Deck Defense, you can also apply the newer product after cleaning. If there has been a film-forming product applied (Vista, Endure or “painted” surfaces), then it will need to be totally removed prior to application of the new Deck Defense.

Is there protection against UV damage in Deck Defense?

Yes, there are UV inhibitors within the product, plus, as transparent iron oxide pigments are also used to produce the desired color, they will enhance the UV protection through sun-blocking properties of the color itself.

Is Deck Defense safe for the user as well as the environment?

The product is considered non-toxic, but as with any product, certain precautions should be observed as they just make good sense. Wear gloves and eye protection when applying the product and avoid inhaling vapors (See precautions on the label). Shrubbery and plants should be rinsed before and after application (or covered). Covering adjacent surfaces like concrete or paver pathways is also a good practice.

Pre-Application steps needed?

First and foremost; the surface needs to be clean and dry. New treated wood needs to “season” prior to application. This process will vary with temperature and humidity and actual moisture content of the new wood. On older wood, a thorough cleaning with Wood Renew will help to restore the color of the wood and remove stains and dirt. Make sure to adequately rinse with water and check the pH of the run-off water to make sure all the surfaces have been rinsed well. Ph of run-off water should be around 6.5 to 7.5 (depending on the pH of the water source). Make sure to check fasteners and condition of wood prior to cleaning and replace any decayed or unstable wood.

Do I need to sand the wood first?

In an ideal world, sanding would be best. But most applicators and homeowners do not want to go through the effort or labor expense to do so. Sanding increases the mechanical adhesion of the surface and will also make the substrate color match better. The sanded surface also opens the substrate and promotes better penetration of the product. If a decision is made to sand, we recommend 60-grit or possibly even 40-grit paper. Media blasting may also be used but may be considered overkill unless the entire home is being media blasted. After sanding or blasting, wash with Log Wash, rinse well, and allow for complete drying prior to application.

How do I mix the product?

Prior to applying Deck Defense, mix well. The colorants used in Deck Defense do not settle hard and re-disperse easily. DO NOT USE POWERED MIXING EQUIPMENT, as this action can possibly shear the backbone of the product and cause possible product failures. As with any product, box the pails together if there are different batch numbers.

How do I apply Deck Defense?

Applying Deck Defense is very easy, and many methods or “tools” can be used. On surfaces such as decking or fencing, a low-pressure pump-up sprayer is the most economical. Deck Defense can also be applied with paint pads designed for deck application, or applied with a quality brush. Rollers can also be used, but due to the low viscosity of the product, there will be some excess “splatter” when rolling. An airless sprayer can be used, and we recommend the use of a 511 or 513 tip due to the low viscosity. Apply the product in a “flooding” method to completely cover the surface to allow good penetration.

Deck Defense should be back brushed when applied by a sprayer, or when using a pad, to make sure the product is spread evenly. Work in the same direction using broad strokes to alleviate “pooling” of product and promote even coverage for the best appearance. Do not allow “pooling” on surfaces. On vertical surfaces, work from the bottom up and back brush as you go. Do not apply in the hot sun as this can cause “flash drying” and interfere with the penetration of the product. Application temperatures are 40-90° F, and that is surface temperature, not air temperature. DO NOT APPLY DECK DEFENSE OVER FILM-FORMING FINISHES (Vista, Endure or “painted” surfaces) AS IT NEEDS TO PENETRATE THE SUBSTRATE FOR THE BEST PERFORMANCE.

How many coats are required?

Deck Defense is designed as a one-coat stain, although due to the deep penetrating properties of the product, it may appear lighter than expected. This is especially true on older surfaces that have been exposed for long periods of time. Also, as this is a semi-transparent product that allows the natural grain and texture of the surface to show through, colors may appear blotchy or uneven, and the user may want to apply another coat. If a second coat is to be applied it should be done in a “wet on wet” application, meaning the first coat needs to be wet when the second is to be applied. If a second coat is desired after the initial application has dried, allow one week for the first application to cure completely.

What is the dry time for Deck Defense?

