Library

Every spring we get lots of calls about carpenter bees drilling into logs, fascia boards, eaves, decks and other unpainted wood surfaces. Carpenter bees are big, black solitary bees that look similar to bumblebees but have bare, shiny backs whereas a bumblebee’s back is hairy. Unlike honey bees that reproduce in hives, carpenter bees drill into wood in order to lay their eggs. Their holes can be identified easily as they are perfectly round and about 1/4 inch in diameter.

Although carpenter bees prefer softwoods such as cedar, redwood, or cypress, they happily attack pine and most other species of wood. Even pressure treated wood is not immune from carpenter bee attack. As the bee drills into the wood, coarse sawdust may be seen coming out of the hole and piling up beneath the hole. Since it only takes a couple of hours for a carpenter bee to drill a hole a few inches deep, lots of holes can appear over a fairly short period of time.

Most carpenter bee activity occurs in early spring when male and female bees emerge after spending the winter in old nest tunnels. Once they have paired and mated, the female bee drills into a suitable site while the male stays nearby to ward off intruders. Male carpenter bees often frighten people with their aggressive behavior but since they have no stinger they are essentially harmless. Females have a stinger but only use it if molested.

Once the initial hole is drilled through the surface, the bee will make a turn and excavate a tunnel along the grain of the wood. This tunnel, which may run for several inches, becomes the cavity where the female deposits her eggs. Several eggs are laid in individual chambers separated by plugs of pollen on which the larvae feed until they emerge as adults during the summer months. In addition to making new holes, carpenter bees also enlarge old tunnels. If left unattended for several years, serious damage to a wood member may result.

In late fall, activity may again be seen as both male and female carpenter bees clean out old nest cavities where they stay over winter. Since carpenter bees tend to migrate back to the same area from which they emerged, it is important to implement some control measures in order to prevent logs and wood members from becoming riddled by these bees.

Prevention

Although carpenter bees prefer bare wood they will attack wood that is stained. Painted wood surfaces, on the other hand, are rarely attacked since the bees must see or feel the grain of the wood in order to recognize it as wood. One of the most effective measures for preventing extensive carpenter bee damage is to fill old or empty holes with Energy Seal. Carpenter bees are attracted to existing holes. Be sure to treat the hole before you fill it since live adult bees will drill right through the caulk on their way out.

One way to keep carpenter bees from drilling into wood is by spraying pesticides that contain either cypermethrin, deltamethrin, or bifenthrin (Ortho Home Defense Max) onto wood surfaces. When it comes to carpenter bees, these products act more as repellants than contact poisons. However, the effectiveness of these applications is only about three to four weeks, so the treatment will have to be repeated every so often. Pesticides should only be used during the periods of peak activity in the spring and perhaps again in late fall. Be sure to follow label directions and read and understand any precautions that must be taken when using these products.

Treating Carpenter Bee Holes

Any carpenter bee holes you can reach should be treated and plugged since existing holes attract more carpenter bees. The way to treat an existing hole and tunnel depends on the time of year, and if bees are present at the time of treatment. If the female is drilling away when you find a hole (you can see sawdust coming out or hear her working inside) spray a contact pesticide like wasp and hornet spray into the hole. She will quickly back out and die. Immediately fill the hole with wood putty or Energy Seal. You need to treat the hole even if it appears empty since the bee may be resting and, if left alive, will drill back through the plug you’ve just inserted.

If you find carpenter bee holes in late spring or early summer it’s difficult to tell if there are bee larvae developing in the tunnels. The best thing to do is to run a length of flexible wire into the tunnels in order to break through the pollen plugs separating the chambers. Then spray a pesticide into the hole and seal it up. The same thing should be done on holes found in the fall or winter to kill any bees that may be over-wintering in the holes. Just remember to plug the holes since they will attract more carpenter bees come spring.

Several people told us that although they sprayed a pesticide into the holes, carpenter bees later emerged, in some cases even after the holes were plugged. How can this happen?

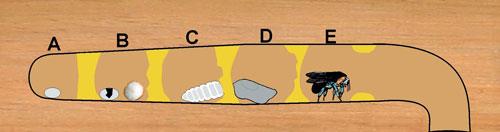

If we take a look at a cross section diagram of a carpenter bee gallery we can see how. After drilling out a four to five inch long gallery, the female carpenter bee lays an egg in back of the gallery then places a plug of pollen she has gathered to form a chamber (A). She continues doing this until there are four to six egg chambers in place. After a few days the egg hatches and a small white grub emerges (B). The grub feeds on the pollen plug for a few weeks (C) until it is ready to pupate (D) and change into an adult bee (E).

If you look at the way the gallery is constructed you can see why spraying a pesticide in the hole may not kill all of the developing bee larvae. The pollen plugs prevent the pesticide from getting to the rear chambers. So before you spray any pesticide into a carpenter bee hole be sure to run a stiff wire all the way to the back of the gallery to break through any pollen plugs. That way all of the larval chambers will be exposed to the pesticide.

