Blog

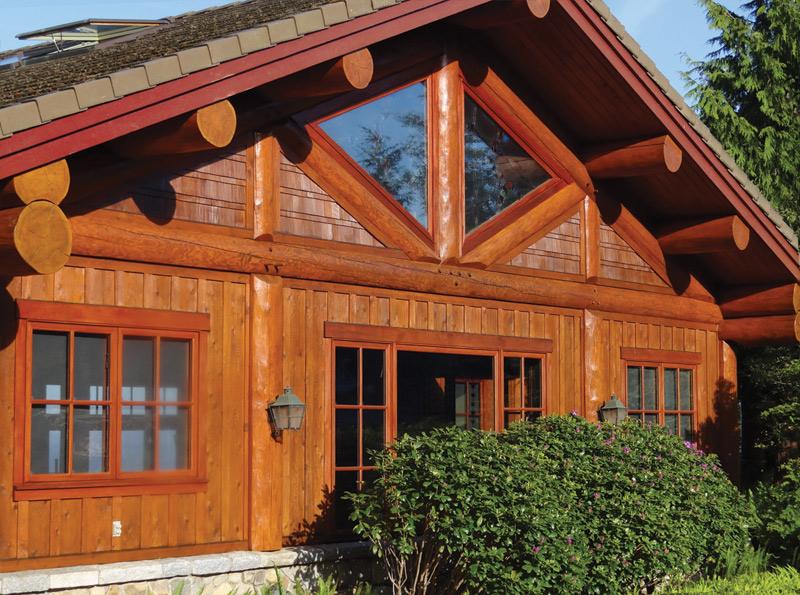

This Michigan log home was completed by the homeowners over 2 years in 2016-2017. Red pine logs were regionally sourced from Wisconsin and northern Michigan. The homeowners peeled, sanded, stained, and sealed the log home themselves, making this home a beautiful labor of love.

The exterior is finished with Lifeline Ultra-2 Sequoia with Advance Gloss, and log gaps sealed with Perma-Chink Stone. Interior logs and beams were finished with Lifeline Ultra-2 Dark Natural and Advance Gloss topcoat for the rest. Gaps were filled with Energy Seal – Dark Natural for interior, Dark Walnut for exterior gaps.

“Using your products was so effortless with easy application, no odor, and easy clean up. We have recommended Perma-Chink to others who have log homes in the area.” – Roger & Diane G.

How do I know what color PCS stain will be on my house?

Transparent stains develop color differently, depending primarily upon the wood species, the surface preparation, the application method and the kind of light illuminating it. Even photos can be edited in a way that alters the true color.

The only way you will really know how the stain will look is to try it on your wood. We will provide complimentary samples of Lifeline for you to try on your own wood before purchasing the product.

Not just Beautiful, but also Durable!

In addition to building a strong home, you want to build a beautiful home, too, which is why the finished appearance of your logs is so important. No doubt that high-quality finishes will save you time and money in the long run. Longer lasting PCS finishes equates to less labor expense over the life of the finish.

Simply Unmatched.

The benefits of Lifeline Ultra are endless, but here are some points that differentiate the Lifeline brand from others.

1. Unsurpassed Adhesion to Wood

The secret behind its durability is Lifeline’s state-of-the-art resin that creates a flexible and tough seal on your home’s logs. Perhaps more importantly than the seal’s strength, the resin ensures a continuous seal, providing protection from holes and gaps that might otherwise develop with an inferior finish.

2. More Resistant to UV Degradation and Color Fading

The transparent iron oxides protect your logs without resulting in a “painted” look that hides the natural texture and beauty of the wood grain. Plus, these pigments provide superior UV protection, blocking the fading and bleaching effects of the sun for a much longer period of time.

3. Water-Resistant and Breathable

All Lifeline finishes form water-resistant film that breathes just like Gore-Tex® to allow trapped moisture to evaporate while protecting the wood.

4. 5-Year Warranty

We are so confident in the performance of Ultra-7 and Ultra-2 that it comes with a 5-year warranty against UV exposure when applied to bare wood and covered with an initial coat of Advance clear topcoat.

5. Meets and Exceeds all Standards for low-VOC

Water-based finishes lack the chemicals in oil-based finishes that are harmful to the environment and difficult to clean up.

Unlimited Color Choices

I think we have already convinced you that the Lifeline Ultra brand is the best there in the industry for any wood home. Now here is the icing on the cake – you can choose any color your heart desires!

Choose from any colors below or send us your desired color chip. Then let us know what base you want the color to be in – Lifeline Ultra-7, Lifeline Ultra-2, Lifeline Accents or Lifeline Exterior.

If you’re looking for a different color than what we offer, we will make a custom stain color for you the same day. Don’t wait, call us today for your custom color at 1-800-548-3554.