Dry times will vary with application, airflow, temperature and humidity. Under ideal conditions – 60° F, and 50% humidity – Deck Defense will dry to the touch in about 20-30 minutes. Dry does not mean “cured”. Wait 4-6 hours before walking on surface and 24 hours before replacing heavy furniture.

What are the coverage rates for Deck Defense?

Coverage rates will vary considerably, based on type of substrate and methods of application. That’s why most folks buy a bit extra when they repaint, as they don’t want to go back and buy another gallon to finish. On rough sawn wood, like fences that really soak up product, it may be as low as 100-175 sqft per gallon. Older deck surfaces will also tend to soak up lots of product, so figure around 175-250 sqft per gallon. On new wood, expect around 250-300 sqft per gallon. A second coat application will require less product.

Is Deck Defense freeze-thaw stable?

Yes, this product is freeze-thaw stable. It’s not the freezing that could cause issues; it is the number of cycles a product is exposed to that causes damages.

What are the maintenance guidelines?

Good maintenance for decks, as well as other wood surfaces, will prolong the need for re-staining or removal. Deck Defense will not flake or peel when properly applied, so a general cleaning should be done every year with Log Wash. Maintenance requirements will vary with exposure and environmental conditions, and heavy traffic. Expect to see wear in high traffic areas such as steps and traffic patterns first. This does not mean protection is gone, but indicates for appearance purposes that it’s time for a light re-coat.

How do I clean up when I am finished?

If done right after application, tools and equipment are easily cleaned with soap and water. Warm water works best.

Due to the penetrating and adhesion properties of Deck Defense; keep overspray areas wet during application and rinsed promptly when finished. Removal after three hours will be difficult, but after three days it will be almost impossible without the use of strippers or solvents. Dispose of containers in accordance with local, state and federal guidelines (Do not reuse containers).

Perma-Chink Systems recently added another beautiful wood finish option for our customers – Log & Timber Defense™. Unlike our traditional Lifeline wood finishes, Log & Timber Defense penetrates your wood much like an oil coating. Once Log & Timber Defense penetrates the wood surface, it forms a strong lattice network within the wood, reinforcing and strengthening the entire system from the inside out. This mechanism greatly reduces the chances of peeling and flaking by leaving the system breathable to water vapor. Many traditional oil-based finishes can also form a network, but are often so high in solids that they can easily blister and peel. Vapor pressure builds up behind the thick, unbreathable solid film and pushes the film away from the wood. This leads to an unfortunate situation requiring removal of the compromised coating down to bare wood.

Log & Timber Defense Application Guidance

Log & Timber Defense is designed to be applied to bare wood in one or two coats. If it is applied to wood that already has an existing coating, this can prevent it from forming the lattice network inside the wood. Some customers ask: “Can I apply a topcoat such as Lifeline Advance™ to Log & Timber Defense?” We do not recommend application of a topcoat. The reason we do not recommend this is because when a maintenance coat is needed in the future, there will be difficulty with penetration into the wood because the topcoat forms a barrier to penetration leaving a film on surface. This could leave undesirable surface defects as well as an uneven appearance. Furthermore, it could lead to peeling and flaking of the finish.

Texture is another property that distinguishes Log & Timber Defense from our Lifeline Stains. Due to its penetrating nature, Log & Timber Defense leaves the surface with a more naturalistic, rustic beauty. It will appear much flatter in appearance. However, if a slightly different look is desired, a second coat of Log & Timber Defense may be applied, but the appearance will remain relatively flat. The second coat will increase color intensity and provide an increased level of overall protection for the system.

Difference of Lifeline Finishes

In contrast, our traditional Lifeline Stains are breathable film formers. This is to say they form a film directly on the surface of the wood but do not penetrate deeply into the wood. When applied correctly, our Lifeline stains are not likely to peel due to their breathability and excellent adhesion. They are, however, only slightly more likely than Log & Timber Defense to peel due to their film forming nature. In addition, our Lifeline Stains are designed to be applied over our existing topcoat with no problems with adhesion, color development, or film defects. The Lifeline stains will provide a much higher level of gloss development than Log & Timber Defense due to the films being primarily on the surface of the wood, with the added benefit of being able to apply the gloss topcoat to finish the system.