A few years ago we requested information about the effect of our gloss topcoat on reducing carpenter bee activity via survey. Out of over 20 responses by letter, phone and e-mail only two reported any penetration of the gloss topcoat by carpenter bees. One home went from 20 to 30 holes the previous year down to 2 this past year and the other went from over 20 holes to 4 holes. This confirms our suspicion that the Lifeline Advance Gloss exterior topcoat appears to provide a finish to the wood that carpenter bees do not find very attractive. That is not saying that the gloss finish repels carpenter bees. It does not. Although bees would occasionally land on the gloss topcoat, they just did not drill through it. So why is it? Well, let’s be clear that the Lifeline Advance Gloss topcoat is not a pesticide nor does it have any pesticide properties. It appears to form a coating on the surface of the wood that carpenter bees are reluctant to drill through. Why? It could be the glossy look or that the hard, slick finish does not appeal to them.

Other Pests?

Dealing with more pests than just carpenter bees? Read our article on best practices for pest prevention for your log home.

Perma-Chink Systems offers wood preservatives designed to protect your home from insects and wood rot. Below are our Tech Tips for our preservatives, along with some general product knowledge on storing procedures.

Following are some comparison points of Lifeline™ finish systems to typical oil-based products.

Environmental Issues

Most oil-based finishes contain some type of organic solvents that evaporate into the air when they dry. These components are known as Volatile Organic Compounds (VOCs). When VOCs are in the vapor state and interact with NOx (Nitrogen Oxides) in the presence of ultraviolet (UV) light, ground level ozone or smog, a health hazard to humans, forms.

Some oil-based products are promoted as being “green” since they are made from renewable plant oils like linseed or soybean oil but even these products require mineral spirits or turpentine (high VOC, disposal regulated products) for clean-up. Although Lifeline water-based finishes also contain some VOCs, they are at a much lower level than oil-based products and clean-up requires only soap and water. That’s why environmental organizations promote the use of water-based products whenever possible.

Preparation

One of the requirements of oil-based finish systems is that the wood must contain less than 18% moisture content before they are applied. Everyone knows that oil and water do not mix. A film of oil will repel any water and water vapor that’s contained in the wood, as well as what hits the surface. On the other hand, if even a minor amount of water is present on the surface of the wood during the application of an oil-based stain, the coverage, adhesion, and penetration of the oil will be compromised with a resulting decrease in durability and performance. This prevents the use of oil-based products on even slightly moist logs or green wood. Recommendations typically include waiting at least three days after stripping or cleaning walls before applying the first coat of any oil-based product.

Lifeline is a film-former that behaves like a semi-permeable membrane allowing water vapor to escape from the wood but preventing liquid water from penetrating into it. That is why Lifeline can be applied to logs containing 30 to 35% moisture content. In addition, Lifeline may be applied the day after cleaning, as long as the wood cells at the surface are not filled with water.

Application Rates

Most oil-based finishes require heavy applications, especially for the first coat on bare wood. Recommended application rates ranging from 75 to 150 square feet per gallon are not unusual. This translates into a lot of oil-based product required to stain a home.

Let’s look at 2400sqft of wood surface that needs staining. If we assume an average coverage rate of 100sqft/gallon, it means that it will take 24 gallons of an oil finish to apply one coat. If two coats are necessary it may take an additional 12 or more gallons to finish the job for a total of 36 gallons. That’s a lot of product.

Lifeline stains have a much higher coverage rate than oil-based products since they do not soak or penetrate into the wood, are specifically designed with low viscosities to maximize the coverage rates, and are easy to apply using airless sprayers. Other than Lifeline, very few stains that we’ve seen and evaluated- including other water-based products- have an initial coverage rate of 350 to 450sqft/gallon on bare wood.

When we compare the amount of Lifeline required to cover 2400sqft to the oil-based example, we end up with 6 gallons for the first coat and 4 gallons for the second coat for a total of 10 gallons of Lifeline stain, verses 36 gallons of the oil-based product.

Product Application

Without a doubt, some oil-based penetrating stains are easy to apply. Some even recommend the use of garden sprayers with no mention of back-brushing. On the other hand, multi-coat oil-based products can present a challenge to the applicator. Virtually all multi-coat oil-based stains require at least 24 hours between coats. Another problem with oil-based finishes is their drying time. Most stay tacky for a week or so after application. If a multi-coat product is used, it is difficult to avoid ladder marks while applying the second or third coats. Of course dirt, dust, leaves, bugs and other flying debris tend to stick to the finish until it finally dries.

Lifeline finishes do require some knowledge to be applied correctly. They are a bit more susceptible to runs, drips and lap marks than oil-based products, but that is why we try to provide product training especially to homeowners through our literature and seminars. To professionals, Lifeline offers some distinct advantages such as being compatible with most airless sprayers and fast drying times which allows multiple coats to be applied the same day.

Clean-Up

The only effective way to clean oil-based products from hands and equipment is with turpentine or mineral spirits. Although the labels of some oil-based products claim soap and water clean-up, we have yet to see one that does not make a mess when these directions are followed. The disposal of used turpentine and mineral spirits in a responsible way is a real challenge to both homeowners and contractors.