There’s something to be said for enjoying a tasty beverage outside at the end of a long day, bbqing on a beautiful summer day, or just enjoying the evening air and the setting sun on a crisp fall evening. Settled on a porch swing, rocking chair, or a bench, relaxing outside your home is a nice, therapeutic stress release. For others it is a way of life, a daily ritual to spend quality time with loved ones. Decks and porches are where many gather for dinner, entertaining, relaxing, and on some occasions, napping.

Whatever the reason for sitting outside, exterior entertaining areas will benefit from Deck Defense stain. The new technology developed for Deck Defense offers superior penetration and protection of wood surfaces. A hybrid-like stain, it’s a water-borne stain that penetrates like oil-based stains, creating a lattice-like coating that supports and strengthen wood’s natural fibers.

More Than Decks!

Deck Defense isn’t only for decking, which requires a durable stain to stand up to foot traffic, furniture moving, rolling BBQs around, and a host of other activities that most stains aren’t designed for. Deck Defense is also designed for railings and fences, two wood surfaces that are exposed to the environment more so than decking.

If a deck or porch is covered as part of a wrap-around porch, gazebo or pergola, then Deck Defense will perform even better, as will all our Lifeline exterior stains. With simple proper maintenance, our stains can last years- if not decades- when utilized under a covered area sheltered from the elements. From small logs to giant feature timbers, soffits to siding, our exterior stains will out-perform expectations wood surfaces.

Check out this deck project that used Deck Defense deck stain.

If you love enjoying being outdoors, even if it’s only a foot or two from the front door, Deck Defense and our family of exterior finishes will protect wood surfaces and add richness to wood’s natural beauty. If your deck is an extension of your entertaining environment, our finishes offer a warm, inviting, and elegant charm to your space.

Available in seven standard colors and any custom color you desire. Call us today at 1-800-548-3554 or order online for Deck Defense or samples.

Deck Inspiration Gallery

Anyone who has trees on their property has probably seen a carpenter ant here or there at one time or another. Foraging ants roam far and wide looking for food and an occasional sighting is common.

However, if you’ve seen more than a few, there are some things you should know. First of all, carpenter ants do not eat wood, but they sure can damage it. They get their name because they chew through wood creating tunnels and galleries. Usually they nest in moist wood, however, if that’s not available they will expand into sound, dry wood where structural damage can take place quickly. Some even nest in foam, fiberglass insulation, or wood/foam composites.

So, whether you have even seen a carpenter ant or not, it is to your benefit to protect your home against them. Shell-Guard RTU is an excellent solution for preventing any problems. It is easy to use, completely odorless and requires just one application for the life of your home. It penetrates the wood where they nest, resulting in quicker control and protection against future infestations. Plus, it is deadly to most wood destroying organisms, so you can remedy a whole slew of problems with one easy application.

When insects come into contact with Shell-Guard treated wood, they live long enough to transport the active ingredients back to their nesting sites on their bodies where it continues to kill other insects in the nest. It works on all types of bare wood, is odorless and can be applied by spray or injection. Shell-Guard RTU is perfect for pre-treatment, remedial treatment and will not discolor your wood. It is the ultimate protection for your home.

For more information you can contact us direct at 1-800-548-3554 or visit our product page online.

Perma-Chink Systems products protect and enhance more than just log homes.

By Wayne Bell, LogHomeCareOnline.com

Log homes come in many varieties – milled, hand-scribed, square (Appalachian style) logs, D-logs, and more. Other forms of solid-timber construction include timber frame and post and beam homes, which provide flexibility to build the architectural style of home you desire, from rustic to modern, while employing modern building and energy-efficient construction methods. In this article, we’ll explore the differences between timber frame and post and beam homes compared to traditional log homes.

Some of these homes blend combinations of timber frame, post and beam, log, and even repurposed barn lumber or other building materials. These “hybrid” homes can include SIP (structural insulated panel) walls and roof components to boost energy efficiency.

Timber frame homes feature posts, beams, and trusses that are square or rectangular in design. These timbers are often cut on CNC machines, hand-fit in a shop, machined for proper fasteners, and finally reassembled on-site where wooden pegs hide any fasteners. Timber frame homes typically feature large timbers and intricate hand-pegged mortise-and-tenon joinery. Post and beam homes, while similar, are typically not fit together with joinery but rather beams sit atop the posts where they butt up to other components and are connected by hardware such as metal plates or “T” connectors.

Caring for a timber frame or post and beam home is very similar to maintenance performed with a log home, and Perma-Chink Systems products have earned the respect of professionals everywhere to protect and enhance the appearance of these beautiful structures. Whether you own a traditional log home or a timber frame home that has exquisite wood features, Perma-Chink Systems is the wood care resource you need.

Proper wood care is important, whether it is a log home or a timber home. Perma-Chink Systems has products that protect, beautify, restore, and repair virtually any wood surface. Perma-Chink log home sealant revolutionized the log home industry. Let our wood finishes revolutionize your timber home. Log & Timber Defense and Deck Defense are two products that will work on any home that features real wood, not just log homes. From siding to fences to decks, we have your wood covered.

