Blog

By Jared Turner

Folks have been trapped inside their homes for lengthy periods of time this winter. Whether it was to escape the cold or shelter from Covid, you are ready for a change. So, as you emerge from your long winter hibernation, take time to stretch, rub the sleepy out of your eyes and put the coffee on. Once you have all of that out of the way, it is time to open your door to Spring and consider the benefits of Forest Living.

For most folks, exposure to forests and trees has wonderful health benefits. For example, both of my parents happen to live in a densely populated urban area. However, each spring and fall they take the time to travel hundreds of miles to dive deep into the forests of Appalachia. They, as well as millions of others, have found these trips to be beneficial to their overall health and wellbeing.

So, what is it about the forests that make them so wonderful for our health? In recent years there is evidence that link people’s exposure to forest with a strengthened immune system, lower blood pressure, reduced stress, improved mood, increased energy level and improved sleep. What is not to like about this list? I believe many of us would be thrilled with improvements in these areas.

Are there other benefits that forests bring to our lives? Absolutely! They help to remove harmful pollution from our air by behaving like giant environmental filters removing harmful toxins from the air we breathe. In addition, forested watersheds provide quality drinking water for over 180 million Americans. Not only do trees filter through the air they also filter through the ground. With temperatures on the rise in most places, forests also help to lower air temperatures by 20-45 ֯F. The evaporation of water from trees has a wonderful cooling influence! Trees absorb carbon dioxide, a harmful greenhouse gas, and store it as carbon while releasing beneficial oxygen back into the air. In addition, trees, properly placed around your home, can help reduce your energy consumption by lowering the cost to cool your home. Finally, trees provide a wildlife habitat for animals to live and thrive.

Densely populated urban areas are just now catching on to all these benefits and are working hard to transform their cities by planting more trees and providing more green space for their citizens. They rightly understand that this approach is part of a more sustainable future. However, living this close to nature does bring with it challenges. At Perma-Chink Systems® we have been helping homeowners live in harmony with nature for over 40 years and as more folks transition to Forest Living, they are going to need a partner who knows how to integrate the two successfully.

Perma-Chink Systems happens to be a one-stop shop for forest living. We supply knowledge, experience, and quality products to help meet the needs of homeowners living in the forest. For example, with spring comes trees blooming and plants flowering, bringing with it pollen and dust. All this dirt, dust and pollen collecting on your home creates challenges for the longevity of your finish system. Once or twice a year we recommend giving your home a good washing. To help with this need we have developed Log Wash™, a highly effective, low pH cleaner designed not to damage your logs or your finish. By removing these contaminates, it will cut down on mold growth and damage caused by absorption of water and sunlight on your finish.

Spring is also a wonderful time to conduct an inspection of your home. Look for damage that needs repaired, cracks or openings that need to be sealed, and observe the overall condition of your finish system. Depending on what you discover, Perma-Chink Systems has products designed to solve most of your needs. We at PCS are actively helping to transition folks to a healthier way of life through a more sustainable Forest Living lifestyle. Please take some time to visit our website for more information.

Just as clear coats are vital to the performance of today’s automotive finishes our Advance Topcoats are an integral part of all of our exterior finish systems.

Not only do they extend the life of the color coats but they do much more. They significantly improve the look of the finish by enhancing the color, clarity and depth of the finish. In other words, they make our finishes the most beautiful log home finishes in the world. Second, they help keep the surface clean. The very nature of a pigmented stain makes it susceptible to dirt pick-up through adhesion or impregnation.

Since we have designed Advance to form a smooth, strong film it makes it much more resistant to dirt. In addition, the smooth surface makes it easy to clean off any dust or pollen that may accumulate on the surface of the logs. A simple wash down with Log Wash and a garden hose will remove the dirt and grime that may be hiding the beauty of your home.

Another feature a smooth topcoat provides is greater resistance to the growth of mold, mildew and algae. In addition to water these organisms need something to grip onto. If the spores land on a tough smooth surface that rapidly sheds water they won’t have an opportunity to germinate and spread. So the surface of your logs stays free of unsightly mold spots and patches of algae.