Water-based products like Lifeline are easily cleaned up with soap and water. The effluent from washing hands and equipment presents no environmental issues and application equipment like sprayers and brushes can be easily and thoroughly cleaned in preparation for the next job.

Performance

On sun exposed walls, the life expectancy of even the best one- or two-coat penetrating oil-based stain is two to three years- at most. Since they are made to penetrate into the wood, they leave very little protection on the surface where it is needed most. Multi-coat, film-forming oil-based products exhibit better performance than the penetrating products, but the new VOC requirements have had a detrimental impact on them. They are not the same products they were five or seven years ago.

For those products that contain extracted plant oils like linseed, tung, or soybean oil, mold growth is a real concern. Although they may claim to contain mildewcides, the level of mildewcides is rarely enough to overcome the susceptibility of these organic oils to biological growth.

Another characteristic of film-forming oil-based finishes is that they darken with age. This is due to the oxidation of the oil components contained in the stain. As previously stated, film-forming oil-based products do not allow water vapor to escape from the wood. They are not breathable. If water does enter the logs through fissures and checks, there is a good chance that the finish will begin to peel off as water vapor builds up pressure under the finish.

Performance is where our Lifeline products differentiate themselves from oil-based and other water-based stains. There is no question that some water-based products perform no better than the poorest quality oil-based stains. But our Lifeline systems are designed for performance, and we have yet to discover another transparent stain system with the equivalent performance of Lifeline finishes with our Advance Topcoat.

When we talk about performance what exactly do we mean? From a technical perspective, we discuss terms like vapor permeability, adhesion, UV resistance, etc. But to a homeowner, performance comes down to how long will it be before the finish looks so bad that it has to be reapplied. We all know that it is impossible to give a definitive answer to this question since so much depends on environmental factors. But we can say that in side by side comparisons, our Lifeline systems have lasted longer than all of the competitive products that we have tested.

Lifeline Stains versus Oil-Based Stains

Lifeline Finishes

Low VOC, low environmental impact. Considered the product of choice by environmental organizations.

For best results, we recommended moisture contents of 20% or less.

Can be applied the day after cleaning as long as surface is dry to the touch.

High coverage rates. Low viscosity allows application of thin coats.

Fast drying. Wait 2 to 4 hours between coats. Topcoat provides a hard protective surface within hours.

Clean-up with soap and water.

Ultra-2 or Ultra-7 and Advance are warranted for three to five years.

Advance topcoat helps retain color for years.

Advance adds addition water repellency and UV protection to the finish system.

Oil-Based Finishes

Not friendly to the environment.

Wood must contain less than 20% moisture content.

Must wait at least three days after cleaning.

Low coverage rates, takes much more product to stain a home.

Slow drying. Wait at least 24 hours between coats. May stay tacky for weeks.

Clean-up requires turpentine or mineral spirits.

One coat products last one to two years.

Film forming products darken with age, especially around knots.

Why do my choices regarding surface prep, stain, and color matter?

When it comes to choosing a finish system for your log home exterior there are many factors to consider and depending on what choices you make it will have a significant impact on the longevity of the finish system. For example, some of these choices include surface preparation, type of stain, and color choice. Let us take a closer look at each one of these factors and discover how they each contribute to a systems performance.

Surface Preparation

First, surface preparation is often overlooked, not taken seriously, or even dismissed entirely. At Perma-Chink Systems we have learned through many years of testing and experience that this is an important step and forms the foundation for a successful finish system.

Does the surface of the wood have mold, dirt, discoloration, existing finishes, metal contaminants or greyed weathering? All these wood conditions will likely lead to problems with your finish system if left unaddressed. Perma-Chink Systems offers a full line of wood restoration and cleaning products and literature to deal effectively with each of these wood conditions.

Increased wood surface porosity is also important and to achieve best results, we recommend sanding your wood with 60 grit sandpaper. This allows for improved mechanical adhesion of the stain with the wood fibers and increases overall performance of the system as well as color uniformity. The overall color development will be much darker than on un-sanded wood. Nevertheless, the protection of the wood surface is increased substantially. Staining on smooth/un-sanded wood can look splotchy due to the reduced porosity and unevenness of the wood. As a result, not much stain goes on the wall and the performance is reduced accordingly.

If, however, surface preparation is skipped or done improperly prior to an application of stain, it will impact the appearance and longevity of the final system. Some of the likely outcomes such as peeling and early discoloration and unhappy homeowners are the usual result.

Choosing the Right Stain

The type of stain you choose also will impact performance. For all horizontal surfaces it is more advantageous to go with a penetrating type of stain such as our Deck Defense™. If you want to coat both horizontal and vertical surfaces another penetrating flat stain such as our Log and Timber Defense™ is an excellent choice. For all vertical surfaces film forming stains such as Lifeline Ultra 7™, Lifeline Ultra 2™ or Lifeline Exterior™ are your choices. For long lasting color fastness and protection on vertical surfaces the best option is our all-acrylic Lifeline Ultra 7.

