Perma-Chink Systems, Inc

Log & Timber Home Care Experts

Perma-Chink Systems, Inc

Log & Timber Home Care Experts

Michael

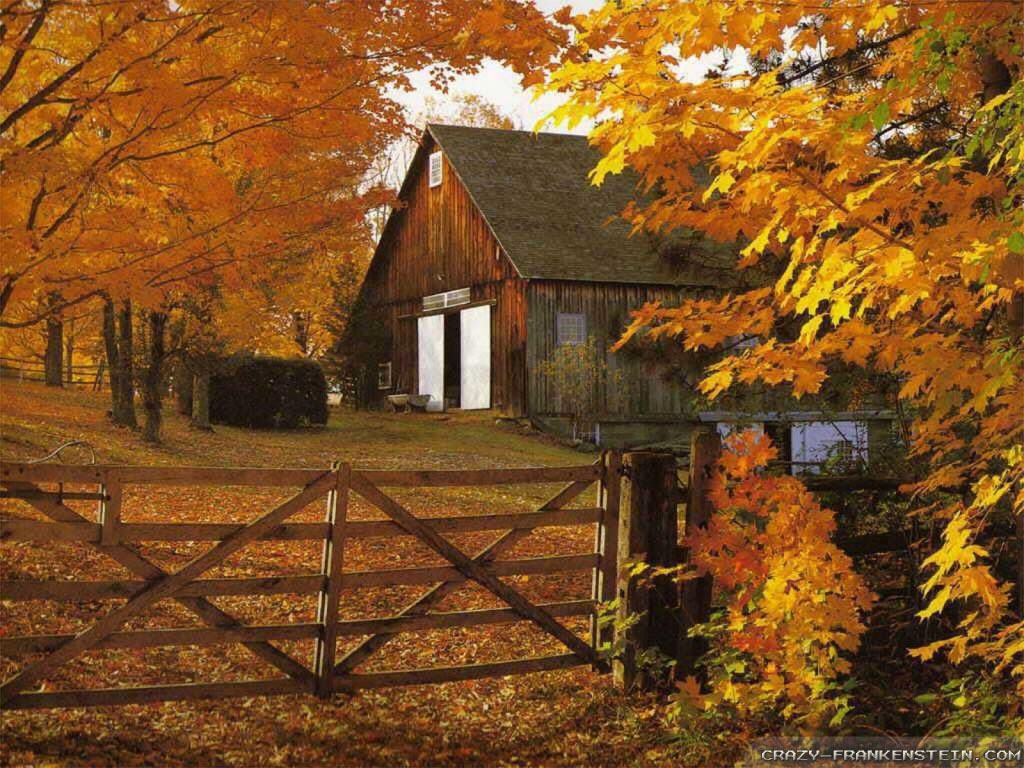

In many areas of the country when cool, fall days arrive, Asian lady beetles (ladybugs), Harmonia axyridis, and boxelder bugs, Boisea trivittatus, congregate on exterior walls. They typically choose the south and west facing walls since these walls are the warmest. Once on the wall they look for nooks, crannies and other dark openings where they can hibernate over the winter. Log checks, gaps between butt joints and corner openings provide ideal wintering sites for these insects. If any opening leads to the inside of the home, they can become a real nuisance, especially if they enter in large numbers. An effective method to handle them inside is with a vacuum cleaner. Spraying them with pesticides is unnecessary and unhealthy.

The best way to keep them out of your home is to block their entry points with a sealant, screening and weather stripping. Using high quality sealants like Energy Seal™ or Woodsman™ will help prevent these and other insects from entering your home for years to come. When sealing, pay special attention to window and door frames. That's where openings typically appear as a home settles and logs season.

Perma-Chink Systems have the best stains for log and timber homes. While we tend to call our stains "finishes," most consumers are used to the phrasing of "wood stain." Why the difference? The quick answer is that stains permeate the wood, while finishes form a film over the surface, protecting the wood. If you want to know more about the difference, our tips below can answer your questions.

The Tech Tips are grouped below by how our system works. Like most things in life, success is determined by a strong foundation. So the first section contains information on getting your log or timber home ready for the finish of your choosing. Following the surface prep section, we've consolidated information about our finishes for both exterior and interior. The final section is dedicated to known issues with log and timber homes that all homeowners have to deal with, regardless of which finish they choose.