What About Protection From Mold & Mildew?

Both our Lifeline Stains and Log & Timber Defense are formulated with ingredients that inhibit the growth of mold and mildew. Log & Timber Defense is both a stain and sealant in one package. It helps to keep liquid water out, which reduces biological growth that can attack and destroy your wood. In contrast, traditional natural oils such as linseed oil can easily promote growth of mold and mildew.

Finally, both Log & Timber Defense and Lifeline Stains are both waterborne, low in odor, have easy soap and water cleanup, and are non-flammable. Each of our stains and finishes offer unique properties designed to give your home the very best protection possible.

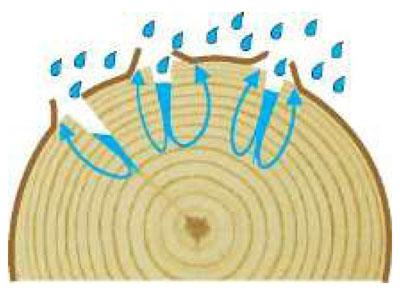

Why is it so Critical to Seal Exposed Ends of Log Homes?

Wood is a hygroscopic material, which means it naturally absorbs and releases moisture from the environment. Logs can safely absorb large quantities of water before reaching moisture content levels that will be inviting for decay fungi.

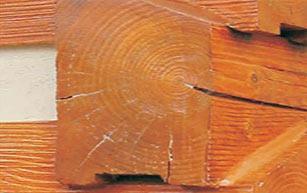

Some of the most vulnerable areas of a log home are the corner log ends. This is because the cross-section end grain is exposed and the ends often stick out beyond the walls allowing sunlight, wind, rain, snow and ice to wear away the stain and expose bare wood.

The exposed end grain acts like small straws by sucking water into the log, giving rot and decay an opportunity to start eating away the wood. In addition, wood cracks and checks are prone to start at the ends. If left unprotected long enough, log or log corner replacement may eventually be required.

Aware of the susceptibility of log ends to weathering, rot, and decay, we developed Log End Seal, a clear polymer finish that prevents water from penetrating into log ends and provides a layer of protection against log end damage. Although it is a sealer, Log End Seal is designed to allow moisture already in the wood to slowly escape. This helps reduce those large checks that often form on log ends.

The first step when applying Log End Seal is to sand the log ends smooth with a belt or orbital sander or sanding disks (available here). Take care not to leave any deep sanding marks or gouges. Most log homes arrive with the log ends sawn off to the proper length. The sawing may leave a rough surface and when stained the log ends typically end up being much darker than the smooth sides. A log end that has been sanded smooth and then stained will be much closer in color to the log walls.

Applying Log End Seal

Once the log ends are sanded and one of our LIFELINE brand stains is applied to the home and allowed to dry, you are ready to put Log End Seal on the exposed ends. Although you can use a short-bristled brush to apply Log End Seal, we found that an applicator pad works best. Be sure to coat the entire face of each log end to avoid any uncoated spots. Wipe off any excess that may have dripped onto the sides of the logs with a damp rag.

Allow the Log End Seal to dry to the touch and finish the job with LIFELINE Advance clear topcoat in gloss or satin.

Drying and Curing Time

Once Log End Seal dries and cures, it may take a while before it loses its milky appearance, especially in checks and fissures. But the end result will be an appealing, clear surface that will offer the utmost protection to the ends of your logs.

Download the application steps of Log End Seal here: Log End Seal Tech Tip

Deck handrails present a real challenge to film forming finishes, especially if they are new. Here’s why. Round log handrails are typically fabricated using green wood. Once in place and begin to dry, handrails shrink, crack, and develop fissures to relieve the stress due to shrinkage. There is no way to prevent this from occurring. If a finish is applied before these fissures open up, and once they do open, they provide a path for water to soak into the rail behind the finish. When the sun comes out and the rail heats up, the water turns into water vapor which may exert enough pressure to actually push the finish right off the wood. In winter months, the water in the wood will freeze and expand and that, too, can pop the finish off the surface.