Two broad categories for stain type are oil and water-based stains. What distinguishes these two types from each other? The advantages of oils are ease of application, extended drying time and initial high gloss appearance. The disadvantages of oil types are, more hazardous to work with due to dangerous flammable solvents as a primary ingredient, the gloss appearance dulls relativity quickly with exposure and due to its high solid content is less breathable and can chip and peel more easily than a water-based stain. Clean up of oils requires dangerous paint thinner solvents and is arguably more difficult. All our water-based stains are non-hazardous and easy soap and water cleanup as well as breathable making them less susceptible to peeling and chipping.

Choosing the Right Colors

Finally, color strongly influences the performance of any finish system. Our stains are designed to be semi-transparent. This allows the observer to more easily see the unique features of the wood such as grain and texture. However, by their very nature transparent type finishes do not offer the kind of protection afforded opaque systems such as paint. In many of our exterior formulations we use Transparent Oxide type pigments. These pigment types still allow light to pass through so that you can see the grain while at the same time providing a high level of protection from the sun. In addition, we avoid using organic type colorants that are not as colorfast as oxide-based colorants. In general, the darker tone colors will provide more protection and longevity for your home while lighter honey tone colors offer reduced protection. Nevertheless, at Perma-Chink we understand that color is a very personal preference and we all cannot agree on exactly what we would like our home to look like. Perma-Chink offers a broad range of color choices to meet our customers’ expectations and desires when it comes to color. Color formulation have been carefully evaluated for color longevity. Pigment loading levels have been formulated to give the greatest protection possible while at the same time providing color choices that meet our customers’ needs.

Some additional choices such as how many coats of stain, topcoat or no topcoat and surface porosity are also important factors. In general, two coats of Lifeline stain are better than one. It helps to even the color out and provides increased protection of the wood. Having a clear topcoat, such as our Lifeline Advance™, is also a great benefit. This helps keep the system sealed, dirt pickup is greatly reduced, performance of the system is increased, and it provides a great look to the final product.

Contact Us for Assistance

As a log homeowner you have many important decisions to make when it comes to the care and maintenance of your home. At Perma-Chink Systems we have spent the last 40 years developing solutions to help meet your needs. Your choices as well as ours do matter and will make a difference. Let us work together to keep your log home looking great well into the future. For more information about our products please give us a call at 1-800-548-3554 and tell us what your needs are. You can also visit our website at www.permachink.com where you can find more information and order our products directly.

Centipedes, millipedes, pill bugs, roaches, crickets, ants, beetles, spiders, wasps, squirrels, opossums, raccoons, bats and mice are just some of the pests that manage to find their way into homes. It’s just about impossible to keep all of them from getting in, but there are several things that you can do to significantly reduce the number of pests that make it inside your home. Most have to do with blocking the ways they can enter. Furthermore, there are also some things you can do outside to make your home less attractive to pest invaders.

Landscaping

Most pests including rodents and insects like shaded, moist environments. All of the plants and shrubs surrounding your home may appeal to you but they also appeal to numerous pests.

It’s not that you have to cut them down and get rid of them, just move or trim them away from your foundation or log walls. What you need is a two foot clear space between the shrubs and your walls and foundation.

Once you move and/or trim them, you need to put some type of cover on the ground to prevent weeds from growing. Do not use pine needles, wood or bark mulch! The objective of these types of mulch is to hold moisture and that’s what you don’t want to do. You want to provide a dry environment that bugs and rodents don’t find attractive. The best thing to use is about three to four inches of coarse crushed stone or pebbles. Yes, it’s more expensive than organic mulch, but it’s permanent. Just keep debris like leaves from building up on top of it, and the stone will keep doing its job for many years.

Gutters

All log homes should be equipped with gutters. One of the most common problems we see is deterioration of lower log courses due to splash up from rain coming off the roof; however, gutters only work if they are kept clean. Blocked gutters provide ideal moist environments for a wide variety of insects including carpenter ants and termites. Although subterranean termites typically live in soil, they can also establish nests above ground as long as there is a consistent source of water. These types of termite colonies are known as aerial infestations and, if left unattended, the termites can cause significant damage over the course of several years.

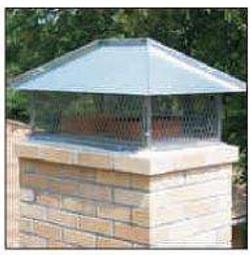

Chimney Caps

If you don’t already have a cap on your chimney, they are a good investment. It is not uncommon for squirrels, raccoons, and birds to take up residence in a chimney during the summer months and become a nuisance. Raccoons are often infested with fleas that can end up in your living areas.

Door Sweeps, Screens and Weather Stripping

Make sure that you have door sweeps installed on all doors accessible to the outside and check to see if they are in good working order. If you can see visible light coming in at the corners they need to be replaced. It only takes a gap of 1/4” for bugs and mice to gain entry. While you are at it, check the bottom seal of your garage doors. Once mice get into your garage they will probably find a way to get into your living area, too.

