Blog

Perma-Chink Systems namesake product, Perma-Chink, is the leading sealant for log homes. We’ve extended the same performance and quality of Perma-Chink in our other sealants, Energy Seal and Woodsman.

Below are our Tech Tips for all our sealants, including our Chink Paint, which provides an excellent solution to refresh old, but sealed, chinking.

Sealants Application Guide

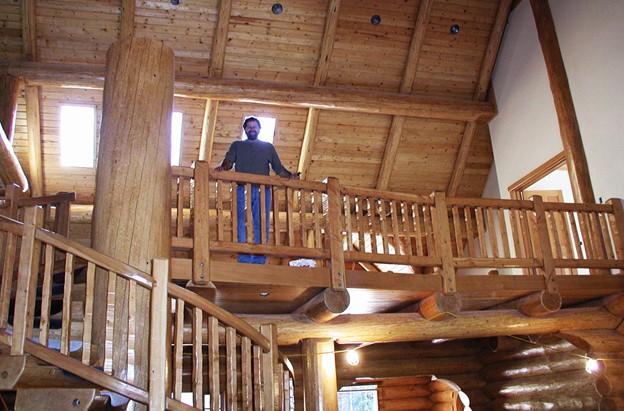

The inside of a home is where you do most of your living. As such, it’s important to take time to select the right interior stains and finishes for your log and timber home. You will achieve an interior that is visually pleasing and performs well for years when a proper stain is chosen.

Two Traits

When it comes to interior finishes, there are two phenomena that homeowners tend to overlook.

1. Surprising surface area. Interior walls and ceilings dramatically increase the amount of surface area that requires treatment. Generally there is about twice as much stainable surface on the interior than the exterior. You’ll be looking at the results of your interior stain for years to come throughout your entire home, so choose wisely.

2. Choices, choices, and more choices! During a new build, homeowners are faced with hundreds of decision points along the way, often with details unfamiliar to them. It’s common for homeowners to ask the general contractor (GC) for advice. Many GCs typically recommend a “safe” off-white color, but that doesn’t always translate well with the natural logs in a cabin. A GC wants to stay on schedule, but selecting your interior stain takes a little time. You can’t easily undo stain.

What’s Your Color?

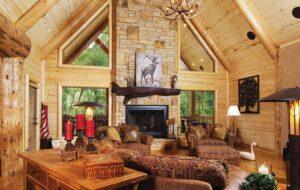

When selecting the perfect interior stain for your log home, consider how you use your space and the atmosphere you want to create. Is your home filled with natural light? Do you lean towards cozy dark walls with a lighter ceiling, or do you prefer a bright and airy ambiance with lighter walls? Keep in mind that wood absorbs light, so a darker stain can make a room appear significantly darker than you might expect.

Next, think about the tint base. Do you favor shades of brown, red, gray, or perhaps a bleached look? Wood stain trends come and go, so it’s essential to explore your options and choose a tint that you’ll love for years to come. Remember, it’s easier to darken a light stain than to lighten a dark one.

Distinct Needs

Not all interior wood is the same. Logs and heavy timbers are not like the wood of cabinets, moldings, and furniture. These smaller wood products are usually sprayed with nitrocellulose lacquer to protect them through a hard, shiny finish. Unlike cabinets, tables and trim, larger timbers and logs are more dynamic. If you try and put a similar lacquer on your interior log walls, the finish will crack and peel as these larger pieces of wood naturally contract and expand. A specialized finish for logs will ensure the interior looks the best for years to come.

Some homeowners wonder if the interior can go “au naturel” and keep the wood plain with no stain or topcoat. While interior logs may not be subjected to the same elements as their external counterparts, unfinished logs and timbers will absorb cooking oil and odors and collect dust, handprints, and water stains if not protected. Have you ever run your hand across rough-cut wood? The roughness of the wood is not very pleasant to feel. All those little crags and jags on the surface need to be covered in a light film; one that’s strong enough to be wiped down and protect the wood while remaining flexible enough to not crack as the log expands, shifts, and contracts over time.

Choose a stain that’s designed for the demands of a log home interior. Exterior stains contain higher levels of biocides and preservatives that you don’t need or want inside your home, especially where you’re eating and sleeping. This is also why you want to avoid an oil-based stain. Oil-based products have high levels of volatile organic compounds (VOCs), which are extremely unhealthy in enclosed spaces.

Smart & Attractive

Start with a stain that gives you the aesthetic and exact level of transparency you desire. Here at Perma-Chink Systems, we recommend using one of our Lifeline Interior stains, which come in a wide array of tones, including clear. After staining, add one or two clear coats of interior finish; Lifeline Acrylic or Sure Shine, a water-based poly finish. Both add enough film to protect your logs and minimize the roughness of logs so they can be easily wiped and cleaned. Lifeline Acrylic and Sure Shine come in gloss or satin. Sure Shine is strong enough to withstand foot traffic, and an excellent alternative to wood floors than smelly and caustic oil-based floor coatings.

