Blog

By Seth Murphy

Homeowners almost always have a list of projects to complete around the house. If interior projects are on your list, don’t let winter slow your progress. The truth is, there are several indoor maintenance projects that are ideal for winter.

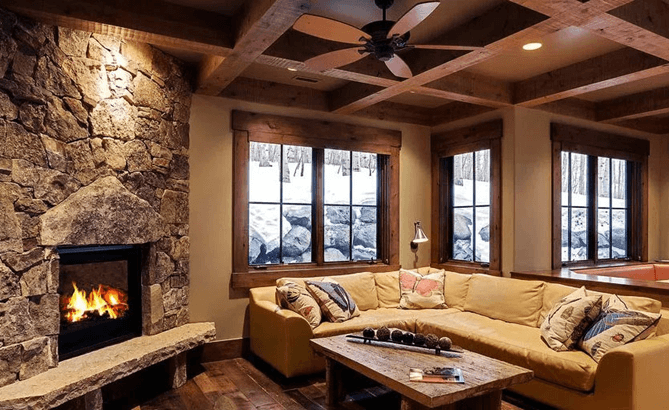

1. Freshen Wood Trim and Moldings, Doors and Window Frames, Cabinets, etc.

Freshening wood trims, cabinets, doors and window frames are perfect indoor maintenance projects for winter. Winter is the best time to stain inside because the air is drier than humid summer air and helps the finishes dry more quickly. You also can crack a few windows in winter to provide proper ventilation without worrying about bugs flying inside. Another reason to stain in winter is that you will get your inside projects done and have more time to do exterior projects when the weather improves. If you plan to hire a contractor, winter is a better time for interior jobs because they are slower in winter and usually offer off-season deals.

Keep in mind that you do things a little differently when staining interior trim than when staining walls. You’ll need to sand your trim until it is smooth, clean the dust, and then apply finish. You can apply color stain before you finish it with a clear topcoat, or just apply a clear primer directly to wood. Then topcoat it with clear Acrylic Gloss or Satin, or Sure Shine diamond finish. Some people repeat the sanding, cleaning, and finishing process to get a smoother finish. If you would like to add more gloss to your wood trim, Sure Shine Gloss is your best choice. Click here for application instructions.

2. Check for Air Leaks

Many indoor winter maintenance projects also help homeowners save money. In fact, one of the best money-saving maintenance tasks is checking for air leaks. According to HomeAdvisor, you can “stop energy-sucking, money-wasting air leaks by caulking, sealing and weather-stripping all of the seams, cracks, and openings in your home.”

There are a few DIY solutions for air leaks. According to the U.S. Department of Energy, reducing air leaks cuts heating and cooling costs, improves durability, increases comfort, and creates a healthier indoor environment for your family. A simple test for air leaks, hold a lit candle or incense stick next to potential sources of air leaks on a windy day. If the smoke blows horizontally, you have a leak to seal. It’s especially important to check for air leaks if you have a log-style home since builders intentionally leave room for settling.

Caulking and weather-stripping are two common solutions. Seal and weather-strip doors and windows that leak air. You also should caulk and seal air leaks where plumbing, ducting, or electrical wiring enters through walls, floors, ceilings, and soffits. You also should cover your kitchen exhaust fan when not using it, ensure your dryer vent is not blocked, and seal air leaks around your chimney, furnace, and gas-fired water heater vents with fire-resistant materials like sheet metal or sheetrock.

Sealing the leak with Energy Seal prevents water penetration along with air infiltration. Next you have to decide if you want to attempt to correct the problems yourself or use a professional contractor. For log home owners, here’s where things can get a bit tricky. Most painters and contractors are familiar with sealing and caulking conventional homes, but log homes are different and it takes someone with log structure experience and expertise to do the job correctly. Plus, general purpose caulks and sealants found at local hardware stores and DIY outlets just don’t offer the performance that’s required for the unique needs associated with log homes.

If you need help finding someone in your area who has experience doing this type of work, give Perma-Chink a call and they will provide you with referrals. 1-800-548-3554.

By Seth Murphy

papadiy.com

Home improvements can be expensive, but they can greatly increase your home’s value. When it comes time to decide which improvements to make, there are a few things to consider. Here are some tips on how to improve your home to increase its resale value.

Small improvements can be big!