Of course the best feature of Advance Topcoat is the protection it provides to the color containing stain. Years ago cars left the manufacturer with a coat of paint. More expensive cars may have had several coats of paint but no matter how many coats were applied after a few years on the road the paint turned dull and started to flake off. Then car coating experts discovered the benefits imparted by clear topcoats. Today’s car finishes remain shiny and last longer than ever thought possible all due to the application of clear topcoats.

What is it about topcoats that contributes to this improvement? The most performance enhancing feature of a clear topcoat is that it reflects sunlight. Sunlight is composed of several components including ultraviolet (UV) light. It’s the UV that is responsible for fading colors and, in the case of wood homes, damaging wood fibers through a process called photo-oxidation. The more UV light that’s reflected off the surface the slower the color coats will fade and the less the wood fibers will be exposed to photo-oxidation thus extending the life of the entire finish system. Although satin finishes reflect a significant amount of sunlight, gloss topcoats reflect more which is why car finishes are shiny and not dull. The same holds true for our Lifeline exterior finish systems. Advance Satin does reflect much of the sunlight but Advance Gloss reflects even more, which is one of the reasons that log home gloss finishes are becoming more popular.

An additional beneficial feature of a clear topcoat is the protection it provides to the color coats against degradation by airborne contaminates like sulfur dioxide, ozone and particulates. Even natural contaminates like tree pollen and bird droppings can damage or discolor the color coats by chemical reactions or supporting mold growth. Our Advance Topcoats provide a barrier that prevents this from occurring.

Although most people use brushes to apply our finish removers they can be applied with airless sprayers as long as you know what to do. Here is some information that will guide you in using airless spray equipment to apply both S-100™ and StripIt®.

Airless Spray Equipment

Most quality airless spray equipment including the Airlessco SP200 available from Perma-Chink Systems will handle our S-100. On the other hand for applying StripIt, you will need a professional grade airless sprayer with an output of at least 0.54 gpm. In either case, there are a couple of minor modifications that have to be made before using them. The first thing is to change the tip to a 0.019 or 0.021 tip orifice. We stock universal 521 tips in case you cannot find one locally. If a smaller diameter orifice tip (<0.019) is used, it will take longer to apply the proper amount of finish remover and the tip may block up. In addition, since a small orifice produces a fine mist there is a greater chance of wind drift onto surfaces that you may not want to strip.

The second thing is to remove any sprayer strainers, screens and/or filters. Our finish removers are somewhat thick and viscous, so having to pass through screens and filters will impede the flow of product through the sprayer and may eventually block it. Once the stripping process is completed, it’s of utmost importance to replace the 0.019 or 0.021 tip with a 0.015 or 0.017 tip for applying our stain and topcoat.

S-100 and StripIt

Our S-100 Finish Remover and StripIt are formulated so that they can be applied “as is” using an airless sprayer. Their viscosity is such that they do not need to be diluted with water to be run through airless spray equipment. However, it is a good idea to thoroughly mix the S-100 with a Jiffy Mixer before spraying it. Just be careful to keep dirt and other debris out of the product.

Application

The first step before starting to remove a finish is to take off downspouts, gutters, and lighting fixtures, and mask off or cover those areas that you don’t want to strip or they may become discolored if contacted by the product you are using. The next step is to wet down and cover any plants and shrubs. Both S-100 and StripIt are pretty gentle on plant life once they are diluted with water during the stripping process, but in their concentrated form they may present a problem. The use of perforated weed blocking film works well over plants, roofs, decks and other areas you want to protect, since it allows water to drain through it but catches lumps of concentrated remover as well as any stripping debris. This makes clean up a lot quicker and easier.

Apply the finish remover to one or two courses of logs at a time in a sweeping motion across the entire wall starting at the bottom of the wall. This will help you avoid coating the chinking or sealant joints if they are present. Be sure to only coat an area that you can finish stripping in the allotted time you have. If you coat the entire wall or too large an area the finish remover may end up drying on the wall and become difficult to remove. Always apply finish removers at the recommended thickness or coverage rate. If applied too thinly, they may not work and you will have wasted your time and money. Once the finish remover has been applied to an area, submerge the spray gun and tip in a pail of water to prevent the product from drying at the tip and possibly blocking it.