Windows are the most common entry points for flying insects in particular. Flies, ladybugs, boxelder bugs, stink bugs, and flying ants are just a few of the insects that can find their way into your home through the windows. Check to see if there are any rips or tears in your window screens, and make sure that the screens fit tightly into the frame. See if the weather stripping is still flexible and maintaining a tight seal when the window is closed. If you have sliding glass doors, check them too.

Weather stripping has a lifespan of about ten to fifteen years so if yours is hard and brittle, it’s time to replace it.

Attic and Crawl Space Vents

Normal window screening is not enough to deter determined pests like squirrels. They can gnaw through normal window screening in a matter of a few hours. To prevent entry of bats, rodents, squirrels and raccoons use 1/4” hardware cloth on the outside followed with small mesh screening on the inside to keep out wasps, ladybugs and large ants.

Caulks and Sealants

If you take a walk around your home and count possible insect entry points, you may be surprised at how many there are. Besides all of the windows and doors you’ll find electrical, telephone, cable, gas, outdoor faucets, air conditioning, and plumbing entry points. If you have a crawl space, you may have a number of vents, plus a door. And don’t forget your clothes dryer vent. All of these are common entry points for insects and rodents.

Let’s first address windows and doors. Round log or log sided homes, in particular, present a real challenge when it comes to sealing around windows and doors. All too often once a window or door is set into place, the edges of the opening are covered with a piece of trim and that’s it. Rarely is the trim properly sealed to the logs and large voids behind the trim are left empty (see “Log Gap Cap and Energy Seal” and “How to Apply Energy Seal and Woodsman” for the proper method for sealing around windows and doors). If these voids are not filled, they become perfect nesting sites for several species of ants, many of which will get into your home.

A good product to use for filling these voids is a Log Gap Cap™. A Log Gap Cap is a pre-cut foam insert that is available in two different sizes that fit most log profiles and log diameters. Once in place, the Log Gap Cap needs to be covered with a layer of Energy Seal™ or Woodsman™, since direct UV light will degrade the foam fairly rapidly.

Foundation vents also need to be sealed to the walls. Screening the vents won’t do any good if open gaps are left between the vent housing and the wall. If there is room for backer rod be sure to use it. If the foundation is brick, block or stone, Energy Seal in gray provides a good color match to the existing mortar.

Examine all of the electrical and plumbing penetrations mentioned earlier. Most were probably initially sealed with mortar. Most likely you’ll find cracks or gaps where the mortar has fallen out over the years. If a cheap construction caulk was used, it’s probably hard and brittle. Try to dig out as much as you can and replace it with a high-quality sealant like Energy Seal or Woodsman. When properly applied, they will keep those pesky bugs out of your home for many years to come.

Common locations to seal in home:

Pesticides

We at Perma-Chink Systems, Inc. discourage the broadcast use of pesticides just to keep nuisance pests out of your home. We are a firm advocate of Integrated Pest Management and since there are so many mechanical methods of control available to homeowners, we believe that they should be used as the primary means of preventing pest invasions. Pesticides should be used only as absolutely needed. Yes, there are situations when the use of pesticides may be the only solution to a problem but you may be surprised how effective some of these simple mechanical recommendations can be.

Just as clear coats are vital to the performance of today’s automotive finishes our Advance Topcoats are an integral part of all of our exterior finish systems.

Not only do they extend the life of the color coats but they do much more. They significantly improve the look of the finish by enhancing the color, clarity and depth of the finish. In other words, they make our finishes the most beautiful log home finishes in the world. Second, they help keep the surface clean. The very nature of a pigmented stain makes it susceptible to dirt pick-up through adhesion or impregnation.

Since we have designed Advance to form a smooth, strong film it makes it much more resistant to dirt. In addition, the smooth surface makes it easy to clean off any dust or pollen that may accumulate on the surface of the logs. A simple wash down with Log Wash and a garden hose will remove the dirt and grime that may be hiding the beauty of your home.

Another feature a smooth topcoat provides is greater resistance to the growth of mold, mildew and algae. In addition to water these organisms need something to grip onto. If the spores land on a tough smooth surface that rapidly sheds water they won’t have an opportunity to germinate and spread. So the surface of your logs stays free of unsightly mold spots and patches of algae.

Of course the best feature of Advance Topcoat is the protection it provides to the color containing stain. Years ago cars left the manufacturer with a coat of paint. More expensive cars may have had several coats of paint but no matter how many coats were applied after a few years on the road the paint turned dull and started to flake off. Then car coating experts discovered the benefits imparted by clear topcoats. Today’s car finishes remain shiny and last longer than ever thought possible all due to the application of clear topcoats.

What is it about topcoats that contributes to this improvement? The most performance enhancing feature of a clear topcoat is that it reflects sunlight. Sunlight is composed of several components including ultraviolet (UV) light. It’s the UV that is responsible for fading colors and, in the case of wood homes, damaging wood fibers through a process called photo-oxidation. The more UV light that’s reflected off the surface the slower the color coats will fade and the less the wood fibers will be exposed to photo-oxidation thus extending the life of the entire finish system. Although satin finishes reflect a significant amount of sunlight, gloss topcoats reflect more which is why car finishes are shiny and not dull. The same holds true for our Lifeline exterior finish systems. Advance Satin does reflect much of the sunlight but Advance Gloss reflects even more, which is one of the reasons that log home gloss finishes are becoming more popular.