Did you know that some home improvements only cost a few hundred dollars? Small but noticeable upgrades like repainting your entryway and adding a few nice flowers can really make a difference in how welcoming your home looks, a.k.a. “curb appeal.” Also, the most popular upgrades for dollars spent versus return in increased value are small kitchen and bathroom upgrades. You don’t need a whole redo of those rooms if the appliances are in good condition. Little touches like new lighting fixtures and backsplashes will greatly improve the look with small expenditures of time and money. Installing loose-fill fiberglass insulation in the attic gives the most return for your investment, and it’s not a large expense. Adding energy-efficient windows to replace older, drafty ones can improve both your current energy bills and your future resale value. So go ahead and see what small improvements you can make to have your house be more inviting to buyers.

Large-scale improvements can greatly increase value

If your home furnishings are older and in need of replacement, be sure to look for energy efficiency and universal design. The latter is a relatively new concept that incorporates ability-awareness features into home pieces so that the elderly or those with mobility concerns can use the furnishings easily. Think walk-in showers or lever-style handles rather than knobs. Such features make any room easier to use by all the people in your household, no matter what the condition of their hands or eyesight.

If you are looking at completely redoing your kitchen or bathroom or other rooms in the house, be sure to check around for reputable contractors and design ideas. The more you know going in and the more specific you are with your design plans, the more likely you’ll end up with a remodel that fits into your planned budget. Look online for ideas and local pricing information. For example, HomeAdvisor indicates that the average price to remodel a kitchen ranges from $15,428 to $38,607. Keep in mind that the labor and fixture expenses may vary greatly, as will the timeframe of the project. Comparison shop online to see what new kitchen appliances, bathroom fixtures, and flooring options cost to help you determine your price range for upgrading those or other rooms in your home.

Another consideration is the outside of your home. If you need a new stain job or new roof or siding for the exterior, that should be done before spending money on interior upgrades. Try to make repairs before upgrades. If something is not working normally or looking good, that will be a tip-off to potential buyers that your home has not been maintained well. So walk through and look at everything like you’re a stranger. What do you see that needs repair? What looks shabby, dirty, or just dark? Start with those areas.

So whether you’re looking at a few cosmetic improvements or major upgrades to your home, you can find all sorts of ideas and price points online to help you decide. Look at the upgrades that will quickly improve energy efficiency or functionality. This will help make your home more appealing to buyers. That, in itself, is worth the money.

July is National Log Home Month. During the month of July, log home manufacturers will honor America’s log home heritage by hosting home tours, log raising demonstrations, log home building seminars and more. There are many different sizes and styles of log home construction to suit any homeowner’s vision.

Here we present the TOP Log Home Manufacturers in the USA and invite you to visit their websites and see what they have to offer. Each manufacturer is outstanding in quality of craftsmanship, and this is not a ranked list.

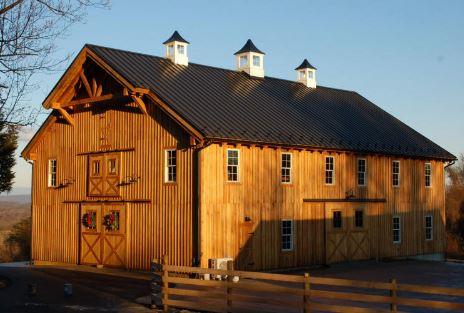

Are American Barns disappearing? Not so fast…

There are thousands of iconic barns throughout America, from different periods in our history. These historic barns were once an integral part of American life.

The traditional design and use of the “barn” has evolved tremendously over the years. We have moved from large, open structures based around cattle stalls and hay storage to huge multi-purpose barn palaces.

A bit of the history

The word barn comes from the Old English language, for barley (or grain in general). The first barns were not American by design but were European-style longhouses that included stables and sleeping quarters. Brought to America along with the first settlers, the oldest barns were constructed in the classic “English barn” style.

As with any structure built for functionality, designs do not follow one pattern for long. English barns were further adapted into larger, timber-framed structures, which became known as the Yankee barn. One of the most fascinating aspects of barn construction is the common use of simple farmstead creativity. The earliest barns were built with timbers hand-hewn to shape, with the rough chopping marks of an axe. Slightly older timbers might be hand-cut with huge two-person saws, while newer barns have the clean-cut lines of sawmill machinery. More history here https://www.almanac.com/extra/evolution-american-barn

Traditional style barns pay homage to a great American tradition. For those seeking a multi-function barn made of traditional materials, these structures are hard to surpass. In keeping with the look and feel of the turn of the century, Hearthstone developed a process for giving the timbers a surface texture that mimicked the circular cuts of timbers that had just come out of an old sawmill.