These stains also contain the right amount of UV protection to avoid “picture framing.” Picture framing is the shadowy discoloration that remains on the wall when you move a bookshelf or a picture. After all, your stain should let you redecorate your log home whenever you want! Perma-Chink interior stains and finishes will ensure that the inside of your log home is just as breathtaking and gorgeous as the outside.

To order free color samples, visit our online store here or call us to discuss custom colors at 1-800-548-3554.

What Makes A Topcoat Different?

There is a common thought out there that believe topcoats are just the regular finish without color added. However, our topcoats are completely different than our finishes because they do different things.

Lifeline Acrylic Gloss and Satin (G/S) and Sure Shine™ Gloss and Satin are totally different formulations than Lifeline Interior or any other finish. Lifeline Interior, Lifeline Accents, and Prelude™ contain a polymer system that offer some distinct adhesion advantages when applied to bare wood. Topcoats are designed to envelope those finishes, protecting the color and wood from environmental damage and everyday living.

Why Do I Need An Interior Topcoat?

When left exposed without a topcoat, interior finishes are more susceptible to dirt pick-up that may not be easily cleaned off. When topcoated with Acrylic G/S or Sure Shine G/S, the finish surfaces become much more impervious to dirt pick-up. The wood surface becomes more slick and smooth, enabling them to be kept clean with much less effort. And as mentioned earlier, the topcoat protects the finish from abrasions, dirt, water, and more. The bottom line is that Lifeline Interior, Lifeline Accents or Prelude are highly recommended to be topcoated with either Acrylic G/S or Sure Shine G/S to get the maximum protection for your log or timber home interior.

When Can I Apply A Topcoat?

The best time to apply a topcoat is when your log home has dry or seasoned logs. Whenever a house is over one or two years old, or you are sure your logs are dry, be sure to obtain samples of both Acrylic G/S and Sure Shine G/S. If Acrylic G/S does not result in the smooth, slick surface that you desire, try Sure Shine G/S. Sure Shine G/S is a water-based acrylic-urethane that builds depth and luster with fewer coats. However, polyurethane films are less breathable, so we do not recommend their use on logs that have not fully seasoned. If your home is finished in Acrylic, in the future Sure Shine G/S can always be applied over the Acrylic G/S if you want an exceptionally smooth, deep finish on your interior walls.

Can I Topcoat Over Bare Wood?

What if you don’t want a pigmented stain on your interior wood? Do you need to apply Prelude or Lifeline Interior Clear before applying Sure Shine G/S or Acrylic G/S? From a technical and performance standpoint, it does not matter which one you choose, although Prelude does include an additive called UV Boost that will help prevent the picture frame effect that occurs over time. Although UV Boost can be added to Interior Clear, Acrylic G/S and Sure Shine G/S, most people prefer not to spend more money than they need to, and using Prelude as a primer on bare interior wood will significantly decrease the amount of more expensive Acrylic G/S or Sure Shine G/S you will require.

How Can I Get Lifeline Acrylic or Sure Shine?

We’re glad you asked! You can order online at Store.PermaChink.com or call us at 1-800-548-3554. We’ll be happy to help get your started on protecting your home.

In loving memory of our late president Rich Dunstan.

In The Beginning

In 1980 my neighbor told me about building a log home in Eastern Washington. He said that he loved the home and the lifestyle but was disappointed wind constantly blew and cold, harsh winters meant there was no real effective way to seal the gaps between the logs. The house leaked air and heat and wind-driven rain came right through the walls.

He tried various caulking materials with little success. Caulking around a bathtub or sink was significantly different from ‘caulking’ literally miles of seams between logs in a log house. After a number of conversations and experiments, we discovered there was no readily available product that could seal the gaps, look like authentic chinking, and last more than a few months.

After months of trial and error it became apparent that if we were going to design a material that would be acceptable to our criteria, we would have to design it ourselves.

The product we were designing was to be a replacement for what was known in the Log Home Industry as “chinking” – the sealant that historically provided the seal between the logs. A chink is a gap – as in Biblical Times, “A chink in his armor’. Therefore, chinking is a material to fill a gap. Throughout the centuries of constructing dwellings out of logs, numerous methods were used to seal in between them. Early builders used pretty much anything they could get their hands on to seal the gaps – mud, straw and mud, cow manure, or mixtures of cement and mortar.

The Criteria For Crafting The Perfect Chinking

During our investigation we determined that in order to be a true solution, the sealant must meet the most important requirements:

- It had to be textured to look like authentic mortar chinking.

- It had to “look like it belonged there.”

- It had to be able to expand and contract to follow perpetual log movement. As logs dry out in the summer, they shrink in diameter – in the winter or rainy months they absorb moisture and swell, increasing in diameter.

- It had to adhere tightly to the logs and form a continuous, watertight seal that doesn’t separate from the wood.

- It had to be easy to apply in gaps up to 4 or 5 inches and not slump or wash out.

- And most importantly, it had to LAST for decades.