After waiting an appropriate amount of time for the stripper to soften the finish (remember the cooler it is the longer it will take), you can begin the pressure washing process. Be sure to wash off any product and wet finish debris that’s still adhering to the wall or other surfaces. If allowed to dry, you may end up having to manually scrub these surfaces clean. Once you reach the top of the wall, or if you run out of time, rinse the entire wall starting at the top before you quit. You don’t want any chemical or finish debris to remain on the surface. If you are through for the day, replace the lid on the pail of finish remover and run clean water through your airless sprayer until clear water comes out of the gun.

Start Saving on Your Heating Bills Now!

Energy Seal is a textured acrylic polymer sealant that provides a long-lasting and resilient seal for any style of log home. Since logs constantly twist, turn, swell, expand and shrink, gaps may appear between logs or between the logs and window and door frames or other areas of the home. These gaps retain moisture and allow the seepage of air and water into the home. Energy Seal eliminates these gaps by forming an air and water tight barrier over them.

So why do people use textured sealant Energy Seal?

First and foremost, to keep water, air and bugs out of places where they don’t belong; second, for its attractive appearance; and third, for the reputation of lasting longer and performing better than competitive products. It should not come as a surprise that log homes are a bit difficult to seal up. When you stack logs on top of one another to make a wall, the logs do not naturally fit tightly to one another so there are usually gaps that must be sealed to prevent air and water from getting inside. That’s what Energy Seal is designed to do.

Most people call log sealants “caulk” but we try to refer to them as “sealants” to help differentiate high quality products from cheap caulks that can be bought at any hardware store. Plus, several of our sealants do not fit the conception most people have of a typical caulk.

There are two reasons that Energy Seal is textured. First, it allows the surface of cured Energy Seal to remain looking “flat.” It does not have that shiny look common to most types of caulk. This allows Energy Seal to blend in with the surrounding stained wood. Second, the texture allows Energy Seal to better accept a stain so that it can virtually disappear on a wall.

Here is a TIP; if you plan to stain over Energy Seal, select an Energy Seal color that’s just a bit lighter than the stain you plan to use. It’s much easier to cover light-colored Energy Seal with a darker color stain than it is to cover dark-colored Energy Seal with a light-colored stain.

Applying Energy Seal

Before Energy Seal is applied, the surface must be clean, dry, and free of oil, wax, or anything else that will interfere with the adhesion of the Energy Seal.

Wherever possible, Energy Seal should be used along with Backer Rod or Grip Strip. If backing material is not used, there may not be enough room for the Energy Seal to expand and a crack may appear across the joint. Backer Rod should be used even if the joint is narrow. The width of the band of Energy Seal may end up a bit wider than you expected but the integrity of the seal will be maintained.

Applying Energy Seal over old caulk is never a good idea even if it looks like the caulk is still adhering to the wood.

Although it can be time consuming and somewhat difficult, old caulk should be removed for several reasons. If a caulk no longer adheres to the wood, it may be due to moisture getting under the caulk creating rot. The old caulk must be removed to properly treat and seal the wood, so the new sealant does not fail.

Once in place, Energy Seal may be tooled smooth with a trowel or putty knife. Spraying a light mist of water on the surface will make tooling a lot easier and will result in a smoother surface.

If masking tape is used to protect the surrounding wood be sure to remove the tape while the Energy Seal is still wet.

To protect recently applied Energy Seal from the weather, a loose covering of plastic film will prevent it from being washed out of the joint until it cures enough to withstand a heavy rain. Typically, a week or so is sufficient.

For more information about Energy Seal, give us a call 1-800-548-3554 or check out our Log Home Sealant Application Guide https://www.permachink.com/wp-content/uploads/2025/08/sealants_guide-1.pdf

HOW TO SEAL AROUND WINDOW AND DOOR FRAMES

We have an excellent tutorial on sealing around windows and doors using Energy Seal and Log Gap Caps. Read it here: https://www.permachink.com/resources/log-gap-cap-and-energy-seal-to-seal-windows-and-doors

During the winter months it’s important to be aware of the freeze-thaw stability of Perma-Chink Systems’ products. The reason may involve shipping conditions or whether it is okay to store a product or products in an unheated shed. In any case you need to be aware of the consequences of allowing any of our products to freeze.

Without a doubt it is always best to prevent any of our finishes and sealants from freezing. They all contain water and the formation of ice crystals within the products can separate the water from the other components. In some products once this occurs it becomes impossible to regain the properties of the original formulation even after thawing and vigorous mixing.