A HEARTHSTONE HEAVY TIMBER BARN IS THE ULTIMATE OUTBUILDING

With the popularity of open-air structures for commercial properties, equestrian, restaurants (especially during pandemic), the Timber Frame Barn’s massive beams create breathtaking effects of open spaces and craftsmanship style rarely seen today. The large sliding doors open to cobble stone floors and the authentic smell of white pine creates an environment of harmonious interaction with nature.

Horse Barn

This beautiful, yet functional, barn was designed to house horses and the occasional social gathering. Because the customer was in the process of restoring a farmstead from early in the 20th Century, the technique & style reflects that period & geography. The naturally weathered Cypress board & batten gives the barn the perfect rustic finish.

Barn Homes

One of the most popular innovations is the “barn home” due to the open, airy floor plans and massive posts and beams. These homes convey the aesthetics of a traditional barn combined with an exciting modern design.

Check out their collection of Wedding Barns, Cottage Barns, Event Barns, Guest Barns and more here: HTTPS://HEARTHSTONEHOMES.COM/BARNS.HTML

All of Hearthstone barns are custom designed and made.

Lifeline Interior is a natural looking, transparent wood finish. It forms a breathable protective layer for your walls and ceilings while highlighting the beauty and grain of the wood. Our unique breathable formula allows natural wood moisture to escape from the wood yet provides a tough surface film that can easily be cleaned and dusted, especially when top coated with our Acrylic Gloss or Satin clear finish.

WHAT EXACTLY DOES ‘BREATHABLE’ MEAN?

To understand, it takes a little bit of chemistry and physics but the concept is fairly simple. Technically, for those of you who want to impress friends, the scientific term is vapor permeability – the ability of water vapor to permeate through a film.

Polymer films are composed of long chains of molecules that are bound together in a three-dimensional matrix. This matrix is quite dense in films like polyurethane and alkyd coatings, and there is not much space between the polymer chains. This prevents small water vapor molecules from making their way through the film. On the other hand, Lifeline finishes form a less-dense matrix with room enough for water vapor molecules to penetrate through the film, but not enough space to allow liquid water to make its way into – or through – the film.

You can think of it in terms of a film with a bunch of small holes, or pores, that filter out large objects but allow smaller objects to pass through them. In chemistry these types of films are known as semi-permeable membranes, but in our industry we call them breathable.

Another factor that influences vapor permeability is the thickness of the film. The thicker the film, the more difficult it becomes for water vapor molecules to make their way through. That’s one reason we encourage you to apply our finishes in thin layers. When applied too thickly, even acrylic latex films can have difficulty breathing.

If you use one of our Lifeline Interior color stains, the colorants in the finish help stabilize color of the wood and slow down, or even prevent, the fading that you may notice when removing pictures or furniture from against the wall. If using Lifeline Interior Clear, we recommend the addition of UV Boost to the first coat to help prevent this “picture frame” effect due to UV light exposure. Since interior surfaces are not exposed to harsh weather, two coats of Lifeline Interior are not necessary. However, you can apply multiple coats of Lifeline Interior in order to achieve the appearance you desire.

Lifeline Interior is easy to apply. It can be applied by brush, spray or pad. Lifeline Interior dries to the touch in one hour and clean-up is easy, just use soap and water.

One of the best reasons to use Lifeline Interior is that it reduces the absorption of pet, fireplace, and cooking odors into the wood.

Lifeline Interior resists yellowing and is non-flammable and virtually odorless. Like all of our premium finishes, it allows the natural look and beauty of all species of wood to come through. Lifeline Interior can be used on new or existing log homes as long as the surfaces are clean and dry.

You can now order Lifeline Interior in any color you desire in addition to our 13 standard colors plus Clear. For a custom color, or color matching please call 1-800-548-3554. You can request wet samples to try on your logs by calling 1-800-548-3554 or by visiting our online store.

Note: All Lifeline stains and finishes are water-based and do not contain petroleum distillates. They comply with all State and Federal regulations for contained volatile organic compound (VOC). In addition, being concerned with keeping living areas as healthy as possible, our interior finishes are specifically formulated to meet the highest interior air quality standards.

Discover the revolutionary products that have transformed log home maintenance! Visit Perma-Chink Systems today to find everything you need to protect and beautify your log home.

Safeguard Your Log Home:

Top Annual Maintenance Tasks to Prioritize

Owning a log home comes with a unique set of responsibilities, particularly when it comes to maintenance. To keep your log home in top condition, regular annual upkeep is essential. From inspecting the exterior for signs of wear to ensuring your home is well-sealed against the elements, these tasks not only preserve the beauty of your log home but also protect your investment. In this article, we’ll explore the key annual maintenance tips every log homeowner should follow to ensure their home remains a rustic haven for years to come.