Wood Finishes Application Guide

Tips For Surface Prepping, Cleaning, & Washing

Tech Tips About Stains & Finishes

Tech Tips For Exterior Finishes

Tech Tips For Interior Finishes

TECH TIP |

|

TECH TIP |

|

| How to Apply Lifeline Interior | Applying Sure Shine | ||

| Interior Color Coats & Topcoats | Finishing Floors |

Tech Tips For Moisture, Mold, & Wood Issues

TECH TIP |

|

TECH TIP |

|

| What is Mill Glaze? | About Water Stains | ||

| About pH | About Moisture Content | ||

| About Moisture Meters | About Mold & Mildew | ||

| About Resin Bleed | Preventing Mold Growth |

Perma-Chink Systems has a full line of wood cleaners designed to clean, restore, and prepare your home for maintenance. We cover the basic cleaning, as well as how to handle known wood issues like resin bleed.

Most people are accustomed to spring cleaning, but if you are a home owner, you know that your house needs attention year-round. Fall maintenance is much like spring house-cleaning, but more preventative and less “cleaning.” And it’s much easier to do it now rather than wait until the weather turns nasty.

Most people are accustomed to spring cleaning, but if you are a home owner, you know that your house needs attention year-round. Fall maintenance is much like spring house-cleaning, but more preventative and less “cleaning.” And it’s much easier to do it now rather than wait until the weather turns nasty.

Have you noticed your heating bill increasing year after year? It could be that your home has cracks that let heat escape, costing you money. Seal up cracks and seams before the weather turns cold and it’s too late to do anything about it.

Specifically designed for milled and scribed log homes, Energy Seal is a revolutionary product offering superior binders that effectively seal all interior and exterior gaps and cracks.

Energy Seal is a 100% acrylic polymer sealant formulated to provide a long-lasting and resilient barrier for any chinkless log home. Since logs constantly twist, turn, swell, and shrink during the life of a log home, annoying gaps can appear. These gaps promote the retention of moisture, which can lead to log decay and damage, as well as seepage of air and water.

What to do if your log home was flooded?

Log homes are actually more durable than traditional homes, and are more likely to survive natural disasters, including flooding. The clean-up and repair of a log home after flooding is also much easier; follow these steps...

Log homes are actually more durable than traditional homes, and are more likely to survive natural disasters, including flooding. The clean-up and repair of a log home after flooding is also much easier; follow these steps...

All About Linseed Oil - And Why It's No Good For Wood

We occasionally get calls about the exterior of a home that has turned black.

Almost without fail it's the result of using an oil-based stain that contained linseed oil.

Linseed oil is a yellowish oil derived from the dried seeds of flax plants, and is also known as flax seed oil. Linseed oil is used as a carrier in many brands of oil-based paints and stains. Since linseed oil is organic, many varieties of mold fungi thrive on it. Over time mold can proliferate to point where the coated surface can turn dark brown to black. One way to tell if the darkening is due to mold rather than UV damage is inspecting areas protected from direct sunlight like under eaves and overhangs; it will be the same dark color as the rest of the wall.

Dear Mr. Kennedy and Perma-Chink:

My log home has just been restored beautifully by Mark Hoge (www.cascaderestores.com) in Oregon. A rough start because of a short working season wound up to be a wonderful experience. Once the job was started, they stayed with it until it was finished. His men were extremely nice and polite and worked tirelessly to get me the best job possible.

This is my second experience with Perma-Chink and the contractor who built the home in 1988, Dan Nicklason of Bet'r Bilt is still recommending your products. In 2007, I had a local painter use the corn-cob method and I was pleased with that except my home was in such bad shape, we kept running out of the corn cob. Anyway, I was pleased then as I am pleased this time. I feel that Mark knows what he's doing and was very patient in answering my questions. I would say he is a master at staining. I am grateful and appreciate Mark and Mr. Kennedy who gave me the names of the people who could help me with Perma-Chink.

Thank you, most sincerely,

Mary Lynn (Satterla)

Umpqua, Oregon

Although there is some controversy regarding its cause, the most commonly held theory about the formation of mill glaze is that it is created on logs, siding and trim by heat and mechanical compression generated during a high speed milling process. The combination of compressed wood fibers and high temperatures that melt the sugars, cellulose, and other water-soluble extractives present in the wood end up forming a surface glaze.

New Age Blast Media Available Sizes

Call 1-800-548-3554 to Order

Features

- Made from recycled glass

- Superior to corn, walnut, sand or soda media