Another problem with green handrails is that all finishes have difficulty adhering to damp surfaces. Green logs normally do not present the same difficulties as handrails since it usually takes several months for logs to go from the debarking process to construction, time enough for the surfaces to dry. In the case of handrails, it may only be a week or two from the time they are debarked to when they are installed, not enough time for even the surfaces to dry.

A third problem with new handrails is that they are frequently quite smooth. They are typically hand peeled with a drawknife and may still have cambium residue remaining on the surface. Finishes have a difficult time adhering to cambium, and even if they do, eventually the cambium will dry up and peel off, taking the finish along with it. Trying to sand this cambium off while the wood is still damp is almost impossible, since the cambium and damp wood fibers quickly blind sandpaper or sanding pads making them ineffective.

Starting Point

So, what do we suggest to assure adhesion of a finish to new handrails? The first thing is to wait until the handrails have reached a moisture content of less than 20% before doing anything. This may take two months or six months depending on how green they are and the diameter of the rails. By then most of the cracks and fissures will have opened up and any remaining cambium will have dried up and peeled off. The problem with this is that some people moving into a new home are not willing to wait to finish their handrails. If that’s the case, the best course of action is to sand the handrails with 60 to 80 grit sandpaper as best you can, wash them down with Log Wash™, let them dry and then apply only one coat of any Deck Defense.

It will be best to apply Deck Defense to posts, spindles, balusters and other vertical components of the deck as well for color and coating consistency. Once the handrails have had a chance to dry, the application of a second coat of Deck Defense will seal any cracks and fissures that may have opened up preventing water penetration into the wood.

If you have elected to allow the handrails time to dry before staining, during the waiting period there’s a good chance that some surface graying will have occurred, so a light sanding with 60 to 80 grit sandpaper, nothing finer, as well as a wash-down with Log Wash is recommended before the application of one or two coats of Deck Defense. Be sure to get some stain into all cracks and fissures and again, no topcoat should ever be applied to horizontal handrails or over Deck Defense.

Discolorations

Like logs, handrails are subject to the same types of discolorations due to mold, tannins and water stains. The bottom sockets are especially susceptible to water infiltration and the resulting water stains. There are two ways to prevent this: drill a hole through the bottom of the socket before installation to allow water to drain out of the socket, or seal around the tenon with Energy Seal™ after installation. Just make sure the socket is dry before sealing it.

Discolorations on handrails due to mold, grayed wood, and tannins can be handled exactly the same as on logs. Always start off with a pressure washing with a Log Wash solution (2 cups per gallon of clean water) and then continue on with Wood Renew™ or Oxcon™ as needed. If you decide to sand the rails, just be sure to use 60 to 80 grit sandpaper and wash the sanded surfaces with a Log Wash solution before applying the first coat of finish.

Maintenance

Since the top rail takes the most beating from the sun, wind, and rain, it will probably need some maintenance every year or two. One thing to look for is any large checks that open up. If the width of a split or check exceeds 1/4 inch, it should be sealed with Check Mate 2®. That will help prevent large amounts of water from getting into the rail. There is not much you can do about small checks and fissures other than making sure to get some finish into them whenever you are applying a coat of Deck Defense.

Repair

Your handrails and railings have suffered and now you have some rot in the railings. Now what? Before you replace the entire railing, you might be able to salvage what’s left of the wood and repair it with E-Wood paste. To save the rails, remove any loose or decayed wood, and brush away any debris. For best results, apply borate wood preservatives to stop rot. Allow to dry and apply M-Balm, a wood consolidator that helps harden damaged wood. Then apply E-Wood paste to replace the damaged wood, shaping it to match the natural contour of the wood. Allow the E-Wood to cure before applying a stain, which will result in a natural-looking repair.