Vigilant Plumbing Oversight

Regular plumbing checks are critical in preventing minor issues from escalating into costly disasters. Inspect your pipes periodically for any signs of leaks or corrosion, and make sure water pressure is at an optimal level. Addressing these problems early can save you a significant amount in future repairs. This proactive approach not only ensures the longevity of your plumbing systems but also maintains the overall health of your log home.

Effective Caulking Is a Must

To keep the harsh elements at bay, inspect and reseal your log home’s windows, doors, and other exterior openings. Effective caulking prevents drafts and water intrusion, which are common in log homes, thereby conserving energy and reducing your heating bills. This task not only enhances comfort but also protects against structural damage caused by moisture. Annual reviews and touch-ups can ensure your home remains sealed against the elements year-round.

Invest in a Home Warranty

Investing in a home warranty can shield you from the financial burden of unforeseen appliance and system breakdowns. Consider a service agreement that encompasses your log home’s climate control system to ensure it remains functional throughout the seasons. Select a policy that allows for straightforward claims processing without the need for documented maintenance histories. This type of coverage proves invaluable, particularly in log homes where system malfunctions can significantly impact your living conditions.

Persistent Pest Patrol

Pest control is essential, as insects and rodents can compromise the structural integrity of your log home. Regularly inspect for signs of infestation, including termites and other wood-loving pests. Early detection and professional extermination can prevent extensive damage, preserving your home’s foundation and aesthetic value. Consider scheduling bi-annual inspections with a pest control professional to ensure your home stays pest-free.

Gutter Maintenance is Key

Maintain clean gutters and downspouts to prevent water buildup that can damage your roof and foundation. Cleaning these areas twice a year, particularly after heavy seasons of fall and spring, prevents water damage and protects the landscaping and exterior of your log home from erosion and other water-related issues. Employing professional cleaning services can enhance this task’s effectiveness, especially in dense, wooded areas.

Roof Resilience

Regular roof inspections help identify and rectify problems with shingles that are missing, damaged, or loose. Repairing these issues promptly prevents leaks and extensive water damage, which can be especially problematic in log homes. This maintenance task is crucial for protecting both the interior and exterior of your home from weather-related damage. Engage a roofing specialist annually to assess and address any potential vulnerabilities in your roof’s structure.

Digital Document Management

To help manage your annual tasks, transitioning your home maintenance records to a digital format enhances their accessibility and preservation. Use a PDF converter to maintain the integrity of your documents, ensuring they look the same across various platforms and devices. This method mitigates risks related to compatibility and accessibility issues. By employing online tools that support drag-and-drop functionality for converting files, you streamline the organization and security of your log home’s historical data.

Maintaining a log home is an ongoing commitment that pays dividends in comfort, safety, and value retention. Through diligent upkeep and strategic improvements, you not only preserve the character of your home but also enhance its functionality. Emphasize preventive measures and professional assessments to avoid costly repairs, and remember that a well-maintained log home is a lasting treasure in the landscape of your life.

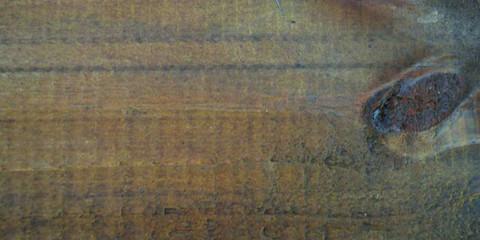

Perma-Chink Systems® newest finish option, Log & Timber Defense™, has been quite the success for customers looking for a hybrid finish for their log homes. Unlike our traditional Lifeline film-forming wood finishes, Log & Timber Defense penetrates your wood. As it absorbs into the wood surface, it forms a strong lattice network within the wood, reinforcing and strengthening the entire system from the inside out. Due to its elastomeric nature and penetration, it greatly reduces the chances of peeling and flaking by leaving the system breathable to water vapor. Many penetrating oil-based finishes can also form a lattice-like network, but unfortunately these finishes contain harmful flammable solvents that make working with them both dangerous for you and our environment. In contrast, our Log & Timber Defense is water-based, making it both easier and safer to work with.

Log and Timber Defense is designed to be applied to bare wood in one or two coats. However, if applied to wood that already has an existing coating, this can interfere with adhesion and could lead to premature failure of the finish. For best results we recommend application of Log & Timber Defense to bare wood that has been cleaned with Wood Renew™.