An additional beneficial feature of a clear topcoat is the protection it provides to the color coats against degradation by airborne contaminates like sulfur dioxide, ozone and particulates. Even natural contaminates like tree pollen and bird droppings can damage or discolor the color coats by chemical reactions or supporting mold growth. Our Advance Topcoats provide a barrier that prevents this from occurring.

Although most people use brushes to apply our finish removers they can be applied with airless sprayers as long as you know what to do. Here is some information that will guide you in using airless spray equipment to apply both S-100™ and StripIt®.

Airless Spray Equipment

Most quality airless spray equipment including the Airlessco SP200 available from Perma-Chink Systems will handle our S-100. On the other hand for applying StripIt, you will need a professional grade airless sprayer with an output of at least 0.54 gpm. In either case, there are a couple of minor modifications that have to be made before using them. The first thing is to change the tip to a 0.019 or 0.021 tip orifice. We stock universal 521 tips in case you cannot find one locally. If a smaller diameter orifice tip (<0.019) is used, it will take longer to apply the proper amount of finish remover and the tip may block up. In addition, since a small orifice produces a fine mist there is a greater chance of wind drift onto surfaces that you may not want to strip.

The second thing is to remove any sprayer strainers, screens and/or filters. Our finish removers are somewhat thick and viscous, so having to pass through screens and filters will impede the flow of product through the sprayer and may eventually block it. Once the stripping process is completed, it’s of utmost importance to replace the 0.019 or 0.021 tip with a 0.015 or 0.017 tip for applying our stain and topcoat.

S-100 and StripIt

Our S-100 Finish Remover and StripIt are formulated so that they can be applied “as is” using an airless sprayer. Their viscosity is such that they do not need to be diluted with water to be run through airless spray equipment. However, it is a good idea to thoroughly mix the S-100 with a Jiffy Mixer before spraying it. Just be careful to keep dirt and other debris out of the product.

Application

The first step before starting to remove a finish is to take off downspouts, gutters, and lighting fixtures, and mask off or cover those areas that you don’t want to strip or they may become discolored if contacted by the product you are using. The next step is to wet down and cover any plants and shrubs. Both S-100 and StripIt are pretty gentle on plant life once they are diluted with water during the stripping process, but in their concentrated form they may present a problem. The use of perforated weed blocking film works well over plants, roofs, decks and other areas you want to protect, since it allows water to drain through it but catches lumps of concentrated remover as well as any stripping debris. This makes clean up a lot quicker and easier.

Apply the finish remover to one or two courses of logs at a time in a sweeping motion across the entire wall starting at the bottom of the wall. This will help you avoid coating the chinking or sealant joints if they are present. Be sure to only coat an area that you can finish stripping in the allotted time you have. If you coat the entire wall or too large an area the finish remover may end up drying on the wall and become difficult to remove. Always apply finish removers at the recommended thickness or coverage rate. If applied too thinly, they may not work and you will have wasted your time and money. Once the finish remover has been applied to an area, submerge the spray gun and tip in a pail of water to prevent the product from drying at the tip and possibly blocking it.

After waiting an appropriate amount of time for the stripper to soften the finish (remember the cooler it is the longer it will take), you can begin the pressure washing process. Be sure to wash off any product and wet finish debris that’s still adhering to the wall or other surfaces. If allowed to dry, you may end up having to manually scrub these surfaces clean. Once you reach the top of the wall, or if you run out of time, rinse the entire wall starting at the top before you quit. You don’t want any chemical or finish debris to remain on the surface. If you are through for the day, replace the lid on the pail of finish remover and run clean water through your airless sprayer until clear water comes out of the gun.

During the winter months it’s important to be aware of the freeze-thaw stability of Perma-Chink’s products. The reason may involve shipping conditions, or whether it is okay to store a product or products in an unheated shed. In any case, you need to be aware of the consequences of allowing any of our products to freeze.

Without a doubt it is always best to prevent any of our finishes and sealants from freezing. They all contain water and the formation of ice crystals within the products can separate the water from the other components. In some products once this occurs it becomes impossible to regain the properties of the original formulation, even after thawing and vigorous mixing. These types of products are not freeze-thaw stable.

With a few exceptions, most of our products are freeze-thaw stable. However, if a product becomes frozen it needs to be thawed slowly, preferably at room temperature. Speeding up the thawing process by heating the container can seriously damage the product making it unusable. If the product is in pails or containers, once it has completely thawed it will require a thorough mixing.

When a waterborne product is subjected to multiple freeze-thaw cycles, each cycle contributes to the degradation process until the product is not suitable for use, i.e. gelation or coagulation of the product. If a product does become frozen it is better to allow it to stay frozen than it is to bring it inside to thaw and then store it where it may freeze again. It’s the succession of freeze, thaw, freeze, thaw sequences that really destroys the integrity of a product.