Common caulking materials were quickly ruled out. Everyone has seen thin caulking beads applied to exterior trim that invariably separate, peel off, flake, crack, and ultimately fail. No caulk could adhere to the wood well enough and could not be applied to the thickness and height required without slumping and running out of the joint. And all caulks had that smooth, artificial look that frankly looked like caulk! Okay for around the tub or sink, but not for my log home, thank you.

So, after months of experimentation and learning a tremendous amount of chemistry about polymers (the chemical building blocks of literally everything that we commonly call paint, plastic, vinyl, glue, etc.), we designed a unique sealant that met all the requirements.

During the design phase we located an innovative small company south of Seattle that manufactured synthetic stucco. They had the experience and the machinery that helped us scale up lab designs to large scale production. We began selling early product in 1981 and the first house we did was in Sun Valley, Idaho – in the middle of winter.

Going To Market

Soon after, we had a saleable product that met EVERY design requirement. I did a little market research and discovered that the largest part of the national log home market was in the eastern United States, particularly the Southeast. I also discovered that of the numerous styles of log homes, the three largest manufactures of dovetail-designed log homes were within 100 miles of Knoxville, Tennessee. I liked the dovetail design because of the nature of the structure, and the way the logs are stacked resulted in a chinking gap of up to 4 inches! In some cases, almost 25% of the wall area was chinking!

So, we set up a manufacturing plant in Knoxville. The timing was right because as soon as log home owners and manufacturers discovered that we could finally provide a dramatically better solution to one of the most significant and perplexing aspects of a log home – the business grew rapidly.

Solving Manufacturer’s Greatest Construction Need

Early adopters such as Hearthstone, Honest Abe, Stone Mill, and Appalachian Log Homes helped pave the way for essentially all others to follow. As a matter of fact, one of the earliest applications for any Manufacturer was Appalachian. Turns out they had a contract with the US Forest Service to build an outhouse. The location was remote, and the house needed to be completely assembled and transported via helicopter. Obviously, mortar chinking could not withstand that type of stress, so they tried Perma-Chink. That outhouse is still standing today and is weather tight – some applications simply CANNOT fail!

The development of synthetic chinking solved one of the most serious and vexing aspects of the log home industry. The chinking formulation is unique and specifically designed for log homes, and not simply ‘caulk with sand in it’ as others have offered.

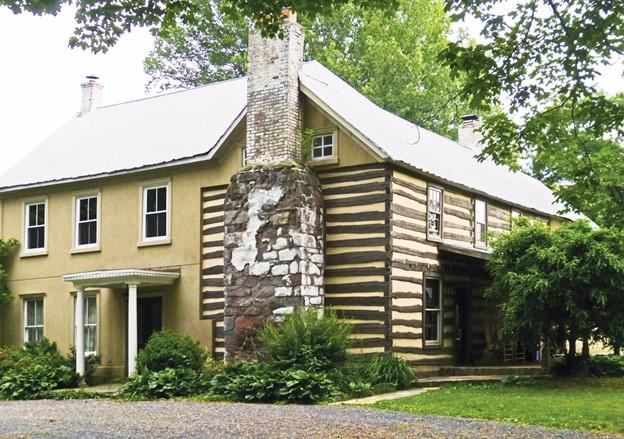

George Washington’s Farm log cabin restored with Perma-Chink Systems log home sealants and stains.

Rick Denton, Honest Abe Log Homes President Emeritus said “Perhaps the invention of Perma-Chink kept Honest Abe in business, as well as every other log home company using a chinked product line.” Read his story here:https://www.honestabe.com/blog/perma-chink/

A Great Success From Fantastic Partners & Customers

What started out as an idea has literally revolutionized the entire industry. Worldwide, most log structures use synthetic chinking, and the largest supplier of the most authentic and highest-performing log home chinking is Perma-Chink.

We used the knowledge and expertise we developed in formulating Perma-Chink Chinking (remember the polymers?) to design the longest-lasting semi-transparent stain in the industry. The formulation is also unique, providing a ‘furniture grade’ appearance that outlasts any exterior stain on the market.

As history has shown, and something we take pride in, whenever a log home owner becomes aware of a concern, whether it be sealing, staining, or preservation or maintenance, we already have a solution.

Driven to Exceed Now & In The Future

We are humbled that Perma-Chink Systems has become the household name in the log home industry and is recognized for its high quality. Our products grace the log homes of such noted Americans as former President Jimmy Carter, clothing designer Ralph Lauren, movie star Tom Cruise, Olympic champion figure skater Kristi Yamaguchi, NASCAR champion Dale Earnhardt (read the story here) and thousands of great American homeowners.

Perma-Chink Systems has a slogan – “Simply Unmatched”. By crafting the best quality products and engaging in providing the best customer service, we will attain our goals and make great strides towards exceeding our customers’ expectations for years to come. To be “Simply Unmatched.”