For all our Lifeline™ wood finishes, we recommend application of a topcoat. However, not so with Log & Timber Defense. The reason for advising against this is because when a maintenance coat is needed in the future, there will be difficulty with penetration into the wood since the topcoat forms a barrier to penetration, leaving a film on surface. Additionally, this could lead to undesirable surface defects, as well as an uneven appearance.

Texture is another property that distinguishes Log and Timber Defense from our Lifeline Stains. Due to its penetrating nature, Log and Timber Defense leaves the surface with a more natural, rustic beauty. In general, it will appear flatter than our Lifeline finishes. However, if slightly more gloss is desired, a second coat of Log & Timber Defense may be applied. The second coat will also increase color intensity and provide an increased level of overall protection for the system.

Finally, Log and Timber Defense is formulated with ingredients that inhibit the growth of mold and mildew. Log and Timber Defense is both a stain and sealant in one package. It helps to keep liquid water out, which reduces biological growth that can attack and destroy your wood. In contrast, traditional natural oils – such as Linseed Oil – can easily promote growth of mold and mildew. Log & Timber Defense is waterborne, low in odor, has easy soap and water cleanup, and is non-flammable. Log & Timber Defense offers unique properties designed to give your home the very best protection possible. For more information about Log & Timber Defense or our other finishes, please visit Log and Timber Defense stain

Perma-Chink Systems® has recently added another beautiful wood finish option for our customers. Unlike our traditional Lifeline film-forming wood finishes, Log & Timber Defense™ penetrates your wood. As it absorbs into the wood surface, it forms a strong lattice network within the wood, reinforcing and strengthening the entire system from the inside out. Due to its elastomeric nature and penetration, it greatly reduces the chances of peeling and flaking by leaving the system breathable to water vapor. Many penetrating oil-based finishes can also form a network but unfortunately often contain harmful flammable solvents that make working with them both dangerous for you and our environment. In contrast our Log & Timber Defense is water-based making it both easier and safer to work with.

Log and Timber Defense is designed to be applied to bare wood in one or two coats. However, if applied to wood that already has an existing coating this can interfere with adhesion and could lead to premature failure of the finish. For best results we recommend application of Log & Timber Defense to bare wood that has been cleaned with Wood Renew™.

For all our Lifeline™ wood finishes, we recommend application of a topcoat, however, not so with Log & Timber Defense. The reason for advising against this is because when a maintenance coat is needed in the future there will be difficulty with penetration into the wood because the topcoat forms a barrier to penetration leaving a film on surface. Additionally, this could lead to undesirable surface defects as well as an uneven appearance.

Texture is another property that distinguishes Log and Timber Defense from our Lifeline Stains. Due to its penetrating nature, Log and Timber Defense leaves the surface with a more naturalistic rustic beauty. In general, it will appear flatter than our Lifeline finishes. However, if slightly more gloss is desired, a second coat of Log & Timber Defense may be applied. The second coat will also increase color intensity and provide an increased level of overall protection for the system.

Finally, Log and Timber Defense is formulated with ingredients that inhibit the growth of mold and mildew. Log and Timber Defense is both a stain and sealant in one package. It helps to keep liquid water out, which reduces biological growth that can attack and destroy your wood. In contrast, traditional natural oils – such as Linseed Oil – can easily promote growth of mold and mildew. Log & Timber Defense is waterborne, low in odor, has easy soap and water cleanup, and is non-flammable. Log & Timber Defense offers unique properties designed to give your home the very best protection possible. For more information about Log & Timber Defense or our other finishes, please visit our website at www.permachink.com then select Wood Finishes.