Images courtesy of Log Home Care Online.

Looking At Refinishing Your Log Home?

One of the facts of life in preserving the beautiful look of natural logs is that they eventually need to be refinished. Conventional homes are repainted, but log homes are restained. There is a lot more to consider with the latter: Is the existing finish intact enough to simply restain? Do you want to restain in a different color? Has the home been a little neglected in the past? Are there water stains or you want a lighter color, what do you do?

If the stain is aged or has water stains, or the logs look quite weathered, returning the logs to a consistent natural appearance is necessary in the restaining process. But what options do you have for getting those logs back to their natural look before applying the stain? We have listed the options for finish removal below, to help you determine which method is the best choice for your situation.

Removing Finishes With Chemical Strippers

If the existing stain is completely worn out, and needs to be removed, finish remover (chemical strippers) is an option. Finish removers do not dissolve finishes; they only soften them enough to allow the finish to be removed with pressure washing. Some finish removers are more environmentally-friendly than others. Never use finish removers containing potassium or sodium hydroxide as they disrupt the chemistry of the wood, leading to discolorations appearing under the finish. Before purchasing any finish remover, be sure to obtain a sample and test it on your existing finish to see how well it works. You can order your free samples online of our StripIt or S-100 removers by clicking on the product name. For a DIY’er, this method can be the easiest method.

To see a video displaying how S-100 works, click here.

Removing Finishes By Sanding Logs

Sanding off the finish is an option. The problem is trying to work with a flat belt on round logs (with lots of corners and crevices) makes sanding a time-consuming process and a lot of work.

The use of sanding disks rather than sandpaper can save you both time and money, but you need to be careful not to create swirl marks in the wood. When sanding exterior surfaces, never use anything finer than 80 grit. You can order Sanding Disks and Osborn brushes on our online store under tools.

Removing Finishes by Using Media Blasting

Sandblasting is yet another alternative, the downside is sand chews up the logs and you are left with a whole pile of it surrounding the house.

A faster and also environmentally-friendly method of removing old finishes from log homes is the Blaster-Buddy. Instead of sand, the blast media used to abrade the finish off the wood is recycled crushed glass. We prefer crushed glass since it is very efficient, relatively inexpensive, and does not impregnate the wood with organic material that can later mold. Also, it is lighter than sand so it removes the stain but doesn’t harm the wood as much. With dry media, you don’t run the risk of blowing water into your house. It will re-expose those beautiful logs quickly and affords minimal cleanup.

There Are Options To Make Your Project A Success

Restaining a log home can be a traumatic process if you’re unaware of the best methods of finish removal, but it is a necessary evil. Do it right – do it as cleanly, efficiently, and easily as possible. You can rent the equipment and do it yourself or hire someone to do it for you. We usually advise do-it-yourself homeowners to use chemical finish removers along with pressure washing because the process can be easily accomplished by the average homeowner. And since it is less susceptible to surface damage, chemical finish removers result in a more attractive finished surface. And we all know the best result of a project is ensuring a proper foundation – or prep work – goes along way in making the job go smoothly.

More than 20 years has passed since NASCAR’s Mike Helton announced to the world, “we lost Dale Earnhardt.” Arguably one of the greatest racers ever, Earnhardt both divided and united fans with his on-track persona as “The Intimidator” and his relationship with his fans and fellow drivers. After two decades since his death, his loss is still felt within the racing community. In rememberance of Earnhardt on the anniversary of his death at the end of the 2001 Daytona 500, our own Tony Huddleston conveys working with Earnhardt on his log home years earlier.

THE LEGEND LIVED IN A LOG HOME

My first meeting with Dale Earnhardt happened at the Knoxville airport as he flew in to meet with me regarding the color choices on his new home. I took stain samples with me for the meeting and he and I applied what we currently had, and he was very clear that he wanted it darker and felt I should travel to the jobsite so we could work out the colors.

I made the trip to Mooresville, NC a short time later armed with a bevy of various tints and clear base to tint the product on the site. Upon arrival at the site, I was unable to find Dale and one of the workers in the shop told me he was down at the chicken house, and to just drive on down to find him. I found Dale working on a piece of equipment and after we talked a bit he said “let’s go up to the house and see what we can put together”. As we approached my truck he said “Give me your truck keys and I will drive.” I asked, “Can you drive a Ford?”, as he was definitely a Chevrolet man. He said “I used to drive a Ford and, as a matter of fact, it was pink one.”

Once at the house, he and I kept adjusting the tint strength and he kept insisting that he wanted it darker, after several tries, we actually ended up with a color he liked, and it was very dark. I remember a comment from one of his crew members asking Dale if he was going to paint a big white number three on the roof to match his car.

Back to Knoxville with the selected color and we worked up the product so I could take it back and get his approval of the color before going any further. He did approve the color and plans went forward for the application. He insisted that I be available at various times for the application to insure the progress.