Do you need to remove any caulk that’s already in place before applying Energy Seal™, Woodsman™, or Check Mate 2®? Applying new sealant over old caulking is never a good idea, even if it looks like the old caulk is still sticking to the wood. The old caulk should be removed for several reasons.

If the caulk has lost some of its adhesion, it may have allowed moisture to seep in under it, possibly creating decay. The old caulk must be removed to properly treat and seal the area, so it does not happen again.

The old caulk may have deteriorated due to age, decomposition, or the wrong type of caulk being used. We often find that silicone caulks were used to seal wood joinery or checks. Although silicone caulk does a good job sealing glass and tile, it does not adhere well to porous materials like wood and deteriorates rather quickly when exposed to direct sunlight.

Butyl rubber caulks and oil-based caulks may out-gas, creating blisters in freshly applied Energy Seal, Woodsman, or Check Mate 2. Inexpensive hardware store caulks harden with time and will pull away from adhesion point surfaces. No matter what type of caulking was previously used, if it is not removed, the adhesion of Energy Seal, Woodsman or Check Mate 2 to the wood will only be as good as what’s left in the old caulk.

All sealants manufactured by Perma-Chink Systems are formulated to have excellent adhesion to wood and other building materials. They contain high-quality acrylic resins to insure that they do not lose adhesion, color, or elasticity when exposed to the elements for decades.

There are some tools that can help make old caulk removal easier. Hawk-billed or linoleum knives are great tools for scraping off old caulk. If the old caulk is silicone-based, it can usually be peeled off by just pulling on it with your fingers or needle-nosed pliers.

Check caulked areas that have failed for evidence of moisture. If the wood has been damp for an extended period, these areas should be treated with a borate and allowed to dry before Energy Seal, Woodsman, or Check Mate 2 is applied.

Energy Seal, Woodsman, and Check Mate 2 work best when applied to bare wood or over stains or topcoats manufactured by Perma Chink Systems, Inc. If it is applied over an existing old caulk, you run the risk of adhesion failure and your time and money will have been wasted.

Note: Please remember that Energy Seal, Woodsman, and Check Mate 2 should always be used in conjunction with Backer Rod wherever possible.

Homeowners ask this question a lot, to make sure the home looks like how they imagine. The answer to this question depends mainly on which sealant is used and how you want your home to look.

Sealant Choice

If you’re using Perma-Chink chinking, we recommend staining your home first with a Lifeline stain of your choice, then seal the log gaps with Perma-Chink, and finish with Lifeline Advance Topcoat. The application of Advance will make the home easier to clean (recommended two times per year with Log Wash).

If you’re using Energy Seal or Woodsman, and you don’t want log gaps or the sealant to be noticeable, we recommend applying the sealant first, then apply your choice of Lifeline stain and topcoat. For the least visible Energy Seal lines, select a color that is a shade lighter than the stain color. If you like the aesthetics of visible lines, you can apply Energy Seal after the application of a Lifeline stain and before Lifeline Advance.

What If I’m just applying a new coat of Lifeline? Do I need to redo my chinking?

If you’re just applying a maintenance coat, or just want a new color for your home, you do not have to rip out your old chinking. You can either mask off the current chinking before staining, or you can use our Chink Paint to refresh the color after staining.

What about when to seal checks?

Another issue you will have is with upward-facing checks. These are the cracks in the wood that end up collecting water and lead to log deterioration. We offer Check Mate 2, a highly flexible sealant that will create a seal in the check, preventing water from entering the log. Checks can appear at any time as the logs age, it’s a natural occurrence.

If your logs have checks before you stain and seal your home, seal the checks now. Check Mate 2 will accept stain. Just make sure you select a Check Mate 2 color one shade lighter before staining.

Final Answer

The order which you apply stains and sealants varies on what you’re currently working with. For the best performance, we recommend stain first, seal second, and apply Advance Topcoat third. This will provide the best protection for your home.

You can read more about applying sealants in our Sealants Guide PDF.

Curious to Know What Makes Your Log Home Exterior Different From the Rest?

Perma-Chink Systems is dedicated to exceeding expectations, ensuring that our products reflect both our commitment to quality and our responsibility to the community. That’s why we go the extra mile to ensure our wood stains and finishes are crafted from the most environmentally friendly materials available. Our commitment to sustainability doesn’t just stop there—our products also deliver a refined, furniture-like finish that enhances the beauty of your wood. But unlike the furniture coatings, our finishes are designed to breathe to let the moisture evaporate from your logs.

LIFELINE stains and finishes from Perma-Chink Systems stand out for several reasons:

- Waterborne Formulation: Lifeline products are water-based, making them environmentally friendly and easy to clean up with soap and water.

- Breathability and Flexibility: These finishes form a breathable, elastic barrier that allows the wood to expand and contract with changing weather conditions, reducing the risk of cracking and peeling.

- UV Protection: Lifeline stains contain high-performance pigments and UV inhibitors that protect the wood from sun damage while highlighting its natural grain.

- Durability: The finishes are designed to be long-lasting, requiring minimal maintenance.