With a few exceptions most of our products are freeze-thaw stable, however, if a product becomes frozen it needs to be thawed slowly, preferably at room temperature. Speeding up the thawing process by heating the container can seriously damage the product making it unusable. If the product is in pails or containers, once it has completely thawed it will require a thorough mixing.

If a product is subjected to multiple freeze-thaw cycles each cycle will contribute to the degradation process until it is no longer suitable for use. If a product becomes frozen it is better to allow it to stay frozen than it is to bring it inside to thaw and then store it where it may freeze again.

It’s the succession of freeze, thaw, freeze, thaw sequences that really destroys the integrity of a product. Before applying any product that’s been frozen be sure to test a small amount to see if it is still usable.

To reiterate:

- It’s best to protect all of our products from freezing.

- If it does get frozen, thaw it slowly at room temperature then thoroughly mix it.

- It’s better to keep it frozen than to subject it to multiple freeze-thaw cycles.

- Before applying any product that’s been frozen be sure to test a small amount to see if it is still usable.

Perma-Chink Systems’ products that are NOT freeze-thaw stable:

- Chink Paint™ Textured & Smooth

- Log End Seal™

- Oxcon™

- StripIt™

Perma-Chink Systems’ products that have limited freeze-thaw stability (5 cycles):

If you need cold-weather storage guidance for a product not shown, just give us a call at 800-548-3554 – we’re happy to help!

During the winter months it’s important to be aware of the freeze-thaw stability of Perma-Chink’s products. The reason may involve shipping conditions, or whether it is okay to store a product or products in an unheated shed. In any case, you need to be aware of the consequences of allowing any of our products to freeze.

Without a doubt it is always best to prevent any of our finishes and sealants from freezing. They all contain water and the formation of ice crystals within the products can separate the water from the other components. In some products once this occurs it becomes impossible to regain the properties of the original formulation, even after thawing and vigorous mixing. These types of products are not freeze-thaw stable.

With a few exceptions, most of our products are freeze-thaw stable. However, if a product becomes frozen it needs to be thawed slowly, preferably at room temperature. Speeding up the thawing process by heating the container can seriously damage the product making it unusable. If the product is in pails or containers, once it has completely thawed it will require a thorough mixing.

When a waterborne product is subjected to multiple freeze-thaw cycles, each cycle contributes to the degradation process until the product is not suitable for use, i.e. gelation or coagulation of the product. If a product does become frozen it is better to allow it to stay frozen than it is to bring it inside to thaw and then store it where it may freeze again. It’s the succession of freeze, thaw, freeze, thaw sequences that really destroys the integrity of a product.

Before applying any product that’s been frozen, be sure to test a small amount to see if it is still usable.

To reiterate:

- It’s best to protect all of our products from freezing.

- If it does get frozen, thaw it slowly at room temperature then thoroughly mix it.

- It’s better to keep it frozen than to subject it to multiple freeze-thaw cycles.

- Before applying any product that’s been frozen be sure to test a small amount to see if it is still usable.

Perma-Chink Systems’ products that are NOT freeze-thaw stable:

- Chink Paint™ Textured

- Chink Paint™ Smooth

- Log End Seal™

- Oxcon™

- StripIt

Perma-Chink Systems’ products that have limited freeze-thaw stability (5 cycles or less):

- Lifeline™ Ultra 7

Most of the Directions for Use for our finishes contain the statement “Do not use Lifeline™ on surfaces that have been brushed or rubbed with steel wool or a wire brush. If you do, rust spots may appear under the finish.” Fortunately we rarely see the consequences of applying one of our finishes over a wall that has been rubbed or brushed with steel wool or a wire brush, but occasionally it does happen.