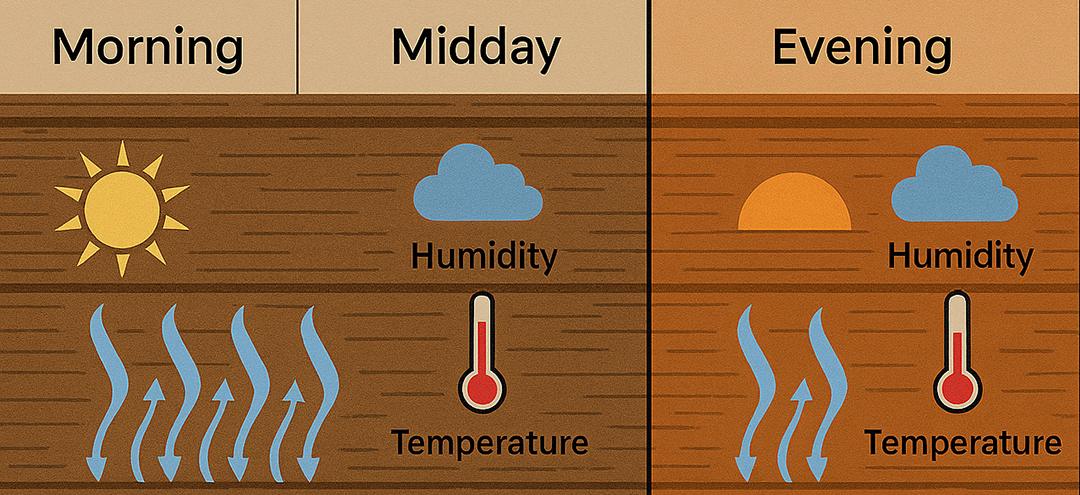

Drying times and curing times relate to two entirely different processes that occur in water-based polymer systems. All water-based products, be it stains, paints, or sealants, contain a percentage of free water, hence their description as water-based.

When applied and exposed to air, the free water begins to evaporate. The rate of evaporation is dependent on the humidity as well as the temperature. The higher the temperature and lower the humidity, the faster the rate of evaporation.

Once most of the water has evaporated from the surface, it feels dry – thus the term “dry to the touch.” The time a product takes to become dry to the touch is its “drying time,” although in the case of sealants, we typically talk about the time it takes a product to “skin over.”

Once a material has dried or skinned over, it does gain some strength in that it becomes impossible to brush out or tool smooth, but to achieve its maximum strength and durability it must be allowed to cure.

Curing time relates to the time it takes for a product to gain enough strength to withstand the parameters for which it was designed. As opposed to drying, curing is more of a chemical reaction that takes place on a molecular level. During the curing process environmental factors such as rain, snow, or high humidity can have a significant impact on the look or performance of a product. For example, in our Advance Topcoats, blushing is caused by water molecules becoming trapped within the polymer matrix during the curing process. Once trapped, it may take a long time for this water to escape from the film as long as environmental conditions remain cool and damp.

In addition to temperature and humidity, the time it takes sealants like Perma-Chink®, Energy Seal™, Woodsman™, and Check Mate 2® to cure depends on the thickness of their application. Once a sealant skins over, it inhibits the evaporation of water from the material under the skin. This prolongs the curing process, so although we may state that the curing time for Perma-Chink is two to eight weeks for a thinner or standard application, it may take several months for a 5/16” thick layer of Perma-Chink to attain its maximum strength.

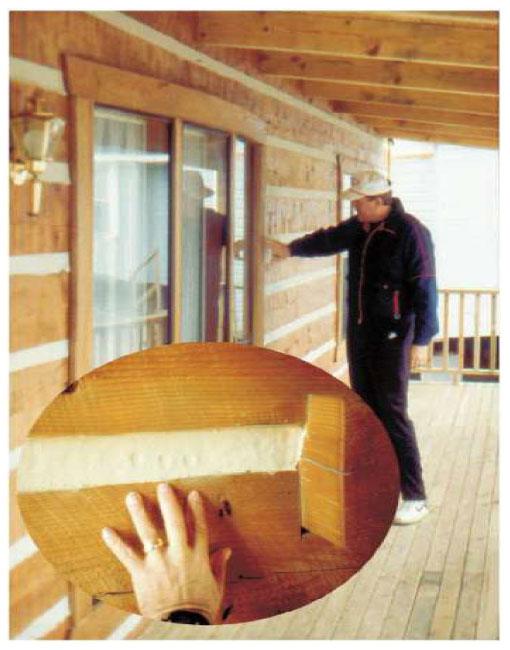

Although we have never identified exactly what it is, there is a magical ingredient in Perma-Chink that acts as a magnet to human fingers. Put an adult or juvenile male anywhere close to a wall with a fresh application of Perma-Chink, and the first thing that happens is one hand comes out of their pocket with one or more fingers magnetically attracted to the chink joint.

Usually with enough force to determine the strength or pliability of the chinking, fingers leave evidence of attraction in the form of small depressions. Occasionally female fingers are magnetically attracted to Perma-Chink. In their case, the amount of applied pressure is usually considerably less since it is more a matter of feeling the texture. In either case, if the Perma-Chink has been freshly applied, evidence of their chinking inspection will be permanently imparted into the chink joint.