- Aesthetic Appeal: Lifeline stains enhance the natural beauty of the wood, providing a rich, vibrant finish that highlights the grain and texture.

- Safety: These products release no toxic fumes and are not flammable, making them safer to use.

- Ease of Application: Lifeline finishes are easy to apply and can be used over existing water-based stains, provided the surface is in good condition.

- Easy Maintenance: Lowest maintenance of any exterior wood finish.

LIFELINE stains are a top choice for log homes and wooden structures, blending protection with stunning aesthetics. One of the key considerations for log and timber homeowners is selecting the right stain color. While many stains may look impressive immediately after application, the real test is whether they retain their beauty over time.

With LIFELINE, you’re choosing a high-performance finish that maintains its vibrant appearance long after application. Engineered with cutting-edge technology, LIFELINEis the most advanced wood stain available for log and timber homes in the world.

Request your free sample today and see for yourself how LIFELINE can preserve the beauty of your home, even as the seasons change. Order free samples by calling your local store at 1-800-548-3554 or order from our online store here.

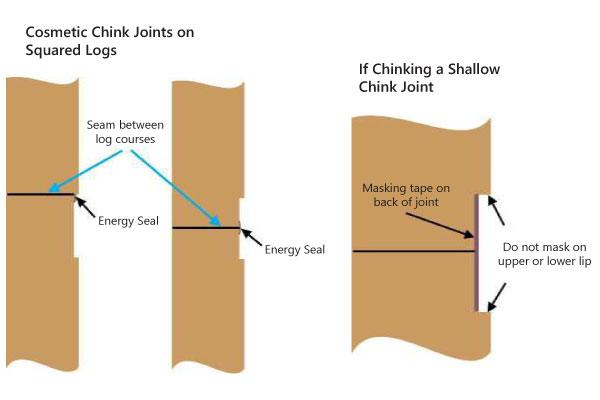

A number of log home manufacturers offer squared log homes with cosmetic chink joints. Although, some owners of these style homes ignore cosmetic joints and just stain over them. Others like the look of a chink-style home, which may be the reason that they bought the home in the first place. For these cosmetic joints, do homeowners need to use Perma-Chink® or can Chink Paint™ be used instead?

For those cosmetic joints that are less than 3/8 inches deep, the answer is fairly easy. Unless the log home manufacturer specifies the use of Perma-Chink, Chink Paint is less expensive and much easier to apply, especially if you are planning to do it yourself. Since there is no room for backing material, we have seen several instances when a thin layer of Perma-Chink was applied directly over bare wood, and blisters formed in the chinking. Even if the bare wood is covered with masking tape, it still is not be a good idea to use Perma-Chink. If the Perma-Chink only has a 1/4” lip of wood to hold onto on the upper and lower edges, there may not be enough surface area for good adhesion. If Perma-Chink is applied and masking tape is used as a backer in shallow chink joints, it’s especially important to make sure that the tape does not cover any edges. If it does, there will be virtually no adhesion of the Perma-Chink at that point.

Whenever Chink Paint is used and a seam is present within the cosmetic joint, the seam may be first sealed with Energy Seal. Once the Energy Seal is dry, Chink Paint can be applied over it. Do not use masking tape under Chink Paint. It will prevent the Chink Paint from adhering to the wood and may eventually peel off.

For cosmetic chink joints that are 3/8 inches deep, or deeper, Perma-Chink may be used; however, you should be aware that Chink Paint is a less expensive alternative that is much easier to apply. If the joint is deep enough to accommodate both backing material and the proper thickness of Perma-Chink, it’s best to actually chink it to prevent water from accumulating on top of the bottom lip.

John Ricketson

Project Manager – Hearthstone, Inc.

www.hearthstonegeorgia.com

At every trade show, I get asked the same question: How long does Perma-Chink last? My answer has always been “I don’t know, we’ve only been using it for 37 years”[ed. note – as of 2019]. I built my log home in 1988 and used Tan Perma-Chink with Dark Honey Lifeline EX stain because I wanted a combination that was not too much of a contrast and the results were exactly what I had intended. The home has weathered and aged over the 32 years and I have re-stained it a couple of times, the last time being 8 years ago. The East side and North side required very little maintenance then, just a light cleaning with Log Wash and a renewal coat of Lifeline Advance. The South and West sides required a little more effort after cleaning due to exposure to weather and the sun. A refresher coat of Lifeline EX and Lifeline Advance Satin on the logs, gable end siding, and roof fascia got it to looking like new again.

So, after 31 years, I took a close look at a log wall that has been exposed on the Southwest side, where it get as much abuse from the elements as possible, and here is what I found: Out of eight horizontal runs of Perma-Chink, only one showed any indication of age. This was course number 5 and is the one directly under the 32′ tie log that runs above the fireplace, where the interaction of the stonework to the log wall can sometimes cause the log to ‘hang up’ and not fully settle. This was confirmed by looking at the dovetail corner notch, where there had been some separation. Even though Energy Seal was not yet available, the caulking originally used there was still in good shape and there was no danger of air or water infiltration on the dovetail notch that sloped away from the home. Even with all of that, the Perma-Chink separation was less than 1/16th of an inch, and in that one run only, the other seven runs were still providing a perfect airtight and watertight seal.