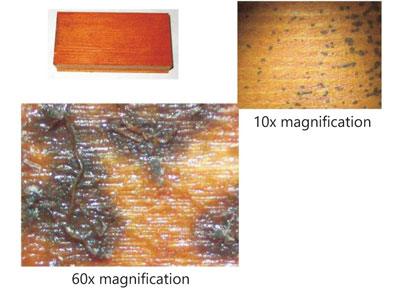

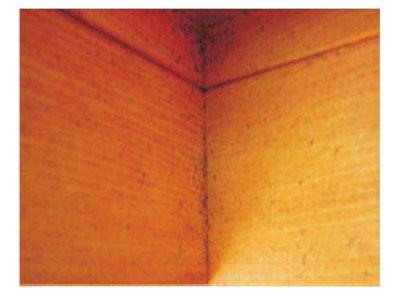

The customer who took this picture thought that the dark spots in the corners were due to mold; however, they appeared within just days after the finish was applied. We were able to obtain a small section of the discolored wood and just looking at it gives the impression that the discolorations could well be mold, or some flecks of dirt that may have been present at the time of staining. Even under the microscope at 10X magnification, there’s no indication of what caused the black spots.

But at 60X magnification it quickly becomes apparent that every black spot is associated with some type of fiber imbedded in the film. These fibers are bits of steel wool. Since the black spots are concentrated in the corners, it’s evident that someone had tried to wipe the wall clean but missed the corners entirely.

Designing a Fortress of Protection for Your Log Home

When I was growing up, I was fascinated with forts. I would often get together with friends from the neighborhood, and we would combine our resources and construct some rather elaborate fortresses. To test our handywork we would end our session with a great battle to decide whose fort was superior. Fast forward nearly forty years and I am still helping design forts! At Perma-Chink Systems the forts we are building are designed to protect your home against the forces of nature such as sunlight, wind, rain, dust, insects and microorganisms. Let us take a closer look at what our fort looks like.

Protection From The Start

We have advocated for many years that the protection of your log home starts with a smart design. For example, many modern log home builders use large overhangs and wide porches to help shield the home’s walls from dangerous radiation from the sun. Let your roof help protect your walls. Planting trees that can help shade your home not only reduces energy consumption, but also helps to prolong your finish system.

Protect From Insects and Ultraviolet Damage

Protecting your home from wood destroying insects is something we have also incorporated into our “fort” design. Bare wood logs or siding can be treated with anyone of our safe, borate-based wood preservatives such as Shell Guard™, Shell Guard RTU™ and Armor Guard™. These products are designed to provide a protective shell of defense for log homes. If a wood-ingesting insect such as a termite or Powder-Post beetle passes through this protective barrier, they are in for quite a nasty surprise. The borates work to interrupt the insects natural digestive cycle, making it difficult – if not impossible – for the organism to process food. These products, while destructive to wood-ingesting insects, pose little danger to humans.

Perma-Chink offers a full line of stains with numerous color choices and benefits. For example, our stains such as Lifeline Ultra 7™, Ultra 2™ and Exterior™ have ingredients designed to protect the wood surface from algae and fungi (mold). In addition, we also have ingredients that work to shield the lignin in your wood from photooxidation. Lignin provides structure and support for the cell walls in wood. If it is destroyed by harmful ultraviolet (UV) radiation, then your coating could delaminate from the wall more easily. Furthermore, our stains also contain UV absorbers designed to filter out harmful radiation. Our colorants also add another level of protection for your finish system. In general, darker tone stains provide a higher level of protection than lighter, honey-tone colors. Choosing a slightly darker tone will act as a shield to help protect your wood more completely and provide more longevity and less color shift.

Protect With Industry-Leading Sealants

Our business was founded forty years ago with a great solution to existing chinking. Back at that time, many folks used concrete between the logs to fill in the gaps. When the logs changed dimensionally this created cracks and open places for water to get in and damage wood structures. Perma-Chink™ seals between the logs and moves with your log home keeping a tight seal that keeps water and insects out. For smaller joints of less than one inch, we also sell Energy Seal™ and Woodsman™ which are great products for sealing around windows and doors.

Protect With The Finishing Touch

The next defensive layer in our “fort” is the topcoat. Our Lifeline Advance Satin™ or Gloss™ has several purposes. First, it provides a hard surface making it more difficult for dirt and debris to collect on the wood and sealant surfaces. Secondly, it contains both UV absorbers and UV stabilizers. Often when you UV light strikes a system it produces harmful free radicals that can be destructive to a coating system. The UV stabilizers are designed to terminate free radicals so they cannot continue their destruction. The UV absorbers act as a shield keeping the dangerous UV light from penetrating deeper into the system. Finally, it works to keep your coating system sealed. If water remains on surface for long periods of time, it can allow microorganisms to grow and multiply. Water will sheet and evaporate relatively quickly with the topcoat present.