For more information on how to use E-Wood and M-Balm, read our Tech Tip here.

Over the past several years we have discovered many things about cleaning wood and existing finishes. First and most importantly is that chlorine bleach is not the best product to use. In addition to its potential for damaging the finish and bare wood fibers, its use and misuse contribute to specific problems including the loss of film adhesion, discolorations due to tannin extraction, streaks, blotches, and premature failures of the finish system. We have also discovered that many wood and deck cleaners available at paint and hardware stores, home improvement centers and Do-It-Yourself outlets contain components that interfere with the proper performance of our finish systems.

Therefore, we have decided that the only cleaning products approved for use with our finishes are those products supplied or recommended by Perma-Chink Systems, Inc. We are not doing this to increase our sales of cleaning products. It is because we have tested our cleaning products with our finish systems and have confidence that when properly used and applied, their use will result in the best possible appearance and performance of the final LIFELINE finish. We can not say the same about the use of other types and brands of wood cleaners, and strongly discourage their use with any of our LIFELINE stains.

Guidelines for Cleaning Bare Wood Prior to Applying Lifeline Stains

New Log Homes

1. If the wood has not grayed, wash the surface with a two (2) cups per gallon Log Wash™ solution and a pressure washer no more than seven (7) days prior to staining. Smooth log siding should be washed using Wood ReNew™. Rinse well and allow the wood to dry.

2. If you are finishing Western Red Cedar, Redwood, Walnut, or Mahogany, use Cedar Wash™, a ready-to-use cleaner, instead of Log Wash for better surface preparation and finish longevity on these specific wood substrates.

3. If there are signs of grayed wood, use Wood ReNew according to the label along with a pressure washer. Rinse well and allow wood surfaces to dry before staining. If more than seven (7) days pass before the home is ready for staining, wash the surface with a two (2) cups per gallon of water Log Wash solution, rinse well with a garden hose, and allow wood surface to dry.

4. If, after steps one or two, there are still dark streaks or discolorations on the surface, use a solution of OxCon™, which contains oxalic acid, on the entire wall according to the directions for use. Rinse well and allow the wood to dry before staining.

Older Log Homes That Have Had a Previous Finish Removed

1. If there are no signs of gray surface wood, wash the surface with a two (2) cups per gallon Log Wash solution no more than seven (7) days prior to staining. Rinse well and allow the wood to dry.

2. If you are finishing Western Red Cedar, Redwood, Walnut, or Mahogany, use Cedar Wash, a ready-to-use cleaner, instead of Log Wash for better surface preparation and finish longevity on these specific wood substrates.

3. If there are areas where grayed wood is still evident or if the wood has darkened after the finish was removed, use Wood ReNew according to the label along with a pressure washer. Rinse well and allow the wood to dry before staining. If the wood has darkened or more than seven days has passed before the home is ready for staining, wash the surface with a two (2) cups per gallon of water Log Wash solution, rinse well with a garden hose, and allow the wood surface dry.

4. If, after steps #1 or #2, there are still dark streaks or discolorations on the surface, use OxCon, an aqueous oxalic acid solution, on the entire wall according to the directions for use. Rinse well and allow the wood to dry before staining.

Log Homes with an Existing Finish That is Still in Good Condition

1. If a maintenance coat of Lifeline stain or topcoat is going to be applied over an existing Lifeline finish, wash the coating surface with a two (2) cups per gallon Log Wash solution no more than seven (7) days prior to staining. Pressure washing is not recommended. Rinse well and allow the wood to dry. For maintenance cleaning of finished surfaces that are not going to be stained or top-coated, use a one (1) cup per gallon Log Wash solution.

A NOTE ABOUT RINSING

No matter what product you use to clean bare wood, nothing is more important than making sure you have adequately rinsed the surface. Any chemical residue remaining on the surface can have serious consequences later on. We always recommend using pH Strips to make sure that the surface of the wood has been sufficiently rinsed. A pH between 6.5 and 7.5 indicates the surface has been properly rinsed. pH Strips are available at most pool supply dealers, aquarium supply shops and Perma-Chink Systems, Inc. They are not expensive, are very easy to use and a great tool to ensure adequate rinsing.