Before applying any product that’s been frozen, be sure to test a small amount to see if it is still usable.

To reiterate:

- It’s best to protect all of our products from freezing.

- If it does get frozen, thaw it slowly at room temperature then thoroughly mix it.

- It’s better to keep it frozen than to subject it to multiple freeze-thaw cycles.

- Before applying any product that’s been frozen be sure to test a small amount to see if it is still usable.

Perma-Chink Systems’ products that are NOT freeze-thaw stable:

- Chink Paint™ Textured

- Chink Paint™ Smooth

- Log End Seal™

- Oxcon™

- StripIt

Perma-Chink Systems’ products that have limited freeze-thaw stability (5 cycles or less):

- Lifeline™ Ultra 7

Most of the Directions for Use for our finishes contain the statement “Do not use Lifeline™ on surfaces that have been brushed or rubbed with steel wool or a wire brush. If you do, rust spots may appear under the finish.” Fortunately we rarely see the consequences of applying one of our finishes over a wall that has been rubbed or brushed with steel wool or a wire brush, but occasionally it does happen.

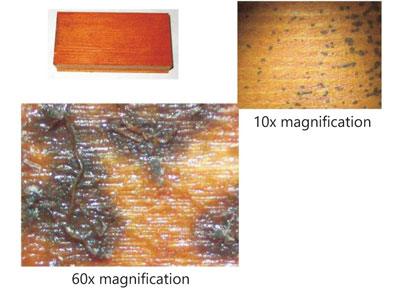

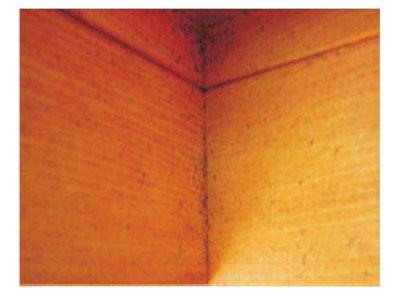

The customer who took this picture thought that the dark spots in the corners were due to mold; however, they appeared within just days after the finish was applied. We were able to obtain a small section of the discolored wood and just looking at it gives the impression that the discolorations could well be mold, or some flecks of dirt that may have been present at the time of staining. Even under the microscope at 10X magnification, there’s no indication of what caused the black spots.

But at 60X magnification it quickly becomes apparent that every black spot is associated with some type of fiber imbedded in the film. These fibers are bits of steel wool. Since the black spots are concentrated in the corners, it’s evident that someone had tried to wipe the wall clean but missed the corners entirely.

Designing a Fortress of Protection for Your Log Home

When I was growing up, I was fascinated with forts. I would often get together with friends from the neighborhood, and we would combine our resources and construct some rather elaborate fortresses. To test our handywork we would end our session with a great battle to decide whose fort was superior. Fast forward nearly forty years and I am still helping design forts! At Perma-Chink Systems the forts we are building are designed to protect your home against the forces of nature such as sunlight, wind, rain, dust, insects and microorganisms. Let us take a closer look at what our fort looks like.

Protection From The Start

We have advocated for many years that the protection of your log home starts with a smart design. For example, many modern log home builders use large overhangs and wide porches to help shield the home’s walls from dangerous radiation from the sun. Let your roof help protect your walls. Planting trees that can help shade your home not only reduces energy consumption, but also helps to prolong your finish system.

Protect From Insects and Ultraviolet Damage

Protecting your home from wood destroying insects is something we have also incorporated into our “fort” design. Bare wood logs or siding can be treated with anyone of our safe, borate-based wood preservatives such as Shell Guard™, Shell Guard RTU™ and Armor Guard™. These products are designed to provide a protective shell of defense for log homes. If a wood-ingesting insect such as a termite or Powder-Post beetle passes through this protective barrier, they are in for quite a nasty surprise. The borates work to interrupt the insects natural digestive cycle, making it difficult – if not impossible – for the organism to process food. These products, while destructive to wood-ingesting insects, pose little danger to humans.

Perma-Chink offers a full line of stains with numerous color choices and benefits. For example, our stains such as Lifeline Ultra 7™, Ultra 2™ and Exterior™ have ingredients designed to protect the wood surface from algae and fungi (mold). In addition, we also have ingredients that work to shield the lignin in your wood from photooxidation. Lignin provides structure and support for the cell walls in wood. If it is destroyed by harmful ultraviolet (UV) radiation, then your coating could delaminate from the wall more easily. Furthermore, our stains also contain UV absorbers designed to filter out harmful radiation. Our colorants also add another level of protection for your finish system. In general, darker tone stains provide a higher level of protection than lighter, honey-tone colors. Choosing a slightly darker tone will act as a shield to help protect your wood more completely and provide more longevity and less color shift.

Protect With Industry-Leading Sealants

Our business was founded forty years ago with a great solution to existing chinking. Back at that time, many folks used concrete between the logs to fill in the gaps. When the logs changed dimensionally this created cracks and open places for water to get in and damage wood structures. Perma-Chink™ seals between the logs and moves with your log home keeping a tight seal that keeps water and insects out. For smaller joints of less than one inch, we also sell Energy Seal™ and Woodsman™ which are great products for sealing around windows and doors.