During the visits to the site, I learned that Dale was a very intense person and worked very hard when he was home. It seemed that he never got many spare moments due to the race schedule and the constant phone calls for him. He always found time when I was there to talk and discuss his project. Being on site various times, I was always welcomed by him and his wife Teresa, and was invited to go with him to the Charlotte night race where they would be racing under the lights for the first time. I have to say I was not prepared for the intensity and pace of the race and the activity that went on in the pits. Crewmembers were friendly, as was team owner Richard Childress, but it was very clear their focus was on the task at hand during the race. Some time later the next year, I received a call from Dale inviting me to the Daytona 500, he said “If you can get here, I would like to have you and everything is on me.”

In looking back at my short-lived association with Dale and those around him, I found him to be pleasant, yet demanding of those around him, and everyone worked hard to make him successful in his endeavors. It truly was a great experience for me, and it was like a family as everyone was fully involved and doing their part.

– Tony Huddleston, Perma-Chink Systems VP of Sales and Operation

The Legacy of Dale Earnhardt’s Log Home

Today, the grounds of Dale Earnhardt Incorporated no longer house the burgeoning race team led by the legendary driver. Instead, the property has been developed as a premier venue space with a unique history. The Venues at Dale Earnhardt Incorporated is now known as the area’s best venue for corporate and private events, with multiple facilities including the former home of Earnhardt. Whether you are looking for a pristine location for your wedding and reception or a corporate event, be sure to check this place. The Legend lived here.

The Lodge

A luxurious log home sitting on pristine grounds overlooking a lake. Old World charm is in the interior decor highlighted by the large stone fireplace. Outside you will find covered and open decks, stone patios and beautifully manicured lawns which give entertaining an over-the-top outdoor experience.

The Pavillion

For more information regarding the event facilities at Dale Earnhardt Incorporated, visit http://www.daleearnhardtvenues.com/.

Over the past years we have discovered many things about cleaning wood. First and foremost is that chlorine bleach should never be used to clean your wood. In addition to its potential for damaging wood fibers, its use and misuse contributes to a number of problems including the loss of film adhesion, discolorations due to tannin extraction, and the formation of iron tannates, streaks, blotches, and premature failures of the finish system.

We have also discovered that a number of wood and deck cleaners available at paint and hardware stores, home improvement centers, and Do-It-Yourself outlets contain components that can interfere with the proper performance of water-based finish systems.

With this in mind, the ONLY cleaning products we recommend for use with our finishes are those products supplied or specifically approved by Perma-Chink Systems, Inc. We have tested our cleaning products with our finish systems and have confidence that when properly used and applied, their use will result in the best possible appearance and performance of a Lifeline™ finish. We cannot say the same about the use of other types and brands of wood cleaners or brighteners, and strongly discourage their use before applying any of our Lifeline finish systems.

Perma-Chink Systems Wood Cleaning Products

Log Wash™ – A general purpose, low-pH cleaner concentrate for removing dirt, grime, pollen, stains from surface mold and mildew from bare wood surfaces and existing finishes. Log Wash will also remove some types of brown stains and lighten the color of bare wood. Log Wash is not effective for removing grayed, oxidized wood fibers. Whenever bare wood surfaces are left exposed to the elements for more than seven days, the surfaces should be cleaned with a solution of Log Wash before the first coat of finish is applied.

For wood species that contain high levels of wood extractives and resin oils, such as red cedar, southern pine, spruce and cypress logs, we highly recommended Cedar Wash™ as a cleaner.

Wood ReNew™ – A concentrated powder that is dissolved in water and applied to bare wood. When used with a pressure washer, it will remove gray, oxidized surface wood as well as dirt, pollen, mold and mildew. Although Wood ReNew usually lightens the color, it can occasionally darken the wood depending on the wood species and the types of chemicals previously applied. Wood ReNew is the product of choice for removing mill glaze from new wood surfaces.

Cleaning Exterior Bare Wood Surfaces

New Log Homes

Step 1: If the wood has not grayed, wash the surface with a two cups per gallon Log Wash solution and a pressure washer no more than seven days prior to staining. Apply and clean from the bottom up and rinse from the top down. Rinse well and allow the wood to dry.

Step 2: If there are signs of gray weathered wood, use Wood ReNew according to the application instructions along with a pressure washer.

Step 3: If after Steps 1 or 2 there are still dark streaks or discolorations on the surface, use a solution of Oxcon™ oxalic acid on the entire wall according to the directions for use. Be sure to dilute the Oxcon concentrate with four parts water. Apply the solution from the bottom up, begin washing it off starting at the bottom then rinse thoroughly from the top down. Be sure to completely rinse the Oxcon solution off the wall and allow the wood to dry before staining. Never use Oxcon unless it is absolutely necessary.

New Log Siding

New log siding must always be cleaned, since it presents an especially difficult challenge to a finish system. Typically used in high exposure locations such as dormers and gable ends, siding is often manufactured from lower quality wood than logs, and frequently green wood. This makes siding more susceptible to twisting, warping, and cracking.