So what is the best way to protect freshly applied chinking until it cures? You can always try a “DO NOT TOUCH” sign, but from our experience it appears that most chinking inspectors can not read or it is taken as an invitation to touch. This means that you need to place some type of physical barrier, i.e. plastic or cardboard, between the finger pokers and the chinking. Just be sure that there is enough space between the barrier and chinking so that air can flow to facilitate the drying of the chinking.

The length of time you will need to leave the barrier in place depends on the weather. If it is warm and dry, the chinking will probably be cured enough in three to four weeks to resist finger poking. However, if it is cool and damp, it may take two to three months before it is safe to remove the barrier. In any case, the effort spent in protecting the chinking is worth the time in preserving the aesthetics of a great looking chinking job for many years.

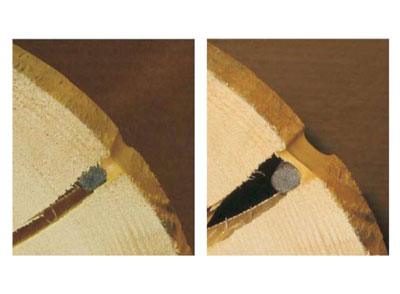

It is virtually impossible to prevent logs from developing cracks and checks as they age and dry. That is because as wood seasons, mechanical stresses build up until the surface stress becomes so great that the wood cracks. We call these stress cracks “checks.”

Do checks need to be sealed? Yes, especially upward facing checks that collect water increasing the interior moisture content of the log. If they continue to collect water and the wood remains damp, they will eventually result in internal wood decay as well as provide nesting sites for carpenter ants and other insects. It is not necessary to seal checks on the bottom half of round logs since they do not collect water, but for a uniform appearance you may want to seal them. It is not usually necessary to seal checks or fissures that are less than 1/4” wide since they can not accumulate that much water.

If your home is new and the logs or siding are green, it may be best to wait a year before addressing the checks. This allows the wood to reach an equilibrium with its environment and by then most of the larger checks will have opened. With seasoned wood or an older home that is in the process of being refinished you can seal the checks either before or after applying a stain.

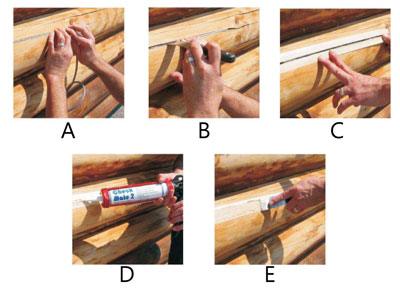

Check Mate 2

Checks and splits in logs present a different set of dynamics than those addressed by a typical caulk. Checks/splits open and close as the log’s moisture content varies throughout the year. The opening width of a check may change as much as 50% from summer to winter. Check Mate 2 is specifically formulated to meet the requirements for sealing checks that appear in logs and log siding.

When initially applied in a 3/8” thick check, Check Mate 2 bonds to the sides of the check (Figure 1). As the check opens, Check Mate 2 stretches to maintain a water-tight seal (Figure 2). The role the Backer Rod is to maintain a Check Mate 2 thickness of 3/8” during the application and two-point contact with the wood. Two-point adhesion enables Check Mate 2 to elongate and contract.

APPLICATION DIRECTIONS

Step 1: Begin by cleaning any dust, dirt, oil, solvent or previous sealer out of the check. Previously applied caulks can usually be easily pulled or scraped out with a hook knife. If the check is upward-facing and has allowed water penetration, pour some Shell-Guard RTU into it. This will kill any decay fungi present and prevent further deterioration of the log due to rot. If the wood within the check is damp from cleaning, rain, or a borate treatment, make sure the check has time to dry before applying Check Mate 2. You can speed up the drying process by blowing the water out of the check with a leaf blower. The last thing you want to do is to trap any water within the check.

Step 2: For sealing checks 1/4” wide or larger, Check Mate 2 should be always used in conjunction with Backer Rod. Insert the Backer Rod into the check and use a trowel or other implement to push the Backer Rod about 3/8” to 1/2” deep (Pictures A & B). If you push it deeper than 1/2”, the cured Check Mate 2 will be too thick and may rip away from the sides of the check. If the Backer Rod is placed too close to the surface the Check Mate 2 may end up too thin and split.

Step 3: For a neat, clean appearance you can use masking tape to mask off the wood on either side of the check (Picture C). Be sure to remove the masking tape right after you tool the Check Mate 2 smooth. If you remove the masking tape after the Check Mate 2 has begun to dry, you will pull the top layer of Check Mate 2 off along with the masking tape.