The surface seemed to be slightly faded, so I got out my Frog tape and taped the lower edges of the chink spaces (because I am not as meticulous with a brush as most people) and proceeded to refresh the surface of the chinking with Chink Paint. Twenty minutes later, the surface on that wall was like new and I am looking forward to answering the question again at the next trade show with: “I don’t know, we’ve only been using it for 37 years and if you want to refresh the color or change the color, a little Chink Paint will quickly get your home as good as new.”

Why Perma-Chink Sealants Are the Best Choice for Your Log Home

Sealants play an essential role in our daily lives, from the windshield of your car to the bathtub, and even your windows. They keep water out, prevent air leaks, and ensure your home stays comfortable and protected. But not all sealants are created equal, and when it comes to log homes, the right sealant can make all the difference.

Everyday Examples of Sealants

You may not realize it, but sealants are all around us:

- The windshield of your car is held in place with a sealant to keep water out.

- There’s a bead of sealant around your bathtub to prevent water from seeping behind tiles.

- Your windows are sealed with a special material to stop cold air, rain, and drafts from entering your home.

If you take a close look, you’ll notice that sealants vary in texture, flexibility, and performance. The best sealants are those that remain flexible and durable across a wide range of temperatures, sunlight, and environmental conditions. And this is where Perma-Chink Systems really shines.

Why Choose Perma-Chink Systems Sealants?

So, why do homeowners choose Perma-Chink Systems sealants for their log homes? Here are three key reasons:

- Keep the Elements Out: First and foremost, Perma-Chink sealants provide a reliable barrier that keeps water, air, and insects where they belong—outside your home.

- Attractive Appearance: Our sealants are designed to blend seamlessly with the natural look of your log home, offering an attractive finish that complements your decor.

- Proven Performance: With a reputation for long-lasting durability and superior performance, Perma-Chink products are trusted by homeowners and professionals alike to deliver reliable, long-term protection.

Why Sealing a Log Home Is Different

Sealing a log home presents unique challenges. Logs are naturally irregular, and when stacked on top of each other, gaps can form between the logs or around window and door frames. These gaps allow cold air, water, and even bugs to infiltrate your home. That’s where Energy Seal® comes in.

Energy Seal: The Ideal Solution for Log Homes

Energy Seal is a textured, acrylic polymer sealant specifically designed for log homes. It provides a flexible, durable seal that adapts to the natural movement of logs as they expand, contract, and shift with changing weather conditions. Here’s why Energy Seal stands out:

- Flexibility: Energy Seal’s flexibility allows it to maintain a tight seal as logs twist, turn, and shift with the seasons, ensuring that gaps don’t reopen over time.

- Water & Air Tight: It creates a resilient, water- and air-tight barrier, preventing moisture infiltration and keeping drafts at bay.

- Texture for a Natural Look: The textured surface of Energy Seal serves two purposes:

- Flat, Non-Shiny Finish: Once cured, Energy Seal doesn’t have the shiny, artificial look of typical caulking. Instead, it achieves a natural, matte finish that blends seamlessly with your logs and stain.

- Better Stain Adhesion: The textured surface also allows Energy Seal to accept stain more effectively, ensuring it blends in and virtually disappears when you stain your log walls.

Pro Tip: Staining Over Energy Seal

If you plan to stain over Energy Seal, here’s a helpful tip: choose a stain that’s slightly lighter than the color you intend to use for your logs. It’s easier to cover light-colored Energy Seal with a darker stain than it is to cover darker sealant with a lighter one.

Seal in Comfort, Save on Energy

By sealing your log home with Energy Seal, you’re ensuring long-lasting protection against the elements while also boosting your home’s energy efficiency. Don’t let gaps and cracks waste your energy and money—choose Perma-Chink Systems sealants for the best in performance, durability, and aesthetics.

Let us help you keep your home snug and energy-efficient this winter.

The RHEOLOGY of Perma-Chink

Theoretical aspects of rheology – a branch of physics – deal with understanding the relation of the flow and deformation behavior of material and its internal structure.

The rheology additives in Perma-Chink help ensure that the polymer properties meet specifications for the end use (texture, product film properties) and product quality.

Rheological properties of Perma-Chink

- Greatly improved low shear (as in standing after application) results in high viscosity to prevent slumping

- High shear (as in pumping ) decreases viscosity to make the product easier to apply and tool.