Since siding does not have the high thermal mass of full logs, during the summer months its temperature can range from 70ºF to 160ºF or higher during the course of one day. This puts a lot of mechanical stress on the siding and its finish, resulting in small fissures forming on the surface. Rainwater can then enter these fissures and get into the wood, behind the finish. Log siding is typically milled quite smooth and often has a mill glaze on the surface, which if not removed, prevents the proper adhesion of the finish.

Step 1: To remove mill glaze and prepare siding for the first coat of finish, clean and pressure wash the surface of the siding using Wood ReNew no more than seven days prior to staining. Apply the solution of Wood ReNew and pressure wash from the bottom up, and rinse from the top down. Allow the siding to dry before staining.

Homes that Have Been Sanded or Media Blasted

Step 1: If the surface of the wood has been sanded or media blasted, it is not considered clean. Wash the surface with a two cups per gallon Log Wash solution and a garden hose (pressure washing is not required) no more than four days prior to staining. Apply and clean from the bottom up, and rinse from the top down. Allow the wood to dry before applying the first coat of Lifeline pigmented stain or Prelude™ Clear Wood Primer.

Homes that Have Had a Finish Removed Using a Chemical Finish Remover

Step 1: If a finish has been removed using a chemical stripper, there may still be some types of discolorations present on the wood. Cleaning with a two cups per gallon Log Wash solution and garden hose, or pressure washer, will remove many types of tannin (brown) stains and even out the color of the bare wood surfaces. If the surface feathered during the finish removal process, and the feathers were removed by sanding, or with an Osborn brush, it will be necessary to clean the surface again with Log Wash. Use a two cups per gallon solution and apply and clean from the bottom up, then rinse with a garden hose from the top down. Allow the wood to dry before applying the first coat of pigmented stain.

Step 2: If, after the finish has been removed, there are areas of grayed wood fibers, apply Wood ReNew according to the directions and clean the surface with a pressure washer. Rinse well and allow the wood to dry before applying the first coat of pigmented stain.

Application of Log Wash

Step 1: Add 1 gallon of water to your sprayer then add approximately 2 cups of Log Wash. If you add the Log Wash first, the sprayer will fill with foam. Be sure solution is mixed well.

Step 2: Spray the surface with the mixed Log Wash solution. Start at the bottom and work up. Allow 10 to 15 minutes contact time. Do not allow the surface to dry.

Step 3: If necessary, scrub the wall starting at the bottom and work up then rinse from the top down until you see no more foam running down the wall.

Application of Wood ReNew

Step 1: Use Wood ReNew to remove grayed surface wood.

Step 2: Only measure out enough Wood ReNew to add to a few gallons of water (0.8 cups per gallon) at a time. You need to use whatever you mix up within 1 to 2 hours.

Step 3: Pour the Wood ReNew into a pail that contains the water. Do not mix Wood ReNew in a sprayer.

Step 4: Mix the Wood ReNew with the water using a paint mixer and an electric drill.

Step 5: Stir for about five minutes or until no undissolved granules are visible. Allow the solution to thicken for 10 minutes before using.

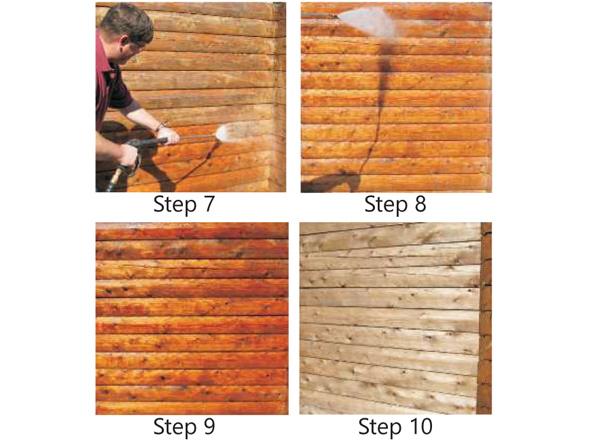

Step 6: Apply the Wood ReNew solution to the wall with a mop, broom, or car wash brush. Start at the bottom of the wall and work up. Allow the solution to remain on the wall for 10 minutes.

Step 7: Pressure wash starting at the bottom of the wall. Work on 2 or 3 courses of logs at a time. Hold the wand at a 30 to 45 degree angle to avoid feathering the wood.

Step 8: Once the entire wall is pressure washed, rinse the wall starting at the top and work down. At this stage water volume is more important than pressure.

Step 9: Never judge the effectiveness of Wood ReNew or any other cleaner while the wood is still wet.

Step 10: Once the wood dries, many of the dark discolorations will disappear. This is the same wall that appears in the previous step after drying for three hours.