Finally, regular cleaning of your home will help keep your home looking beautiful well into the future. Buildup of dirt and debris can provide a foothold for fungi and algae to grow, decreasing the longevity of your finish system. To aid in this annual cleaning, Perma-Chink provides a safe cleaner called Log Wash™ which does a fantastic job removing these unwanted contaminates from your log home.

Protect By Moving Forward

As you can see, we have many layers of defense built into our fortress. The forces of nature are powerful and unforgiving at times. Over the years we at Perma-Chink have gained tremendous respect for what it can do to damage your home. We have learned a great deal over these last forty years and have adjusted tactics where needed to counter our foe. Let us put our experience building forts to work for you. Please visit our website at www.permachink.com to learn more about our products and how they can help you protect your home.

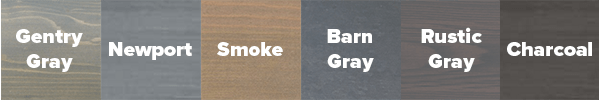

Occasionally we get a call from someone whose home has a gray aged patina that appeals to them. They typically want to apply some type of clear water repellent to seal and protect their home, but they don’t want to remove the grayed wood. The gray color is an indication that the surface wood has been photo-oxidized by ultraviolet (UV) light and the wood fibers have lost their integrity.

The application of any film-forming finish over grayed wood presents a problem since the finish will not adhere to the degraded wood fibers. It would be like trying to paint over a rusted metal surface. Within a few months the paint begins to peel off; consequently, the same thing can happen with a film-forming log home finish applied over grayed wood. With this in mind, we never recommend applying any of our stains or topcoats over gray, photo-oxidized wood.

Gray Color Choices in Lifeline Stains

Although there are solvent-based products that can be applied to grayed wood surfaces they only last about six months or so. If you truly want to protect your home, you will have to remove the grayed wood, and if you like the gray look, use one of our gray colored stains. If you are not willing to clean the surface down to bare wood, the best recommendation we can give you is to leave the surface alone but make sure that all chink joints, checks and other places that may allow water entry are well sealed.

Log Homes in Gray Colors

Pressure washing (also referred to power washing) is the function of using highly pressurized water to remove mildew, mold, dirt, pollen, UV graying, etc. You’ll hear different recommendations whether or not pressure washing your logs is the best cleaning method.

Generally speaking, pressure washing is the quickest and least expensive choice.

One fallacy is that you’re saturating and “damaging” your logs with water as a result of pressure washing. This simply isn’t true. On hard, sound, rot-free logs, you’re only introducing water into the top fibers of the wood.

The time it takes to pressure wash and the results generated are often directly associated with the type of finish being removed as well as how many coats have been applied. While some older, obsolete linseed based oil stains are more difficult to remove than newer products, practically everything can be removed with proper pressure washing techniques and good finish removers. Some of these older type products will often need S-100 or StripIt stripper applied first in order to soften the bond to the wood.

Condition of Wood Surface

Traditionally, newer, recently peeled logs have a greater surface hardness and can withstand highly aggressive pressure washing (if needed) easier than a log wall which has been fully exposed to direct sun for 20 years. You might notice your upper and lower fascia boards have aged and darkened at an accelerated rate compared to your logs. Because these areas are often made from softer (i.e. pine) wood, they are more likely to absorb water leading to more prominent mildew growth. These areas can easily resemble new wood once cleaned.

Pressure washing of new constructions can also easily remove the UV graying of the logs that can start occurring just weeks after the logs are stacked, particularly if exposed to direct sunlight.

In addition to log and wood sided structures, other areas where pressure washing can be utilized include driveways, stone walkways, pool decking, stone walls, fencing, gutters, downspouts, roofing and other areas. Concrete slowly builds up a browning/green appearance over time which usually consists of grease, dirt, mildew and algae which can easily be cleaned.

Pressure washing can be done in practically any temperature and weather conditions, although chemical strippers, which are often applied prior to cleaning, work much better in warmer weather.

Whether you hire a professional or undertake the project yourself, pressure washing with wood cleaners from Perma-Chink Systems can bring back the beauty of your logs, preparing them for a fresh coat of stain and protective clear topcoat finish.