For the past 30-plus years, the most accepted and effective method for preventing infestations of wood destroying insects and decay fungi in log homes has been by impregnating the wood with a solution containing the element boron. Boron salts are referred to as borates, and the most commonly used borate utilized for this purpose is disodium octaborate tetrahydrate (DOT), the active ingredient found in our wood preservative products.

The reason for using this material instead of borax or boric acid is because it has a much higher boron content per pound and is significantly more water soluble than other boron-containing compounds. But what is it about boron that makes it so effective for preserving and protecting wood? In the case of wood consuming insects, like termites and wood-boring beetles, boron disrupts their digestion process by killing the bacteria that allows the insects to digest cellulose. There is also some evidence that boron interferes with the insects’ metabolic systems. These modes of actions do take some time, and it is not unusual for insect activity to continue for several months after being exposed to a borate treatment. However, once eliminated, the wood will be protected from future wood consuming insect infestations as long as the boron remains within the wood’s cellular structure.

In the case of decay fungi, the presence of boron disrupts the cellular production of enzymes that allow the fungi to extract nutrients from the wood. As opposed to insects, a borate treatment will kill decay fungi rather rapidly, usually within a day or two.

Borate Treatment Methods

Pressure Treatments

Pressure treating wood with preservatives dates back to the 19th century when railroad ties were impregnated with creosote under pressure. Since then, a number of chemical formulations have been used for pressure-treating logs and dimensional lumber, but most have been discontinued due to their toxicity or health and environmental hazards. Due to their low mammalian toxicity and environmental friendliness, borates are now being used by a number of pressure-treating companies for treating both logs and dimensional lumber. The one limitation of borate pressure-treated lumber is that it cannot be used for wood in contact with the soil, since the moisture in the soil will extract out the water-soluble borate within a few years.

Dip Treatments

A number of log home manufacturers dip their logs in a solution of borate before they are shipped to the customer. Although there are set standards for the “Dip Diffusion” process, very few companies actually meet these standards, since it requires dipping green, unseasoned logs in a hot, concentrated borate solution and then storing the logs in a covered building for a minimum of two weeks. Most log suppliers simply dip their logs in a borate solution for a few minutes then allow them to dry. Although this procedure does not meet set standards, it has been used for over four decades and as long as the borate concentration in the dipping solution is maintained at or above 10%, we rarely hear of this process not providing adequate protection to new logs.

Topical Treatments

Back in the late 1980s, Perma-Chink Systems developed the very first borate preservative that could be applied to wood in the field during or after construction. Since then, hundreds of thousands of log and conventionally constructed homes have been borate-treated using the technology originally developed by Perma-Chink Systems. What made this possible was combining the borate with a combination of glycols that allow the borate to penetrate into the wood rather than remaining just on the surface. In addition, the glycols increase the efficacy of the boron allowing less applied product to be just, if not more effective than higher concentrations of borate water solutions alone.

Pure borate/water solutions are also used for topical applications, but since they do not contain anything that aids in the penetration of the borate into the wood, we recommend that they be used only on new, un-infested logs and be reapplied any time the home is stripped of its existing finish.

The one limitation of any topically-applied borate is that it must be applied to bare wood. If there is anything on the surface that inhibits the absorption of water into the wood, the borate solution will remain on the surface and no protection will be imparted to the wood itself.

Conclusion

The success rate of properly applied borate treatments is truly astounding. In the 40 years that we have been involved with borate-treated wood, the number of reported complaints is miniscule, and most of them involved insects that do not consume wood for nourishment like carpenter bees, parasitic wasps, house ants, and other pests that are not included on the label. We occasionally get calls about a continuing beetle infestation after a borate treatment, but it’s almost always within a week or two of the product being applied and that’s just not long enough for the borate to completely eliminate an active infestation of wood boring beetles. However, give the borate time to work until the activity ends, that will be the end of the infestation and they never return.