*A NOTE ABOUT RINSING*

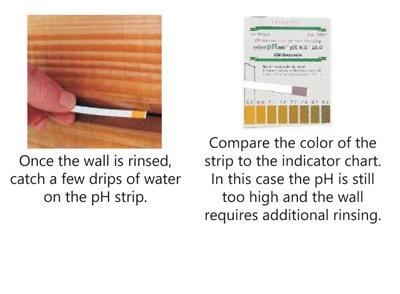

No matter what product you use to clean bare wood, nothing is more important than making sure you have adequately rinsed the surface. Any chemical residue remaining on the wood can have serious consequences later on. We always recommend using pH strips to make sure that the surface of the wood has been sufficiently rinsed, preferably to a pH of between 6.5 and 7.5. pH strips are available at most pool supply dealers, aquarium supply shops, and Perma-Chink Systems, Inc. They are not expensive and are very easy to use.

Cleaning Interior Bare Wood Surfaces

Interior walls and ceilings must be cleaned prior to finishing. If your home is completed, you are somewhat limited in the available cleaning methods since the use of a pressure washer is typically not an option. If you want your interior walls smooth, sanding may be your best and only choice. As opposed to exterior surfaces, you can sand interior wood surfaces using 120 grit sandpaper or Osborn brush.

Although your interior wood surfaces may appear to be clean, they are never clean enough to apply a finish to them without first washing them with an appropriate cleaning solution like Log Wash.

Step 1: Mix one half or one cup of Log Wash Concentrate with one gallon of warm water, if available, in a pail.

Step 2: Apply the Log Wash solution to the wall with a rag or sponge starting at the bottom and work up. Allow the solution to remain on the wall for at least 10 minutes.

Step 3: Using a clean rag or sponge and a pail of clean water, wipe the Log Wash solution off of the surface. Frequently rinse the sponge or rag in the pail of water and occasionally exchange the water in the pail with clean water.

Step 4: Allow the surface to completely dry before applying the first coat of finish.

Making an Old Deck New Again with Deck Defense

By Danny M. Nichols

A Transforming Experience

Spring finally arrived. With continued rains in our area, much of spring silently slipped away before we realized summer 2020 was upon us and a project launched the year before needed to be completed. A house my wife and I own and currently used as a rental house was in dire need of renovation. During a short period in 2019 when the house was empty, we set about doing a facelift of the entire interior of the home. Walls were painted, some new fixtures installed and floors were sanded and refinished throughout the house.

With the inside of the house finished and ready to go, a new renter moved in whose priorities did not immediately include the need or use of the wooden deck outside the kitchen door. The deck was built as an original feature of the house in 1990 and was much-used when my wife was raising her children there. Most of the outside woodwork of the home was in need of painting or replacing. To put it more correctly, it looked sad. We agreed to wait until the following spring to tackle the deck and front porch needs.

Assessment

The front porch posts, gingerbread trimmings and door could all do with a fresh coat of paint. The wooden deck off the kitchen, however, needed a miracle. Floor boards had deteriorated as well as the steps, banister and railings. Only the treated 4×4 wooden posts and floor joists providing the underneath support for the deck were still holding up well. A new deck floor would have to be constructed along with new banisters and railing. And finally, a sealer with stain would have to be applied to the boards.

Action

Off with the old and on with the new! Our first step involved moving all the old boards and railings. To our dismay and surprise, all the deck boards were nailed with 3” construction grade nails making them a bit difficult to remove. The upside was that it may well have been those nails that helped this deck survive the 30 years of its life!

Once all the deck boards and railings were removed, we hired a carpentry service to install all new wood again.

Affixed in place during the fall and winter, the deck boards were allowed to dry thoroughly before attempting to stain and finish the floor. This provided us with an opportunity to search and compare the various stains and finishes available in the marketplace. Our desire was not to have to reapply a finish to the deck for a long time.

One product stood out among the many we looked at. Perma Chink Systems, Inc. makes a product called Deck Defense, which appeared to offer all the qualities we hoped for. It offered UV protecting pigments that protected it from the sun and was specifically formulated to protect against mold and mildew. Exactly what we were looking for!

We were able to select from a wide variety of stain colors from their website. We chose Honey Maple #1930 for our stain. Other factors we found desirable was the clean-up could be done with soap and water, and the product is manufactured in the U.S.A. At 40 lbs. per 5 gallon bucket, it helped also that this product could be conveniently delivered to our front door.

Application

With help from a family friend, the project was coordinated with the painting of the railings, bannister, step riser and underpinning. Painting came first as we believed it would be easier to accomplish while saving the deck for the last step. Once begun, however, we were surprised at how easy the stain and finish could be applied.

We used a pad specifically designed for this purpose, and it worked very well. The stain was beautiful as it contrasted and blended the beige vinyl siding on the house with the dark green paint we selected for the railing and bannister. The staining process was far easier than that of painting.

In stepping back and looking at our work once the project was completed, we were in awe at the transformation possible when using well-chosen products and materials. We are very happy with the results.

Questions About Deck Defense?

Read our Deck Defense FAQs for more information about Deck Defense.

CHEMIST’S CORNER: Can All Wood Species Be Prepared the Same Way, Using the Same Cleaning Products?