By Jeff Kyger

Northwest Log Home Care

www.northwestloghomecare.com

Pressure washing (also referred to power washing) is the function of using highly pressurized water to remove mildew, mold, dirt, pollen, UV graying, etc. You’ll hear different recommendations whether or not pressure washing your logs is the best cleaning method.

Generally speaking, pressure washing is the quickest and least expensive choice.

One fallacy is that you’re saturating and “damaging” your logs with water as a result of pressure washing. This simply isn’t true. On hard, sound, rot-free logs, you’re only introducing water into the top fibers of the wood.

The time it takes to pressure wash and the results generated are often directly associated with the type of finish being removed as well as how many coats have been applied. While some older, obsolete linseed based oil stains are more difficult to remove than newer products, practically everything can be removed with proper pressure washing techniques and good finish removers. Some of these older type products will often need S-100 or StripIt stripper applied first in order to soften the bond to the wood.

Condition of Wood Surface

Traditionally, newer, recently peeled logs have a greater surface hardness and can withstand highly aggressive pressure washing (if needed) easier than a log wall which has been fully exposed to direct sun for 20 years. You might notice your upper and lower fascia boards have aged and darkened at an accelerated rate compared to your logs. Because these areas are often made from softer (i.e. pine) wood, they are more likely to absorb water leading to more prominent mildew growth. These areas can easily resemble new wood once cleaned.

Pressure washing of new constructions can also easily remove the UV graying of the logs that can start occurring just weeks after the logs are stacked, particularly if exposed to direct sunlight.

In addition to log and wood sided structures, other areas where pressure washing can be utilized include driveways, stone walkways, pool decking, stone walls, fencing, gutters, downspouts, roofing and other areas. Concrete slowly builds up a browning/green appearance over time which usually consists of grease, dirt, mildew and algae which can easily be cleaned.

Pressure washing can be done in practically any temperature and weather conditions, although chemical strippers, which are often applied prior to cleaning, work much better in warmer weather.

Whether you hire a professional or undertake the project yourself, pressure washing with wood cleaners from Perma-Chink Systems can bring back the beauty of your logs, preparing them for a fresh coat of stain and protective clear topcoat finish.

Every spring we get lots of calls about carpenter bees drilling into logs, fascia boards, eaves, decks and other unpainted wood surfaces. Carpenter bees are big black solitary bees that look similar to bumblebees but have bare, shiny backs whereas a bumblebee’s back is hairy. Unlike honey bees that reproduce in hives, carpenter bees drill into wood in order to lay their eggs. Their holes are perfectly round and about 1/4 inch in diameter.

Although carpenter bees prefer hardwoods such as cedar, redwood, or cypress, they happily attack pine and most other species of wood. Even pressure treated wood is not immune from carpenter bee attack. As the bee drills into the wood, coarse sawdust may be seen coming out of the hole and piling up beneath the hole. Since it only takes a couple of hours for a carpenter bee to drill a hole a few inches deep, lots of holes can appear over a fairly short period of time.

Most carpenter bee activity occurs in early spring when male and female bees emerge after spending the winter in old nest tunnels. Once they have paired and mated the female bee drills into a suitable site while the male stays nearby to ward off intruders. Male carpenter bees often frighten people with their aggressive behavior but since they have no stinger they are essentially harmless. Females have a stinger but only use it if molested.

Once the initial hole is drilled through the surface, the bee will make a turn and excavate a tunnel along the grain of the wood. This tunnel, which may run for several inches, becomes the cavity where the female deposits her eggs. Several eggs are laid in individual chambers separated by plugs of pollen on which the larvae feed until they emerge as adults during the summer months. In addition to making new holes, carpenter bees also enlarge old tunnels. If left unattended for several years, serious damage to a wood member may result.

In late fall activity may again be seen as both male and female carpenter bees clean out old nest cavities where they stay over winter. Since carpenter bees tend to migrate back to the same area from which they emerged, it is important to implement some control measures in order to prevent logs and wood members from becoming riddled by these bees.

Prevention

Although carpenter bees prefer bare wood or distressed wood, they will attack wood that is stained. Painted wood surfaces, on the other hand, are rarely attacked since the bees must see or feel the grain of the wood in order to recognize it as wood. One of the most effective measures for preventing extensive carpenter bee damage is to fill old or empty holes with Energy Seal. Carpenter bees are attracted to existing holes. Be sure to treat the hole before you fill it since live adult bees will drill right through the caulk on their way out.