Tips On Applying Perma-Chink

Some people think that Perma-Chink sealant is just like any other caulking product on the market, so they apply and finish it with the same methods. Typically, silicone caulking can be smoothed just by running a damp finger along the bead of caulking. Using that method with Perma-Chink will give you less than desirable results. To get a smooth, clean finish with Perma-Chink, spray the sealant liberally with water then tool it with a metal spatula or similar. It may seem counter-intuitive to apply water to smooth it, but it’s the best method. Unlike smooth caulking, the texture in Perma-Chink (and Energy Seal) needs more water to maintain a smooth finish. And it’ll be much, much easier.

*Substrate conditions such as substrate outgassing, volatiles in the wood and backing materials can contribute to formation of blisters.

Want to learn how to apply log home chinking? Download our Sealants Application Guide here.

MOBILE LOG CABINS (or PLUG & PLAY TRADITIONAL LOG HOME)

By Dan Waring, British Log Cabins

Mobile homes…Traditionally an ugly metal box, BLC have taken the parameters defining the mobile home and delivered a beautiful alternative LOG CABIN!

Developed in response to an increase in the popularity of ‘Log Cabin Holidays’ our Mobile Log Homes include everything. The entire building is prefabricated off site in our log building yard on a specially designed rolling chassis.

The building comes complete including a kitchenette, bathroom suite, LPG boiler, radiators, log burner and all internal finishes.

All that is required on site is a concrete slab and waste and water connections – they really are a plug and play, traditional log home!.

Log building as a construction method and art form has been around for centuries. It’s origins were in Eastern Europe and Scandinavia. As a trade it has a long established history. The often romanticized vision of a cozy, traditional log cabin in a holiday area is now a reality.

As a mobile home, The Nook is not only completed to a very high standard in both design and construction and very well insulated but it is also VAT free. The mobile home is delivered in two halves and re-joined on site. This reduces the impact of onsite construction works.

If you want a mobile home log cabin within your garden to be used as an extra room in addition to the main house then you will not need planning permission unless you live in a conservation area.

Mobile cabins are a great idea if you are thinking of starting or expanding a holiday business . The cabins are of high quality, and provide a wow factor that normal static caravans do not.

To find out more about The Nook, visit British Log Cabins website https://www.britishlogcabins.com/mobile-log-cabins

Perma-Chink’s Technical Team has devoted a tremendous amount of time on projects to develop high quality products. These projects involved a significant amount of scientific testing that helped define our product portfolio with new and improved products.

Here are 4 things we have learned along the way:

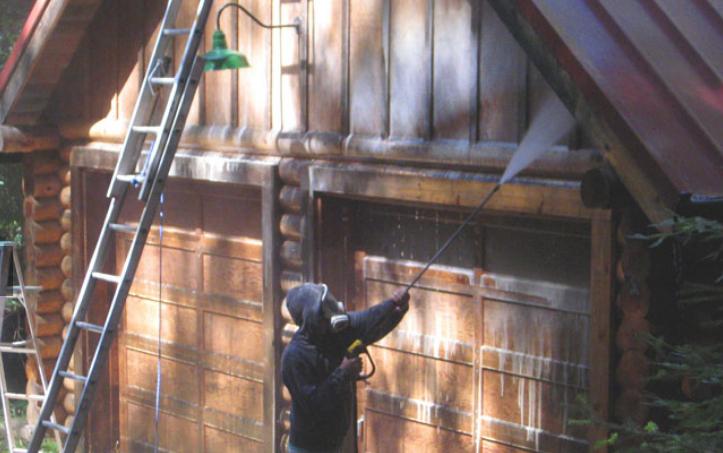

1. The more sterile the log surface is prior to staining, the less chance there is for mold formation underneath the stain.

Although this statement seems to be self-explanatory, it can never be overstated. The most important step prior to applying a wood finish is surface preparation. The surface of the logs really needs to be clean and sterile prior to applying any stain; it helps eliminate adhesion failures due to surface contamination.

Before you apply a new coat of stain, you should pressure wash or media blast the surface. This cleans off dirt and debris and removes the old finish that has lost ability to adhere to the wood. Along with pressure washing, you may need a chemical log cleaner. The two wood cleaning solutions we recommend are Wood ReNew (Sodium Percarbonate) or Log Wash.

Apply the cleaning solution with a garden sprayer to the logs from bottom to top and allow the solution to remain on the wood for 15-20 minutes (do not let cleaner dry). Now use the pressure washer to wash down the wall with clean water from top to bottom. Use pH strips as a quantitative tool to determine if all of the cleaning chemicals have been removed from the surface of the logs.

Measure the pH of the rinse water to determine a baseline pH. Then measure the pH of the run-off at a several places on the wall once you are through rinsing. You need to continue rinsing until the pH of the run-off is in the range of 6.8-7.4. PH Strips with a range of 6 to 9 can be found at most pool supply stores, local drug stores, or discount stores.

Now here is where many people get into trouble. Let’s say that it has been five days or longer since the logs have been cleaned and you are still not ready to stain. The day before you are going to stain a wall, go out and wash it down with Log Wash.

This process will remove any dirt and pollen that may have accumulated on the logs since you cleaned them, and kills any mold spores that may be adhering to the wood. This helps to eliminate the risk of mold formation under the stain by removing both the mold and its food source.