The obvious answer to this question is NO. Although all wood species contain many of the same components – including cellulose and hemicellulose and minor amounts of extraneous materials – it is the wood extractives that differentiate wood species from one another. That’s why we developed Cedar Wash.

Understanding the Bleeding of Wood Extractives.

Wood extractives are compounds present in the softwood and heartwood of a tree that contribute to such properties like color, odor, decay and insect resistance, density, and flammability. When used for log homes, naturally occurring extractives in the wood can migrate to the surface and discolor paint and finishes (water soluble extractives) as well as create adhesion issues (oil soluble extractives) for many coating types.

The organic components of the extraneous materials are referred to as extractives because they can be removed by extraction with solvents without altering the cellulose/lignin structure of the wood. Extractives include tannins and other polyphenolics, coloring matter, essential oils, fats, resins, waxes, gums, and starch. Depending upon such factors as species and growing conditions, the total extractive content of wood substance may range from less than 1% to 30% in extreme cases.

Wood Species and the Level of Extractives

All wood species contain wood extractives; however, there are a handful of wood species that are characterized as extractive-rich woods. This group includes Redwood, Western Red Cedar, Walnut and Mahogany. The second group of wood species that also contains higher levels of wood extractives but less than extractive-rich woods include Southern Pine, Douglas Fir, Spruce and Cypress.

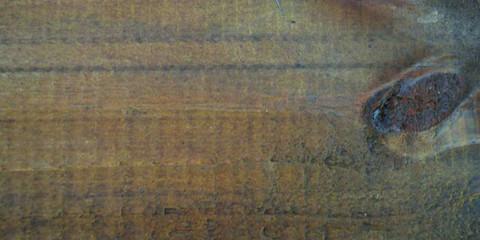

The percentage of extractives in trees is generally low, but a high concentration is found in knots and heartwood of the tree. Knot bleeding can occur when a knot contains an excessive number of extractives. In these cases, the extractives consist mainly of rosin, fats and turpentine, and these extraneous materials can make up as much as 50% of the knot by weight. The ratio of extractives can change with the season and weather (if the tree is stressed).

Extractives Affecting Wood Color

Staining or discoloration of wood may result from chemical processes that convert originally colorless or light-colored extractives into intensely colored products. Most of the “chemical stains” result from oxidation of certain wood extractives during air seasoning or kiln drying. Some resins can bleed out of the wood, as seen in pine wood. Sometimes the extractive can react with foreign material.

Using Cedar Wash For High-Extractive Wood Species

Cedar Wash is a wood cleaner with a high pH solution, which can dissolve, soften, loosen, or react with different types of extractives found in extractive-rich woods used in log homes. If a chemical is soluble in a liquid, it is easier to remove than a chemical that is only softened by that liquid. Being soluble is preferred as this means the particles are broken down to become so tiny we can no longer see them. Cedar Wash is designed to remove surface resin oils and high concentrations of water-soluble wood extractives such as sugar and protoplasm, in addition to dirt, grease, grime, pollen, and surface mold and mildew without harming the wood.

Cedar Wash was developed by Perma-Chink Systems as a Ready-to-Use cleaner specifically formulated for preparing the surface of wood species that contain high levels of wood extractives and resin oils. It is also safe for chinking and sealants.

- Easy to use, Ready-to-Use formula.

- Low environmental impact

- Designed specifically for Western Red Cedar, Redwood (Softwoods), Walnut, and Mahogany (Hardwoods)

- Removes resin oils and wood extractives from the surface of the wood

All our finish labels and application instructions emphasize the necessity for back-brushing during the application process. What exactly is “back-brushing,” and why is it so important? Back-brushing is the term we use to describe the process of working the finish into the wood and obtaining an intact, uniform film over the entire surface.

Back-brushing is typically used when applying stain with an airless sprayer; however, back-brushing is just as important if the product is manually applied with a brush. Although the directions for most log home stains call for a liberal first coat or flood coat, Lifeline™ finishes are designed to go on in thin coats, including the first coat. If applied too thick, the long-term performance of Lifeline finishes can be diminished. In other words, more is not necessarily better when it comes to applying Lifeline to your log home.

The first step in the process is to obtain a high-quality brush. A cheap, three-dollar brush from Walmart will not give you satisfactory results. You need a good quality brush like a Purdy or Wooster. For back-brushing logs, use brush preferably three to four inches wide. Using a narrow brush takes longer and may result in visible brush marks. If you plan to hand apply the finish with a brush and pail, you will use the same brush for both the application and the back-brushing.

The objective is to carry the finish to the surface with the brush and then to spread the finish out as far as it will go, making sure to work it into all cracks and crevices, and to uniformly distribute it over the area you are coating. This entails some vigorous back-brushing over the area that has finish applied to it. Lifeline finishes dry fairly quickly, so it’s important to back-brush as you go along and not wait more than a couple of minutes before you back-brush the coat.