Protect With The Finishing Touch

The next defensive layer in our “fort” is the topcoat. Our Lifeline Advance Satin™ or Gloss™ has several purposes. First, it provides a hard surface making it more difficult for dirt and debris to collect on the wood and sealant surfaces. Secondly, it contains both UV absorbers and UV stabilizers. Often when you UV light strikes a system it produces harmful free radicals that can be destructive to a coating system. The UV stabilizers are designed to terminate free radicals so they cannot continue their destruction. The UV absorbers act as a shield keeping the dangerous UV light from penetrating deeper into the system. Finally, it works to keep your coating system sealed. If water remains on surface for long periods of time, it can allow microorganisms to grow and multiply. Water will sheet and evaporate relatively quickly with the topcoat present.

Finally, regular cleaning of your home will help keep your home looking beautiful well into the future. Buildup of dirt and debris can provide a foothold for fungi and algae to grow, decreasing the longevity of your finish system. To aid in this annual cleaning, Perma-Chink provides a safe cleaner called Log Wash™ which does a fantastic job removing these unwanted contaminates from your log home.

Protect By Moving Forward

As you can see, we have many layers of defense built into our fortress. The forces of nature are powerful and unforgiving at times. Over the years we at Perma-Chink have gained tremendous respect for what it can do to damage your home. We have learned a great deal over these last forty years and have adjusted tactics where needed to counter our foe. Let us put our experience building forts to work for you. Please visit our website at www.permachink.com to learn more about our products and how they can help you protect your home.

Occasionally we get a call from someone whose home has a gray aged patina that appeals to them. They typically want to apply some type of clear water repellent to seal and protect their home, but they don’t want to remove the grayed wood. The gray color is an indication that the surface wood has been photo-oxidized by ultraviolet (UV) light and the wood fibers have lost their integrity.

The application of any film-forming finish over grayed wood presents a problem since the finish will not adhere to the degraded wood fibers. It would be like trying to paint over a rusted metal surface. Within a few months the paint begins to peel off; consequently, the same thing can happen with a film-forming log home finish applied over grayed wood. With this in mind, we never recommend applying any of our stains or topcoats over gray, photo-oxidized wood.

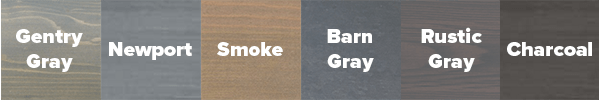

Gray Color Choices in Lifeline Stains

Although there are solvent-based products that can be applied to grayed wood surfaces they only last about six months or so. If you truly want to protect your home, you will have to remove the grayed wood, and if you like the gray look, use one of our gray colored stains. If you are not willing to clean the surface down to bare wood, the best recommendation we can give you is to leave the surface alone but make sure that all chink joints, checks and other places that may allow water entry are well sealed.

Log Homes in Gray Colors

Pressure washing (also referred to power washing) is the function of using highly pressurized water to remove mildew, mold, dirt, pollen, UV graying, etc. You’ll hear different recommendations whether or not pressure washing your logs is the best cleaning method.

Generally speaking, pressure washing is the quickest and least expensive choice.

One fallacy is that you’re saturating and “damaging” your logs with water as a result of pressure washing. This simply isn’t true. On hard, sound, rot-free logs, you’re only introducing water into the top fibers of the wood.

The time it takes to pressure wash and the results generated are often directly associated with the type of finish being removed as well as how many coats have been applied. While some older, obsolete linseed based oil stains are more difficult to remove than newer products, practically everything can be removed with proper pressure washing techniques and good finish removers. Some of these older type products will often need S-100 or StripIt stripper applied first in order to soften the bond to the wood.

Condition of Wood Surface

Traditionally, newer, recently peeled logs have a greater surface hardness and can withstand highly aggressive pressure washing (if needed) easier than a log wall which has been fully exposed to direct sun for 20 years. You might notice your upper and lower fascia boards have aged and darkened at an accelerated rate compared to your logs. Because these areas are often made from softer (i.e. pine) wood, they are more likely to absorb water leading to more prominent mildew growth. These areas can easily resemble new wood once cleaned.

Pressure washing of new constructions can also easily remove the UV graying of the logs that can start occurring just weeks after the logs are stacked, particularly if exposed to direct sunlight.

In addition to log and wood sided structures, other areas where pressure washing can be utilized include driveways, stone walkways, pool decking, stone walls, fencing, gutters, downspouts, roofing and other areas. Concrete slowly builds up a browning/green appearance over time which usually consists of grease, dirt, mildew and algae which can easily be cleaned.

Pressure washing can be done in practically any temperature and weather conditions, although chemical strippers, which are often applied prior to cleaning, work much better in warmer weather.

Whether you hire a professional or undertake the project yourself, pressure washing with wood cleaners from Perma-Chink Systems can bring back the beauty of your logs, preparing them for a fresh coat of stain and protective clear topcoat finish.