One way to keep carpenter bees from drilling into wood is by spraying pesticides that contain either cypermethrin, deltamethrin, or bifenthrin (Ortho Home Defense Max) onto wood surfaces. When it comes to carpenter bees, these products act more as repellants than contact poisons. However, the effectiveness of these applications is only about three to four weeks, so the treatment will have to be repeated every so often. Pesticides should only be used during the periods of peak activity in the spring and perhaps again in late fall. Be sure to follow label directions and read and understand any precautions that must be taken when using these products.

A few years ago we requested information about the effect of our gloss topcoat on reducing carpenter bee activity via survey. Out of over 20 responses by letter, phone and e-mail, only two reported any penetration of the gloss topcoat by carpenter bees. One home went from 20 to 30 holes the previous year down to 2 this past year and the other went from over 20 holes to 4 holes. This confirms our suspicion that the Lifeline Advance Gloss exterior topcoat appears to provide a finish to the wood that carpenter bees do not find very attractive. That is not saying that the gloss finish repels carpenter bees. It does not. Although bees would occasionally land on the gloss topcoat, they just did not drill through it. So why is that? Well, let’s be clear that the Lifeline Advance Gloss topcoat is not a pesticide nor does it have any pesticide properties. It appears to form a coating on the surface of the wood that carpenter bees are reluctant to drill through. Why? It could be the glossy look or that the hard, slick finish does not appeal to them, so the bees will search for another target. Many other online “How-To” documents related to carpenter bees describe the actions of carpenter bees on bare or distressed wood. That stands to reason that well-maintained log homes with stain and a solid topcoat should dissuade most carpenter bees from nesting inside logs.

Another possible solution, with hit-and-miss results, is a bee trap specifically for carpenter bees. Much like a minature bird house, the bee trap invites the carpenter bees inside, and they get trapped in a glass jar. In the past we offered these types of traps, and the results weren’t 100% positive. You can find bee traps online, both DIY plans and for purchase.

Treating Carpenter Bee Holes

Any carpenter bee holes you can reach should be treated and plugged since existing holes attract more carpenter bees. The way to treat an existing hole and tunnel depends on the time of year, and if bees are present at the time of treatment. If the female is drilling away when you find a hole (you can see sawdust coming out or hear her working inside) spray a contact pesticide like wasp and hornet spray into the hole. She will quickly back out and die. Immediately fill the hole with wood putty or Energy Seal. You need to treat the hole even if it appears empty since the bee may be resting and, if left alive, will drill back through the plug you’ve just inserted.

If you find carpenter bee holes in late spring or early summer it’s difficult to tell if there are bee larvae developing in the tunnels. The best thing to do is to run a length of flexible wire into the tunnels in order to break through the pollen plugs separating the chambers. Then spray a pesticide into the hole and seal it up. The same thing should be done on holes found in the fall or winter to kill any bees that may be over-wintering in the holes. Just remember to plug the holes since they will attract more carpenter bees come spring.

Several people told us that although they sprayed a pesticide into the holes, carpenter bees later emerged, in some cases even after the holes were plugged. How can this happen?

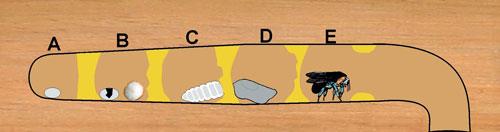

If we take a look at a cross section diagram of a carpenter bee gallery we can see how. After drilling out a four to five inch long gallery, the female carpenter bee lays an egg in back of the gallery then places a plug of pollen she has gathered to form a chamber (A). She continues doing this until there are four to six egg chambers in place. After a few days the egg hatches and a small white grub emerges (B). The grub feeds on the pollen plug for a few weeks (C) until it is ready to pupate (D) and change into an adult bee (E).

If you look at the way the gallery is constructed, you can see why spraying a pesticide in the hole may not kill all of the developing bee larvae. The pollen plugs prevent the pesticide from getting to the rear chambers. So, before you spray any pesticide into a carpenter bee hole be sure to run a stiff wire all the way to the back of the gallery to break through any pollen plugs. That way all of the larval chambers will be exposed to the pesticide.