2. Iron tannates are responsible for some discolorations commonly attributed to mold and mildew.

Tannins are compounds in wood that are found at highest concentrations in heartwood and bark. Under the right conditions tannins can react with heavy metals such as iron to form a dark blue/black stain known as metal tannates.

Visually these stains have a similar appearance to mold and mildew. However, under the microscope these stains are crystalline in structure.

One additional visual difference is that metal tannate stains almost always appear on the surface of wood, not on top of the coating. Dark streaks and dark runs down the surface of the log are also indicators of the presence of metal tannates. Wood ReNew (even bleach) will not remove this type of stain since it is not biological in origin. However, an oxalic solution like OxCon will completely remove the metal tannate stain. The oxalic acid reacts to change the oxidation state of the metal (iron tannate) to form a colorless species, thus removing, or “blonding,” the stain.

3. Many Industrial Wood Cleaners and Household Cleaners have detrimental effects on log finishes.

Many household and industrial wood cleaners are either strong organic solvents or highly alkaline and corrosive with a pH above 12. These types of cleaners can have detrimental effects on existing wood finishes, especially if they are left on the surface of the finish for too long, or if they are applied at concentration greater than recommended. Although the damage might not be visibly evident at the time, the use of these cleaners can reduce the longevity of the wood finish by increasing the erosion rate.

Our wood cleaner Log Wash will perform all of the functions of a typical cleaner without disrupting the look and performance of our wood finishes. Log Wash has slightly acidic pH, similar to that of wood. This means that when applied to wood it does not disrupt the wood’s chemistry.

4. Wood finish removers do not dissolve finishes; they only soften them enough to allow the finish to be removed with pressure washing.

A few years ago, pressure washing was the only way to go when it came to removing old finishes. With the introduction of media blasting, some people began to consider pressure washing as a secondary, inferior method of finish removal. Actually, pressure washing is still an excellent cleaning method for many situations.

It is always best to use finish removers supplied or approved by Perma-Chink Systems. Never use finish removers containing potassium or sodium hydroxide. They disrupt the chemistry of the wood and can lead to discoloration appearing under the finish. Before purchasing any finish removers, be sure to obtain a sample and test it on your existing finish.

Our S-100 Finish Remover and StripIt are formulated so that they can be applied “as is” using an airless sprayer. Their viscosity is such that they do not need to be diluted with water to be run through airless spray equipment. However, it is a good idea to thoroughly mix the S-100 with a Jiffy Mixer before spraying it. Just be careful to keep dirt and other debris out of the product.

APPLICATION

The first step before starting to remove a finish is to take off downspouts, gutters, and lighting fixtures, and mask off or cover those areas that you don’t want to strip; they may become discolored if contacted by the product you are using. The next step is to wet down and cover any plants and shrubs. Both S-100 and StripIt are pretty gentle on plant life once they are diluted with water during the stripping process, but in their concentrated form they may present a problem. The use of perforated weed blocking film works well over plants, roofs, decks and other areas you want to protect, since it allows water to drain through it but catches lumps of concentrated remover as well as any stripping debris. This makes clean up a lot quicker and easier.

Apply the finish remover to one or two courses of logs at a time in a sweeping motion across the entire wall starting at the bottom of the wall. This will help you avoid coating the chinking or sealant joints if they are present. Be sure to only coat an area that you can finish stripping in the allotted time you have. If you coat the entire wall, or too large an area, the finish remover may end up drying on the wall and become difficult to remove. Always apply finish removers at the recommended thickness or coverage rate. If applied too thinly, they may not work and you will have wasted your time and money. Once the finish remover has been applied to an area, submerge the spray gun and tip in a pail of water to prevent the product from drying at the tip and possibly blocking it.

After waiting an appropriate amount of time for the stripper to soften the finish (remember the cooler temperature it is, the longer it will take), you can begin the pressure washing process. Be sure to wash off any product and wet finish debris that’s still adhering to the wall or other surfaces. If allowed to dry, you may end up having to manually scrub these surfaces clean. Once you reach the top of the wall, or if you run out of time, rinse the entire wall starting at the top before you quit. You don’t want any chemical or finish debris to remain on the surface. If you are through for the day, replace the lid on the pail of finish remover and run clean water through your airless sprayer until clear water comes out of the gun.

Project Highlight

The project: Full exterior renovation of 40-year-old log home, including improving energy efficiency. The project required cleaning and mold/mildew removal, wood lightening, wood brightening and hand sanding. The Log Home Restoration project by T Paul Sec Painting won first place in PWC’s first annual Green Awards.

What made it green: All prep products used were eco-friendly and low VOC, manufactured by Perma-Chink Systems, Inc.

Here is a link to this project with more pictures http://www.greenpaintingcontractor.com

We have tested our cleaning products with our finish systems and have confidence that when properly applied, their use will result in the best possible appearance and performance of the final Lifeline finish.