We have formulated our Lifeline finishes to be most easily applied using airless spray equipment. There are two methods typically used to apply finishes with an airless sprayer.

The first method is to step back from a wall and use the sprayer to cover a larger area. This works well for a contractor with a crew since a large wall can be coated in a short period of time. This method requires at least two people, one spraying and at least one person back-brushing. When using this technique, back-brushing becomes important since the sprayer puts out lots of small droplets, which result in a lot of small dots of finish, not a uniform film. It takes back-brushing to convert these dots into an intact film, as well as to work the product into any cracks and fissures that are present on the surface.

The other method is to use the airless sprayer to carry the finish to the wall where it can be brushed out. The trick is to work on small areas at a time. Although it takes longer than spraying large areas at a time, a single person can use this technique to finish their entire home. The objective is to apply some finish on a one- to two-foot section of one or two courses of logs, and then brush out what you have applied as far as it will go. You don’t want to apply too much finish, and you need to be quick with the back-brushing to prevent stain from running down the wall. Just remember – A THIN, EVEN COAT is the key.

What’s the Difference Between Caulking and Log Chinking?

High-quality sealants help older cabins last for generations and give newer ones the rustic good looks many desire. Our sealants provide protection that will let them carry their historic styles far into the future. But when it comes to the language surrounding the sealant between logs, many people call chinking “log caulk.” Log caulk and log chinking are often used interchangeably, but these sealants are completely different. In fact, you should never, ever caulk a log home.

Caulking vs. Chinking

Caulk typically comes from a tube and is used to fill a small crack or seal edges along windows, trim, sinks, and bathtubs. This material is designed to be squeezed out in small amounts, then blend in and disappear. Caulks are completely waterproof, easy to apply, and easy to clean up. Today, there is an overwhelming selection of caulks including waterborne, oil-based, and silicone. Prices range from $2 for an 11oz. tube to $26 for the same size.

There are three main reasons why you don’t want to use a general caulk on a log cabin:

- Caulk is impenetrable. Wood is an organic material and internal moisture is an inherent quality of any log. A caulk will trap moisture, which leads to mold, rot, and unsightly stains.

- Caulk is not engineered to adhere to wood. Some turn hard and develop a cracked “alligator” skin appearance, or they separate from the wood entirely. In these scenarios, the sealant has failed, and water will get underneath, leading to rot and stains. When that happens, more water penetrates the log walls and rotting gaps become a haven for insects.

- Caulk is a low-quality product. Despite the spectrum of price points, caulks are essentially a bottom-line resin effective for a very narrow set of purposes. This does not include sealing your prized log home.

Chinking, on the other hand, is specifically designed for the purpose of sealing log homes, able to withstand the onslaught of environmental attacks and wood movement. Unlike caulk, which tends to be smooth and glossy, chinking has definitive texture that complements wood’s organic surface. Historically, chinking materials were made from what was regionally available. In Northern Europe, they used a special moss that did not cause log rot. Other places mixed horsehair or grass with mud or clay. Even today, it’s possible to purchase “log caulk” that has sand mixed with it to approximate a desirable rustic texture. None of these options are known for their effectiveness in withstanding movement and maintaining a proper seal over time.

In addition to offering the appropriate texture, our chinking is the kind of sealant a log cabin needs and deserves, and has four distinct qualities that sets it apart from caulk. For log homeowners, these qualities should be considered requirements when considering chinking.

- Log Home chinking must be breathable to let moisture escape the wood, while preventing new moisture from entering.

- Log Home chinking must have elastic qualities so it can move with wood’s daily and seasonal expansion and contraction.

- Log Home chinking must stick to the gap between the logs, even for log homes where the chinking remains invisible.

- Log Home chinking must resist the weather’s relentless tests — snow, rain, heat, and ice.

Chinking Superpower

Not only do our log sealants excel in the requirements that a high-performance chinking must possess, but we’ve devised a special formula with a distinct property. Our chinking sealants are thixotropic to provide exceptional peformance and fight environmental damage. A non-thixotropic sealant is prone to slumping and blistering, leading to issues that require a reapplication of the sealant and hoping the same issues don’t happen a second time.

Our thixotropic sealants stay exactly where the applicator leaves it, making them easier to apply with accuracy. In fact, we’ve spent years perfecting our formula to find the ideal balance between viscosity and thixotropic abilities. Our sealants can be easily pumped, squeezed, and applied by professionals and do-it-yourselfers alike. Professionals love our thixotropic sealants because they can get the job done right the first time.

We offer three types of sealants to accommodate different log home construction methods. Perma-Chink, our original elastic log home chinking, is designed for log gaps sized 1-inch or larger. Energy Seal has a more refined texture for log gaps less than 1-inch. Finally, Woodsman is a smooth and lightly textured log sealant that goes between stacked logs with no gaps.

All our sealant products come in an array of rich, earthy colors to complement any log home and work as an extra-strong, protective system with our wood stains and finishes. Perma-Chink lets your log home be permanently beautiful for your permanent enjoyment.