Step 4: Cut the tip of the Check Mate 2 tube to about the same diameter as the checks you plan to fill (a little smaller diameter is better than one too large). Fill the space between the Backer Rod and log surface with Check Mate 2 using a standard caulk gun. Check Mate 2 must have good contact with wood on either side of the check and be sure the crack or check is completely sealed from end to end (Picture D).

Step 5: Tool the surface smooth with a trowel, spatula or wet finger and remove overflow immediately with a damp cloth (Picture E). Don’t forget that the masking tape must be removed while the Check Mate 2 is still wet.

Step 6: Check Mate 2 will dry to the touch in about one hour, but complete curing may take several days, depending on application thickness, temperature, and weather conditions. The color of Check Mate 2 as it comes out of the tube is always lighter than the final cured color.

Note: Newly applied Check Mate 2 Clear is white but turns clear when cured.

Step 7: Clean tools and hands with soap and water.

Hi there, sports fans! Can you believe it is November? Seems to me I was just getting used to summer! Cold weather is coming and it pays to get serious about closing those last few orders and thinking about comfort and home protection over the winter.

You can assure customers by suggesting they’ve spent their last winter with drafts, cool air, and high energy costs with a properly sealed home. They will be much more comfortable, increase their home value, and protect their log home investment by chinking now, before the winter cold sets in.

If the logs themselves could use some additional protection, suggest LIFELINE natural wood finish, which is specifically designed for log homes. LIFELINE is easy to apply, enhances the natural beauty of the logs, and provides premium protection against the ravages of the coming winter.

And for sure note that if you apply LIFELINE finishes to the home now, we assure compatibility with Perma-Chink chinking for later applications. Works great the other way around, too – chink now with Perma-Chink or Energy Seal and follow up with LIFELINE for a dynamite sealant system.

Q: I am always pressed for time, how soon after LIFELINE application can I apply Perma-Chink?

A: LIFELINE will dry to the touch in an hour or so, and Perma-Chink can easily be applied the following day.

Q: Do we put Bora-Care wood preservative on the inside or outside of the home?

A: To protect the log completely against the target organism, you must get the required amount of active ingredient into the log surface. To do this you should treat the entire surface of the log per the label instructions. The simplest way is to apply Bora-Care to both sides of the logs before chinking or staining. Don’t worry about overspray on the floor or interior framing- in fact, it’s a good idea to spray Bora-Care two feet in from the walls on all floor members during this phase of construction.

Q: Does LIFELINE Stain have Mildewcide?

A: Yes, LIFELINE stains for exterior wood surfaces have an effective mildewcide, however in conditions conductive to the growth of mildew, even the most effective mildewcide can be overwhelmed. Mildewcide in LIFELINE finishes helps prevent mildew from growing in or on the stain film only. So, mildew or fungus should be removed completely before application of the LIFELINE stain.

Q: How dry should logs be before they are ready to stain?

A: Wet logs pose the most serious problems to oil-based stains that do not adequately penetrate wet wood surfaces, and to any film-forming stains that prohibit evaporation, thereby trapping moisture inside logs. LIFELINE stains and finishes let logs breathe to allow moisture to evaporate from wet logs. Extremely wet logs might reduce the life of the first application of stain, but there are good reasons to stain as soon as is possible. Exposure to the weather causes fading of the natural wood color, which can affect the final home color. The longer bare wood is exposed to the elements, the more mold and mildew spores settle on the surface.

Cleaning the logs, then immediately applying LIFELINE and a topcoat of LIFELINE Advance stabilizes the color, adds a water repellant film, and provides a protective film containing mildewcides and UV inhibitors. If you are in a geographic location where mold and mildew are prevalent, we advise you to include additional mildewcide additives in your first coat of LIFELINE finish.

Q: Will Perma-Chink stick to oil or solvent based stains?

A: Yes. Oils in conventional stains have a tendency to evaporate fairly quickly, leaving loosely bound tint on the surface of the logs. Remove any loose material and try the water drop test. If Perma-Chink doesn’t have to fight its way through a layer of goop or oil, it will bond to the wood tighter than any material.

Q: Can Perma-Chink be applied to a milled log home?

A: Yes. Perma-Chink log chinking can be applied to any style log home. But we recommend our specialty sealant for milled log homes – Energy Seal. It will seal out damaging water and virtually eliminate air infiltration, making your home much more livable and protected in the winter months to come.

Q: Can I apply Deck Defense to treated wood?

A: Yes, Deck Defense can be applied to treated wood, cedar and redwood, etc. It is designed for any horizontal surface, particularly if abrasion and traffic patterns are a concern.